-

摘要:

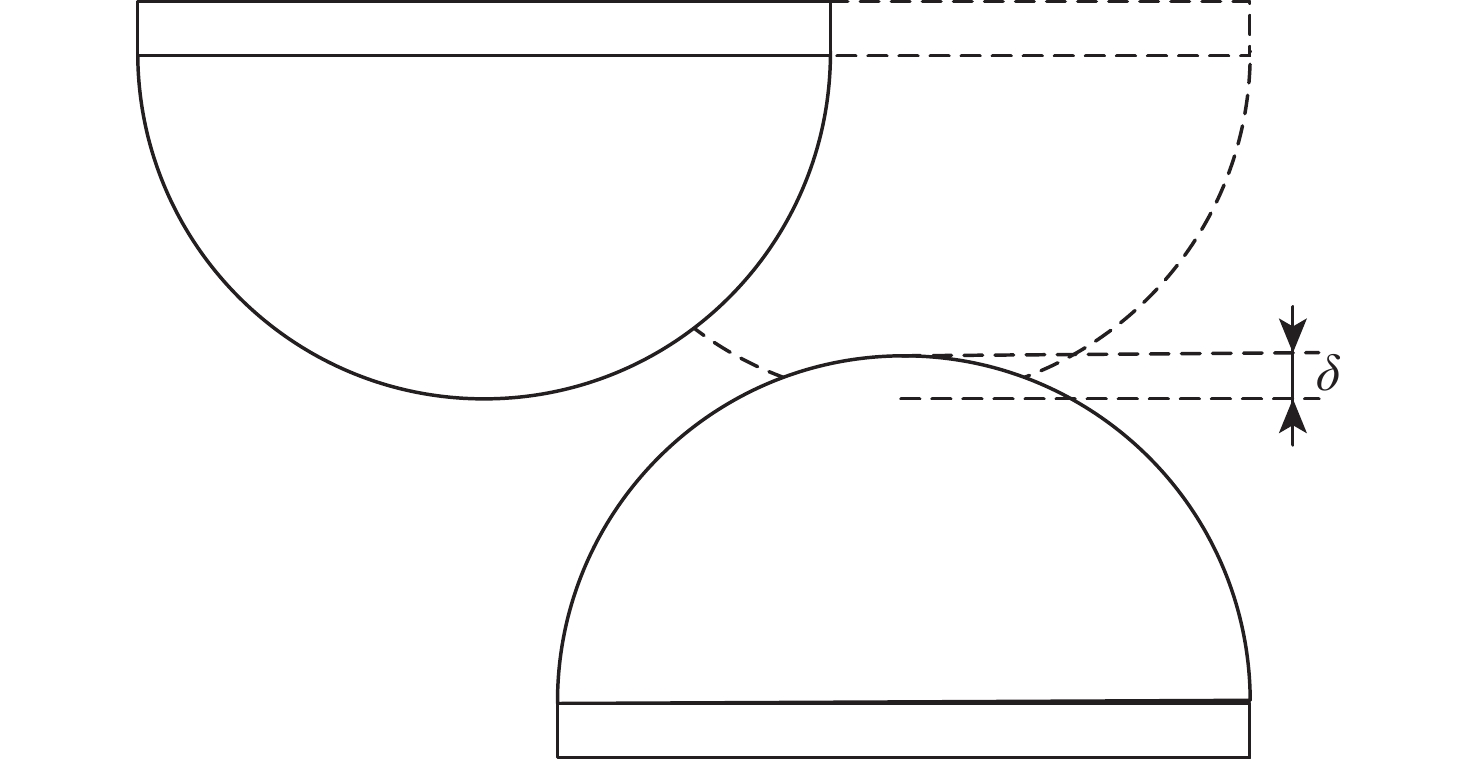

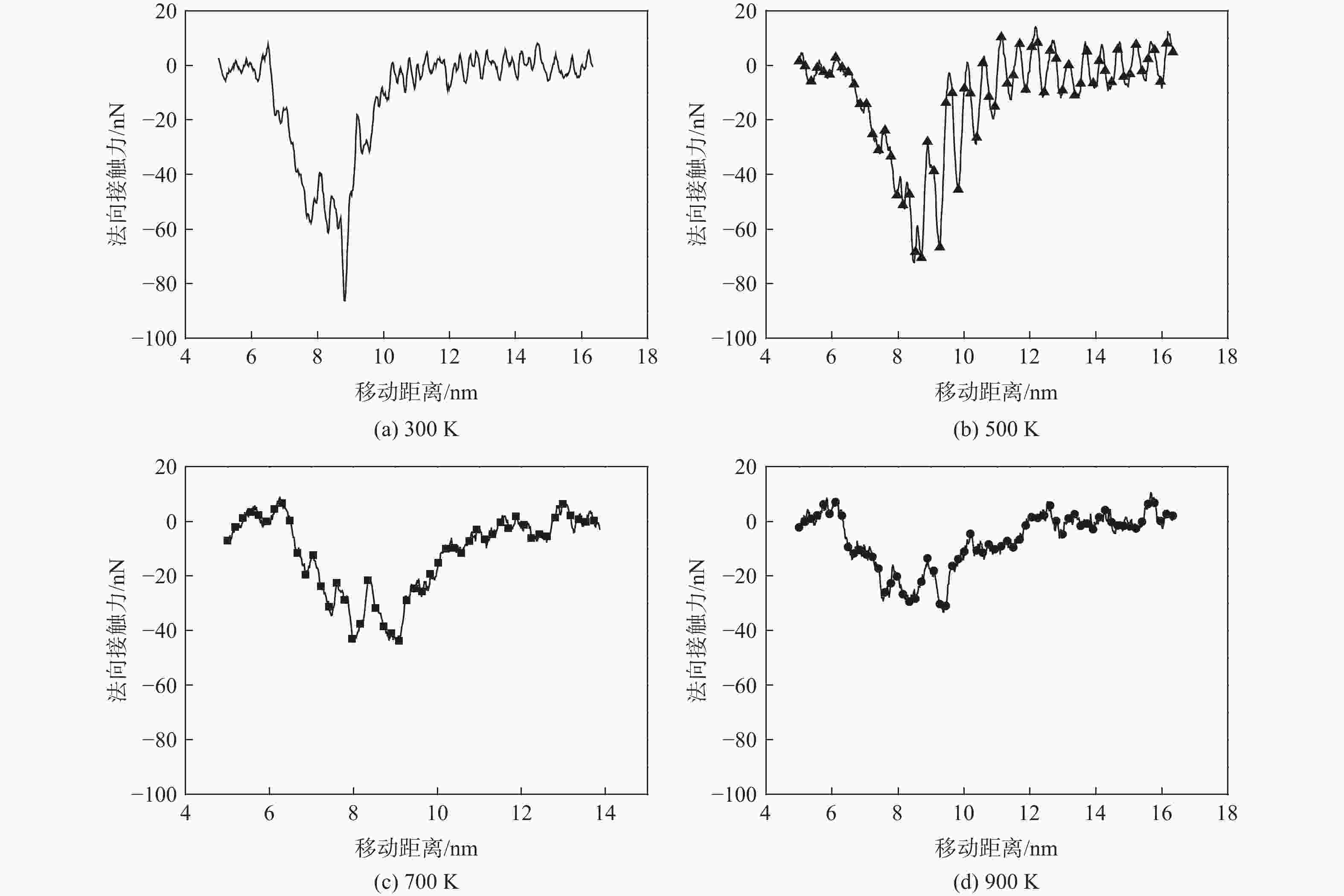

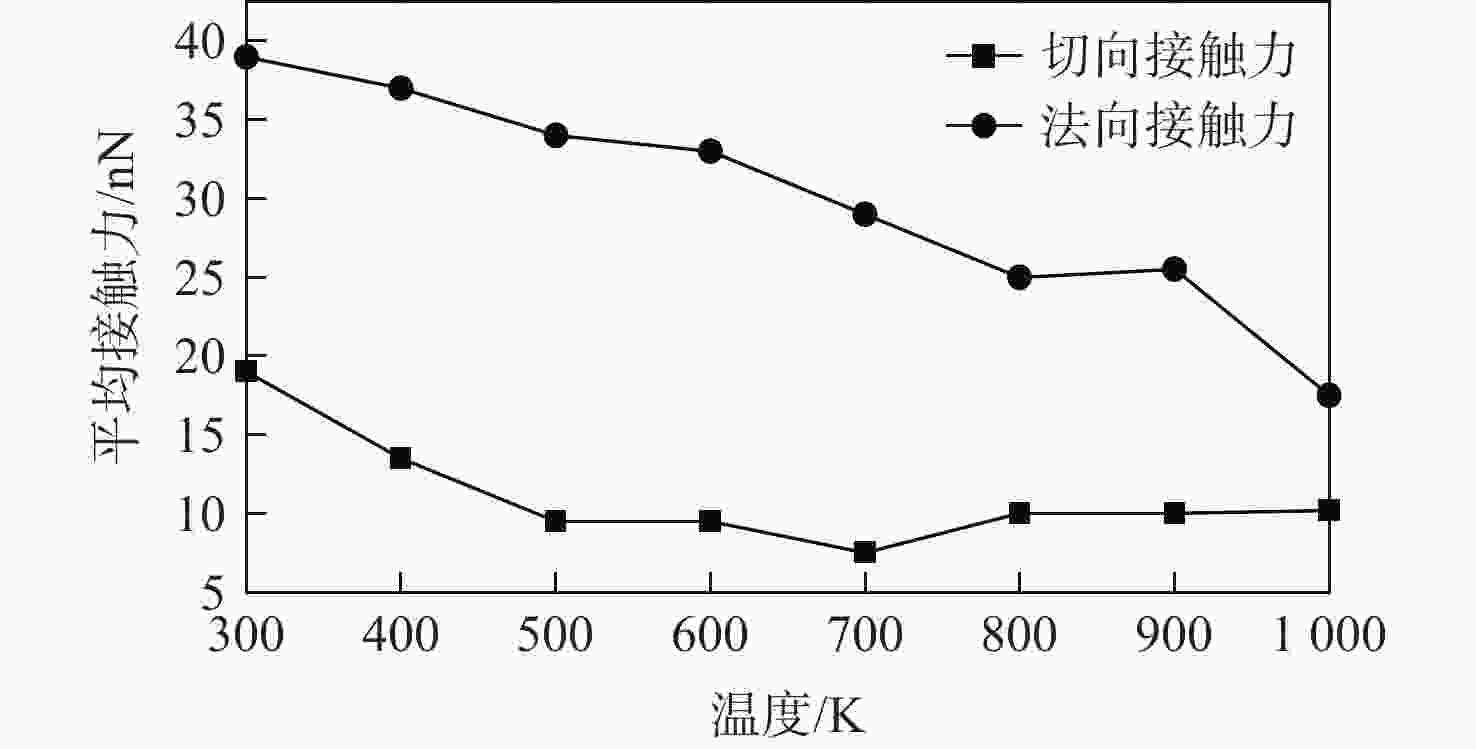

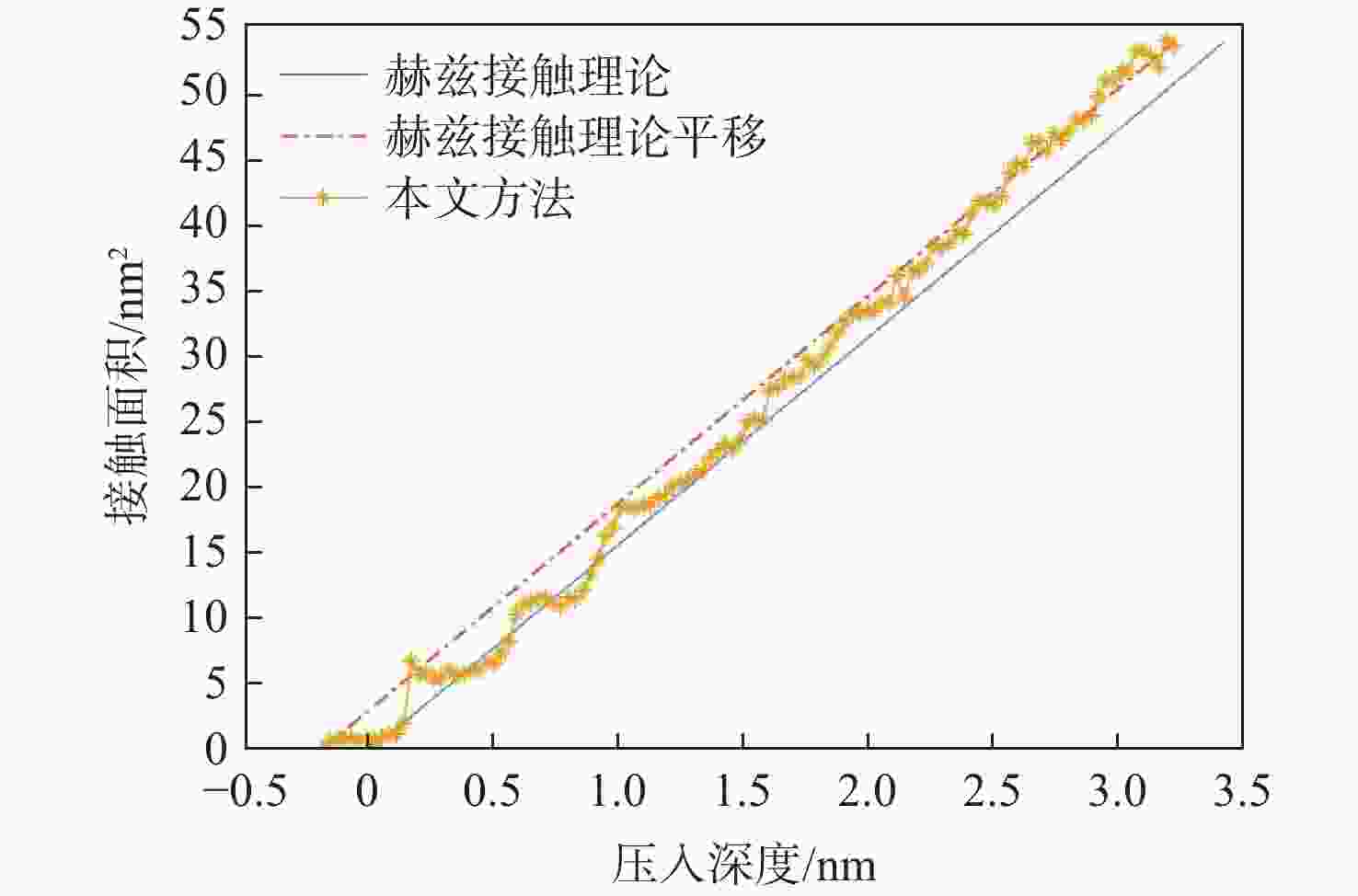

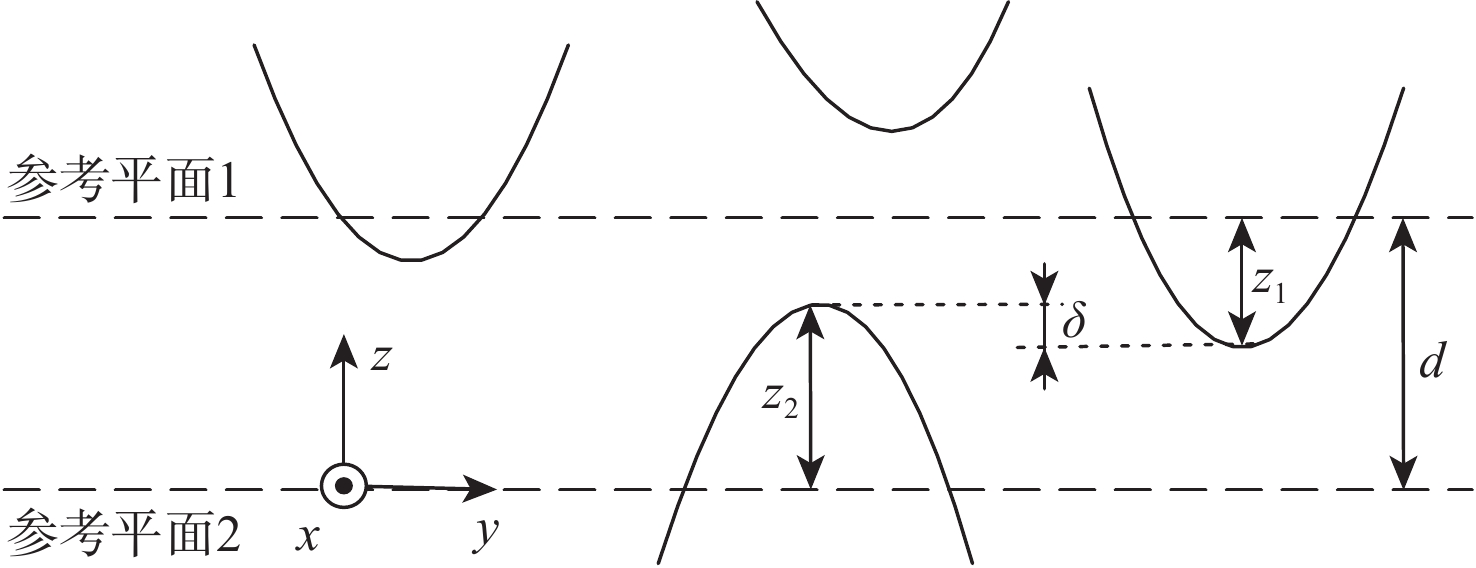

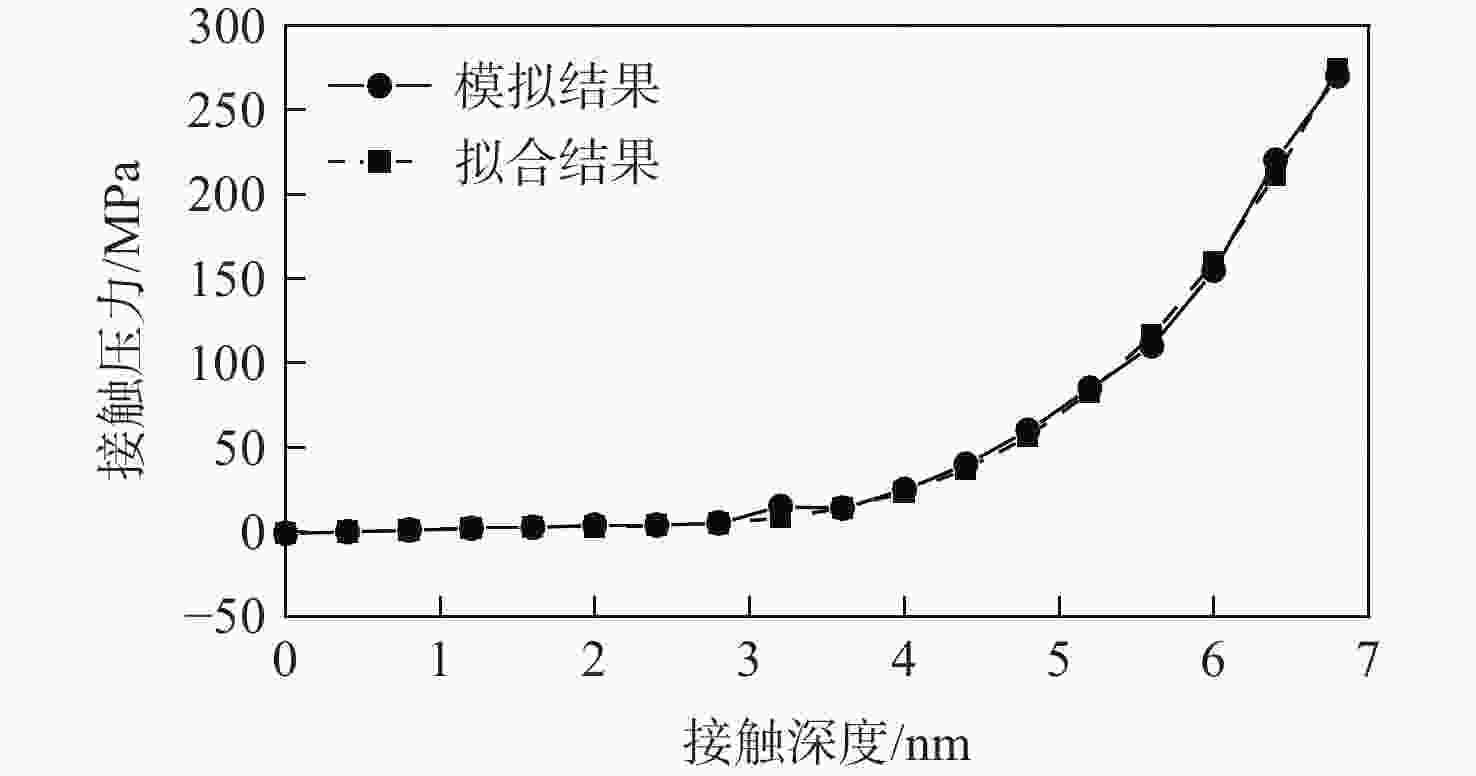

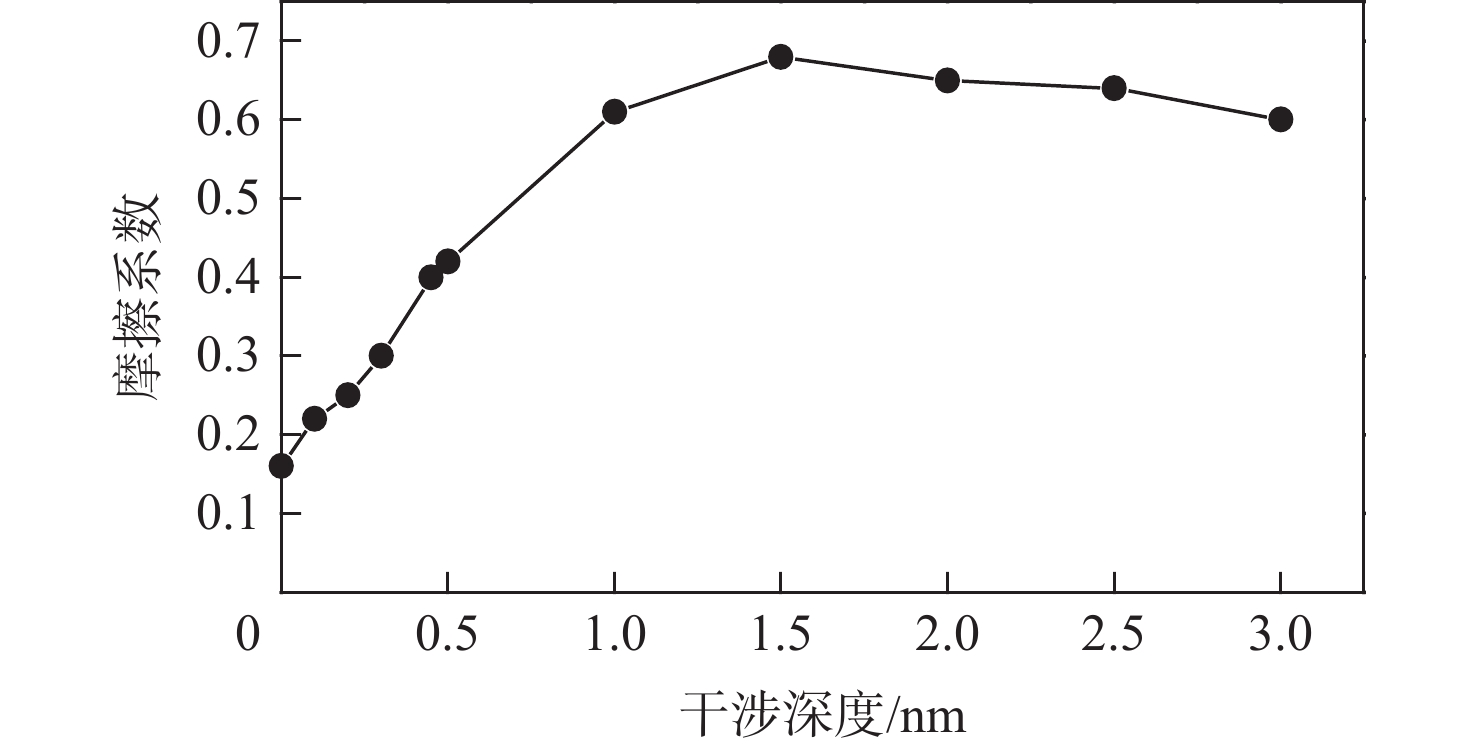

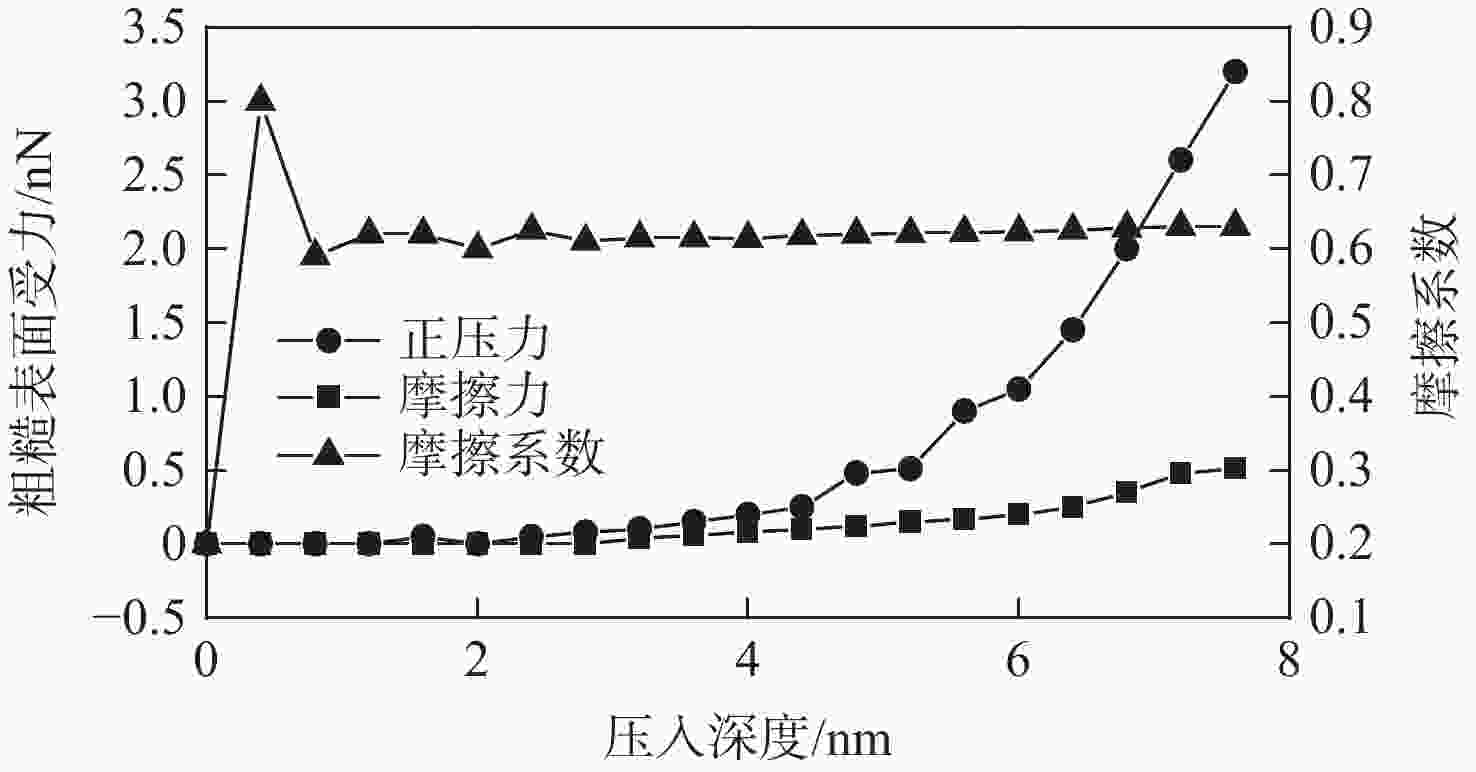

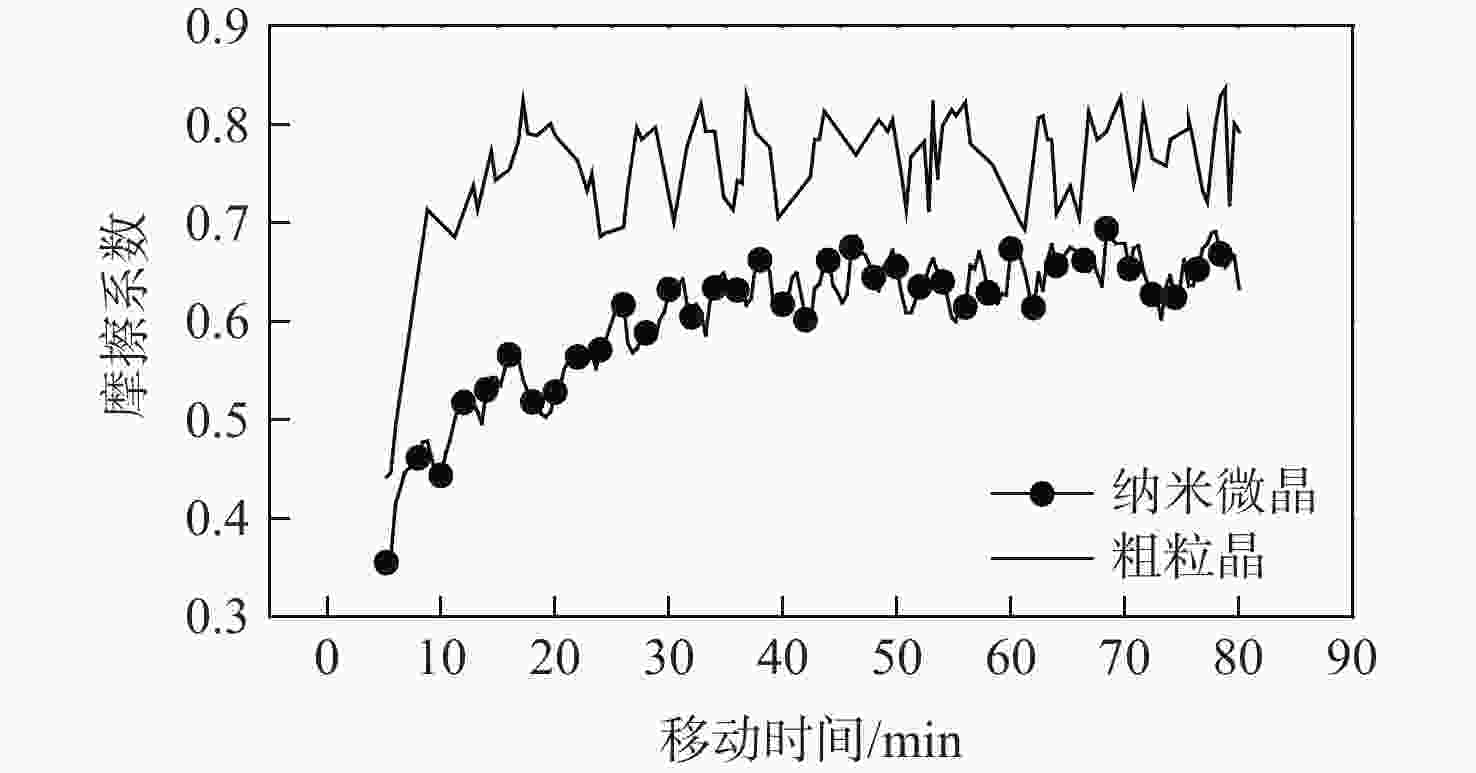

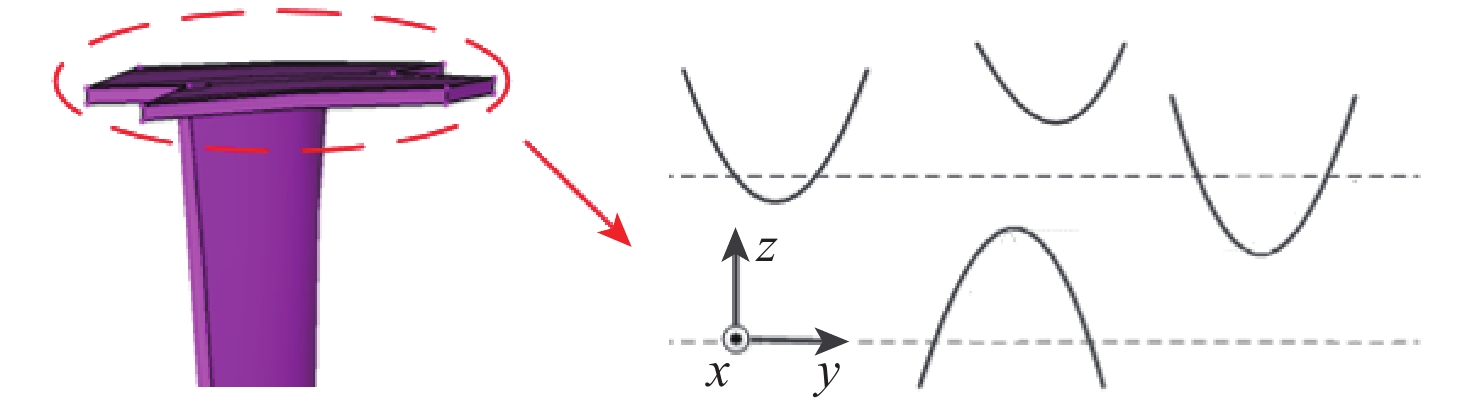

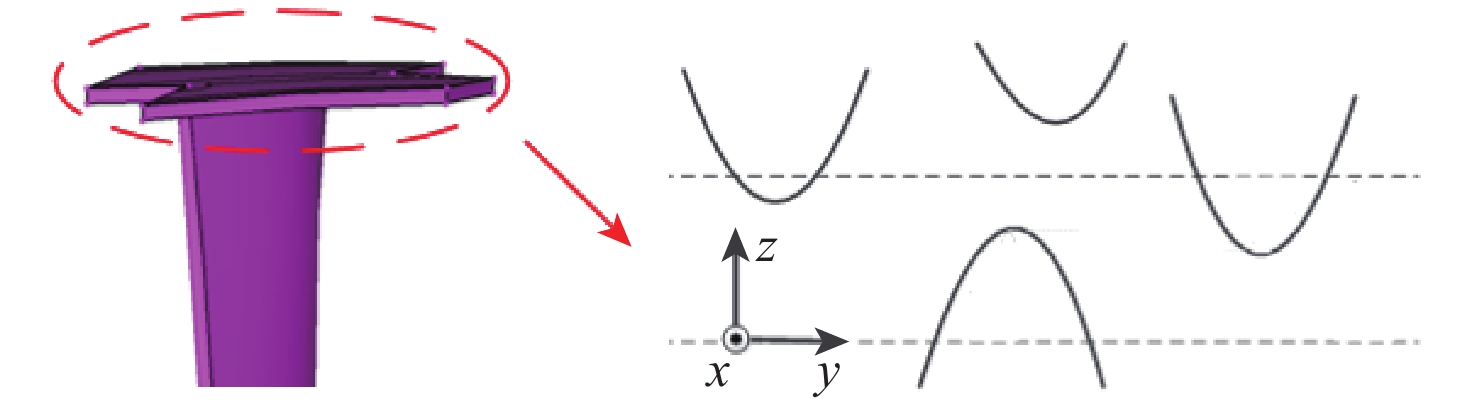

基于多尺度方法对干摩擦行为进行预测已成为当前研究热点。对于航空发动机等高温机械系统,温度对干摩擦行为影响至关重要。针对高温影响下微动界面摩擦行为开展分子动力学建模与分析,研究不同温度下微凸体的切向碰撞过程;考虑温度的升高使摩擦界面微凸体黏着作用增强,提出不同于赫兹接触理论预测的真实面积计算方法;基于所建的分子动力学模型和G-W接触模型,研究不同温度下接触面的摩擦系数,与实验测量的摩擦系数结果吻合,验证所提方法的正确性。对于在高温环境下接触、摩擦及微动等界面力学问题的研究提供了可借鉴的方法,同时为高温旋转机械动力学多尺度方法提供了可参考的解决手段。

Abstract:The prediction of friction factors based on multi-scale methods has become a research hotspot. The influence of temperature is the main issue for mechanical systems that operate at high temperatures, such as aero-engines. In this paper, we propose a novel method for predicting friction factors based on molecular modeling and the contact force under the influence of different temperatures. Considering that the increase in temperature enhances the adhesion of the micro convex body, a real area calculation method different from Hertz contact theory is proposed. The correctness of the proposed method is verified by comparing it with the experiment. The results show that the increase in temperature leads to the enhancement of adhesion of the micro convex body at the rough face. Real contact area is bigger than what the Hz contact theory predicts when adhesion is high due to the substantial plastic deformation of the micro convex body. On the other hand, it also leads to the attenuation of the mechanical properties of materials. With the increase in temperature, the tangential and normal contact forces decrease. Based on the multi-scale method, we provide a feasible research scheme for the prediction of friction factors of a high-temperature machine.

-

Key words:

- multiscale /

- molecular dynamics /

- rough surface /

- G-W contact model /

- aero-engine

-

-

[1] 李琳, 刘久周, 李超. 航空发动机中的干摩擦阻尼器及其设计技术研究进展[J]. 航空动力学报, 2016, 31(10): 2305-2317.LI L, LIU J Z, LI C. Review of the dry friction dampers in aero-engine and their design technologies[J]. Journal of Aerospace Power, 2016, 31(10): 2305-2317(in Chinese). [2] 何冰冰. 涡轮叶片干摩擦阻尼器动力学特性及减振特性研究[D]. 西安: 西北工业大学, 2018.HE B B. Dynamic and vibration reduction characteristics analysis of turbine blades with dry friction damper[D]. Xi’an: Northwestern Polytechnical University, 2018 (in Chinese). [3] 单颖春, 郝燕平, 朱梓根, 等. 干摩擦阻尼块在叶片减振方面的应用与发展[J]. 航空动力学报, 2001, 16(3): 218-223.SHAN Y C, HAO Y P, ZHU Z G, et al. Application and development of platform friction damper for depressing resonant vibration of blades[J]. Journal of Aerospace Power, 2001, 16(3): 218-223(in Chinese). [4] ABRAHAM F F, BROUGHTON J Q, BERNSTEIN N, et al. Spanning the length scales in dynamic simulation[J]. Computers in Physics, 1998, 12(6): 538. doi: 10.1063/1.168756 [5] BROUGHTON J Q, ABRAHAM F F, BERNSTEIN N, et al. Concurrent coupling of length scales: Methodology and application[J]. Physical Review B, 1999, 60(4): 2391-2403. doi: 10.1103/PhysRevB.60.2391 [6] LUAN B Q, HYUN S, MOLINARI J F, et al. Multiscale modeling of two-dimensional contacts[J]. Physical Review E, 2006, 74(4): 046710. doi: 10.1103/PhysRevE.74.046710 [7] PEN H, BAI Q, LIANG Y C, et al. Multiscale simulation of nanometric cutting of single crystal copper effect of different cutting speeds[J]. Acta Metallurgica Sinica (English Letters), 2009, 22: 440-446. doi: 10.1016/S1006-7191(08)60121-0 [8] 赵晟, 江五贵. 纳米尺度下切削过程的准连续介质力学模拟[J]. 摩擦学学报, 2009, 29(6): 505-511. doi: 10.3321/j.issn:1004-0595.2009.06.004ZHAO S, JIANG W G. Quasicontinuum simulations of nano-cutting process[J]. Tribology, 2009, 29(6): 505-511(in Chinese). doi: 10.3321/j.issn:1004-0595.2009.06.004 [9] SHIARI B, MILLER R E, KLUG D D. Multiscale simulation of material removal processes at the nanoscale[J]. Journal of the Mechanics and Physics of Solids, 2007, 55(11): 2384-2405. doi: 10.1016/j.jmps.2007.03.018 [10] 樊江, 戴琦晖, 王晋斌, 等. 带涂层干摩擦阻尼器的分子动力学仿真[J]. 航空动力学报, 2018, 33(10): 2333-2342.FAN J, DAI Q H, WANG J B, et al. Molecular dynamics simulations of dry friction dampers with coating[J]. Journal of Aerospace Power, 2018, 33(10): 2333-2342(in Chinese). [11] 潘帅航, 尹念, 张执南. 微动界面连续干摩擦行为的分子动力学模拟[J]. 机械工程学报, 2018, 54(3): 82-87. doi: 10.3901/JME.2018.03.082PAN S H, YIN N, ZHANG Z N. Molecular dynamics simulation for continuous dry friction on fretting interfaces[J]. Journal of Mechanical Engineering, 2018, 54(3): 82-87(in Chinese). doi: 10.3901/JME.2018.03.082 [12] ZHENG X, ZHU H T, KOSASIH B, et al. A molecular dynamics simulation of boundary lubrication: The effect of n-alkanes chain length and normal load[J]. Wear, 2013, 301(1-2): 62-69. doi: 10.1016/j.wear.2013.01.052 [13] ZHENG X, ZHU H T, TIEU A K, et al. Roughness and lubricant effect on 3D atomic asperity contact[J]. Tribology Letters, 2014, 53(1): 215-223. doi: 10.1007/s11249-013-0259-y [14] LIU X M, LIU Z L, WEI Y G. Nanoscale friction behavior of the Ni-film/substrate system under scratching using MD simulation[J]. Tribology Letters, 2012, 46(2): 167-178. doi: 10.1007/s11249-012-9932-9 [15] 罗旋, 费维栋, 李超, 等. 材料科学中的分子动力学模拟研究进展[J]. 材料科学与工艺, 1996, 4(1): 124-128.LUO X, FEI W D, LI C, et al. Advance of molecular dynamics simulation in materials science[J]. Material Science and Technology, 1996, 4(1): 124-128(in Chinese). [16] 杨继明. 纳米尺度摩擦行为的分子动力学模拟研究[D]. 重庆: 重庆大学, 2012.YANG J M. Molecular dynamics simulation of nano-scale friction behavior[D]. Chongqing: Chongqing University, 2012 (in Chinese). [17] GREENWOOD J, WILLIAMSON J. Contact of nominally flat surfaces[J]. Proceedings of the Royal Society of London Series A Mathematical and Physical Sciences, 1966, 295: 300-319. [18] HOOVER W G. Canonical dynamics: Equilibrium phase-space distributions[J]. Physical Review A, 1985, 31(3): 1695-1697. doi: 10.1103/PhysRevA.31.1695 [19] 李强. 接触力学与摩擦学的原理及其应用[M]. 北京: 清华大学出版社, 2011.LI Q. Principles and applications of contact mechanics and tribology [M]. Beijing: Tsinghua University Press, 2011(in Chinese). [20] 刘如铁, 李溪滨, 苏春明, 等. 镍基高温自润滑材料的摩擦学特性研究[J]. 粉末冶金材料科学与工程, 1998, 3(3): 206-210.LIU R T, LI X B, SU C M, et al. Study on the tribological characteristics of high-temperature self-lubricating nickel-base material[J]. Materials Science and Engineering of Powder Metallargy, 1998, 3(3): 206-210(in Chinese). [21] 张甜甜, 黄传兵, 兰昊, 等. 镍基耐高温自润滑刷式封严涂层研究[J]. 航空制造技术, 2017, 60(8): 24-29.ZHANG T T, HUANG C B, LAN H, et al. Investigation of Ni-based brush seal coatings with self-lubricating property at elevated temperature[J]. Aeronautical Manufacturing Technology, 2017, 60(8): 24-29(in Chinese). [22] DAW M S, BASKES M I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals[J]. Physical Review B, 1984, 29(12): 6443-6453. doi: 10.1103/PhysRevB.29.6443 [23] MA G L, YANG J Q, LIU Y, et al. Friction and wear behavior of nanocrystalline nickel in air and vacuum[J]. Tribology Letters, 2013, 49(3): 481-490. doi: 10.1007/s11249-012-0089-3 -

下载:

下载: