Reliability analysis of nozzle adjustment mechanism with interval distribution parameters

-

摘要:

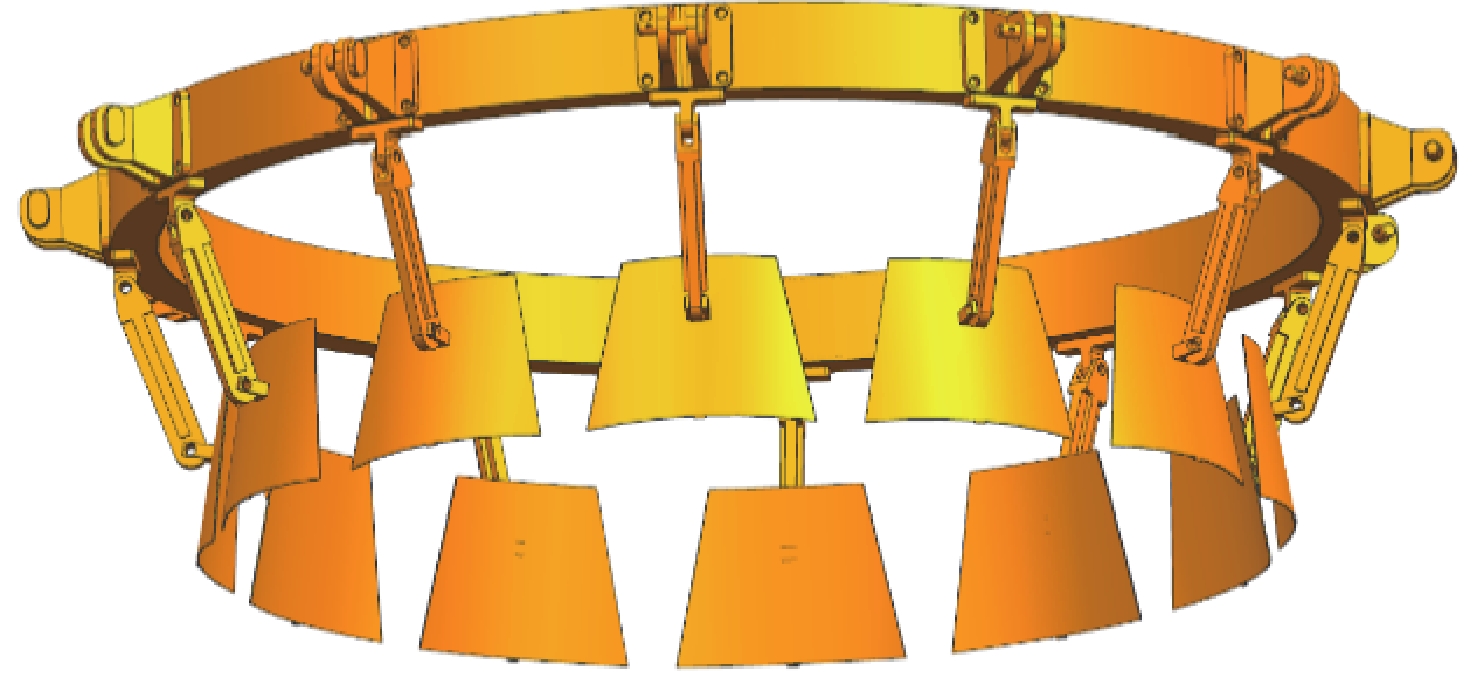

为提高尾喷管调节机构的可靠性分析效率,提出一种结合拒绝采样和主动学习Kriging代理模型的分析方法。在ADAMS中建立了某发动机尾喷管调节机构虚拟样机仿真模型,通过运动学分析对所建模型进行验证;考虑其输入变量含区间分布参数的情形,建立基于调节机构定位精度的极限状态函数;引入主动学习Kriging代理模型,在分布参数随机变化的情况下,通过拒绝采样方法来捕捉样本空间的变化,从而构建适用于整个样本空间内的Kriging代理模型。通过数值算例验证所提方法的可行性,并采用所提方法对调节机构失效概率的上下限进行了计算分析,为提高区间分布参数下的可靠性分析效率提供了一种新的思路。

-

关键词:

- 调节机构 /

- Kriging代理模型 /

- 拒绝采样 /

- 区间分布参数 /

- 可靠性

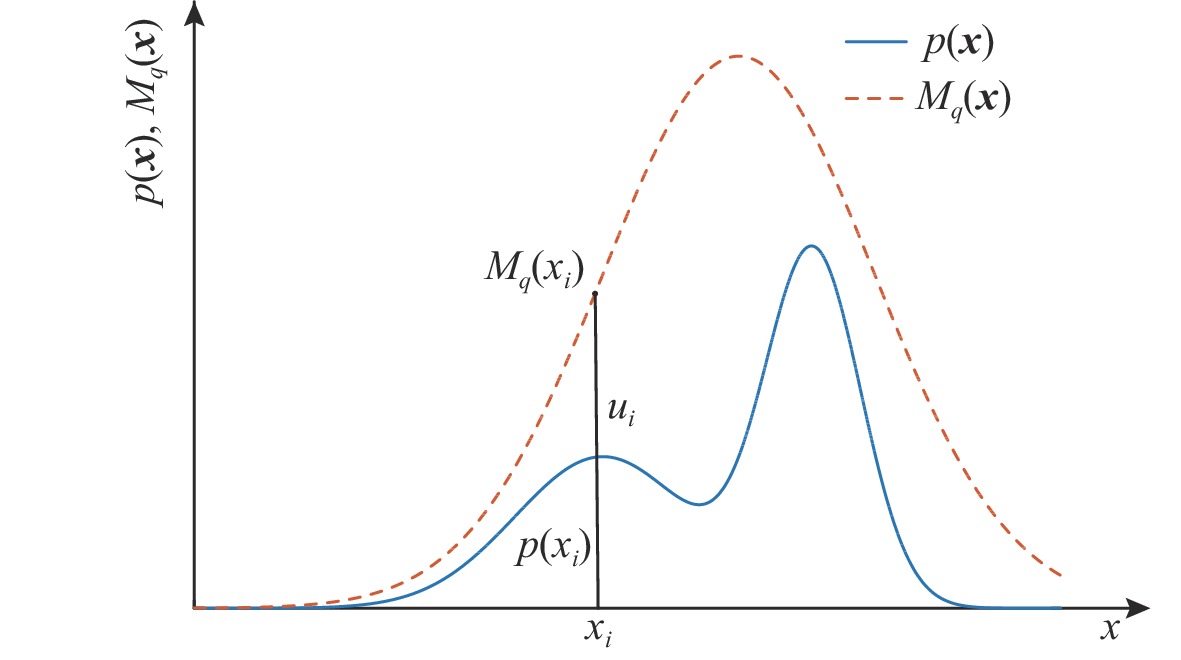

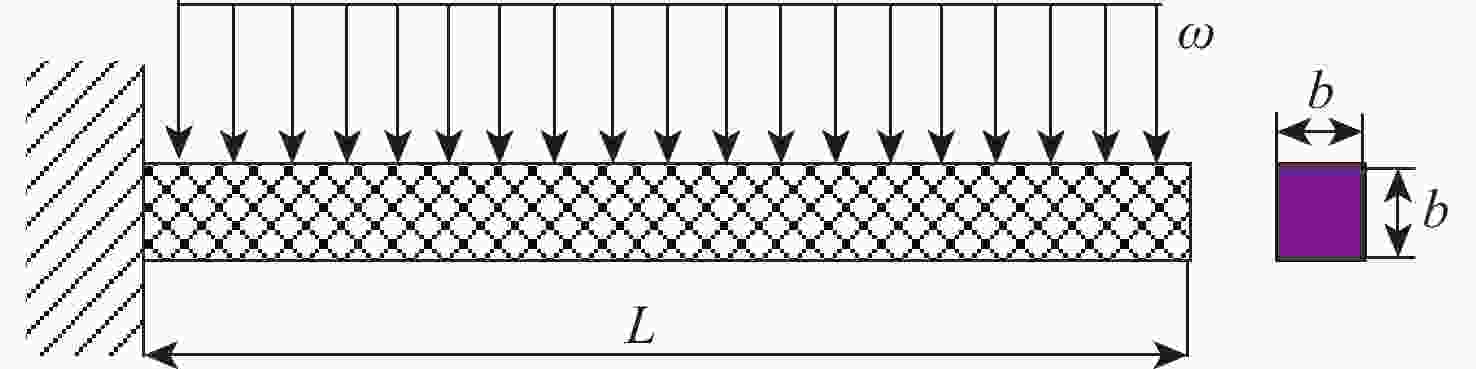

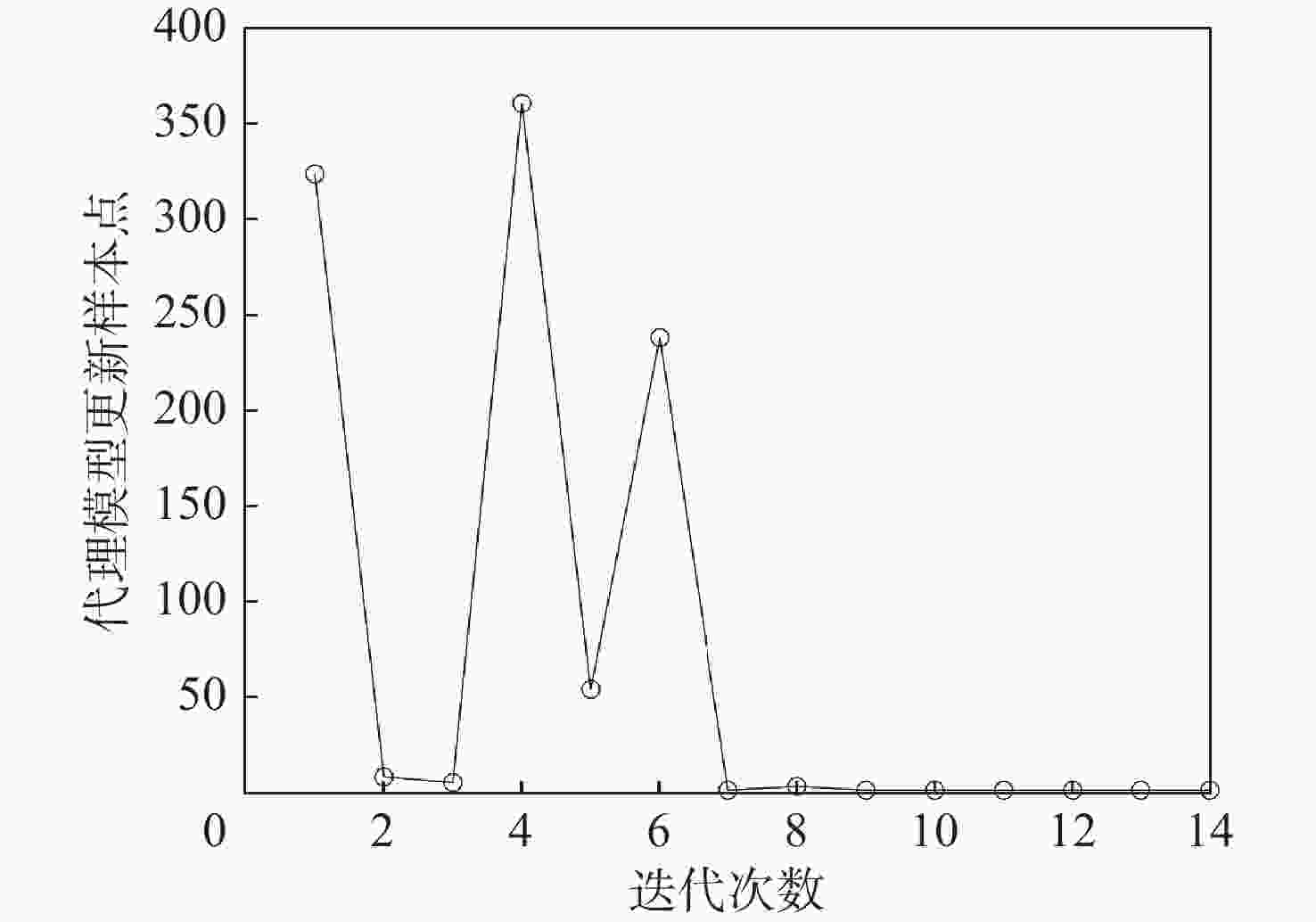

Abstract:To improve the reliability analysis efficiency of the engine nozzle adjustment mechanism, an analysis method combining rejection sampling and active learning Kriging surrogate model is proposed. A virtual prototype simulation model of an engine nozzle adjustment mechanism was established in ADAMS, and the established model is verified by kinematics analysis. Considering the situation that its input variables contain interval distribution parameters, a limit state function based on the positioning accuracy of the adjusting mechanism is established. When distribution parameters change at random, the rejection sampling approach captures the changes in the sample space in order to build a Kriging surrogate model that is appropriate for the full sample space. A numerical example that validates the viability of the suggested approach is used to calculate and analyze the upper and lower boundaries of the adjustment mechanism failure probability. It provides a new method to improve the reliability analysis efficiency under interval distributed parameters.

-

表 1 输入变量分布参数

Table 1. Input variable distribution parameters

变量 销轴B半径X1/mm 销轴C半径X2/mm 销轴B处摩擦系数X3 销轴C处摩擦系数X4 阻力矩X5/(N·m) 均值 [2.65, 2.75] [2.65, 2.75] [0.08, 0.12] [0.08, 0.12] [55.92, 60.92] 标准差 0.05 0.05 0.005 0.005 1.120 表 2 悬臂梁问题随机变量分布参数

Table 2. Random variable distribution parameters for cantilever problem

表 3 数值算例可靠性分析结果

Table 3. Reliability analysis results of numerical example

方法 失效概率(下限)/10−4 失效概率(下限)误差/% 失效概率(上限) 失效概率(上限)误差/% 计算时间/s 样本量 候选样本池规模 MCS 4.2 0.2640 AK-MCS 4.7 11.90 0.2646 0.22 733 15+107 31×105 本文方法 4 4.76 0.2643 0.11 124 15+80 92528 表 4 调节机构可靠性分析结果

Table 4. Reliability analysis results of adjustment mechanism

失效概率(下限) 失效概率(上限) 4×10−5 0.0158 -

[1] 徐惊雷. 超燃冲压及TBCC组合循环发动机尾喷管设计方法研究进展[J]. 推进技术, 2018, 39(10): 2236-2251.XU J L. Research progress of nozzle design method for scramjet and turbine based combined cycle[J]. Journal of Propulsion Technology, 2018, 39(10): 2236-2251(in Chinese). [2] SLOAN B, WANG J, SPENCE S, et al. Aerodynamic performance of a bypass engine with fan nozzle exit area change by warped chevrons[J]. Proceedings of the Institution of Mechanical Engineers, Part G:Journal of Aerospace Engineering, 2010, 224(6): 731-743. doi: 10.1243/09544100JAERO529 [3] ARIF I, MASUD J, SHAH S. Computational analysis of integrated engine exhaust nozzle on a supersonic fighter aircraft[J]. Journal of Applied Fluid Mechanics, 2018, 11(6): 1511-1520. doi: 10.29252/jafm.11.06.28989 [4] 张春宜, 宋鲁凯, 费成巍, 等. 柔性机构动态可靠性分析的先进极值响应面方法[J]. 机械工程学报, 2017, 53(7): 47-54. doi: 10.3901/JME.2017.07.047ZHANG C Y, SONG L K, FEI C W, et al. Advanced extremum response surface method for dynamic reliability analysis on flexible mechanism[J]. Journal of Mechanical Engineering, 2017, 53(7): 47-54(in Chinese). doi: 10.3901/JME.2017.07.047 [5] 刘胜利, 王兴东, 孔建益, 等. 多源不确定性下平面变胞机构运动可靠性分析[J]. 机械工程学报, 2021, 57(17): 64-75. doi: 10.3901/JME.2021.17.064LIU S L, WANG X D, KONG J Y, et al. Kinematic reliability analysis of planar metamorphic mechanism with multi-source uncertainties[J]. Journal of Mechanical Engineering, 2021, 57(17): 64-75(in Chinese). doi: 10.3901/JME.2021.17.064 [6] 贾洁羽, 崔卫民, 张玉刚, 等. 飞机舱门锁机构多失效模式可靠性分析方法[J]. 航空工程进展, 2020, 11(4): 524-531.JIA J Y, CUI W M, ZHANG Y G, et al. Reliability analysis method of aircraft hatch lock mechanism with multi-failure modes[J]. Advances in Aeronautical Science and Engineering, 2020, 11(4): 524-531(in Chinese). [7] 游令非, 张建国, 翟浩, 等. 模糊-随机混合参数的机构运动可靠度计算方法[J]. 北京航空航天大学学报, 2019, 45(4): 714-721.YOU L F, ZHANG J G, ZHAI H, et al. Computation method on motional reliability of mechanism under mixed parameters with fuzziness and randomness[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(4): 714-721(in Chinese). [8] 陈炎, 董萌. 民用飞机襟翼运动机构运动可靠性分析及优化设计[J]. 机械设计与制造工程, 2021, 50(6): 38-42.CHEN Y, DONG M. Movement reliability analysis and optimization of civil aircraft’s flap mechanism[J]. Machine Design and Manufacturing Engineering, 2021, 50(6): 38-42(in Chinese). [9] LING C Y, LU Z Z, ZHANG X B. An efficient method based on AK-MCS for estimating failure probability function[J]. Reliability Engineering & System Safety, 2020, 201: 106975. [10] WANG P, ZHANG Z, HUANG X Y, et al. An application of active learning Kriging for the failure probability and sensitivity functions of turbine disk with imprecise probability distributions[J]. Engineering With Computers, 2022, 38(4): 3417-3437. doi: 10.1007/s00366-021-01366-y [11] WANG W X, GAO H S, ZHOU C C, et al. Reliability analysis of motion mechanism under three types of hybrid uncertainties[J]. Mechanism and Machine Theory, 2018, 121: 769-784. doi: 10.1016/j.mechmachtheory.2017.12.010 [12] HOFER E, KLOOS M, KRZYKACZ-HAUSMANN B, et al. An approximate epistemic uncertainty analysis approach in the presence of epistemic and aleatory uncertainties[J]. Reliability Engineering & System Safety, 2002, 77(3): 229-238. [13] BEER M, FERSON S, KREINOVICH V. Imprecise probabilities in engineering analyses[J]. Mechanical Systems and Signal Processing, 2013, 37(1-2): 4-29. doi: 10.1016/j.ymssp.2013.01.024 [14] ZHANG J H, XIAO M, GAO L. An active learning reliability method combining Kriging constructed with exploration and exploitation of failure region and subset simulation[J]. Reliability Engineering & System Safety, 2019, 188: 90-102. [15] 韩忠华. Kriging模型及代理优化算法研究进展[J]. 航空学报, 2016, 37(11): 3197-3225.HAN Z H. Kriging surrogate model and its application to design optimization: A review of recent progress[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(11): 3197-3225(in Chinese). [16] KOEHLER J R, OWEN A B. 9 computer experiments[J]. Handbook of Statistics, 1996, 13: 261-308. [17] LOPHAVEN S N, SONDERGAARD J, NIELSEN H B. DACE a MATLAB Kriging toolbox[EB/OL]. (2002-08-01)[2022-01-08]. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.17.3530&rep=rep1&type=pdf. [18] 周长聪, 赵浩东, 常琦, 等. 飞机舱门泄压阀机构磨损可靠性与灵敏度分析[J]. 北京航空航天大学学报, 2021, 47(4): 690-697. doi: 10.13700/j.bh.1001-5965.2020.0024ZHOU C C, ZHAO H D, CHANG Q, et al. Reliability and sensitivity analysis of relief valve mechanism of aircraft door considering wear[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(4): 690-697(in Chinese). doi: 10.13700/j.bh.1001-5965.2020.0024 [19] CHENG L, LU Z Z, ZHANG L G. Application of rejection sampling based methodology to variance based parametric sensitivity analysis[J]. Reliability Engineering & System Safety, 2015, 142: 9-18. [20] 程蕾, 张磊刚, 雷豹, 等. 一种平均矩独立重要性指标及其拒绝抽样方法[J]. 北京航空航天大学学报, 2019, 45(1): 66-73.CHENG L, ZHANG L G, LEI B, et al. An average moment-independent importance index and its rejection sampling method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(1): 66-73(in Chinese). [21] RIDLEY G, FORGET B. A simple method for rejection sampling efficiency improvement on SIMT architectures[J]. Statistics and Computing, 2021, 31(3): 1-11. [22] 李勇, 韩非非, 张昕喆, 等. 基于遗传算法-序列二次规划的涡扇发动机最低油耗性能寻优控制[J]. 推进技术, 2020, 41(7): 1638-1648.LI Y, HAN F F, ZHANG X Z, et al. Performance seeking control of turbofan engine minimum fuel consumption model based on GA-SQP[J]. Journal of Propulsion Technology, 2020, 41(7): 1638-1648(in Chinese). [23] MANSOORNEJAD B, MOSTOUFI N, JALALI-FARAHANI F. A hybrid GA-SQP optimization technique for determination of kinetic parameters of hydrogenation reactions[J]. Computers & Chemical Engineering, 2008, 32(7): 1447-1455. -

下载:

下载: