Research on characteristics of variable speed load sensitive inlet and outlet independent control system

-

摘要:

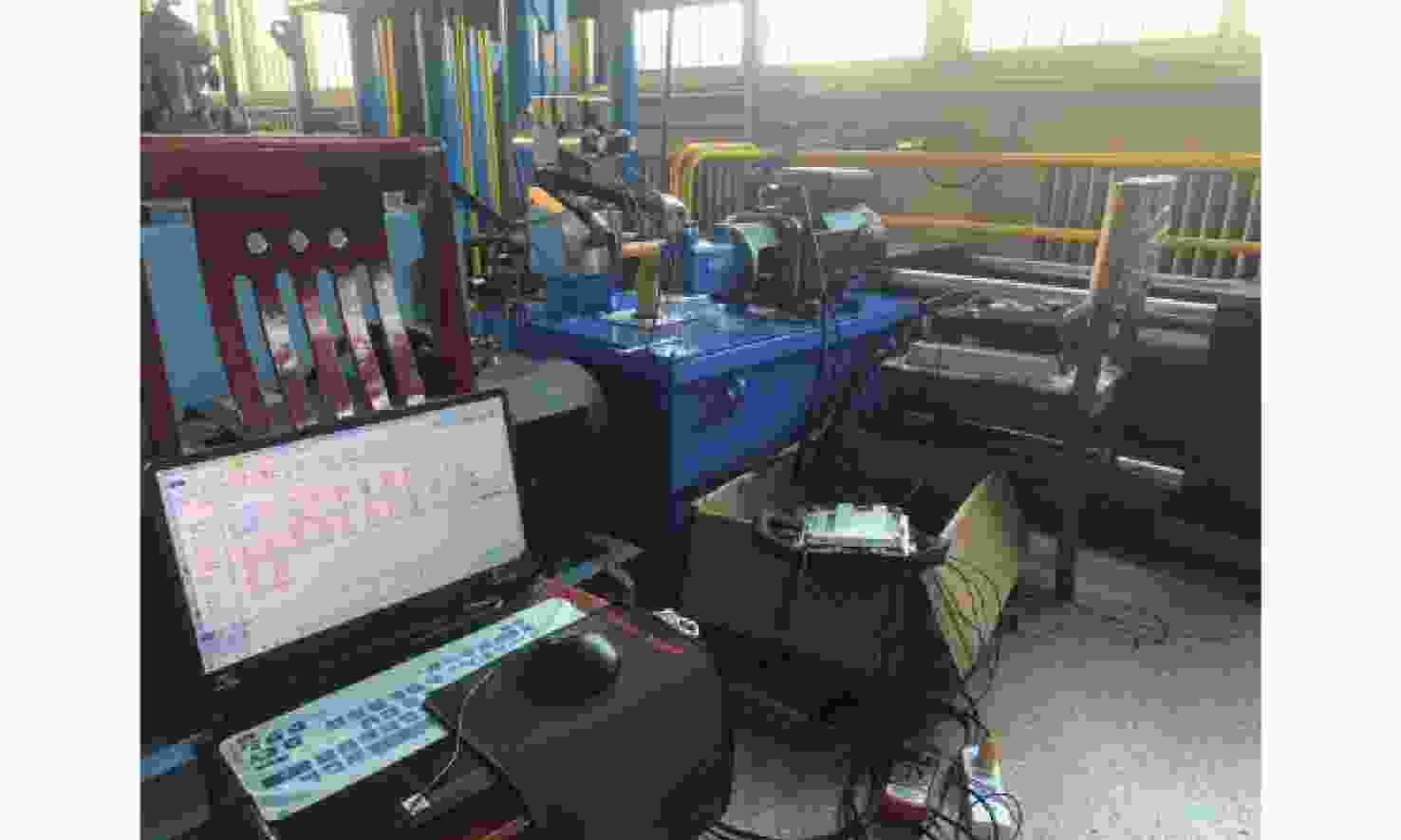

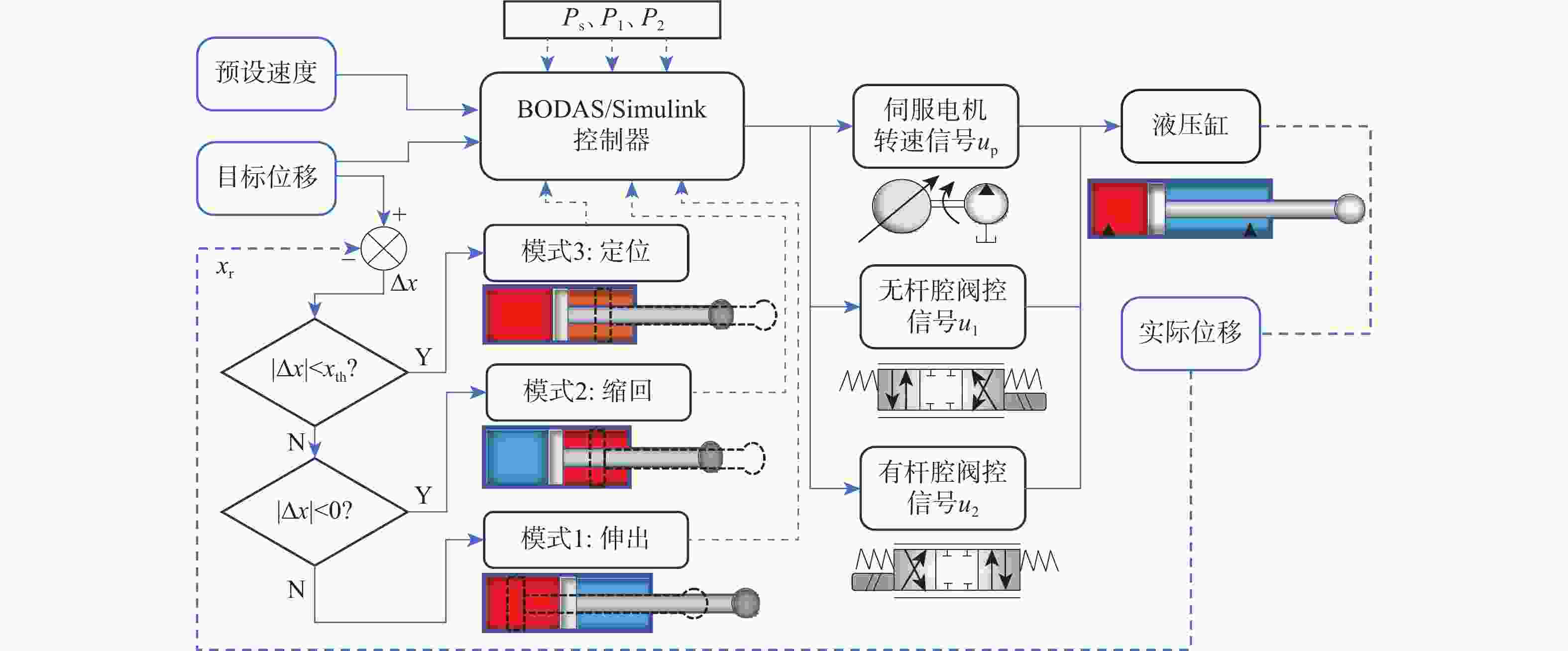

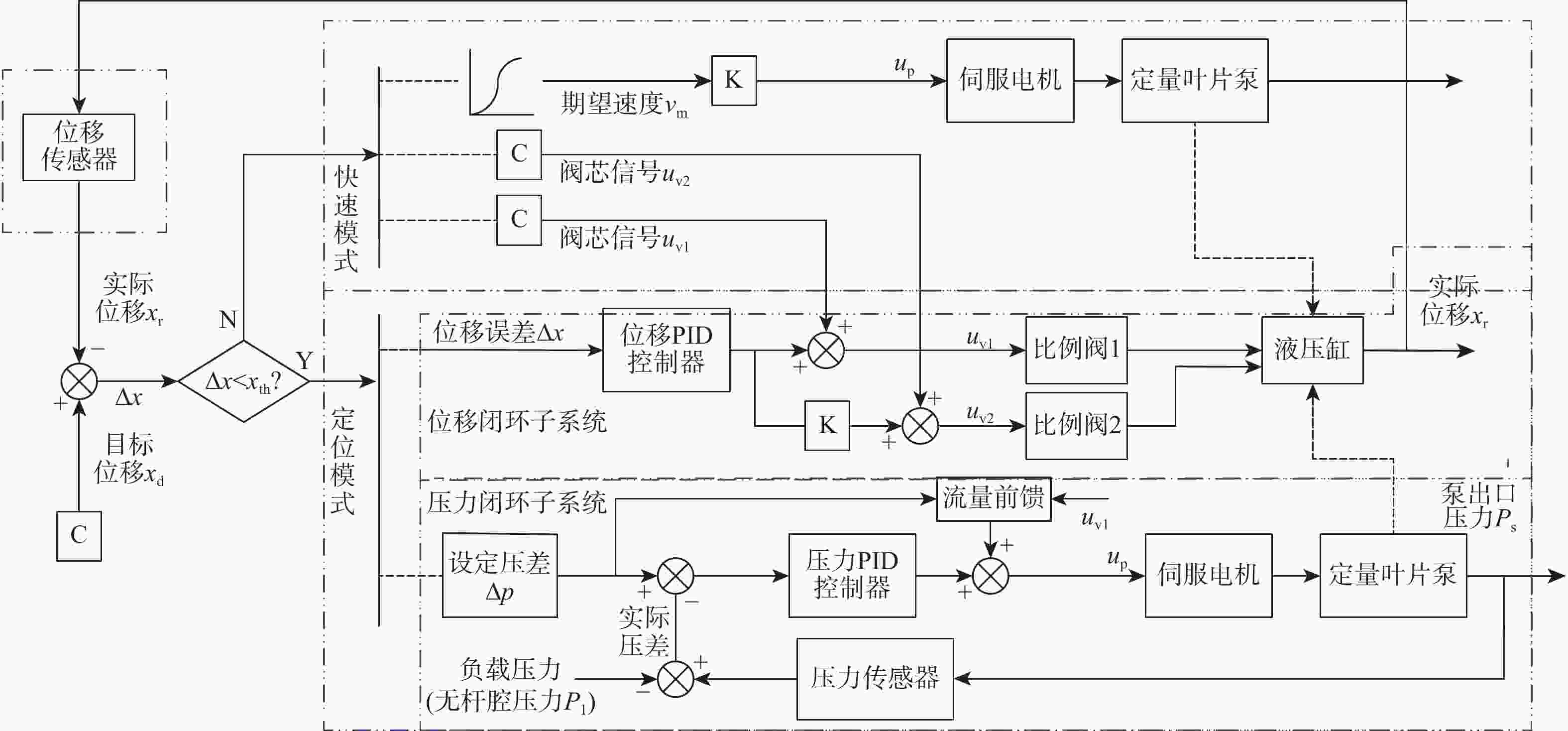

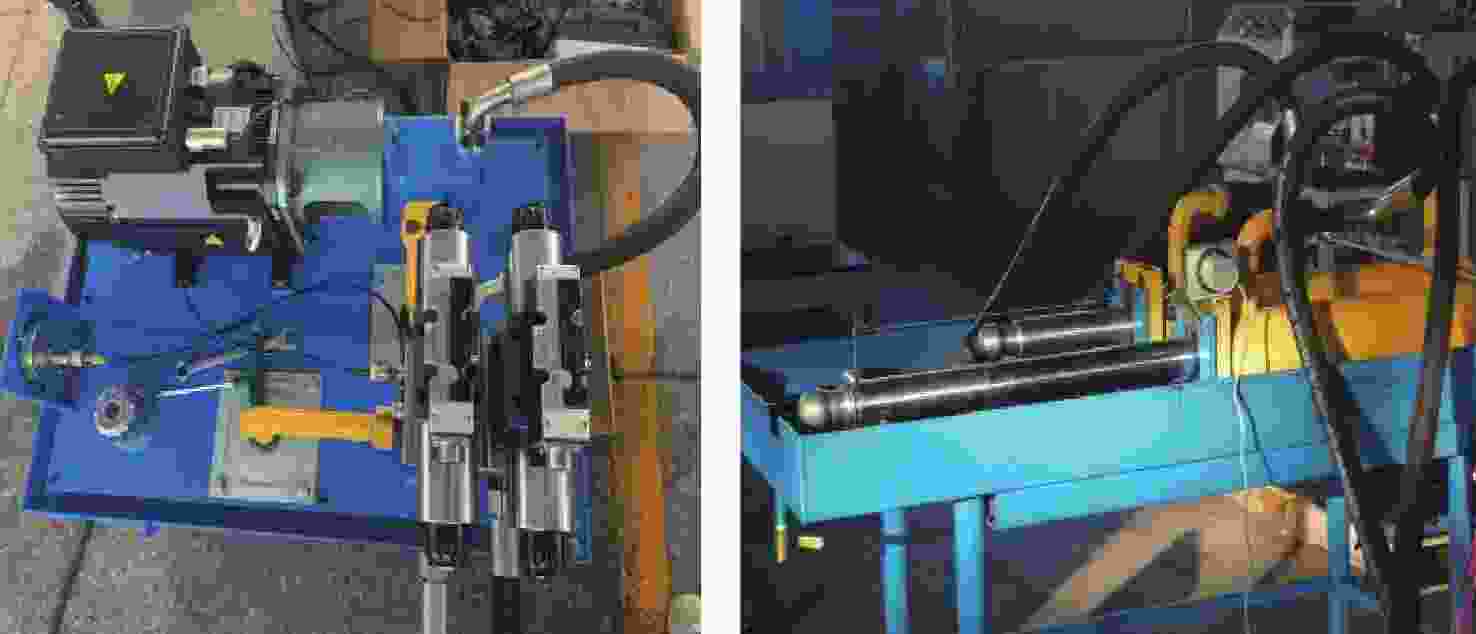

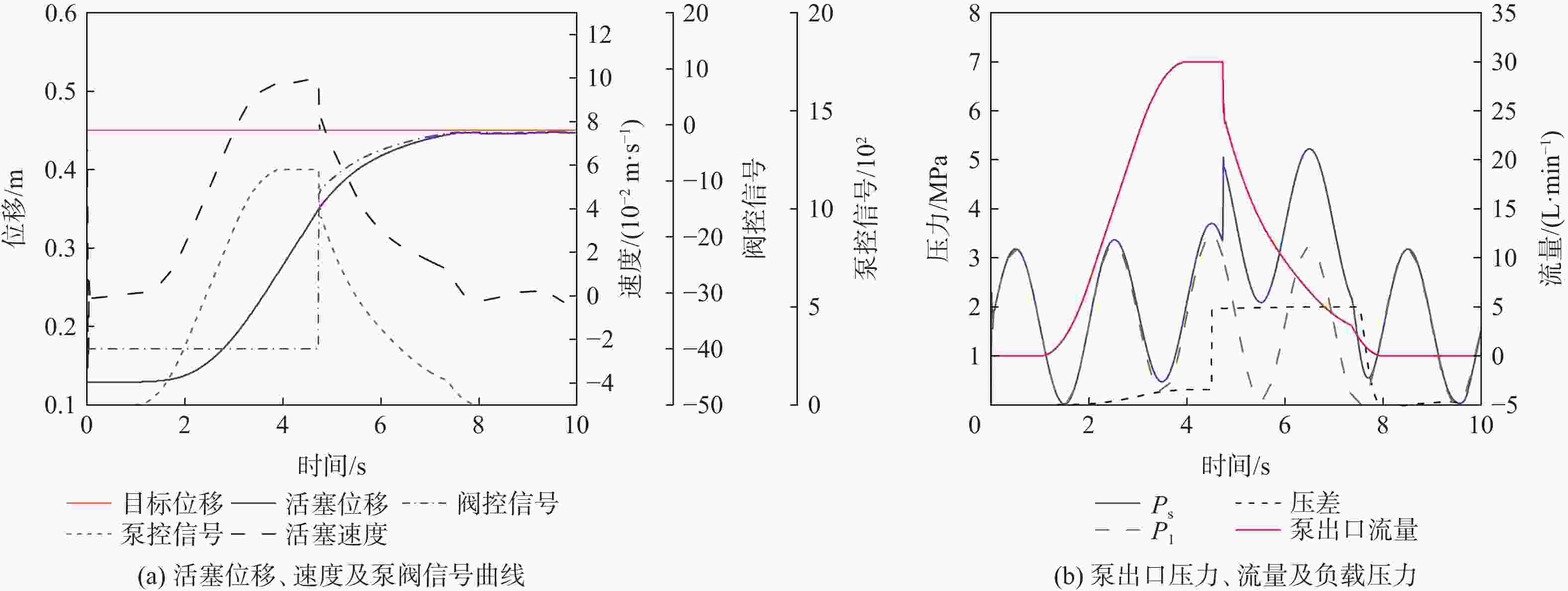

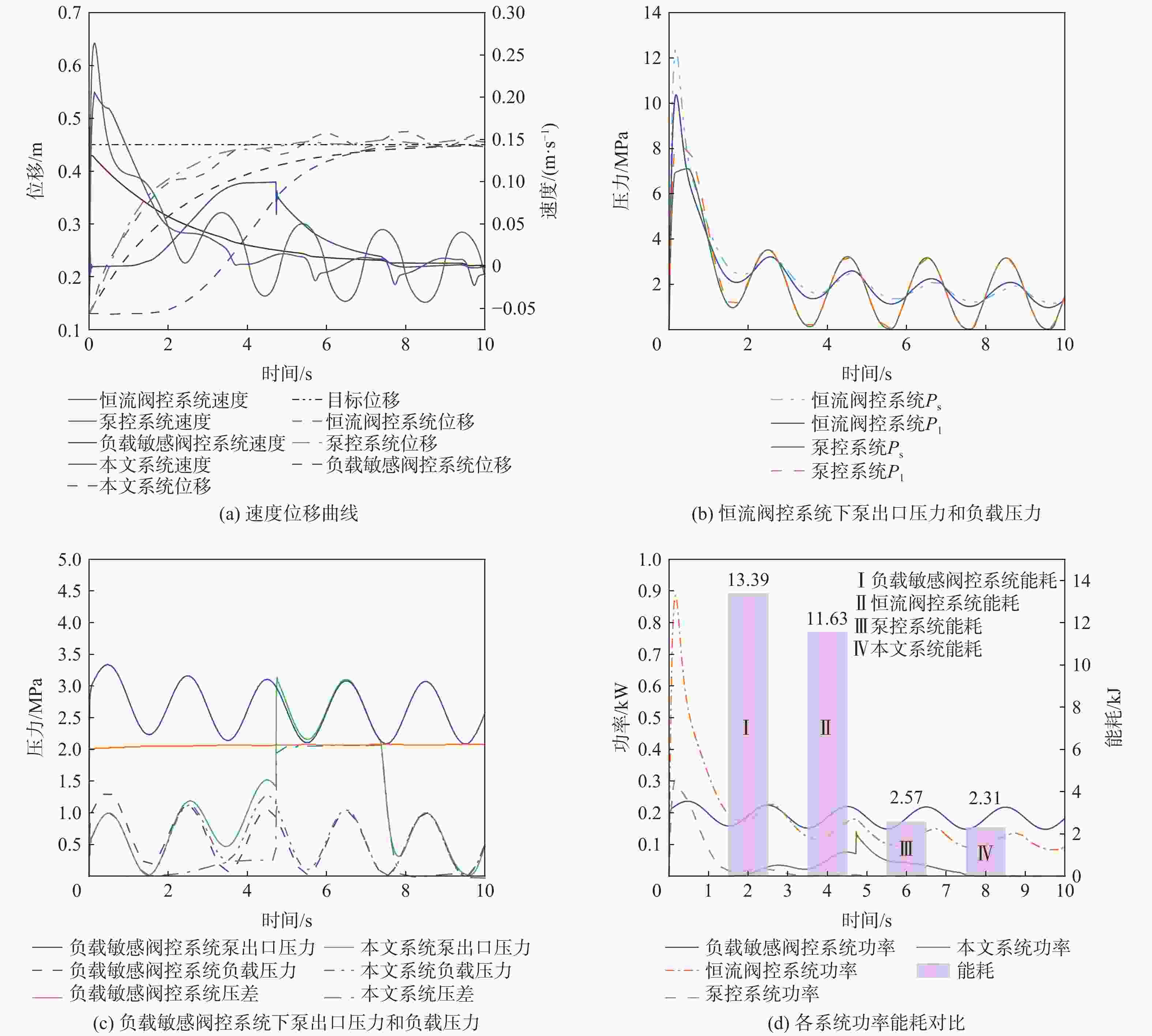

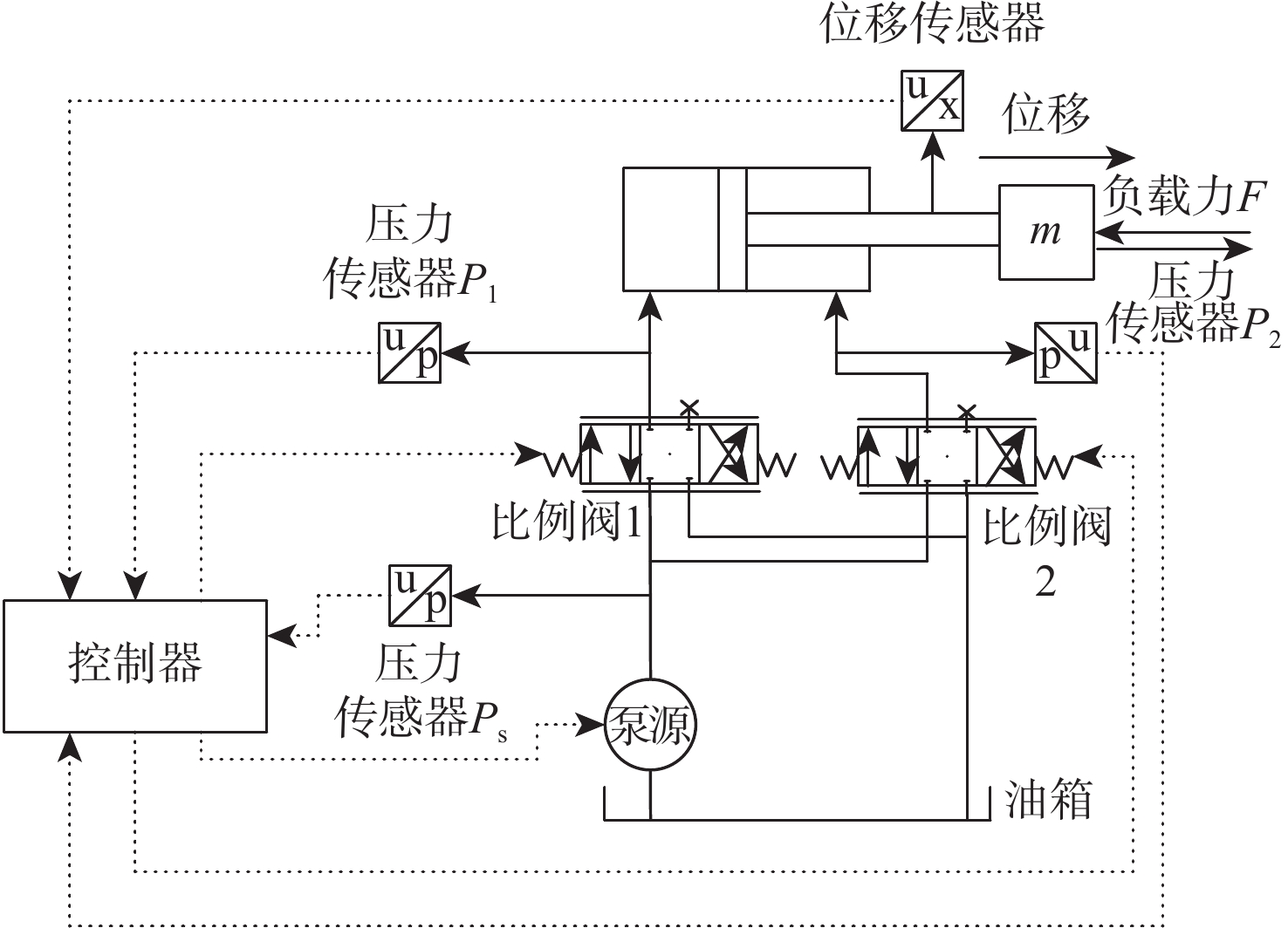

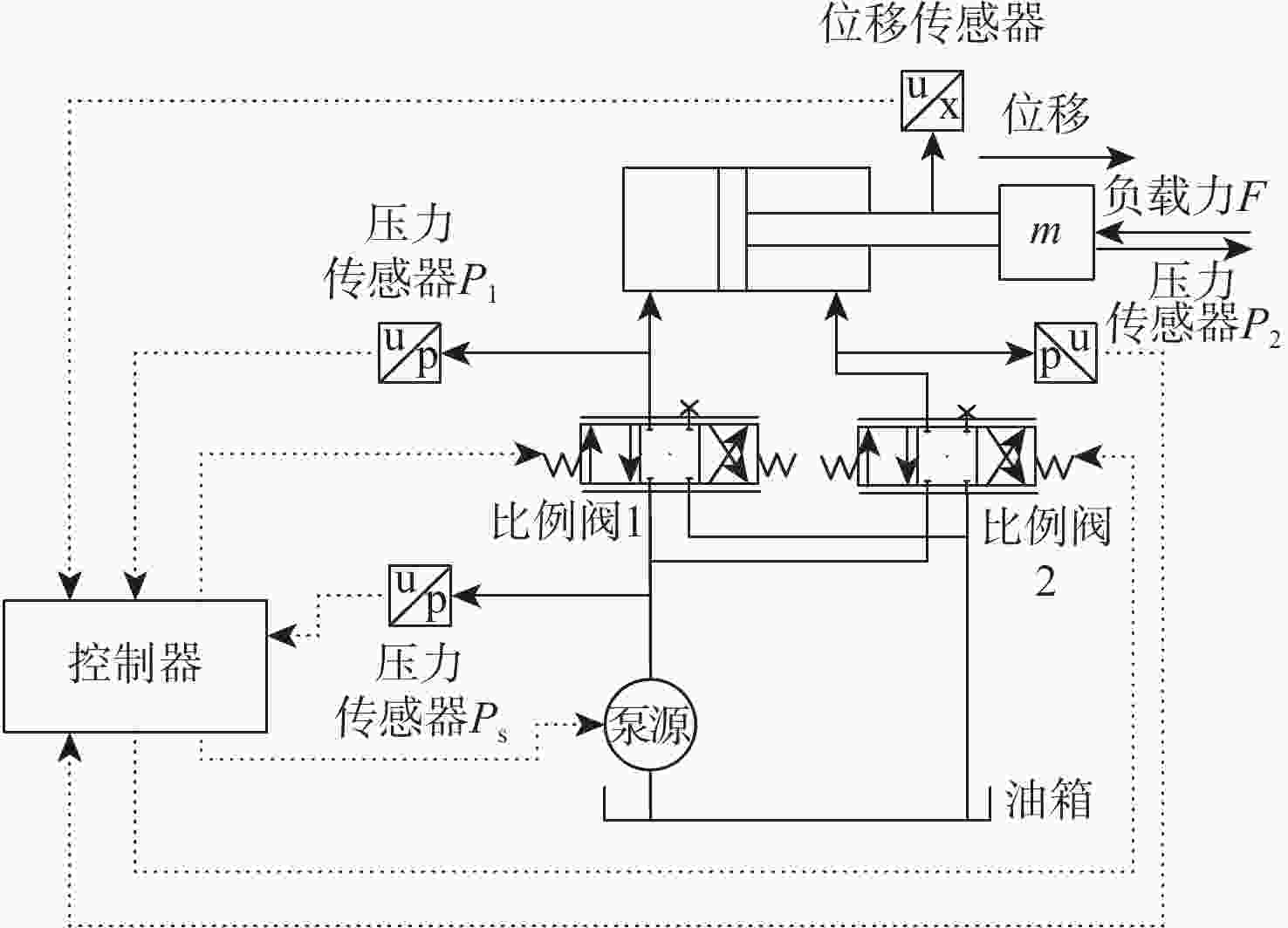

针对泵控位置系统效率高但控制精度不足、阀控位置系统响应快但能耗损失较大的问题,提出了基于模式切换下变转速负载敏感进出口独立的控制系统,设计了针对工程机械中能耗损失大的阻滞型负载工况的控制策略。根据所提控制系统原理,建立变转速负载敏感进出口独立控制系统的数学模型;分别搭建基于加载油缸的变转速负载敏感泵控系统和空载油缸的进出口独立阀控系统的试验平台与AMESim-MATLAB仿真模型并进行分析研究;将所建系统模型中添加正弦和随机信号来模拟变化的负载,分析系统在应对变化的外负载时,位置与压力的控制效果。将所建系统与恒流阀控系统、传统负载敏感阀控系统、传统泵控系统三者进行比较分析,结果表明:所设计变转速负载敏感压力控制器对系统压力的控制效果良好;以伺服电机驱动双作用叶片泵作为动力源的负载敏感进出口独立控制系统的位置控制性能和节能效果高于传统泵控和阀控系统,比传统泵控系统节能10.12%。

-

关键词:

- 变转速负载敏感 /

- 进出口独立控制 /

- BODAS控制器 /

- AMESim-MATLAB /

- 模式切换

Abstract:An independent import and export control was developed, based on variable speed load sensitivity at mode switching, to address the issues of high efficiency but insufficient control precision of the pump control position system and rapid reaction but significant energy loss of the valve control position system. A control strategy is designed for stagnant load conditions with large energy loss in construction machinery. First, a mathematical model of the variable speed load-sensitive independent position control system for the import and export was established, according to the above control principle. Second, the test platform and AMESim-MATLAB simulation model based on the load sensing system of the loaded cylinder and the position control system of the empty cylinder were established and analyzed. Then, sinusoidal and random signals are added to the built system model to simulate varying loads, and the control and pressure of system position accuracy were analyzed under variable load. Finally, the built system was analyzed and compared with a constant current valve control system, traditional load-sensing valve control system, and traditional pump control system. The results show that the designed variable speed load-sensitive pressure controller has a good control effect on system pressure; the position control performance and energy saving effect of the load-sensitive inlet and outlet independent control system with servo motor-driven double-acting vane pump as the power source are higher than those of traditional pump control and valve control systems, which saves the energy by 10.11% over the traditional pump control system.

-

表 1 试验参数

Table 1. Test parameters

参数 数值 液压缸缸筒直径/mm 280 液压缸活塞直径/mm 220 液压缸活塞行程/mm 200 控制系统伺服电机额定功率/kW 4.5 控制系统伺服电机额定转速/(r·min−1) 1800 控制系统定量叶片泵排量/(ml·r−1) 25 控制系统比例阀额定流量/(L·mm−1) 60 加载系统电机额定功率/kW 15 加载系统电机额定转速/(r·min−1) 1700 加载系统定量叶片泵排量/(ml·r−1) 25 表 2 控制缸参数

Table 2. Control cylinder parameters

mm 工作装置参数 数值 液压缸缸筒直径 80 液压缸活塞直径 45 液压缸活塞行程 480 -

[1] 刘华, 汪成文, 郭新平, 等. 电液负载敏感位置伺服系统自抗扰控制方法[J]. 北京航空航天大学学报, 2020, 46(11): 2131-2139.LIU H, WANG C W, GUO X P, et al. Active disturbance rejection control method for position servo system based on electro-hydraulic load sensing[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2131-2139(in Chinese). [2] SHEN W, PANG Y, JIANG J H. Robust controller design of integrated direct drive volume control architecture for steering systems[J]. ISA Transactions, 2018, 78: 116-192. [3] 袁士豪, 殷晨波, 刘世豪. 机械负载敏感定量泵系统性能分析[J]. 农业工程学报, 2013, 29(13): 38-45.YUAN S H, YIN C B, LIU S H. Performance analysis of machinery load sensitive quantitative pump system[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(13): 38-45(in Chinese). [4] IMAMURA T, SAWADA Y, ICHIKAWA M, et al. Energy-saving hybrid hydraulic system comprising highly efficient IPM motor and inverter, for injection molding and manufacturing machine[J]. Proceedings of the JFPS International Symposium on Fluid Power, 2008, 2008(7-1): 117-120. doi: 10.5739/isfp.2008.117 [5] 谢文. 串联式泵阀协控电液伺服控制系统研究[D]. 北京: 北京理工大学, 2015: 31-37XIE W. Research on serial type pump-valve coordinated electric-hydraulic servo control system[D]. Beijing: Beijing Institute of Technology, 2015: 31-37(in Chinese). [6] 张哲. 基于变频调节的快锻液压机泵阀复合控制研究[D]. 秦皇岛: 燕山大学, 2014: 36-40.ZHANG Z. The study on accumulator fast forging subsystem of 0.6MN sinusoidal pump-controllde press[D]. Qinhuangdao: Yanshan University, 2014: 36-40(in Chinese). [7] 付胜杰, 林添良, 王浪, 等. 基于变转速控制的负载敏感系统研究[J]. 中国公路学报, 2020, 33(5): 189-196.FU S J, LIN T L, WANG L, et al. Load sensitive system based on variable speed control[J]. China Journal of Highway and Transport, 2020, 33(5): 189-196(in Chinese). [8] 梁涛. 变转速动力源及容腔独立控制液压挖掘机特性研究[D]. 太原: 太原理工大学, 2018: 11-12LIANG T. Research on characteristics of hydraulic excavator with speed variable power source and separate chamber control system[D]. Taiyuan: Taiyuan University of Technology, 2018: 11-12(in Chinese). [9] 张红娟, 权龙, 李斌. 注塑机电液控制系统能量效率对比研究[J]. 机械工程学报, 2012, 48(8): 180-187.ZHANG H J, QUAN L, LI B. Comparative study on energy efficiency of the electro-hydraulic control system in injection molding machine[J]. Journal of Mechanical Engineering, 2012, 48(8): 180-187(in Chinese). [10] BACKE W. Design systematics and performance of cartridge valve controls[C]//International Conference on Fluid Power, Tampere: ICFP, 1987: 1-48. [11] CHOI K, SEO J, NAM Y, et al. Energy-saving in excavators with application of independent metering valve[J]. Journal of Mechanical Science and Technology, 2015, 29(1): 387-395. doi: 10.1007/s12206-014-1245-5 [12] 师建鹏, 权龙, 张晓刚, 等. 进出口独立复合控制挖掘机的动臂速度位置特性[J]. 浙江大学学报(工学版), 2017, 51(9): 1797-1807.SHI J P, QUAN L, ZHANG X G, et al. Velocity and position characteristics of excavator’s boom by separate meter-in and meter-out compound control[J]. Journal of Zhejiang University (Engineering Science), 2017, 51(9): 1797-1807(in Chinese). [13] 董致新, 黄伟男, 葛磊, 等. 泵阀复合进出口独立控制液压挖掘机特性研究[J]. 机械工程学报, 2016, 52(12): 173-180. doi: 10.3901/JME.2016.12.173DONG Z X, HUANG W N, GE L, et al. Research on the performance of hydraulic excavator with pump and valve combined separate meter in and meter out circuits[J]. Journal of Mechanical Engineering, 2016, 52(12): 173-180(in Chinese). doi: 10.3901/JME.2016.12.173 [14] 丁孺琦, 徐兵, 张军辉. 负载口独立控制系统压力速度复合控制的耦合特性[J]. 浙江大学学报(工学版), 2017, 51(6): 1126-1134.DING R Q, XU B, ZHANG J H. Coupling property of pressure and velocity compound control in individual metering systems[J]. Journal of Zhejiang University(Engineering Science), 2017, 51(6): 1126-1134(in Chinese). [15] 张鹏, 郭志军. 节流独立控制负载敏感液压系统特性及其仿真分析[J]. 液压与气动, 2021, 45(4): 82-86.ZHANG P, GUO Z J. Characteristics and simulation analysis of load sensitive hydraulic system with independent throttle control[J]. Chinese Hydraulics & Pneumatics, 2021, 45(4): 82-86(in Chinese). [16] 刘凯磊, 李宇, 康绍鹏, 等. 挖掘机工作装置负载口独立控制系统节能特性研究[J]. 液压与气动, 2021, 45(3): 86-93. doi: 10.11832/j.issn.1000-4858.2021.03.012LIU K L, LI Y, KANG S P, et al. Energy saving characteristics of independent metering control system of excavator working equipment[J]. Chinese Hydraulics & Pneumatics, 2021, 45(3): 86-93(in Chinese). doi: 10.11832/j.issn.1000-4858.2021.03.012 [17] 李小军. 双作用叶片泵的内部结构对流量脉动及其噪声的影响分析[D]. 兰州: 兰州理工大学, 2016: 15-16LI X J. Analysis of the influence of the internal structure of the double acting vane pump on the flow pulsation and noise[D]. Lanzhou: Lanzhou University of Technology, 2016: 15-16(in Chinese). [18] IEC. Programmable controllers-part 3: Programming languages: IEC61131—3[S]. Geneva: IEC, 2013. [19] MERRITT H E. Hydraulic control systems[M]. New York: John Wiley & Sons, 1967: 90-100. [20] DJUROVIC M, HELDUSER S. New control strategies for electrohydraulic load-sensing[C]//Bath Workshop on Power Transmission and Motion Control. Dresden: Professional Engineering Publishing, 2004: 201. -

下载:

下载: