-

摘要:

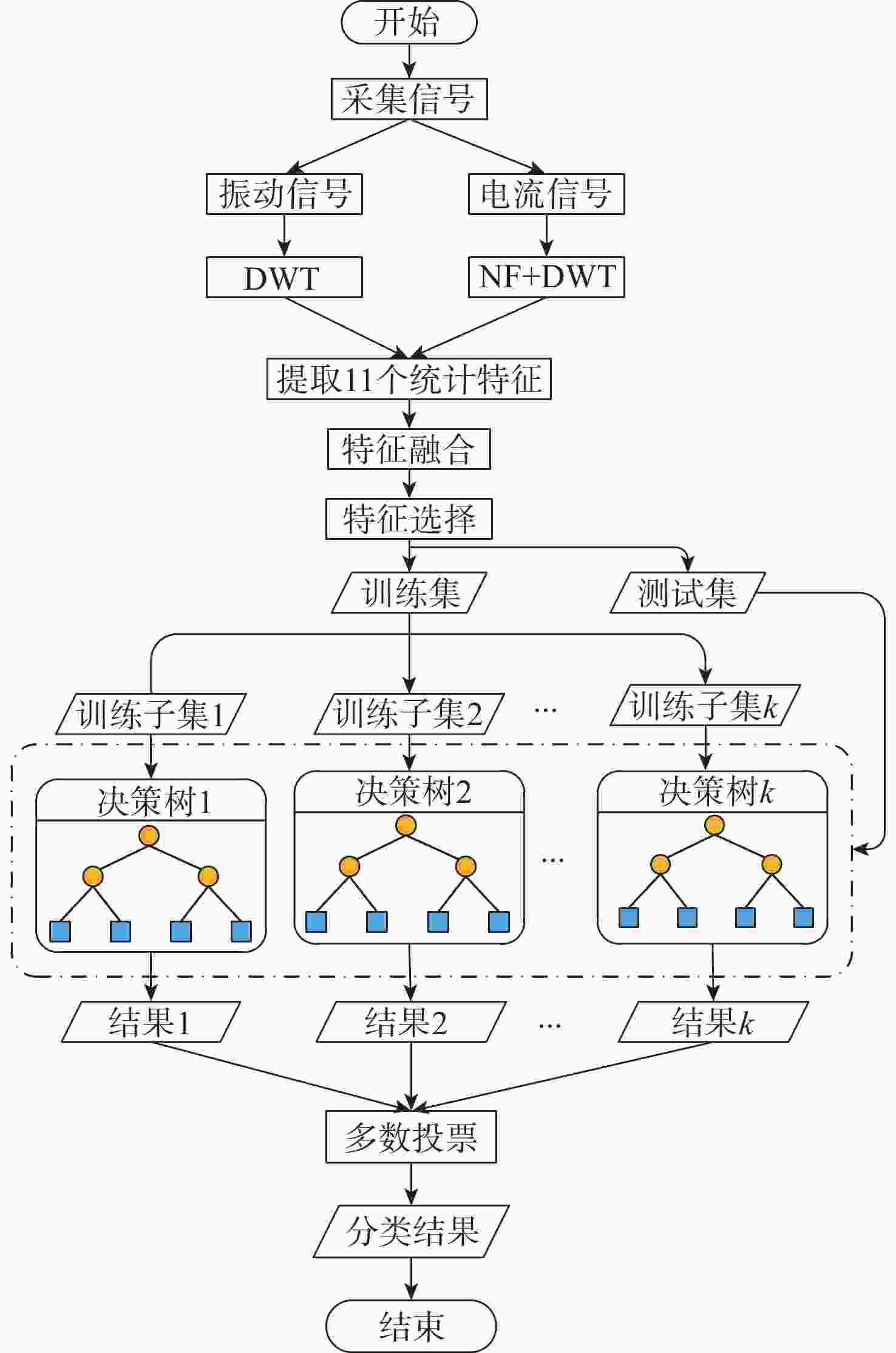

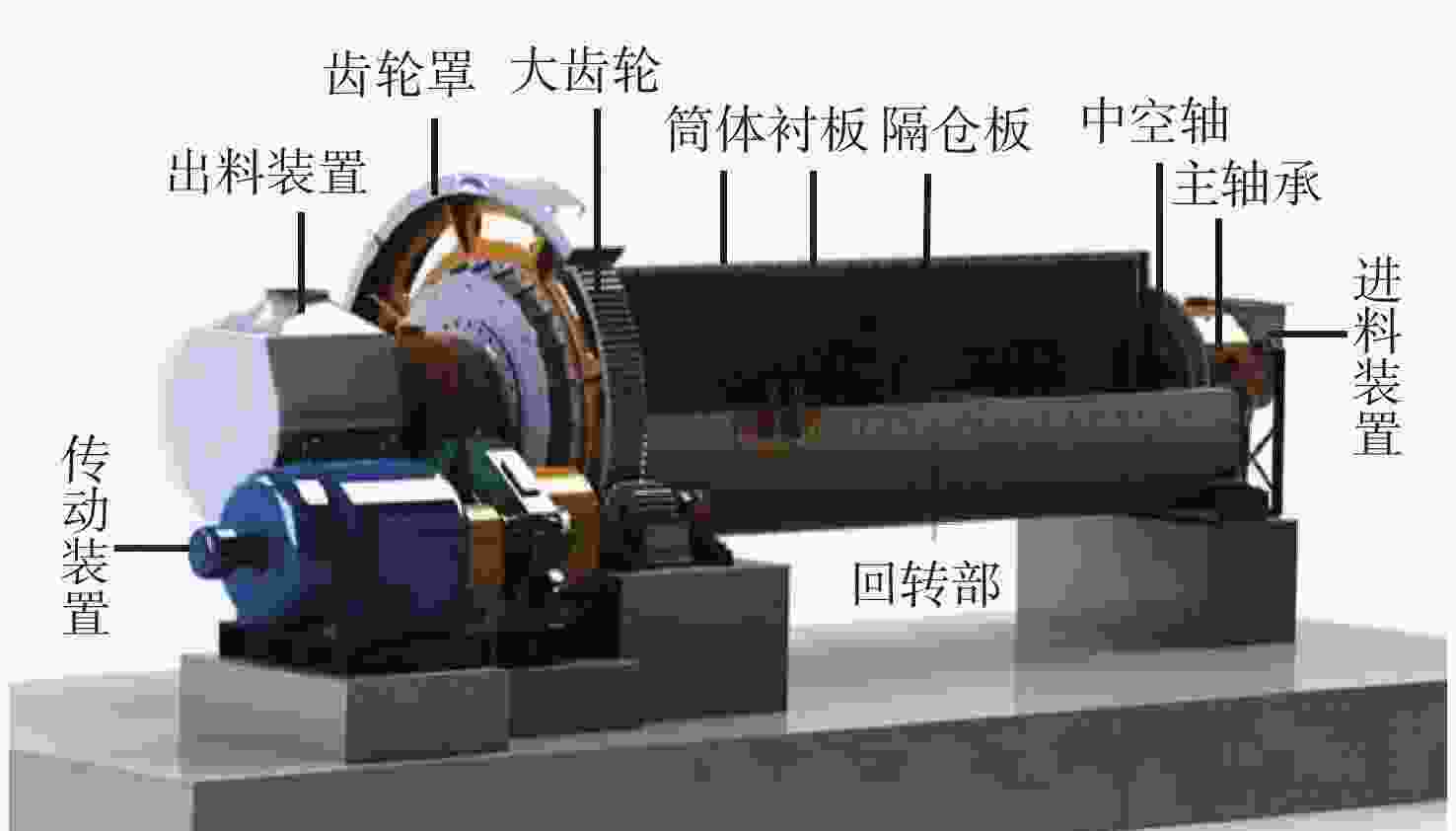

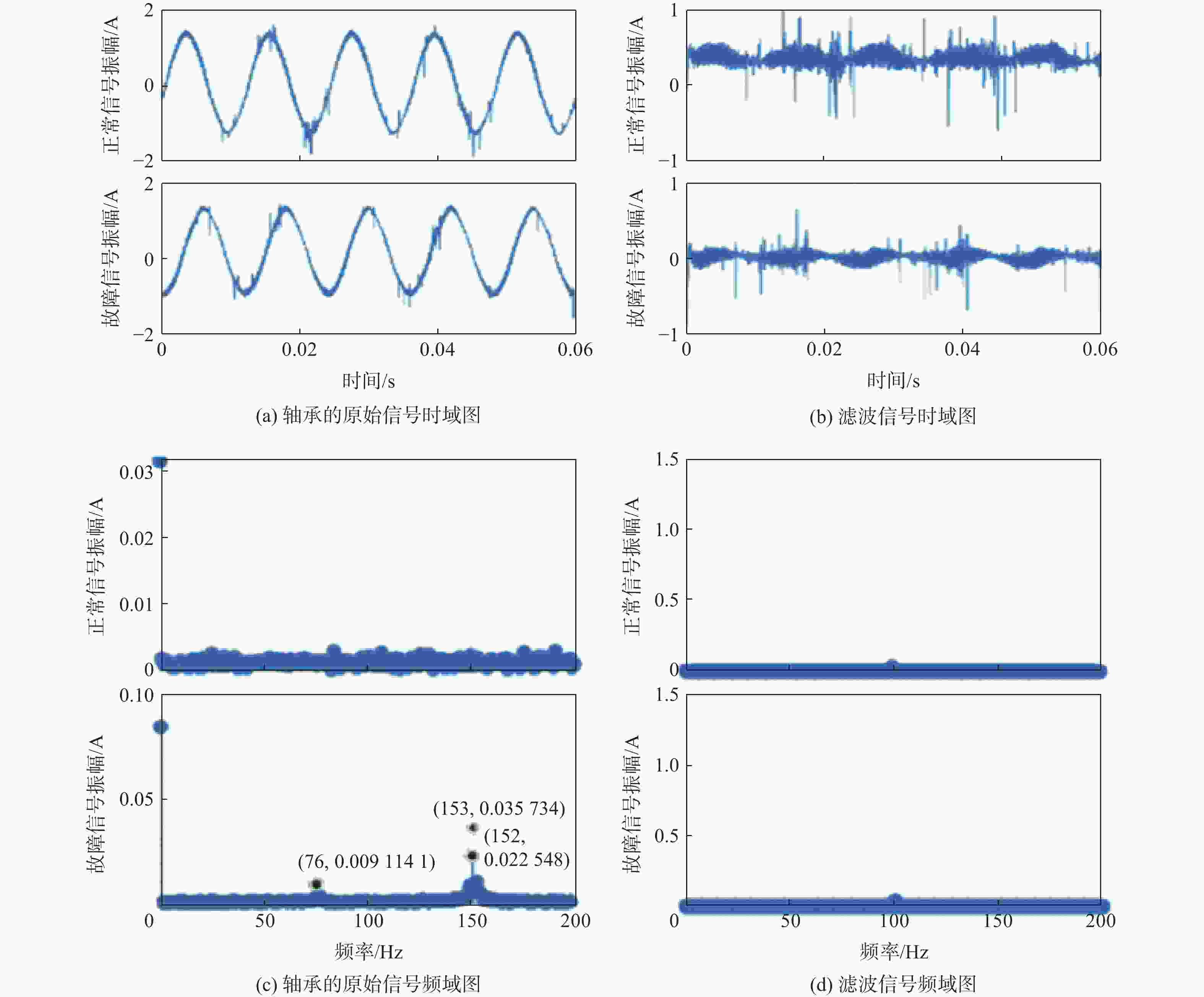

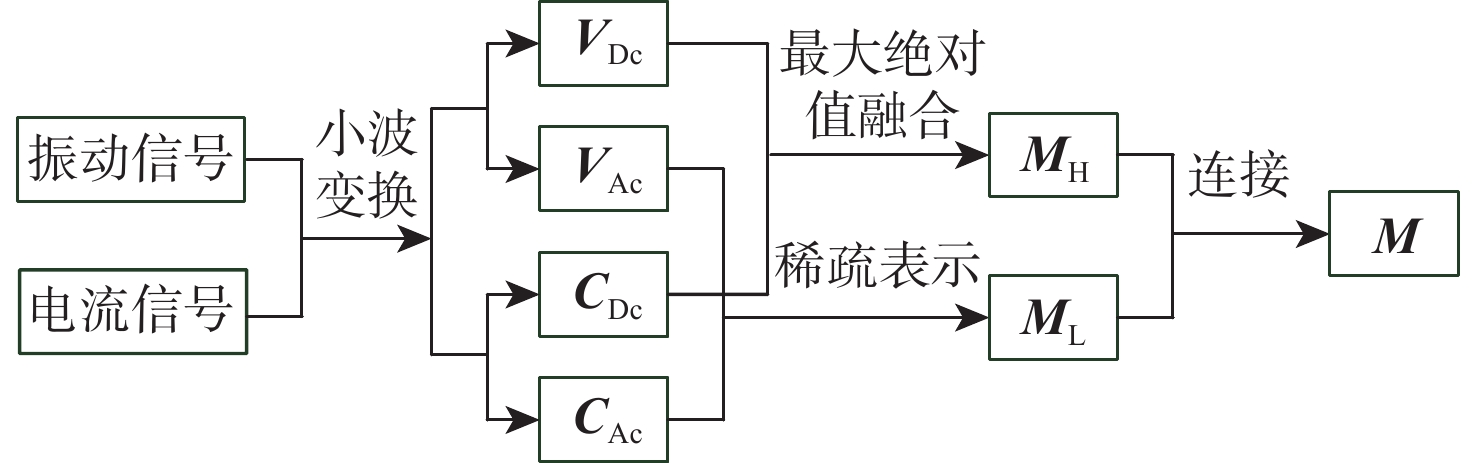

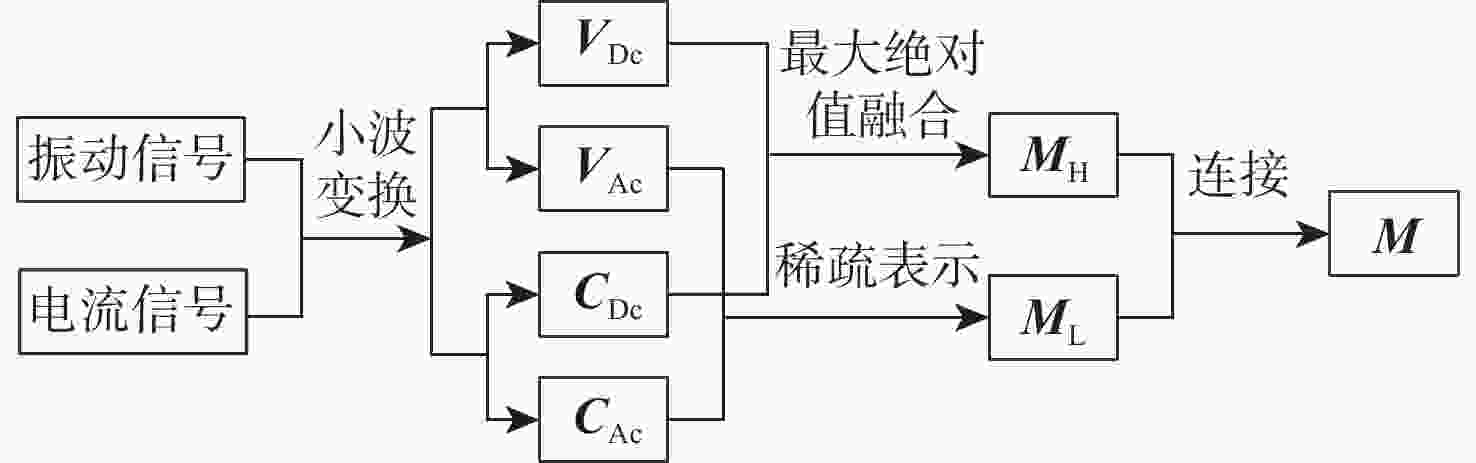

由于冶金工业工况复杂,很难从单一信号中获取高质量的故障特征,诊断效果不佳。针对直接使用电流和振动信号进行融合,不能体现2类信号在不同频段上的优势和彼此之间的互补信息,而影响诊断性能的问题,提出一种基于振动和电流信号的多特征互补融合故障诊断方法。将振动信号和电流信号的高频系数特征通过最大绝对值规则融合,形成体现高频段特征的互补特征;将振动信号和电流信号的低频系数特征通过稀疏表示(SR )融合,形成体现低频段特征的互补特征。通过定义由多特征组成的特征矩阵融合全频段特征,增强全局特征表征能力。采用递归特征消除法消除融合后的冗余特征,提高分类精度,结合随机森林( RF )对轴承故障状态进行分类。实验结果表明:所提方法相比基于振动信号和基于电流信号的诊断结果更加准确。

Abstract:The diagnosis effect is unsatisfactory because it is challenging to extract high-quality fault characteristics from a single signal given the complicated working conditions of the metallurgical industry. Aiming at the problem of directly using current and vibration signals for fusion, which cannot reflect the advantages of the two types of signals in different frequency bands and the complementary information between each other, but affects the diagnostic performance, this paper proposes a multi-feature complementary fusion fault diagnosis method based on vibration and current signals. First, the high-frequency coefficient features of the vibration signal and the current signal are fused through the maximum absolute value rule to form complementary features that reflect the high-frequency characteristics. The low-frequency coefficient features of the vibration signal and the current signal are fused through sparse representation (SR) to form complementary features that reflect the low-frequency features. By defining a feature matrix composed of multiple features to fuse full frequency band features, the global feature characterization capability is enhanced. After feature fusion, redundant features are removed to increase classification accuracy and categorize the bearing defect state using a combination of random forest (RF) and recursive feature elimination. Experimental results show that this method is more accurate than the diagnosis results based on vibration signals and current signals.

-

Key words:

- feature fusion /

- fault diagnosis /

- ball mill /

- feature extraction /

- random forest

-

表 1 实测数据集上不同方法分类准确率对比

Table 1. Comparison of classification accuracy of various methods on real datasets

方法 信号类型 平均准确率/% 平均F1分数/% KNN 振动 66.18 66.18 电流 56.37 59.37 DT 振动 89.71 89.65 电流 83.08 83.08 RF 振动 93.38 94.38 电流 89.46 89.44 本文方法 振动 +电流 99.02 99.02 表 2 实验数据的轴承代号

Table 2. Bearing code used for experimental data

故障类别 轴承代号 标签 正常(HBD) K001, K002, K003, K004, K005, K006 0 外圈故障(OR) KA04, KA15, KA16, KA22, KA30 1 内圈故障(IR) KI04, KI14, KI16, KI17, KI18,KI21 2 表 3 公共数据集上不同方法分类准确率对比

Table 3. Comparison of classification accuracy of various methods on public datasets

-

[1] 蔡改贫, 刘鑫, 罗小燕, 等. 基于多尺度模糊熵和改进极限学习机的球磨机负荷状态识别[J]. 吉林大学学报(工学版), 2020, 50(6): 2055-2067. doi: 10.13229/j.cnki.jdxbgxb20190716CAI G P, LIU X, LUO X Y, et al. Load state recognition of ball mill based on multi-scale fuzzy entropy and improved extreme learning machine[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(6): 2055-2067(in Chinese). doi: 10.13229/j.cnki.jdxbgxb20190716 [2] JIANG G, ZHAO J, JIA C, et al. Intelligent fault diagnosis of gearbox based on vibration and current signals: A multimodal deep learning approach[C]//Proceedings of the Prognostics and System Health Management Conference. Piscataway: IEEE Press, 2019: 1-6. [3] YAN R, GAO R X, CHEN X. Wavelets for fault diagnosis of rotary machines: A review with applications[J]. Signal Processing, 2014, 96: 1-15. doi: 10.1016/j.sigpro.2013.04.015 [4] LEI Y, LIN J, HE Z, et al. A review on empirical mode decomposition in fault diagnosis of rotating machinery[J]. Mechanical Systems and Signal Processing, 2013, 35(1-2): 108-126. doi: 10.1016/j.ymssp.2012.09.015 [5] JIANG G Q, PING X, XIAO W, et al. Intelligent fault diagnosis of rotary machinery based on unsupervised multiscale representation learning[J]. Chinese Journal of Mechanical Engineering, 2017, 30(6): 1-11. [6] SOUALHI A, MEDJAHER K, ZERHOUNI N. Bearing health monitoring based on Hilbert-Huang transform, support vector machine and regression[J]. IEEE Transactions on Instrumentation and Measurement, 2015, 64(1): 52-62. doi: 10.1109/TIM.2014.2330494 [7] 胡显能, 蔡改贫, 罗小燕, 等. 基于 CEEMDAN 和多尺度排列熵的球磨机负荷识别方法[J]. 噪声与振动控制, 2018, 38(3): 146-151.HU X N, CAI G P, LUO X Y, et al. Load identification method of ball mill based on CEEMDAN and multi-scale permutation entropy[J]. Noise and Vibration Control, 2018, 38(3): 146-151(in Chinese). [8] CHEN Z, LI W. Multisensor feature fusion for bearing fault diagnosis using sparse autoencoder and deep belief network[J]. IEEE Transactions on Instrumentation and Measurement, 2017, 66(7): 1693-1702. doi: 10.1109/TIM.2017.2669947 [9] LU D, GONG X, QIAO W. Current-based diagnosis for gear tooth breaks in wind turbine gearboxes[C]//Proceedings of the IEEE Energy Conversion Congress and Exposition. Piscataway: IEEE Press, 2012: 3780-3786. [10] SUN L L, ZHANG K K, LU X D. Stator inter-turn fault diagnosis of induction motor based on wavelet packet decomposition and random forest[C]//Proceedings of the Renewable Power Generation Conference. London: IET, 2019: 1-6. [11] WIDODO A, YANG B S, GU D S, et al. Intelligent fault diagnosis system of induction motor based on transient current signal[J]. Mechatronics, 2009, 19(5): 680-689. doi: 10.1016/j.mechatronics.2009.02.002 [12] WANG J, FU P, ZHANG L, et al. Multilevel information fusion for induction motor fault diagnosis[J]. IEEE/ASME Transactions on Mechatronics, 2019, 24(5): 2139-2150. doi: 10.1109/TMECH.2019.2928967 [13] XIA M, LI T, XU L, et al. Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks[J]. IEEE/ASME Transactions on Mechatronics, 2018, 23(1): 101-110. [14] HOU L, BERGMANN N W. Novel industrial wireless sensor networks for machine condition monitoring and fault diagnosis[J]. IEEE Transactions on Instrumentation and Measurement, 2012, 61(10): 2787-2798. doi: 10.1109/TIM.2012.2200817 [15] LI C, SANCHEZ R V, ZURITA G, et al. Gearbox fault diagnosis based on deep random forest fusion of acoustic and vibratory signals[J]. Mechanical Systems and Signal Processing, 2016, 76-77: 283-293. [16] MA M, SUN C, CHEN X. Deep coupling autoencoder for fault diagnosis with multimodal sensory data[J]. IEEE Transactions on Industrial Informatics, 2018, 14(3): 1137-1145. doi: 10.1109/TII.2018.2793246 [17] JING L Y, WANG T Y, ZHAO M, et al. An adaptive multi-sensor data fusion method based on deep convolutional neural networks for fault diagnosis of planetary gearbox[J]. Sensors (Switzerland), 2017, 17(2): 414. [18] WU J D, CHEN J C. Continuous wavelet transform technique for fault signal diagnosis of internal combustion engines[J]. NDT & E International, 2006, 39(4): 304-311. [19] LI Z, FENG Z, CHU F. A load identification method based on wavelet multi-resolution analysis[J]. Journal of Sound and Vibration, 2014, 333(2): 381-391. doi: 10.1016/j.jsv.2013.09.026 [20] ERIŞTI H, UÇAR A, DEMIR Y. Wavelet-based feature extraction and selection for classification of power system disturbances using support vector machines[J]. Electric Power Systems Research, 2010, 80(7): 743-752. doi: 10.1016/j.jpgr.2009.09.021 [21] BLODT M, GRANJON P, RAISON B, et al. Models for bearing damage detection in induction motors using stator current monitoring[J]. IEEE Transactions on Industrial Electronics, 2008, 55(4): 1813-1822. doi: 10.1109/TIE.2008.917108 [22] MALLAT S G, ZHANG Z. Matching pursuits with time-frequency dictionaries[J]. IEEE Transactions on Signal Processing, 1993, 41(12): 3397-3415. doi: 10.1109/78.258082 [23] TROPP J A, GILBERT A C. Signal recovery from random measurements via orthogonal matching pursuit[J]. IEEE Transactions on Information Theory, 2007, 53(12): 4655-4666. doi: 10.1109/TIT.2007.909108 [24] TROPP J A, GILBERT A C, STRAUSS M J. Algorithms for simultaneous sparse approximation. Part I: Greedy pursuit[J]. Signal Processing, 2006, 86(3): 572-588. doi: 10.1016/j.sigpro.2005.05.030 [25] YANG B, LI S. Pixel-level image fusion with simultaneous orthogonal matching pursuit[J]. Information Fusion, 2012, 13(1): 10-19. doi: 10.1016/j.inffus.2010.04.001 [26] BREIMAN L. Random forests[J]. Machine Learning, 2001, 45(1): 5-32. doi: 10.1023/A:1010933404324 [27] WAN L, GONG K, ZHANG G, et al. An efficient rolling bearing fault diagnosis method based on spark and improved random forest algorithm[J]. IEEE Access, 2021, 9: 37866-37882. doi: 10.1109/ACCESS.2021.3063929 [28] TOMA R N, KIM J M. Bearing fault classification of induction motors using discrete wavelet transform and ensemble machine learning algorithms[J]. Applied Sciences, 2020, 10(15): 5251. doi: 10.3390/app10155251 [29] HOANG D T, KANG H J. A motor current signal-based bearing fault diagnosis using deep learning and information fusion[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(6): 3325-3333. [30] LESSMEIER C, KIMOTHO J K, ZIMMER D, et al. Condition monitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: A benchmark data set for data-driven classification[C]//Proceedings of the European Conference of the Prognostics and Health Management Society.[S.l.]: PHM Society, 2016: 1-17. -

下载:

下载: