-

摘要:

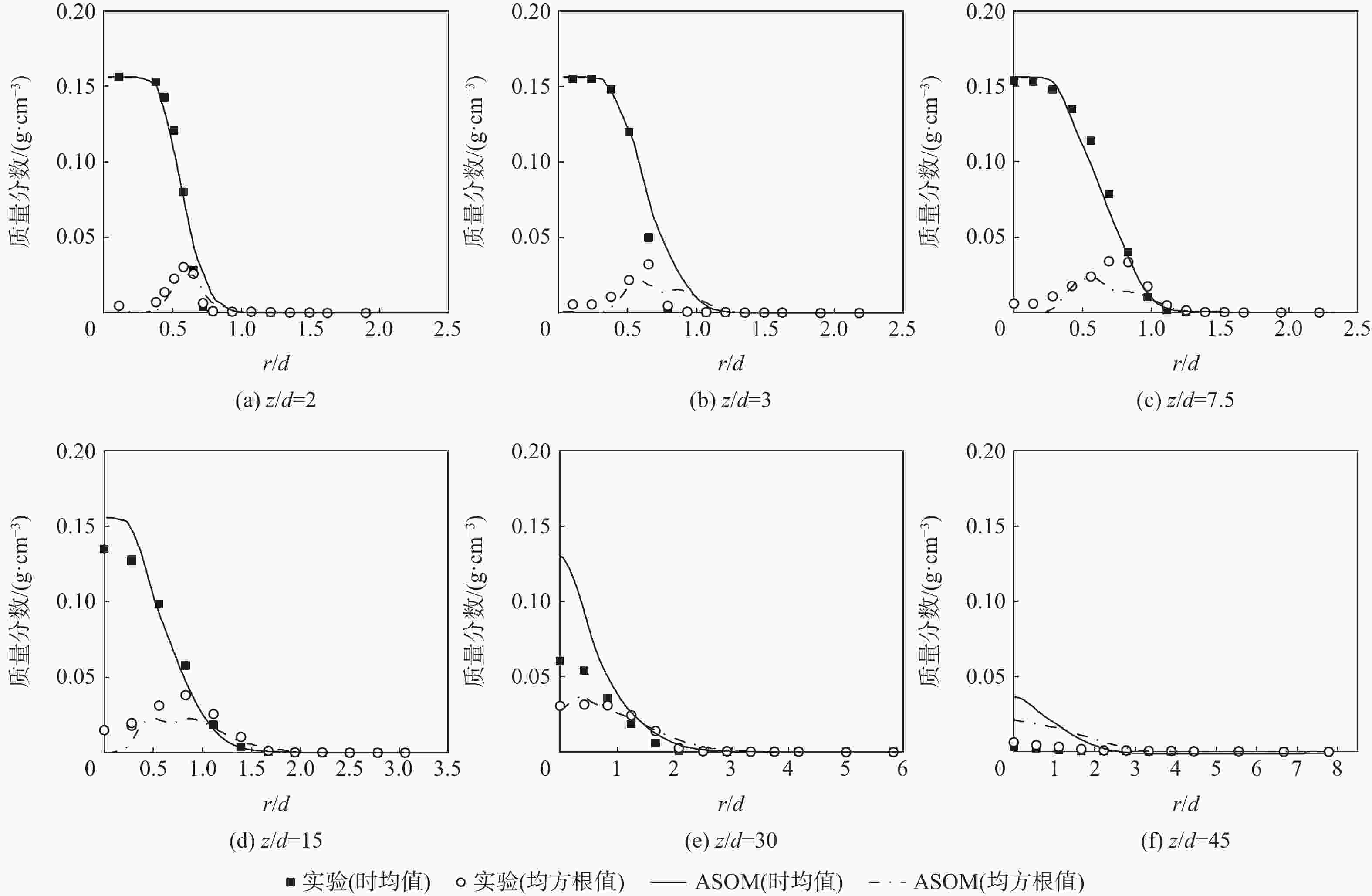

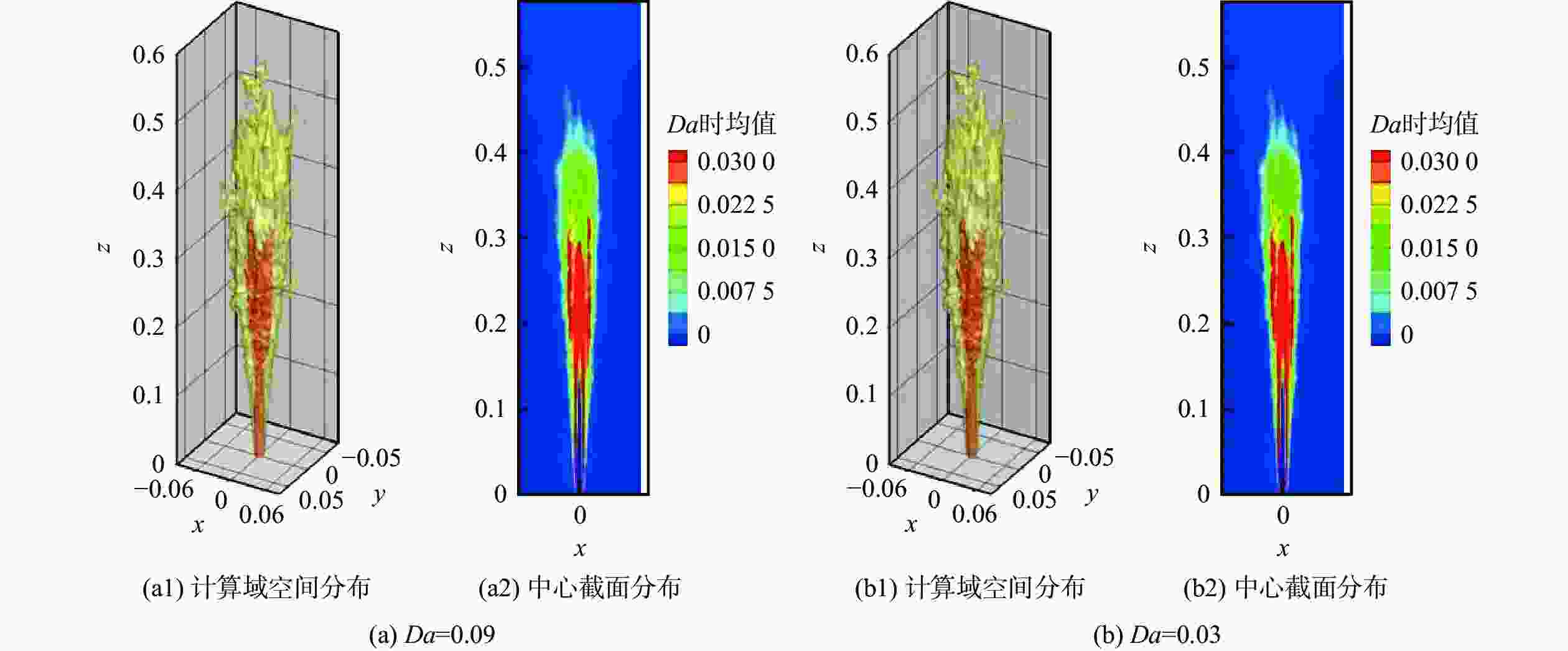

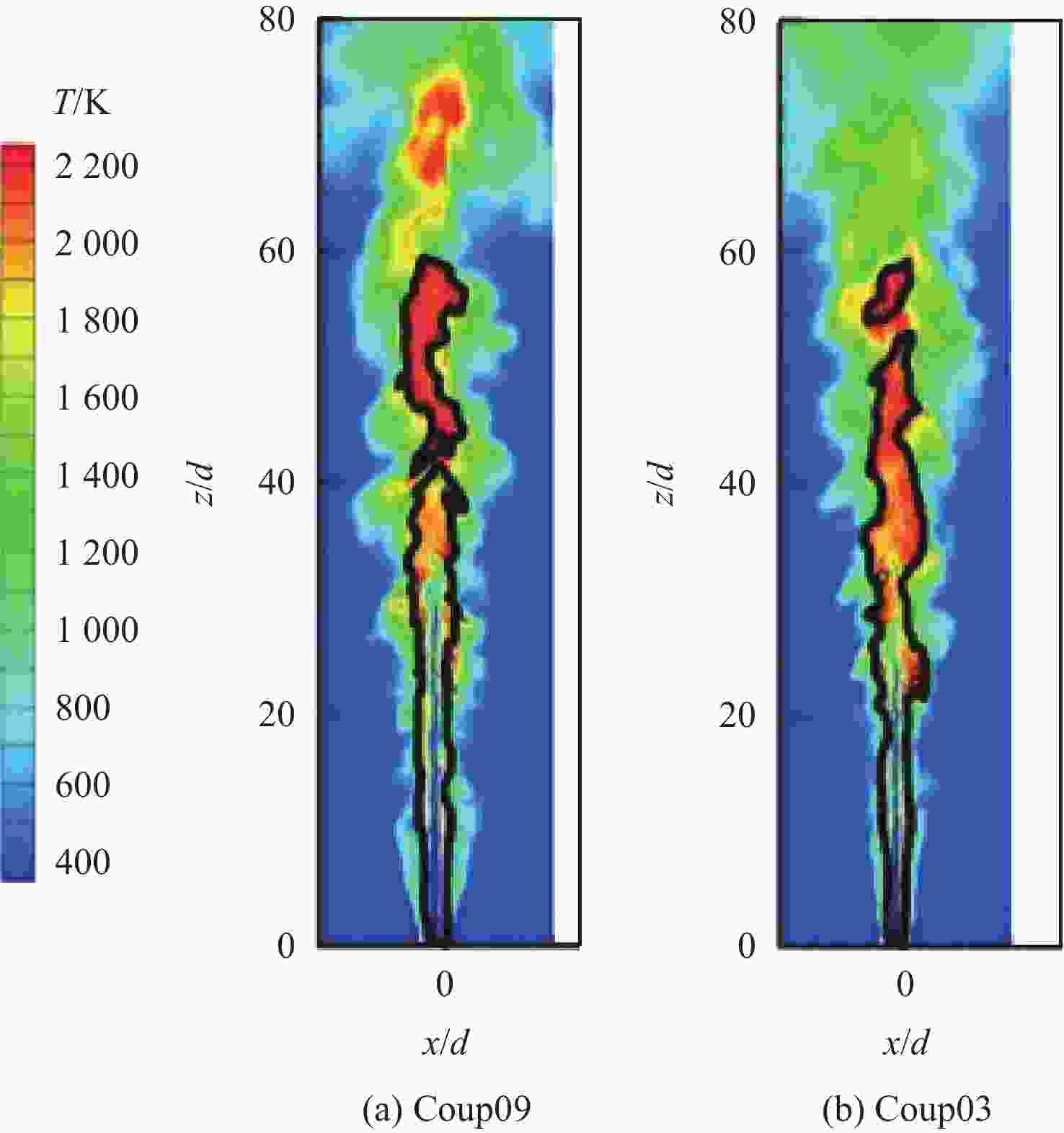

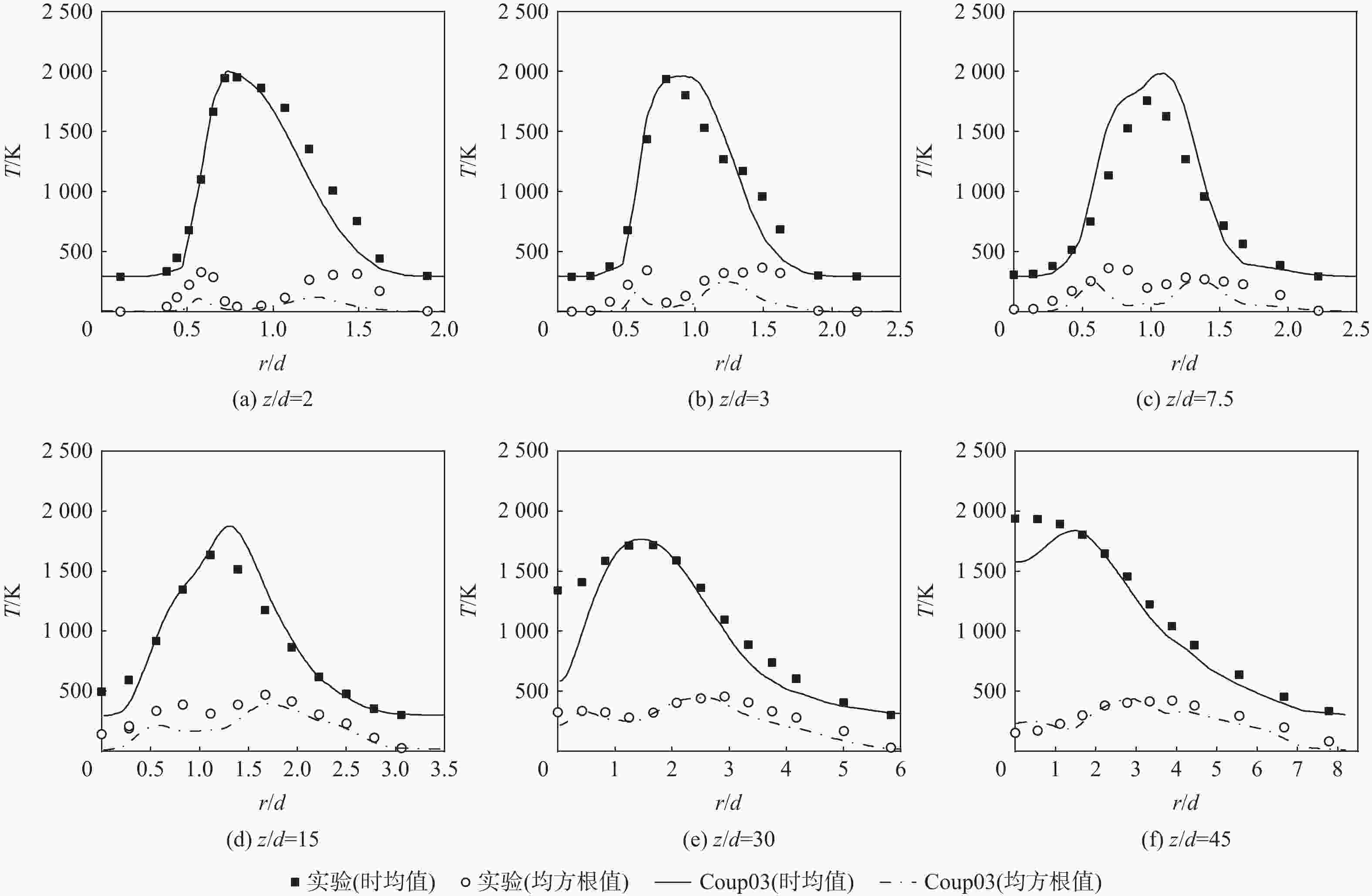

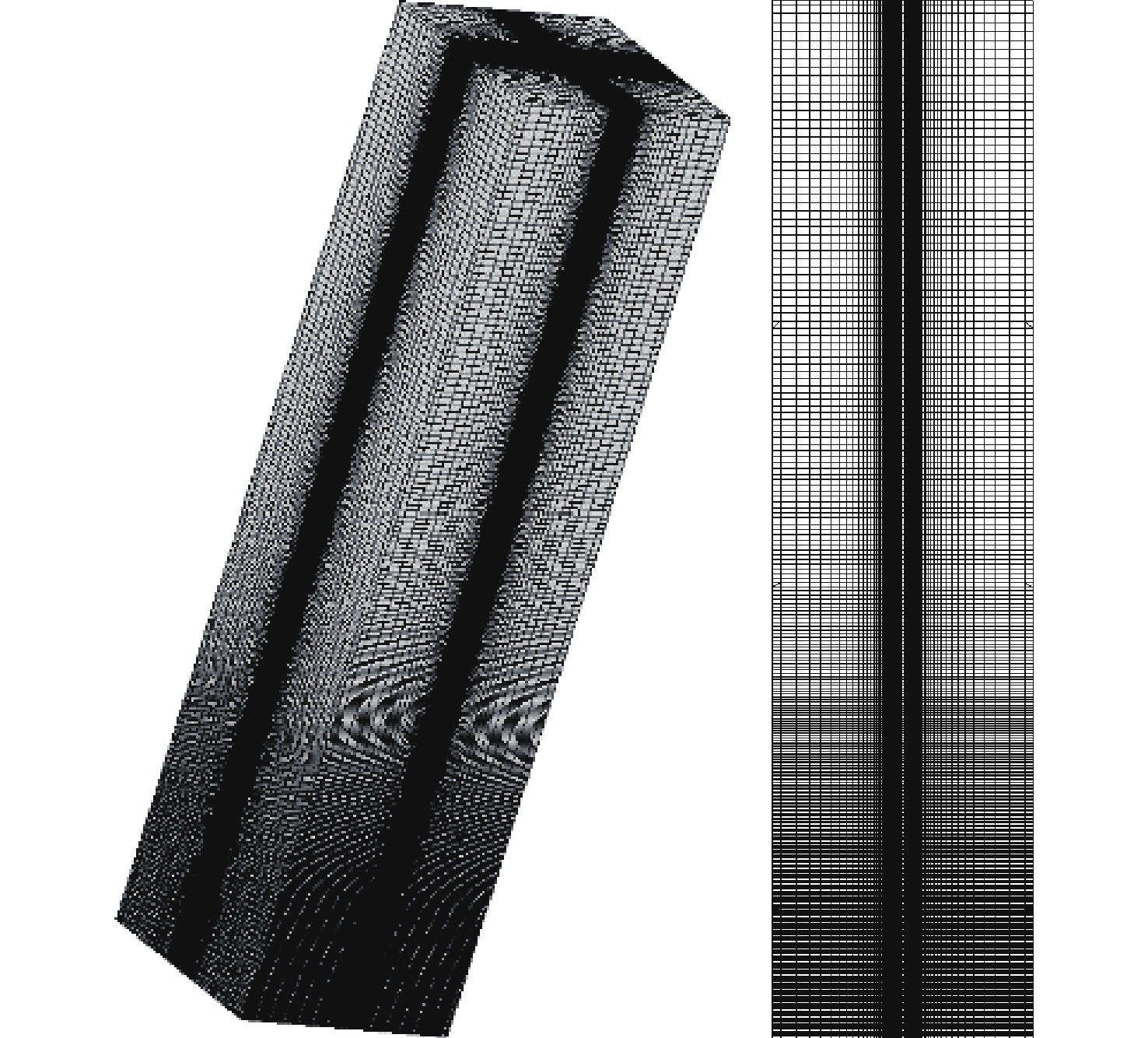

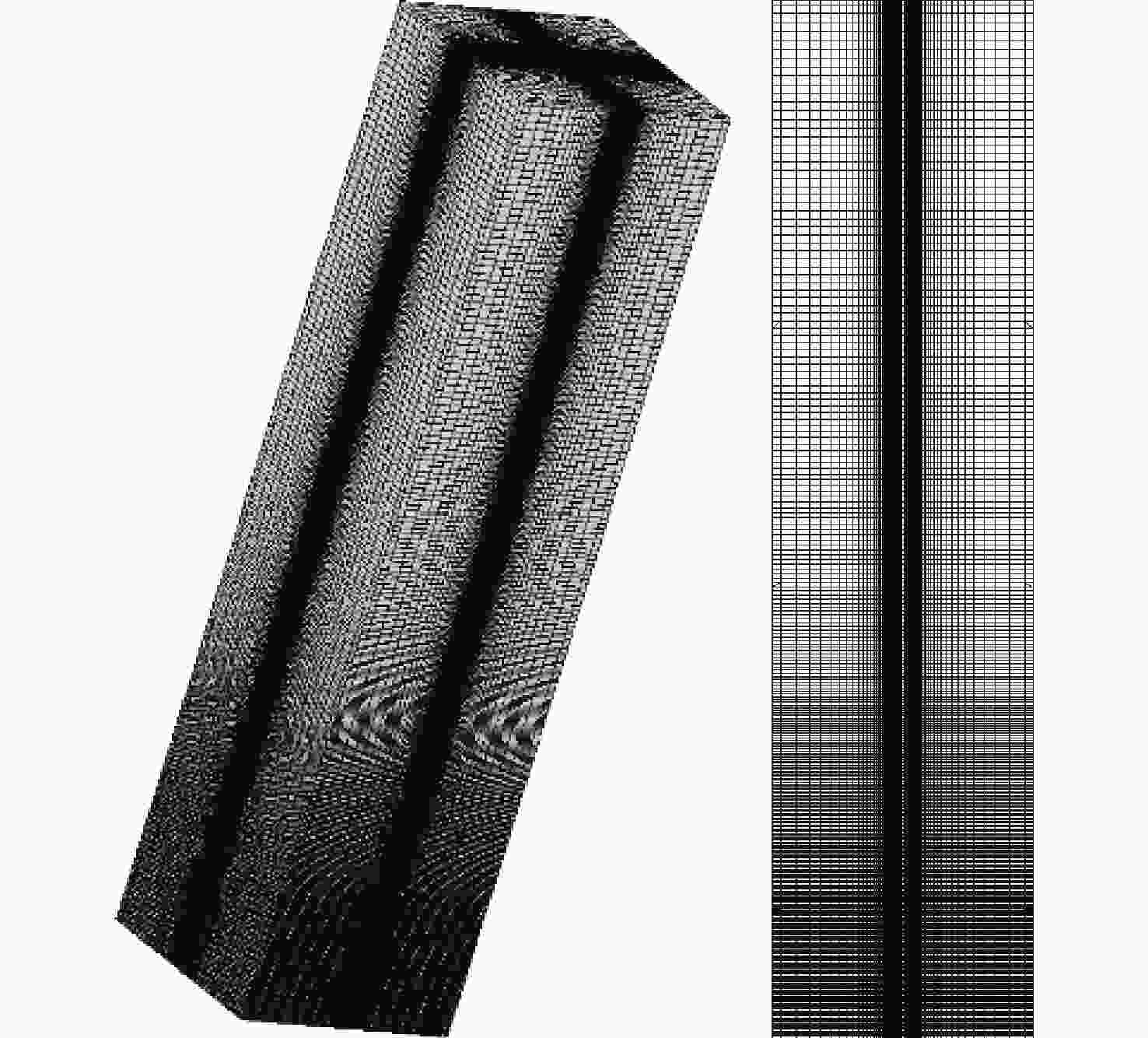

先进航空发动机燃烧室设计要求对湍流火焰精确控制,现有模拟方法需提高精度和效率。输运概率密度函数(TPDF)湍流燃烧模型精度高,代数二阶矩(ASOM)湍流燃烧模型计算成本低,类比离散涡模拟思想,基于

Da 数将湍流燃烧场区分“高精度”和“低成本”2个区域,在输运方程框架下采用随机场TPDF(高精度)和ASOM(低成本)方法重构TPDF-ASOM复合湍流燃烧模型,以提高模拟的整体精度和效率。在大涡模拟(LES)-TPDF程序平台创建ASOM并进一步实现TPDF-ASOM复合湍流燃烧模型,用Flame D实验数据检验所建模型和方法。结果表明:所建模型的预测结果与实验值接近,而且能够兼顾精度和计算效率。-

关键词:

- 复合湍流燃烧模型 /

- 随机场输运概率密度函数-方程湍流燃烧模型 /

- 代数二阶矩湍流燃烧模型 /

- Da数 /

- Flame D

Abstract:Advanced aero-engine combustor designs require precise control of turbulent flames, and existing simulation methods need to improve accuracy and efficiency. The probability density function transport equation (TPDF) turbulent combustion model possesses high accuracy and the algebraic second-order moment (ASOM) turbulent combustion model low simulation cost. This study uses the

Da number to categorize the turbulent combustion field into “high accuracy” and “low cost” categories, which is similar to the concept of detached eddy simulation (DES). To increase overall accuracy and simulation effectiveness, the TPDF-ASOM composite turbulent combustion model (TAM) was built using the random field TPDF (high accuracy) and ASOM (low simulation cost). This paper created the ASOM model on the large eddy simulation (LES)-TPDF program platform, and further realized the TPDF-ASOM composite turbulent combustion model,which is tested by the Flame D experimental data. The results show that the prediction results of the new model match the experimental values and reconcile the accuracy and simulation efficiency. -

表 1 Flame D火焰边界条件设置

Table 1. Flame D boundary condition settings

边界 边界条件 燃料进口 温度T=293 K,速度U=49.6 m/s 体积分数:甲烷25%,空气75% 值班火焰 温度T=1880 K,速度U=11.4 m/s 已燃气 伴流进口 温度T=293 K,速度U=0.9 m/s 空气 出口边界 压力出口边界 其他边界 绝热固壁无滑移边界 表 2 甲烷JL4机理反应动力学参数

Table 2. Reaction kinetic parameters of CH4 by Xfour-step mechanism

计算式 反应级数 $ A $/(cm3·mol−1·s−1) $ \beta $ $E$/J·mol−1) 式 (16) $\left[\mathrm{CH}_{4}\right]^{0.5}\left[\mathrm{O}_{2}\right]^{1.25}$ $ 7.82 \times 10^{18} $ 0 126 000 式 (17) $ \left[\mathrm{CH}_{4}\right]\left[\mathrm{H}_{2} \mathrm{O}\right] $ $ 0.30 \times 10^{11} $ 0 126 000 式 (18) $\left[\mathrm{H}_{2}\right]^{0.5}\left[\mathrm{O}_{2}\right]^{2.25 }\left[\mathrm{H}_{3} \mathrm{O}\right]^{-1}$ $4.45 \times 10^{18}$ −1 167 000 式 (19) $ [\mathrm{CO}]\left[\mathrm{H}_{2} \mathrm{O}\right] $ $ 2.75 \times 10^{12} $ 0 83 700 -

[1] POPE S B. Small scales, many species and the manifold challenges of turbulent combustion[J]. Proceedings of the Combustion Institute, 2013, 34(1): 1-31. doi: 10.1016/j.proci.2012.09.009 [2] HOCHGREB S. Mind the gap: Turbulent combustion model validation and future needs[J]. Proceedings of the Combustion Institute, 2019, 37(2): 2091-2107. doi: 10.1016/j.proci.2018.05.003 [3] PETERS N. Turbulent combustion[M]. Cambridge: Cambridge University Press, 2000. [4] PITSCH H. Large-eddy simulation of turbulent combustion[J]. Annual Review of Fluid Mechanics, 2006, 38: 453-482. doi: 10.1146/annurev.fluid.38.050304.092133 [5] 邢竞文, 金捷, 王方. 基于释热率分析的钝体贫油熄火过程分析[J]. 北京航空航天大学学报, 2022, 48(3): 473-484. doi: 10.13700/j.bh.1001-5965.2020.0588XING J W, JIN J, WANG F. Lean blowoff process of bluff body based on heat release rate analysis[J]. Journal of Beijing University of Aeronautics and Astronautics, 2022, 48(3): 473-484(in Chinese). doi: 10.13700/j.bh.1001-5965.2020.0588 [6] 王方, 韩宇轩, 窦力, 等. 详细化学反应机理对预混丙烷钝体熄火模拟影响[J]. 推进技术, 2021, 42(10): 2295-2305. doi: 10.13675/j.cnki.tjjs.200126WANG F, HAN Y X, DOU L, et al. Effects of detailed chemical mechanism on premixed propane bluff body blow-off simulation[J]. Journal of Propulsion Technology, 2021, 42(10): 2295-2305(in Chinese). doi: 10.13675/j.cnki.tjjs.200126 [7] 魏观溢, 金捷, 王方, 等. 基于PDF-LES的凹腔支板大涡模拟[C]//中国化学会第二届全国燃烧化学学术会议论文集. 北京: 中国化学会, 2017: 33.WEI G Y, JIN J, WANG F, et al. The large-eddy simulation of cavity flameholder by PDF-LES method[C]//Proceedings of the Second National Conference on Combustion Chemistry. Beijing: Chinese Chemical Society, 2017: 33 (in Chinese). [8] 曾家, 金捷, 张晟, 等. 基于LES-PDF方法的双旋流模型燃烧室数值模拟[J]. 气体物理, 2019, 4(5): 52-64. doi: 10.19527/j.cnki.2096-1642.0789ZENG J, JIN J, ZHANG S, et al. Numerical simulation of double-swirled model combustor based on LES-PDF[J]. Physics of Gases, 2019, 4(5): 52-64(in Chinese). doi: 10.19527/j.cnki.2096-1642.0789 [9] ZHOU L X. Development of SOM combustion model for Reynolds-averaged and large-eddy simulation of turbulent combustion and its validation by DNS[J]. Science in China Series E:Technological Sciences, 2008, 51(8): 1073-1086. doi: 10.1007/s11431-008-0157-y [10] ZHOU L X, QIAO L, CHEN X L, et al. A USM turbulence-chemistry model for simulating NOx formation in turbulent combustion[J]. Fuel, 2002, 81(13): 1703-1709. doi: 10.1016/S0016-2361(01)00173-9 [11] WANG F, ZHOU L, XU C. Large-eddy simulation of correlation moments in turbulent combustion and validation of the RANS-SOM combustion model[J]. Fuel, 2006, 85(9): 1242-1247. doi: 10.1016/j.fuel.2005.11.006 [12] 王方, 周力行, 许春晓, 等. 预混燃烧大涡模拟和燃烧模型的检验[J]. 推进技术, 2008, 29(1): 33-36. doi: 10.13675/j.cnki.tjjs.2008.01.003WANG F, ZHOU L X, XU C X, et al. Large-eddy simulation of premixed combustion and validation of the combustion model[J]. Journal of Propulsion Technology, 2008, 29(1): 33-36(in Chinese). doi: 10.13675/j.cnki.tjjs.2008.01.003 [13] HU L Y, ZHOU L X, ZHANG J. Large-eddy simulation of a swirling diffusion flame using a SOM SGS combustion model[J]. Numerical Heat Transfer, Part B:Fundamentals, 2006, 50(1): 41-58. doi: 10.1080/10407790500459395 [14] ZHOU L, HU L, WANG F. Large-eddy simulation of turbulent combustion using different combustion models[J]. Fuel, 2008, 87(13-14): 3123-3131. doi: 10.1016/j.fuel.2008.04.025 [15] HU L Y, ZHOU L X, LUO Y H. Large-eddy simulation of the Sydney swirling NonPremixed flame and validation of several subgrid-scale models[J]. Numerical Heat Transfer, Part B:Fundamentals, 2008, 53(1): 39-58. doi: 10.1080/10407790701632477 [16] WANG F, ZHOU L X, XU C X, et al. DNS-LES validation of an algebraic second-order-moment combustion model[J]. Numerical Heat Transfer, Part B:Fundamentals, 2009, 55(6): 523-532. doi: 10.1080/10407780902864821 [17] XU C, AMEEN M M, SOM S, et al. Dynamic adaptive combustion modeling of spray flames based on chemical explosive mode analysis[J]. Combustion and Flame, 2018, 195: 30-39. doi: 10.1016/j.combustflame.2018.05.019 [18] DUAN Y F, XIA Z X, MA L K, et al. LES of the Sandia flame series D-F using the Eulerian stochastic field method coupled with tabulated chemistry[J]. Chinese Journal of Aeronautics, 2020, 33(1): 116-133. doi: 10.1016/j.cja.2019.09.022 [19] 杨天威, 尹钰, 周华, 等. 空间分区自适应燃烧建模研究[C]//中国工程热物理学会燃烧学年会论文. 北京: 中国工程热物理学会, 2022.YANG T W, YIN J, ZHOU H, et al. The research of combustion modeling by adaptive spatial-division[C] //Proceedings of Combustion Annual Meeting of Chinese Society of Engineering Thermophysic. Beijing: Chinese Society of Engineering Thermophysic, 2022(in Chinese). [20] 王方, 窦力, 魏观溢, 等. 基于PDF-LES模型的凹腔支板火焰稳定器模拟[J]. 工程热物理学报, 2021, 42(3): 758-767.WANG F, DOU L, WEI G Y, et al. Simulation of flame stabilizer with concave cavity plate based on PDF-LES model[J]. Journal of Engineering Thermophysics, 2021, 42(3): 758-767 (in Chinese). [21] LUO K, BAI Y, YANG J S, et al. A-priori validation of a second-order moment combustion model via DNS database[J]. International Journal of Heat and Mass Transfer, 2015, 86: 415-425. doi: 10.1016/j.ijheatmasstransfer.2015.03.023 [22] LUO K, LIU R Z, BAI Y, et al. A-priori and a-posteriori studies of a direct moment closure approach for turbulent combustion using DNS data of a premixed flame[J]. Proceedings of the Combustion Institute, 2021, 38(2): 3003-3011. doi: 10.1016/j.proci.2020.06.269 [23] JONES W P, PRASAD V N. Large eddy simulation of the sandia flame series (D–F) using the Eulerian stochastic field method[J]. Combustion and Flame, 2010, 157(9): 1621-1636. doi: 10.1016/j.combustflame.2010.05.010 [24] SCHNEIDER C, DREIZLER A, JANICKA J, et al. Flow field measurements of stable and locally extinguishing hydrocarbon-fuelled jet flames[J]. Combustion and Flame, 2003, 135(1-2): 185-190. doi: 10.1016/S0010-2180(03)00150-0 [25] BARLOW R S, FRANK J H. Effects of turbulence on species mass fractions in methane/air jet flames[J]. Symposium (International) on Combustion, 1998, 27(1): 1087-1095. doi: 10.1016/S0082-0784(98)80510-9 [26] MUSTATA R, VALIÑO L, JIMÉNEZ C, et al. A probability density function Eulerian Monte Carlo field method for large eddy simulations: Application to a turbulent piloted methane/air diffusion flame (Sandia D)[J]. Combustion and Flame, 2006, 145(1-2): 88-104. doi: 10.1016/j.combustflame.2005.12.002 [27] DI RENZO M, COCLITE A, DE TULLIO M D, et al. LES of the Sandia flame D using an FPV combustion model[J]. Energy Procedia, 2015, 82: 402-409. doi: 10.1016/j.egypro.2015.11.824 [28] SHEIKHI M, DROZDA T, GIVI P, et al. Large eddy simulation of a turbulent nonpremixed piloted methane jet flame (Sandia Flame D)[J]. Proceedings of the Combustion Institute, 2005, 30(1): 549-556. doi: 10.1016/j.proci.2004.08.028 [29] GE Y, CLEARY M J, KLIMENKO A Y. A comparative study of Sandia flame series (D-F) using sparse-Lagrangian MMC modelling[J]. Proceedings of the Combustion Institute, 2013, 34(1): 1325-1332. doi: 10.1016/j.proci.2012.06.059 [30] JONES W P, LINDSTEDT R P. Global reaction schemes for hydrocarbon combustion[J]. Combustion and Flame, 1988, 73(3): 233-249. doi: 10.1016/0010-2180(88)90021-1 [31] YAMASHITA H, SHIMADA M, TAKENO T. A numerical study on flame stability at the transition point of jet diffusion flames[J]. Proceedings of the Combustion Institute, 1996, 26(1): 27-3. doi: 10.1016/S0082-0784(96)80196-2 -

下载:

下载: