Influence of wedge erosion deformation on working characteristics of jet pipe servo valve

-

摘要:

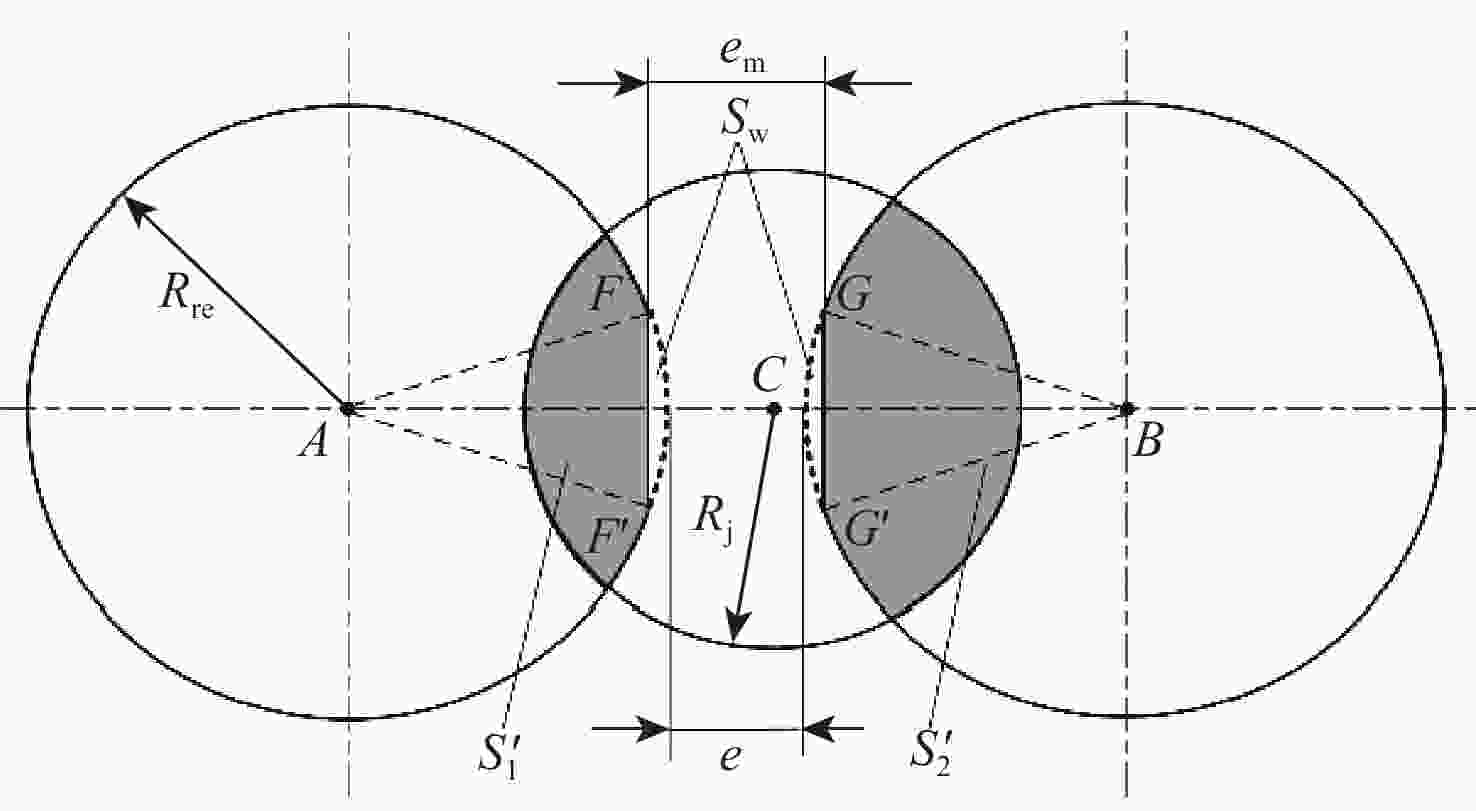

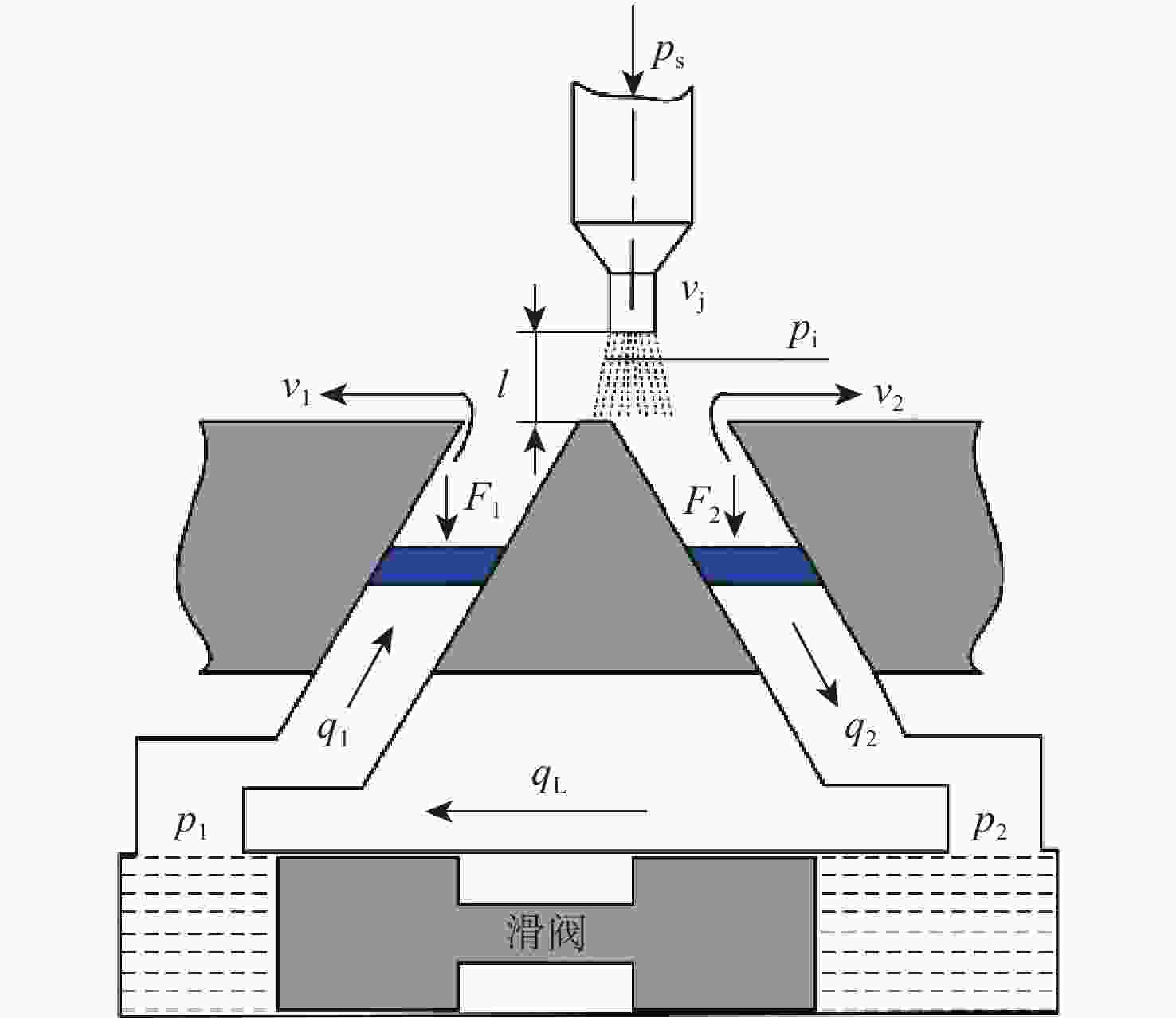

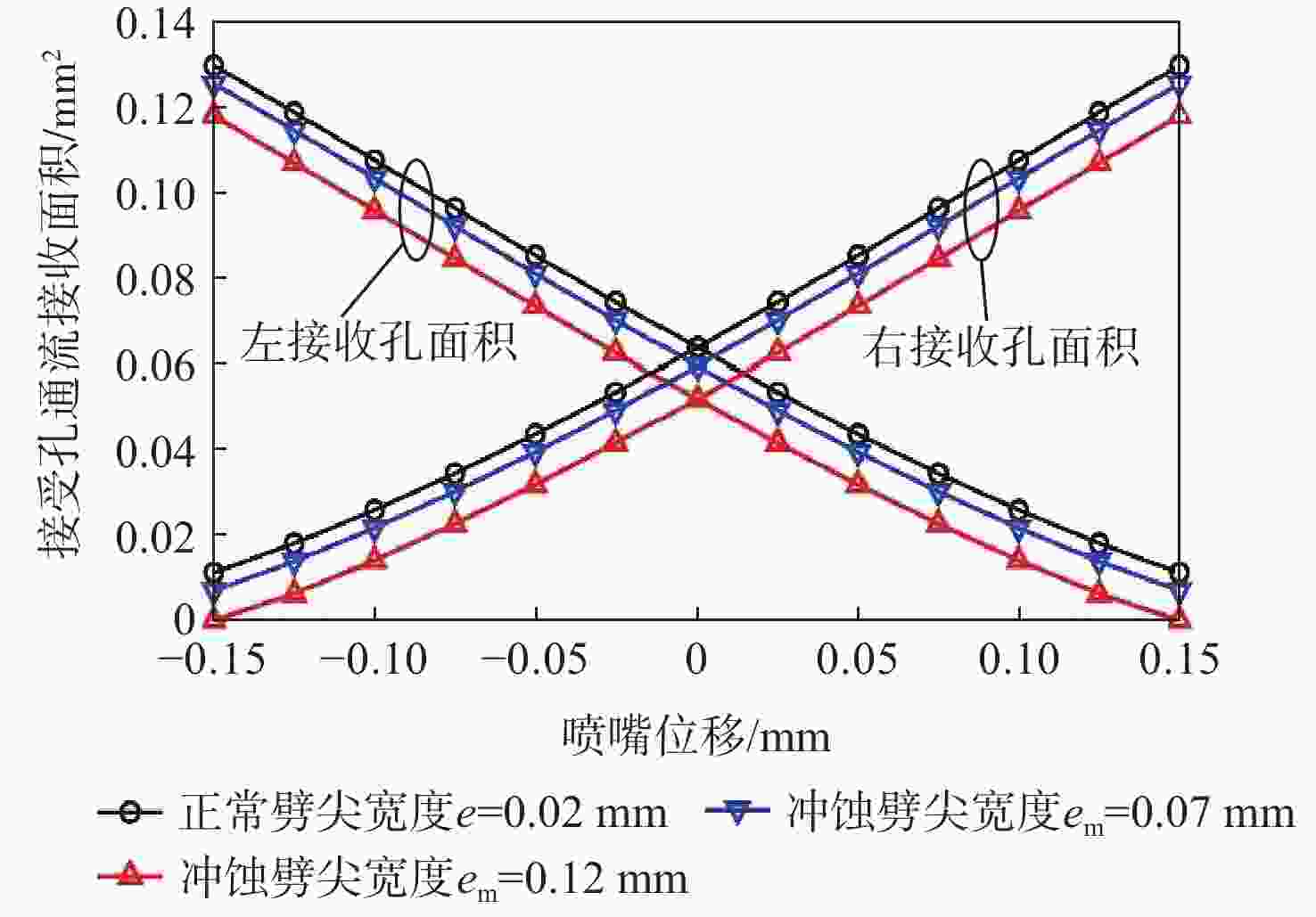

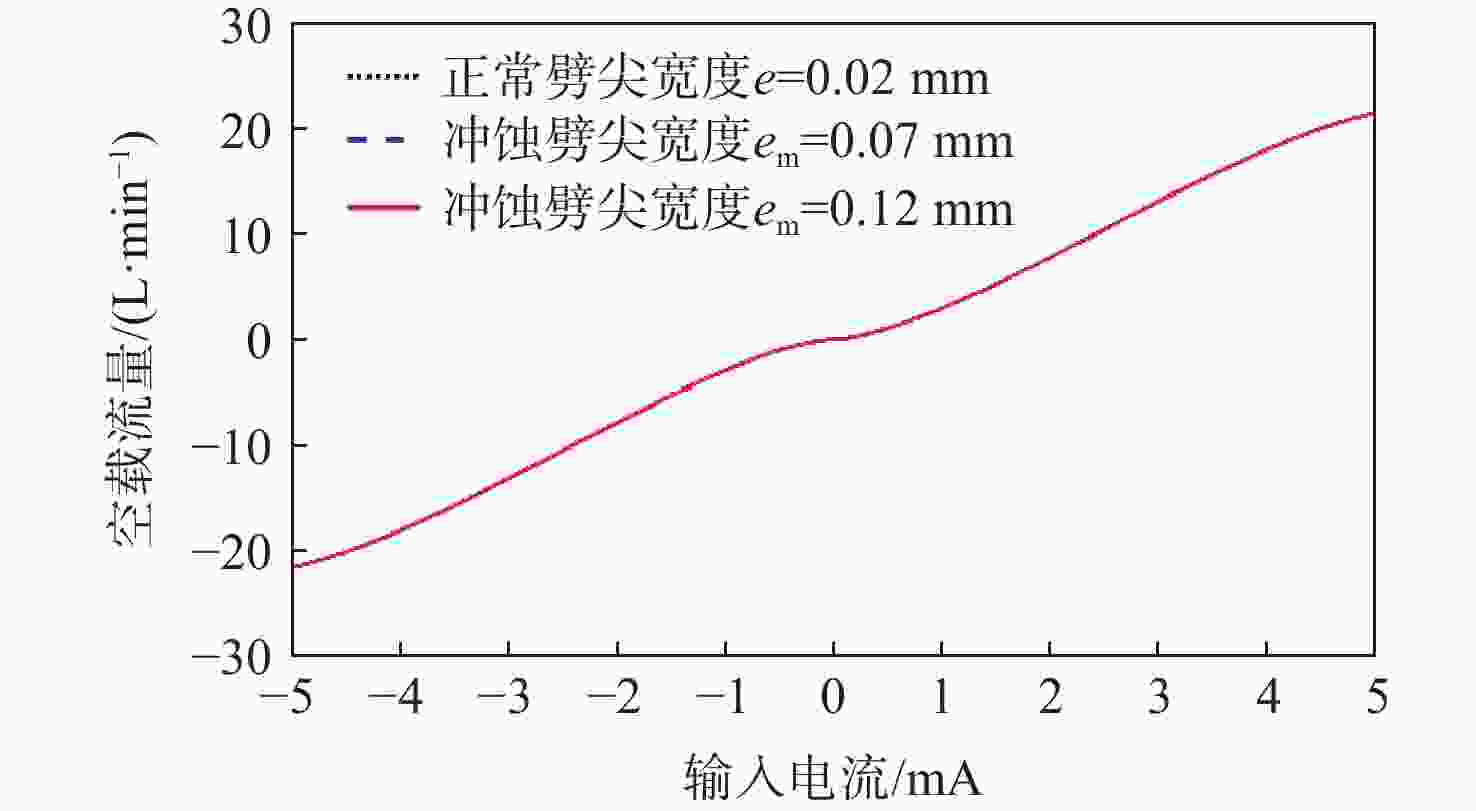

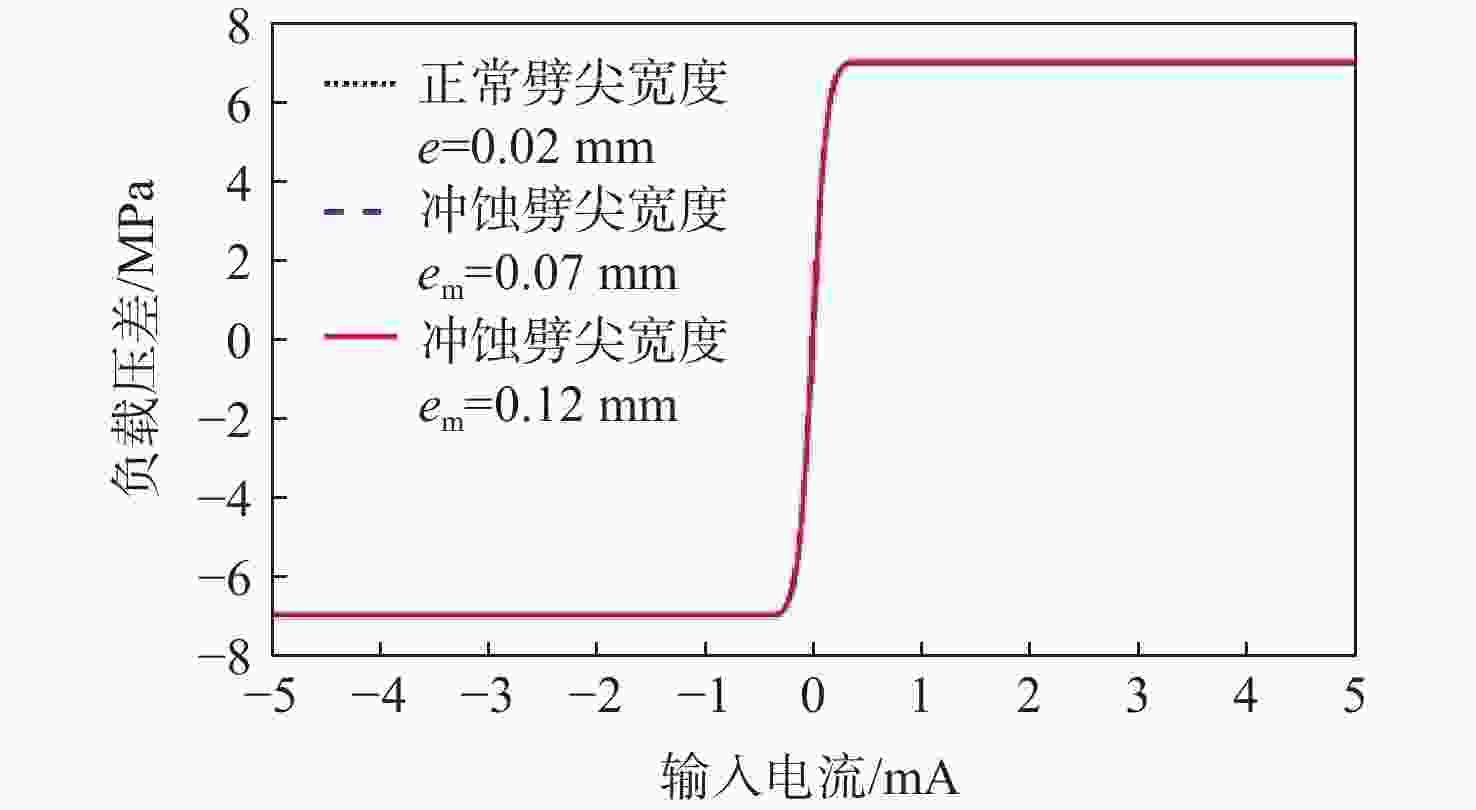

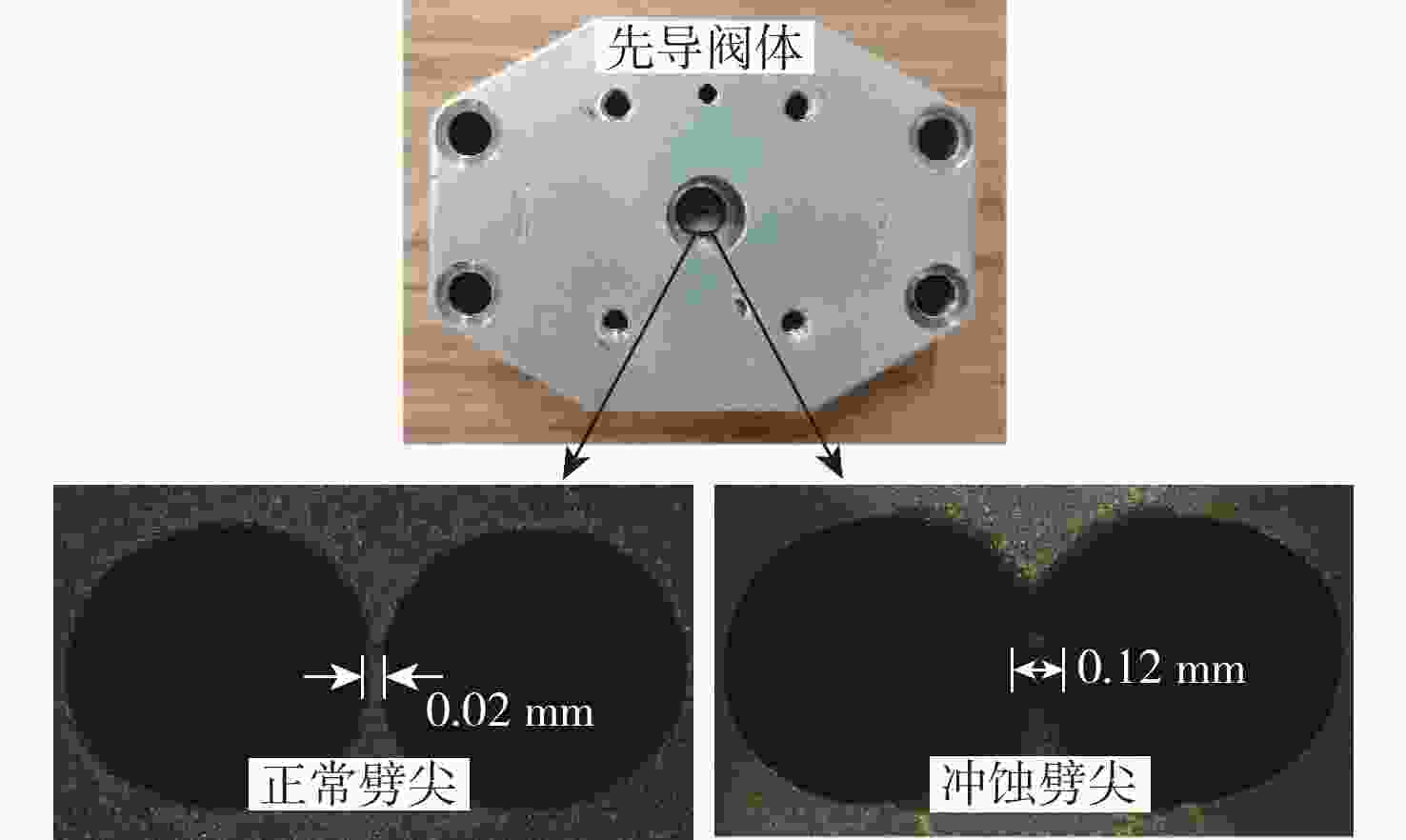

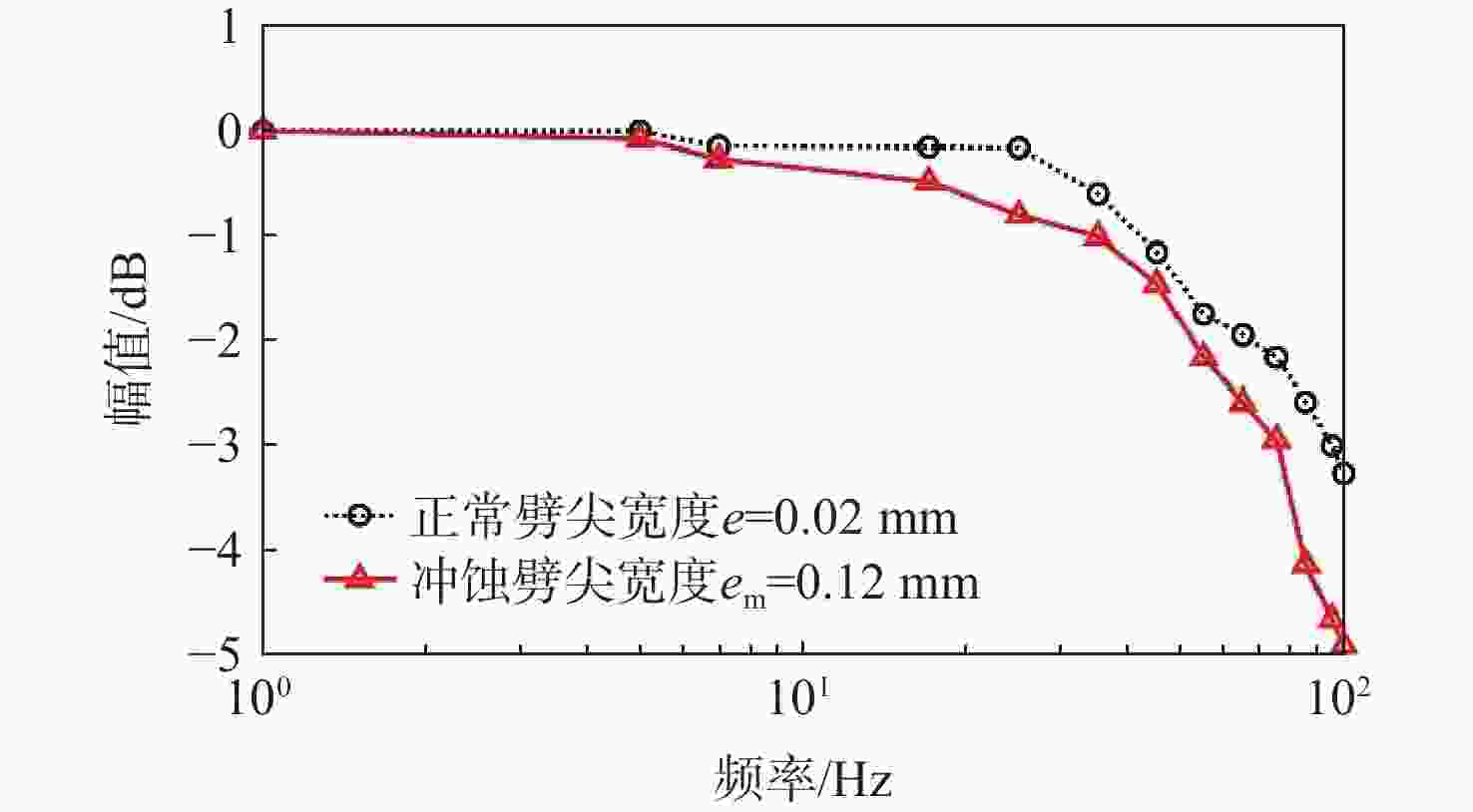

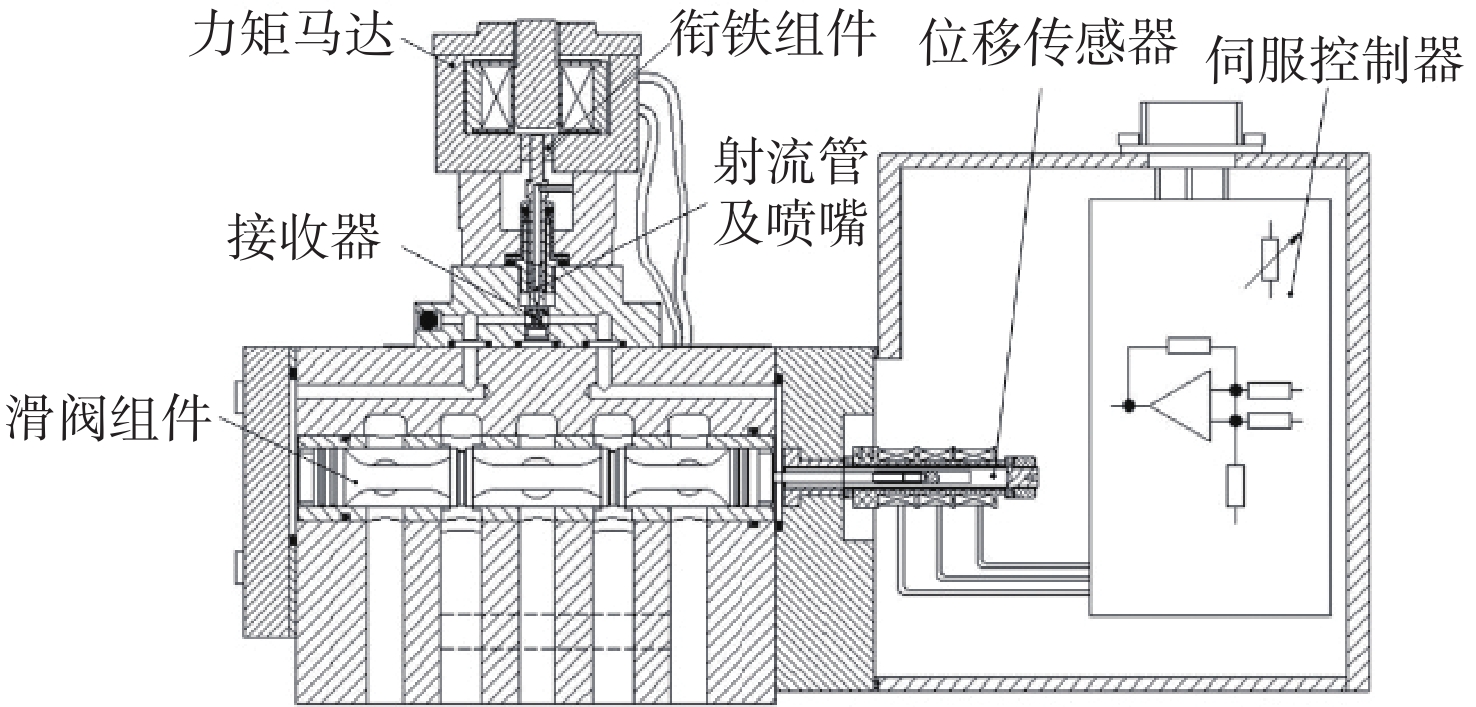

为研究射流管伺服阀前置级劈尖的冲蚀变形对伺服阀工作性能的影响,采用Fluent仿真软件,对射流管伺服阀的前置级进行冲蚀仿真,并将仿真结果与冲蚀实物进行对比分析,发现劈尖是前置级冲蚀最为严重的部位;根据劈尖冲蚀前后的前置级结构形状,构建前置级的数学模型,分析了劈尖冲蚀变形对前置级压力的影响。利用AMESim仿真软件,搭建射流管伺服阀的整阀仿真模型,研究了劈尖冲蚀变形对整阀工作性能的影响;通过实验验证了AMESim仿真结果的正确性。研究结果表明,劈尖冲蚀变形后,射流管伺服阀前置级的恢复压力和负载压差减小,导致整阀的阶跃上升时间延长,幅频带宽减小,但整阀的空载流量特性和压力特性几乎不受影响。

Abstract:To study the influence of the erosion deformation of the pre-stage wedge on the working characteristics of the jet pipe servo valve, the erosion simulation of the pre-stage is carried out by Fluent simulation software, and the simulation result is compared with the erosion object, which shows that the wedge is the most serious erosion part in the pre-stage. The mathematical model of the pre-stage is constructed in accordance with the structural shape of the pre-stage prior to and following wedge erosion, and is used to examine the impact of the wedge erosion deformation on the pre-stage pressure. The simulation model of jet pipe servo valve is built based on AMESim simulation software, and the influence of wedge erosion deformation on the working characteristics of jet pipe servo valve is further studied. Finally, the correctness of AMESim simulation results is verified by experiments. The outcomes demonstrate that the recovery pressure and differential pressure of the pre-stage can decrease after the erosion deformation of the wedge, which results in an increase or decrease in the step-up time and amplitude-frequency bandwidth of the jet pipe servo valve, respectively. However, the unload flow characteristic and pressure characteristic of the servo valve are essentially unaffected.

-

Key words:

- jet pipe servo valve /

- pre-stage /

- erosion /

- wedge deformation /

- working characteristics /

- finite element simulation

-

表 1 冲击角函数

Table 1. Function of impact angle

序号 β/(°) f(β) 1 0 0 2 20 0.8 3 30 1 4 45 0.5 5 90 0.4 表 2 某型号射流管电反馈式伺服阀主要参数

Table 2. Main parameters of a certain type of jet pipe servo valve with electric feedback

参数 数值 电磁力矩常数Kt/(N·m·A−1) 0.456 磁弹簧刚度Km/(N·m·rad−1) 3.836 衔铁组件转动惯量Ja/(N·m·s2·rad−1) 2.8×10−7 衔铁组件阻尼系数Ba/(N·m·s·rad−1) 5×10−4 支撑杆刚度Kf/(N·m·rad−1) 3.95 供油压力ps/MPa 7 喷嘴出口油液压力pi/MPa 1.1 油液密度ρ/(kg·m−3) 850 喷嘴直径Dj/mm 0.45 接收孔半径Rr/mm 0.325 喷嘴到接收器端面距离l/mm 0.3 劈尖初始宽度e/mm 0.02 左右接收孔轴线夹角一半θr/(°) 15 喷嘴流量系数Cdj 0.91 接收孔流量系数Cd 0.61 射流管喷嘴旋转半径L/mm 17.4 阀芯质量mv/kg 0.021 油液体积弹性模量Ey/(N·m−2) 7×109 阀芯端面面积/Av/mm2 132.7 滑阀零位时的阀芯端部体积V0/mm3 159.8 阀芯阻尼系数Bv/(N·m−1·s) 90 稳态液动力刚度kv/(N·m−1) 1.5×104 额定电流I/mA 10 伺服控制器增益Ku 0.68 位移传感器增益Ka/(A·m−1) 7.69 -

[1] 戴城国, 王晓红, 张新, 等. 基于模糊综合评判的电液伺服阀FMECA[J]. 北京航空航天大学学报, 2011, 37(12): 1575-1578. doi: 10.13700/j.bh.1001-5965.2011.12.017DAI C G, WANG X H, ZHANG X, et al. Fuzzy comprehensive evaluation in FMECA of electro-hydraulic servo valve[J]. Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(12): 1575-1578(in Chinese). doi: 10.13700/j.bh.1001-5965.2011.12.017 [2] MA L, YAN H, CAI C K, et al. Mechanism of temperature-induced zero drift on electro-hydraulic servo valve[J]. AIP Advances, 2021, 11(6): 1-3. [3] ZHANG Y, CHEN J S. Numerical simulation of jet pipe servo valve[J]. Tehnicki Vjesnik-Technical Gazette, 2020, 27(2): 391-398. [4] ZHANG Q F, YAN L, DUAN Z H, et al. High torque density torque motor with hybrid magnetization pole arrays for jet pipe servo valve[J]. IEEE Transactions on Industrial Electronics, 2020, 67(3): 2133-2142. doi: 10.1109/TIE.2019.2903761 [5] 胡建军, 朱晴, 陈冬冬, 等. 射流管伺服阀通油冷却建模与仿真分析[J]. 液压与气动, 2021(2): 23-29. doi: 10.11832/j.issn.1000-4858.2021.02.004HU J J, ZHU Q, CHEN D D, et al. Modeling and simulated analysis of cooling the jet-pipe servo-valve by oil circulation[J]. Chinese Hydraulics & Pneumatics, 2021(2): 23-29(in Chinese). doi: 10.11832/j.issn.1000-4858.2021.02.004 [6] 胡建军, 杨泽贺, 金瑶兰, 等. 射流管伺服阀前置级建模及参数匹配研究[J]. 北京理工大学学报, 2019, 39(11): 1101-1106. doi: 10.15918/j.tbit1001-0645.2018.430HU J J, YANG Z H, JIN Y L, et al. Modeling and parameter matching for the pilot stage of jet pipe servo valve[J]. Transactions of Beijing Institute of Technology, 2019, 39(11): 1101-1106(in Chinese). doi: 10.15918/j.tbit1001-0645.2018.430 [7] WU L, CHEN K S, GUO Y A. Research on cavitation phenomena in pilot stage of jet pipe servo-valve with a rectangular nozzle based on large-eddy simulations[J]. AIP Advances, 2019, 9(2): 025109. doi: 10.1063/1.5038402 [8] 訚耀保, 李聪. 射流管伺服阀前置级不对称性对零偏的影响[J]. 华南理工大学学报(自然科学版), 2021, 49(5): 111-119.YIN Y B, LI C. Influence of pre-stage asymmetry on jet-pipe servo valve zero deviation[J]. Journal of South China University of Technology (Natural Science Edition), 2021, 49(5): 111-119(in Chinese). [9] 李长明, 訚耀保, 汪明月, 等. 高温环境对射流管伺服阀偶件配合及特性的影响[J]. 机械工程学报, 2018, 54(20): 251-261. doi: 10.3901/JME.2018.20.251LI C M, YIN Y B, WANG M Y, et al. Influence of high temperature on couples matching and characteristics of jet pipe electrohydraulic servovalve[J]. Journal of Mechanical Engineering, 2018, 54(20): 251-261(in Chinese). doi: 10.3901/JME.2018.20.251 [10] 张坤, 姚金勇, 姜同敏, 等. 基于CFD的电液伺服阀污染磨损耐久性仿真分析[J]. 液压与气动, 2014(4): 54-59.ZHANG K, YAO J Y, JIANG T M, et al. Durability simulation of electro-hydraulic servo valve under contaminant wear with CFD[J]. Chinese Hydraulics & Pneumatics, 2014(4): 54-59(in Chinese). [11] 褚渊博, 袁朝辉, 张颖. 射流管式伺服阀冲蚀磨损特性[J]. 航空学报, 2015, 36(5): 1548-1555.CHU Y B, YUAN Z H, ZHANG Y. Erosion wear characteristic of jet pipe servo valve[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(5): 1548-1555(in Chinese). [12] 訚耀保, 付嘉华, 金瑶兰. 射流管伺服阀前置级冲蚀磨损数值模拟[J]. 浙江大学学报(工学版), 2015, 49(12): 2252-2260.YIN Y B, FU J H, JIN Y L. Numerical simulation of erosion wear of pre-stage of jet pipe servo valve[J]. Journal of Zhejiang University (Engineering Science), 2015, 49(12): 2252-2260(in Chinese). [13] 孟令康, 朱玉川, 王玉文, 等. 射流管电液伺服阀滑阀冲蚀磨损特性分析[J]. 液压与气动, 2022, 46(2): 124-130. doi: 10.11832/j.issn.1000-4858.2022.02.016MENG L K, ZHU Y C, WANG Y W, et al. Characteristics analysis of erosion wear of spool valve for jet pipe servo valve[J]. Chinese Hydraulics & Pneumatics, 2022, 46(2): 124-130(in Chinese). doi: 10.11832/j.issn.1000-4858.2022.02.016 [14] EDWARDS J K. Development, validation, and application of a three-dimensional, CFD-based erosion prediction procedure[D]. Tulsa: The University of Tulsa, 2000. [15] 褚渊博, 袁朝辉, 李聪英. 射流管式伺服阀耐久性仿真分析[J]. 西北工业大学学报, 2015, 33(2): 326-331. doi: 10.3969/j.issn.1000-2758.2015.02.028CHU Y B, YUAN Z H, LI C Y. Durability simulation analysis of jet pipe servovalve[J]. Journal of Northwestern Polytechnical University, 2015, 33(2): 326-331(in Chinese). doi: 10.3969/j.issn.1000-2758.2015.02.028 [16] 李跃松, 朱玉川. 电液伺服阀建模与Simulink仿真[M]. 北京: 机械工业出版社, 2020: 76-78.LI Y S, ZHU Y C. Modeling and simulink simulation of electro-hydraulic servo valve[M]. Beijing: China Machine Press, 2020: 76-78(in Chinese). [17] LI Y S. Mathematical modeling and linearized analysis of the jet-pipe hydraulic amplifier applied to a servovalve[J]. Proceedings of the Institution of Mechanical Engineers, Part G:Journal of Aerospace Engineering, 2019, 233(2): 657-666. doi: 10.1177/0954410017740386 [18] LI Y S. Mathematical modelling and characteristics of the pilot valve applied to a jet-pipe/deflector-jet servovalve[J]. Sensors and Actuators A:Physical, 2016, 245: 150-159. doi: 10.1016/j.sna.2016.04.048 [19] 李跃松, 朱玉川, 吴洪涛, 等. 超磁致伸缩执行器驱动的射流伺服阀参数优化[J]. 航空学报, 2011, 32(7): 1336-1344.LI Y S, ZHU Y C, WU H T, et al. Parameter optimization of jet-pipe servovalve driven by giant magnetostrictive actuator[J]. Acta Aeronautica et Astronautica Sinica, 2011, 32(7): 1336-1344(in Chinese). [20] MENG L K, ZHU Y C, LING J E, et al. Research on mathematical modeling of the servo valve torque motor considering the variation of working air-gaps leakage flux[J]. Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science, 2022, 236(11): 6347-6362. doi: 10.1177/09544062211064971 [21] 金瑶兰, 渠立鹏, 章敏莹. 射流管伺服阀AMESim建模与仿真[J]. 液压气动与密封, 2010, 30(8): 45-47. doi: 10.3969/j.issn.1008-0813.2010.08.011JIN Y L, QU L P, ZHANG M Y. AMESim modeling and simulation of jet-pipe servovalve[J]. Hydraulics Pneumatics & Seals, 2010, 30(8): 45-47(in Chinese). doi: 10.3969/j.issn.1008-0813.2010.08.011 -

下载:

下载: