-

摘要:

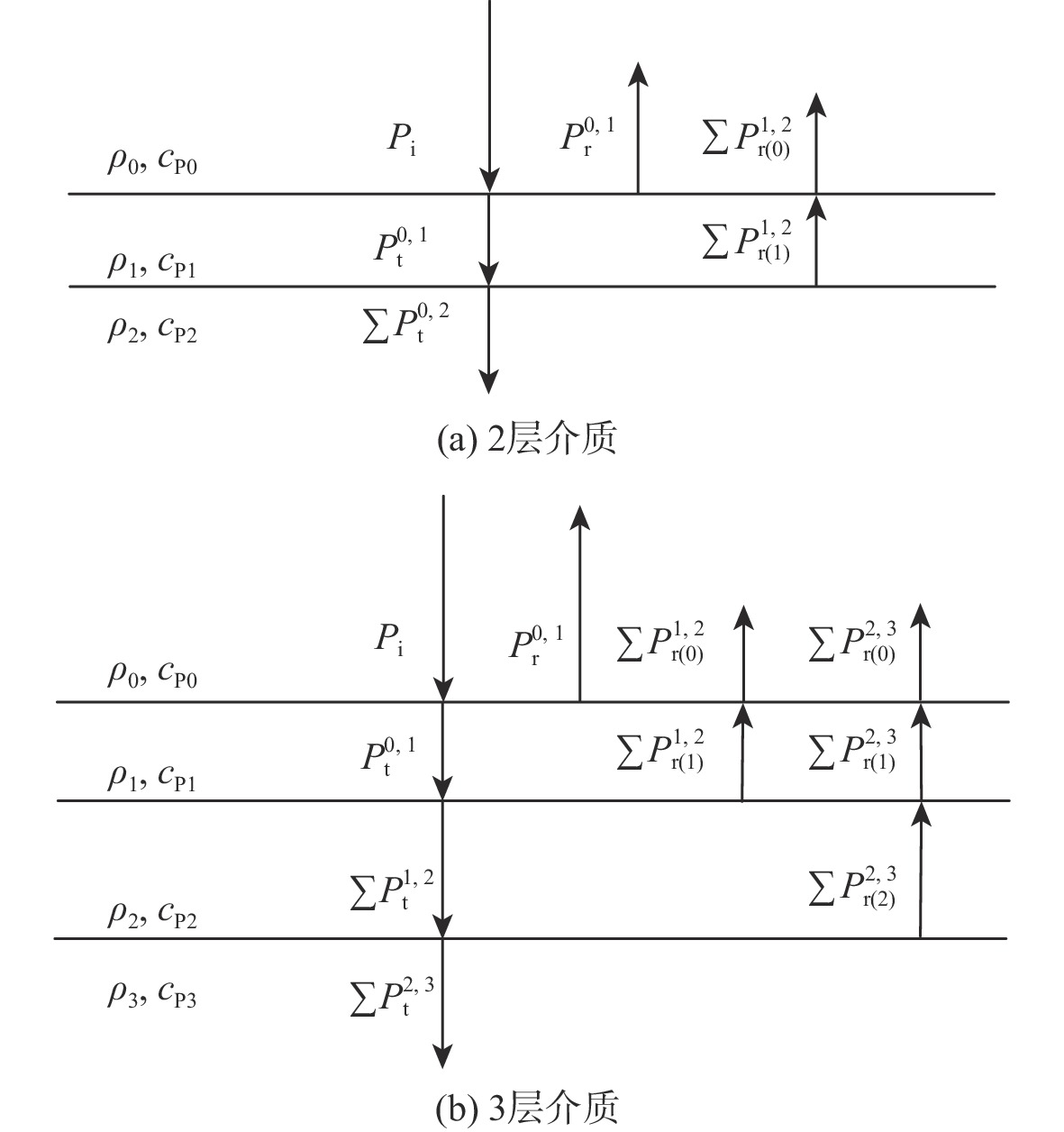

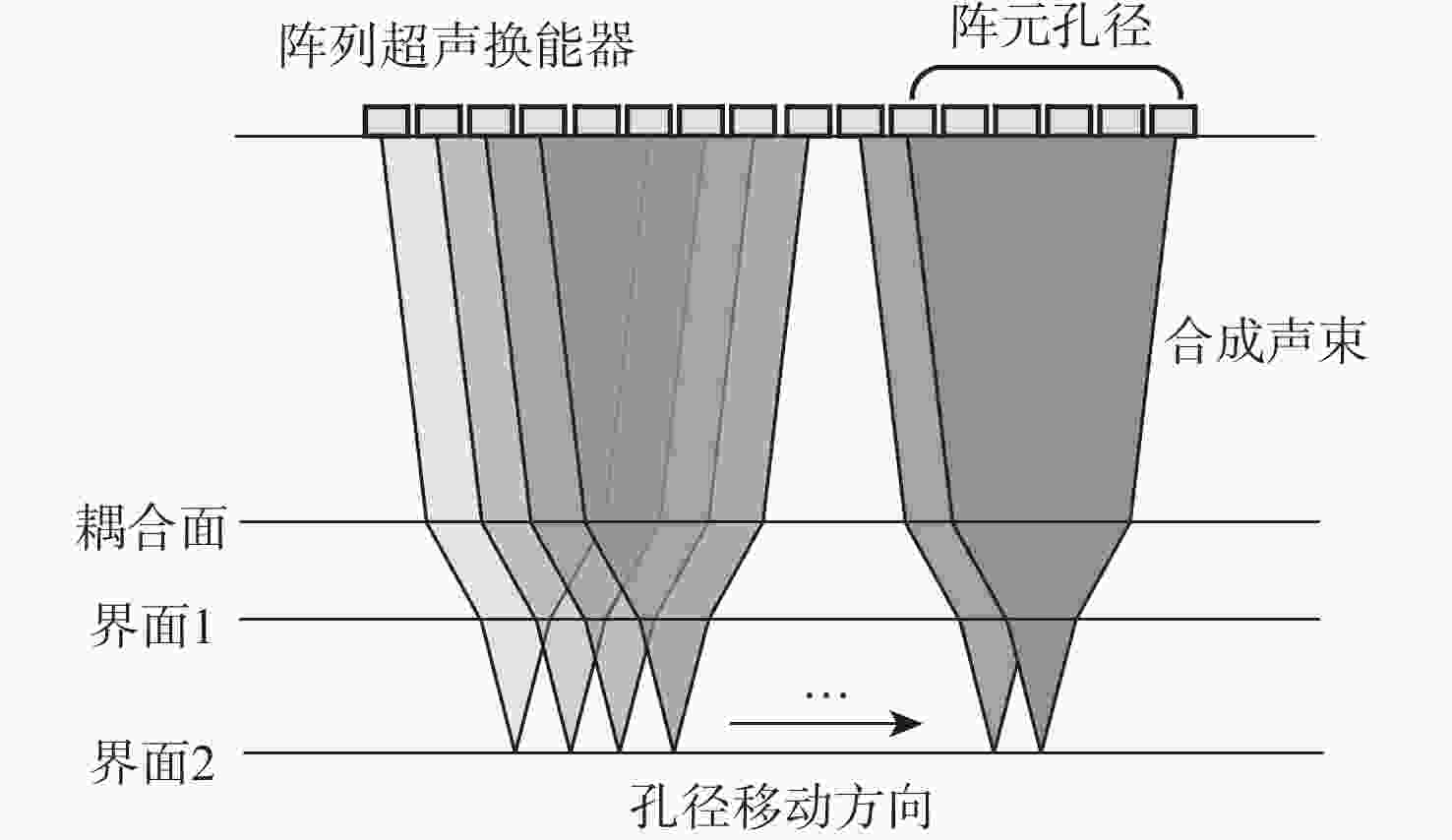

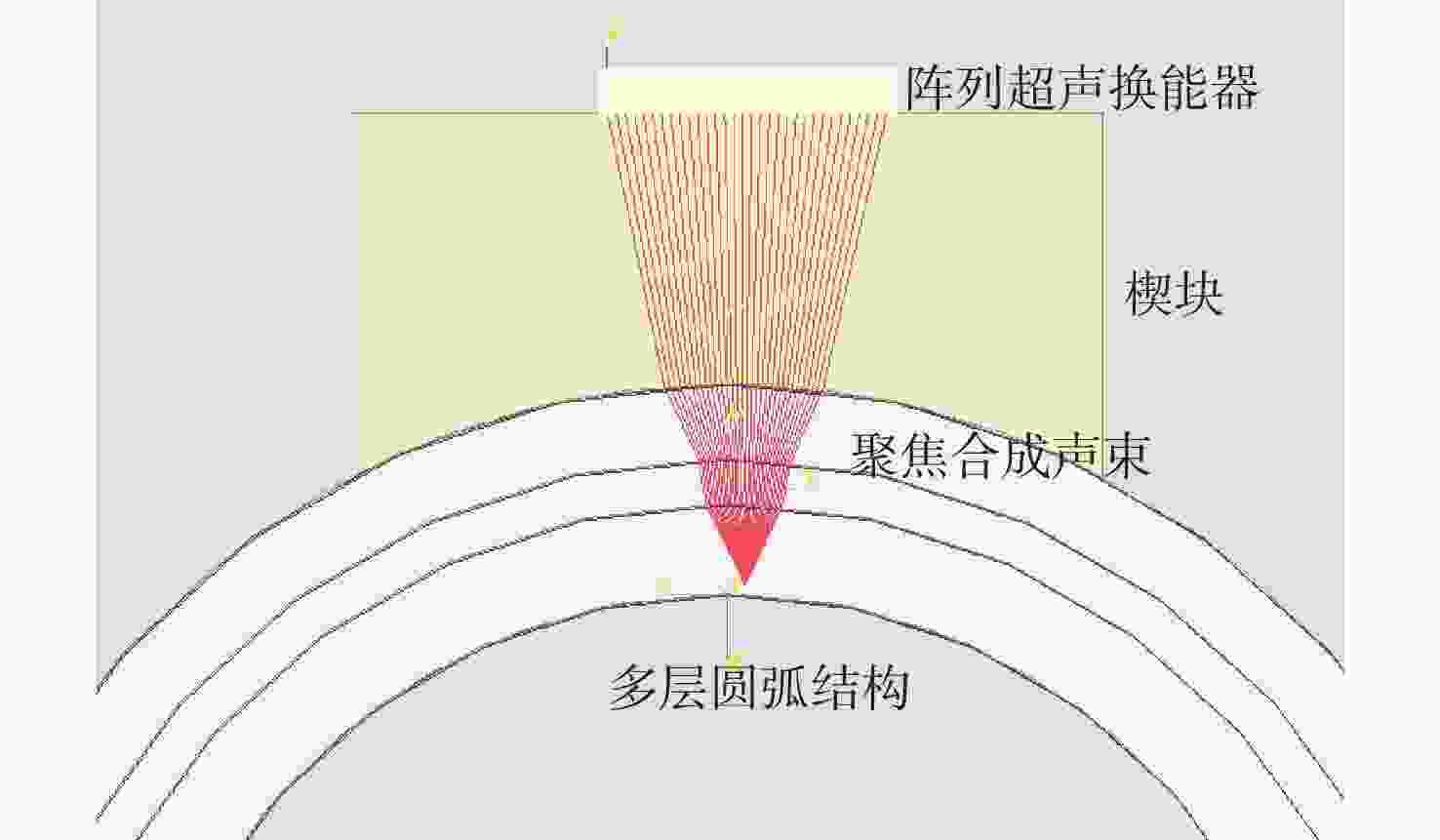

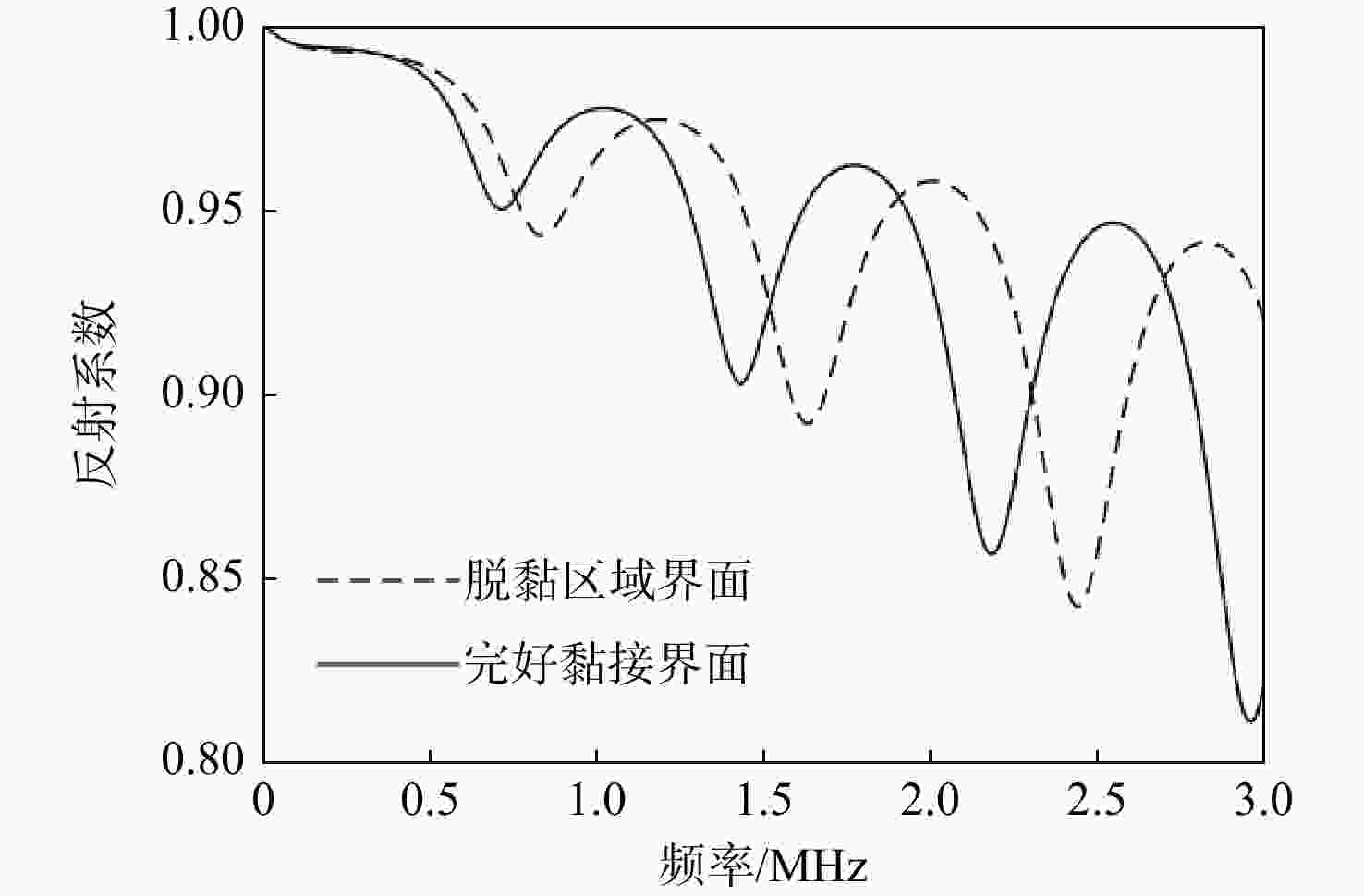

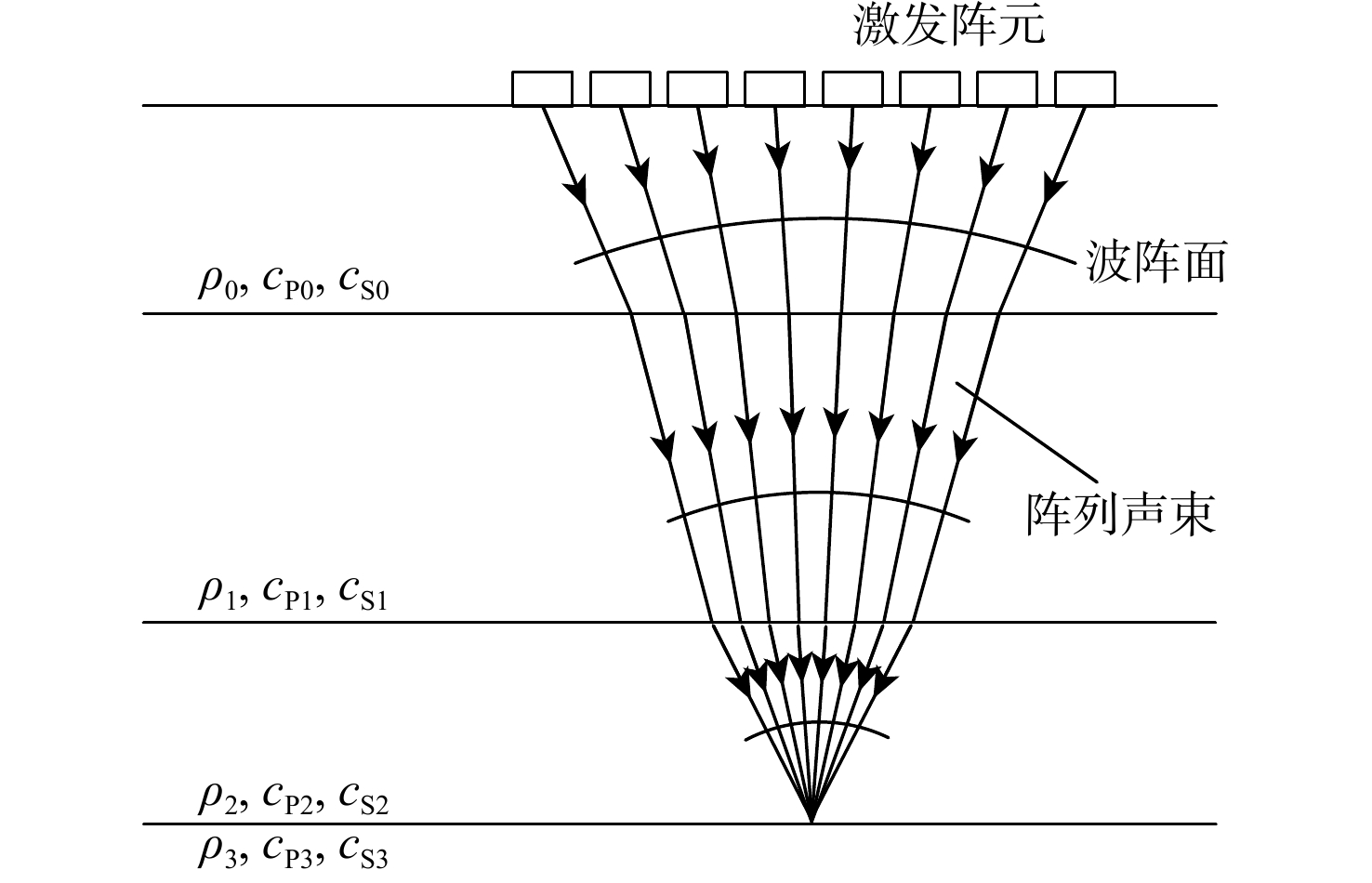

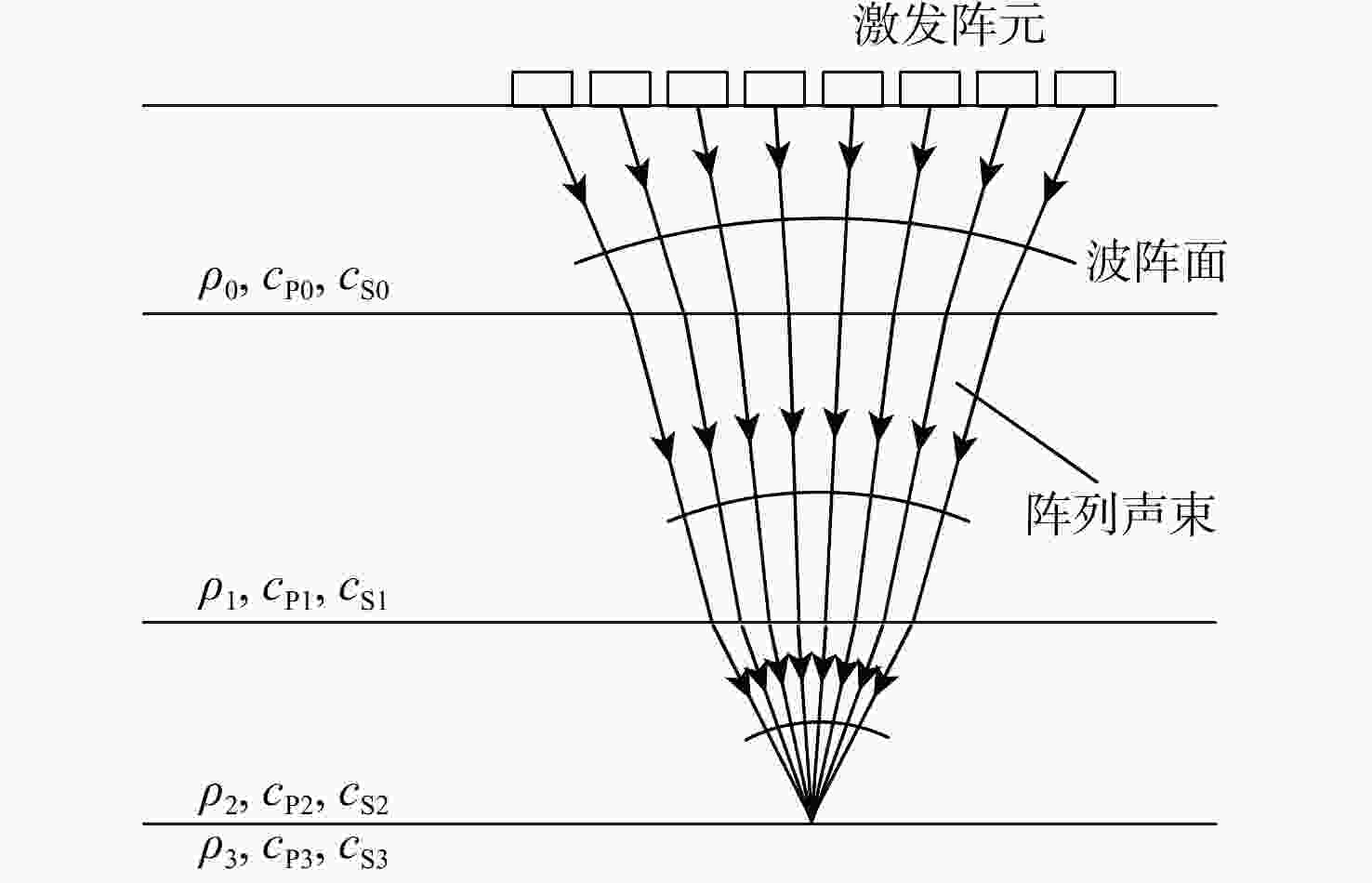

在金属与橡胶等非金属材料的多层黏接结构的超声检测中,介质间声阻抗差异和超声衰减显著,致使脱黏缺陷检测信噪比低,缺陷识别困难。为了提高多层黏接结构中脱黏缺陷的检出能力,提出了基于线性阵列超声换能器的超声检测评价方法。分析了声波在黏接界面的传播特性,得出声波在多介质层系的反射系数频谱关系;基于多层黏接结构的三维CAD检测模型,建立多层结构的阵列超声声束路径通用计算方法,依据多层介质的刚度矩阵传递模型,构建数值仿真分析模型,实现阵列超声聚焦方案和检测工艺的设计;分析了不同黏接状态下界面回波信号的幅度谱,提出采用幅度谱特征进行C扫描成像的方法。实验结果表明:所提阵列超声检测评价方法可有效提升多层黏接结构的检测效率,提高检测信噪比,降低脱黏缺陷C扫描成像表征的复杂度。

Abstract:In the ultrasonic detection for multi-layer bonding structures of metal and non-metal materials such as rubber, the signal to noise ratio of debonding defect is low, and the defect identification is difficult, due to the significant difference in acoustic impedance between media and large ultrasonic attenuation. In order to improve the detection ability of de-bonding defects in multilayer structures, a novel ultrasonic detection and evaluation method based on linear array ultrasonic transducers is proposed. Firstly, the propagation characteristics of ultrasonic waves at the bonding interface are analyzed, and the spectral relationship of the reflection coefficient in a multilayer system is described. Further, a numerical simulation analysis model is built in accordance with the stiffness matrix transfer model of multilayer medium, which is used to realize the design and calculation of the ultrasonic array focusing scheme and detection process. These methods are based on the 3D CAD inspection model. Finally, by analyzing the amplitude spectrum characteristics of interface echo signals under different bonding states, a C-scan imaging method using amplitude spectrum characteristics is proposed. The experiment results show that the method proposed can effectively improve the detection efficiency of multilayer bonded structures and improve the signal-to-noise ratio of detection results, and reduce the complexity of C-scan imaging characterization of de-bonding defects.

-

Key words:

- non-destructive testing /

- ultrasonic array /

- multi-layer structure /

- de-bonding /

- reflection coefficient

-

表 1 单通道及阵列超声方法检测效果对比

Table 1. Comparison of detection effect between single-channel ultrasonic and ultrasonic array method

检测方法 检测用时/min 平均信噪比/dB 缺陷定量误差/% 单通道超声检测 12.35 13.77 7.57 阵列超声检测 0.46 15.89 13.64 -

[1] 李明轩, 王小民, 安志武. 粘接界面特性的超声检测与评价[J]. 应用声学, 2013, 32(3): 190-198. doi: 10.11684/j.issn.1000-310X.2013.03.005LI M X, WANG X M, AN Z W. Ultrasonic testing and evaluation of bonding characteristics[J]. Applied Acoustics, 2013, 32(3): 190-198(in Chinese). doi: 10.11684/j.issn.1000-310X.2013.03.005 [2] 姬文苏, 丁玉奎. 火箭发动机多层粘接结构超声检测研究[J]. 兵工学报, 2015, 36(S1): 364-368.JI W S, DING Y K. Study on ultrasonic testing of multi-layer bonding structure of rocket engine[J]. Acta Armamentarii, 2015, 36(S1): 364-368(in Chinese). [3] 董俊冬. 金属-橡胶多界面粘接质量的超声检测方法研究[D]. 南昌: 南昌航空大学, 2019.DONG J D. Study on ultrasonic testing method of metal rubber multi interface bonding quality[D]. Nanchang: Nanchang Hangkong University, 2019(in Chinese). [4] 刘嘉同, 金永, 张浩亚, 等. 基于多层界面脱粘的超声检测方法研究[J]. 国外电子测量技术, 2020, 39(9): 58-62. doi: 10.19652/j.cnki.femt.2002163LIU J T, JIN Y, ZHANG H Y, et al. Research on ultrasonic testing method based on multi-layer interface debonding[J]. Foreign Electronic Measurement Technology, 2020, 39(9): 58-62(in Chinese). doi: 10.19652/j.cnki.femt.2002163 [5] 王强, 毛捷, 李威, 等. 橡胶-钢粘接结构的谐振超声编码检测方法[J]. 机械工程学报, 2020, 56(20): 36-41.WANG Q, MAO J, LI W, et al. Resonant ultrasonic code testing method for rubber steel bonded structure[J]. Journal of Mechanical Engineering, 2020, 56(20): 36-41(in Chinese). [6] 周昌智, 李明轩, 毛捷. 利用多阶谐振频率对多层结构背覆薄层厚度的反演[J]. 声学技术, 2007, 26(5): 1006-1007. doi: 10.3969/j.issn.1000-3630.2007.05.064ZHOU C Z, LI M X, MAO J. Inversion of the thickness of overlying thin layer of multi-layer structure by using multi-order resonant frequency[J]. Acoustic Technology, 2007, 26(5): 1006-1007(in Chinese). doi: 10.3969/j.issn.1000-3630.2007.05.064 [7] ZHOU H, LIU G. A model-based ultrasonic quantitative evaluation method for bonding quality of multi-layered material[J]. Measurement, 2012, 45(6): 1414-1423. doi: 10.1016/j.measurement.2012.03.023 [8] VELICHKO A, WILCOX P D. An analytical comparison of ultrasonic array imaging algorithms[J]. The Journal of the Acoustical Society of America, 2010, 127(4): 2377-2384. doi: 10.1121/1.3308470 [9] ANAND C, GROVES R, BENEDICTUS R. A Gaussian beam based recursive stiffness matrix model to simulate ultrasonic array signals from multi-layered media[J]. Sensors, 2020, 20(16): 4371. doi: 10.3390/s20164371 [10] JIN H, CHEN J. An efficient wavenumber algorithm towards real-time ultrasonic full-matrix imaging of multi-layered medium[J]. Mechanical Systems and Signal Processing, 2021, 149: 107149. doi: 10.1016/j.ymssp.2020.107149 [11] DOLMATOV D O, SEDNEV D A, BULAVINOV A N, et al. Applying the algorithm of calculation in the frequency domain to ultrasonic tomography of layered inhomogeneous media using matrix antenna arrays[J]. Russian Journal of Nondestructive Testing, 2019, 55(7): 499-506. doi: 10.1134/S1061830919070040 [12] 张海澜. 理论声学 [M]. 2版. 北京: 高等教育出版社, 2012.ZHANG H L. Theoretical acoustics[M]. 2nd ed. Beijing: Higher Education Press, 2012(in Chinese). [13] SCHMERR L W. Fundamentals of ultrasonic nondestructive evaluation[M]. Berlin: Springer, 1998: 121-137. [14] BREKHOVSKIKH L M, LIEBERMAN D, BEYER R T, et al. Waves in layered media[J]. Physics Today, 1962, 15(4): 70-74. [15] LI Y, ZHOU Z G, WANG J. Analysis of linear non-destructive testing and evaluation methods for thin-walled structure inspection using ultrasonic array[J]. Coatings, 2019, 9(2): 146. doi: 10.3390/coatings9020146 [16] 徐娜, 李洋, 周正干, 等. FDTD方法的改进及在超声波声场计算中的应用[J]. 北京航空航天大学学报, 2013, 39(1): 78-82. doi: 10.13700/j.bh.1001-5965.2013.01.007XU N, LI Y, ZHOU Z G, et al. Improvement of FDTD method and its application in ultrasonic sound field calculation[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(1): 78-82(in Chinese). doi: 10.13700/j.bh.1001-5965.2013.01.007 -

下载:

下载: