Thermal model of aircraft fuel tank based on oxygen consumption inerting technology

-

摘要:

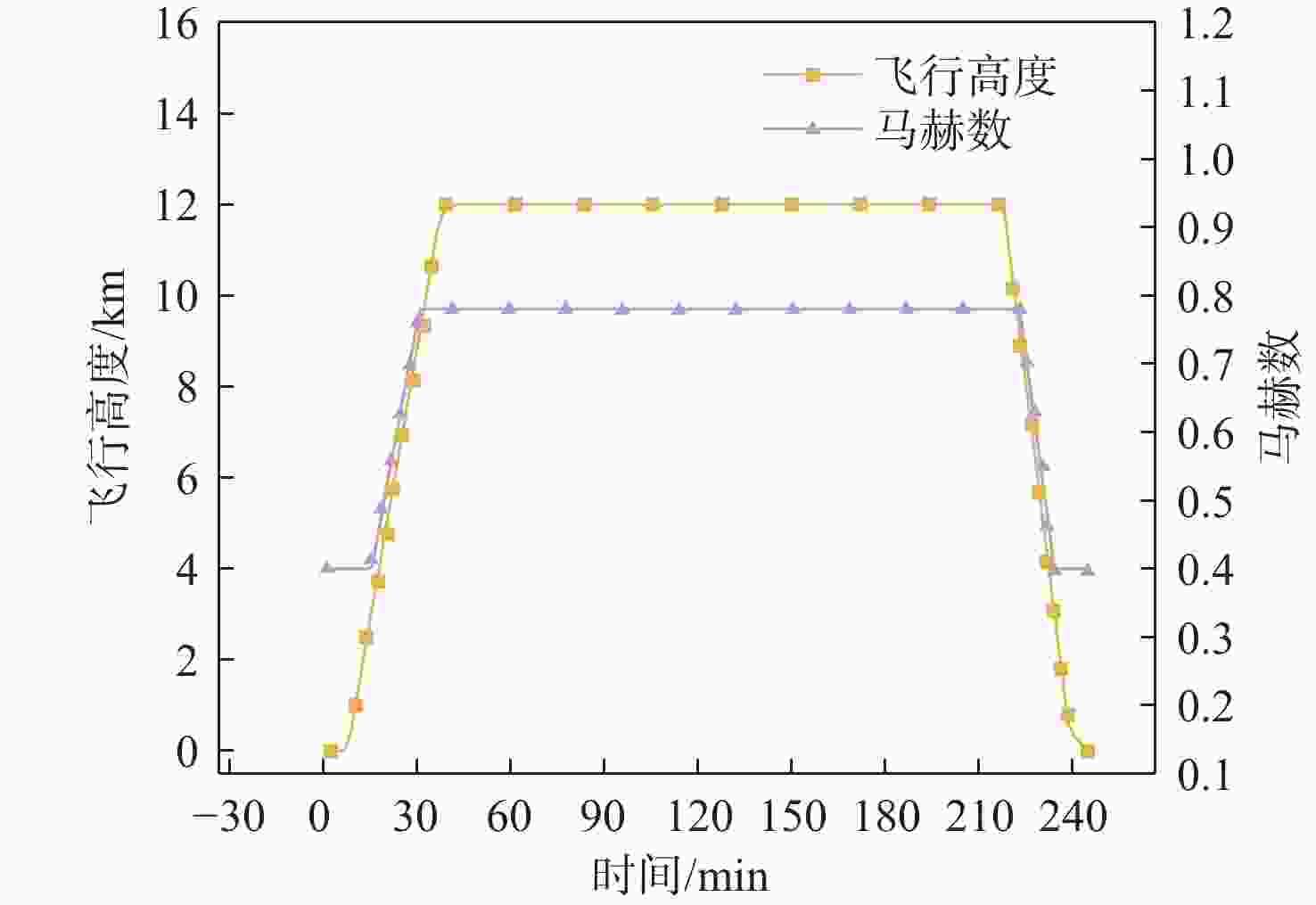

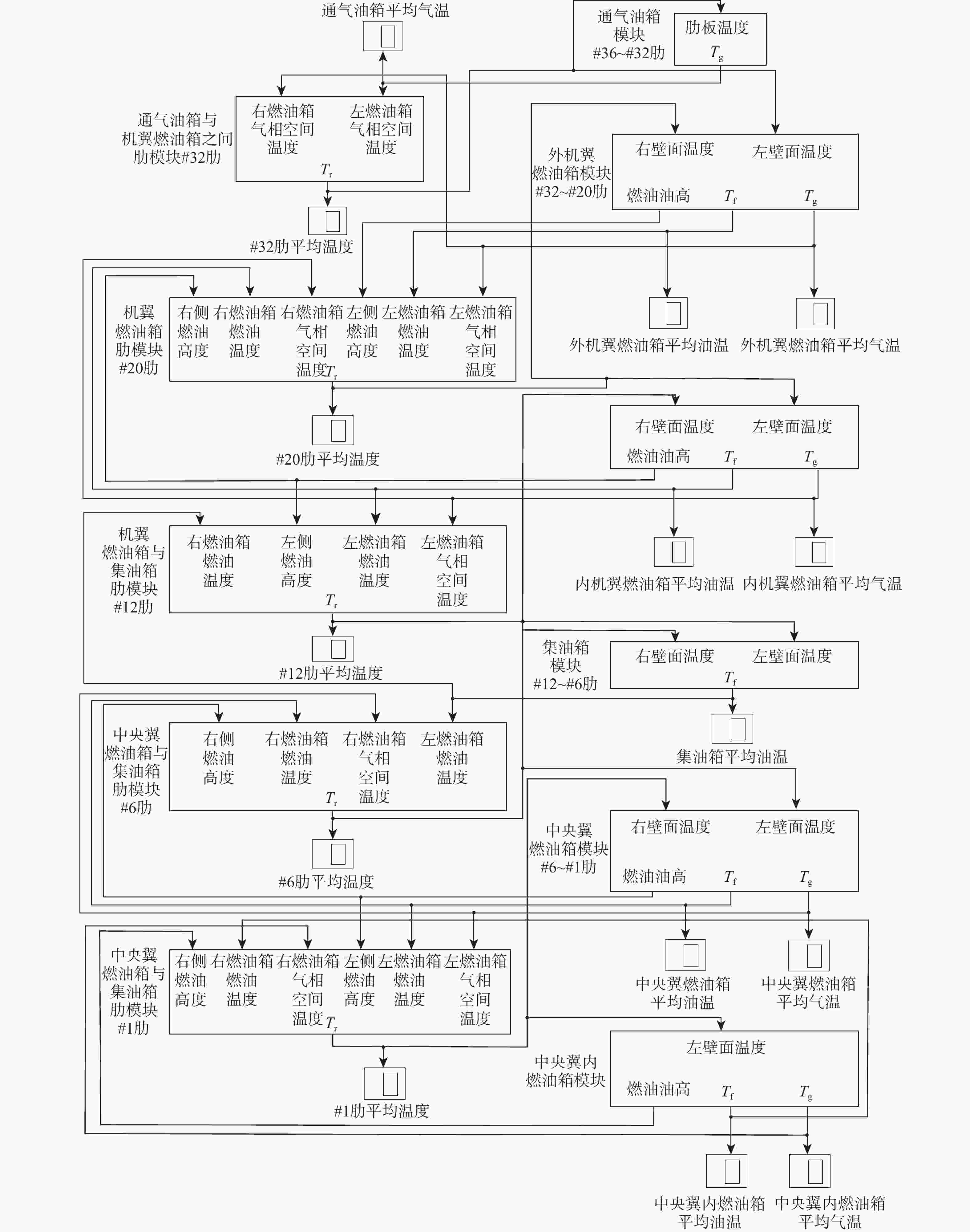

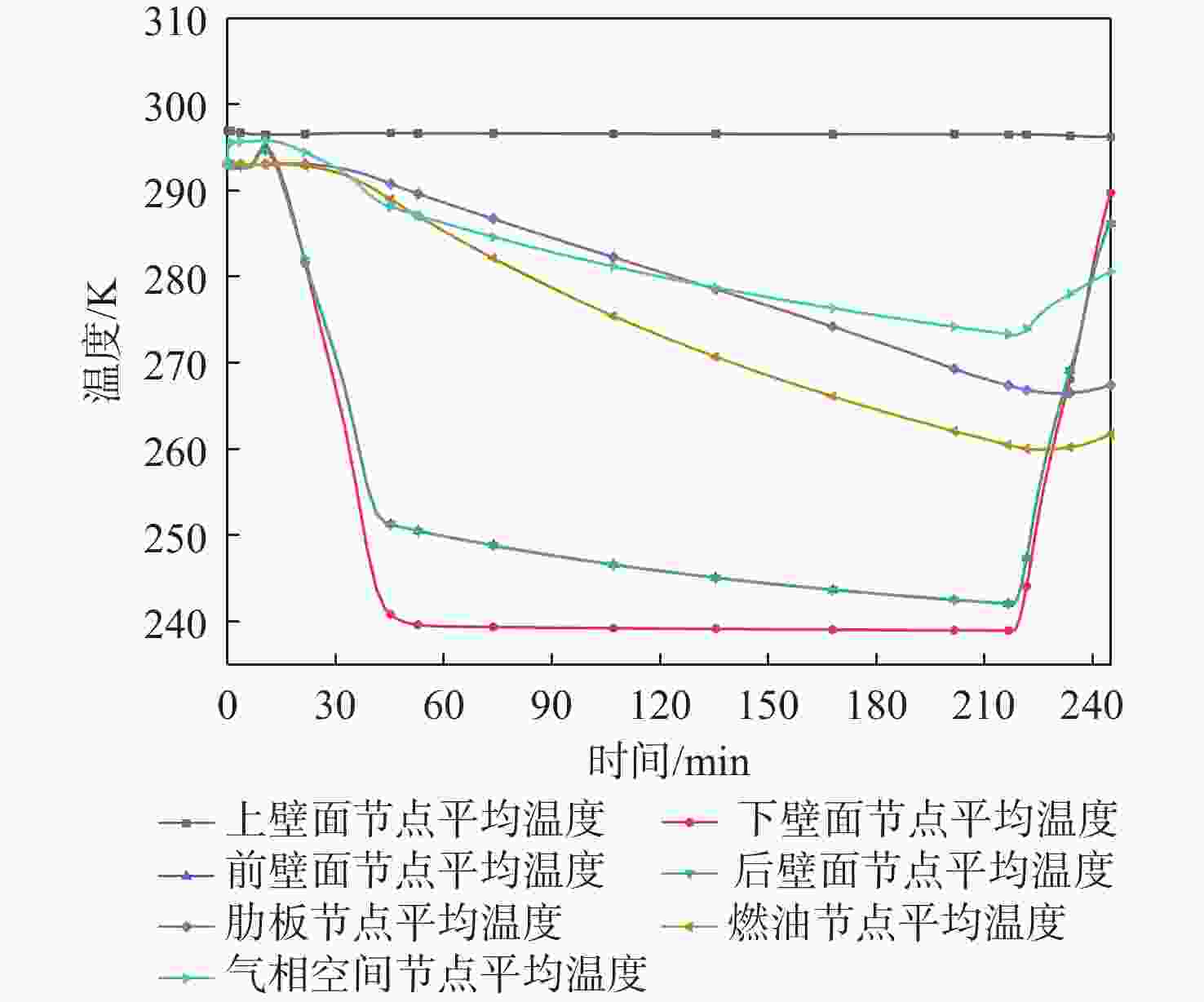

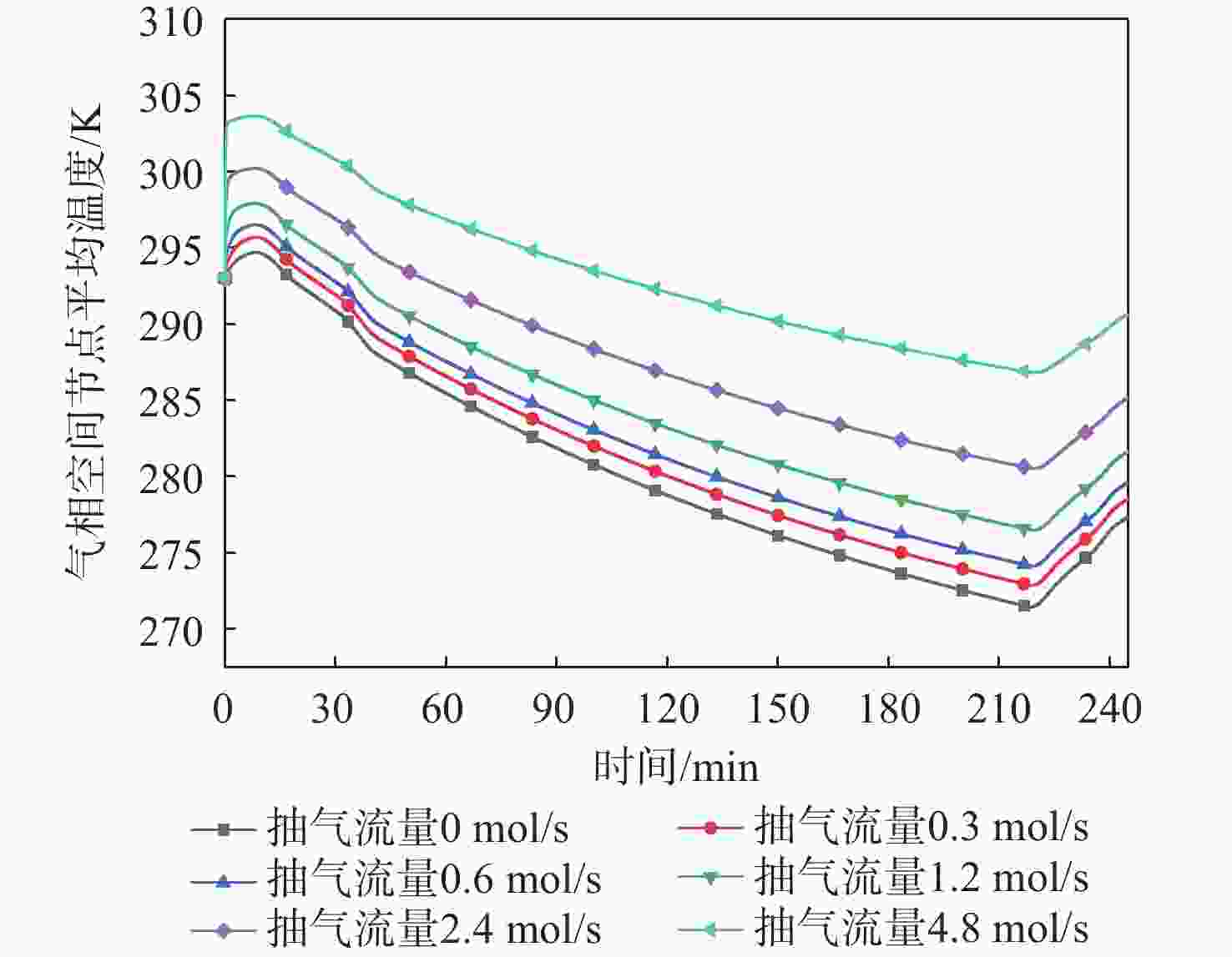

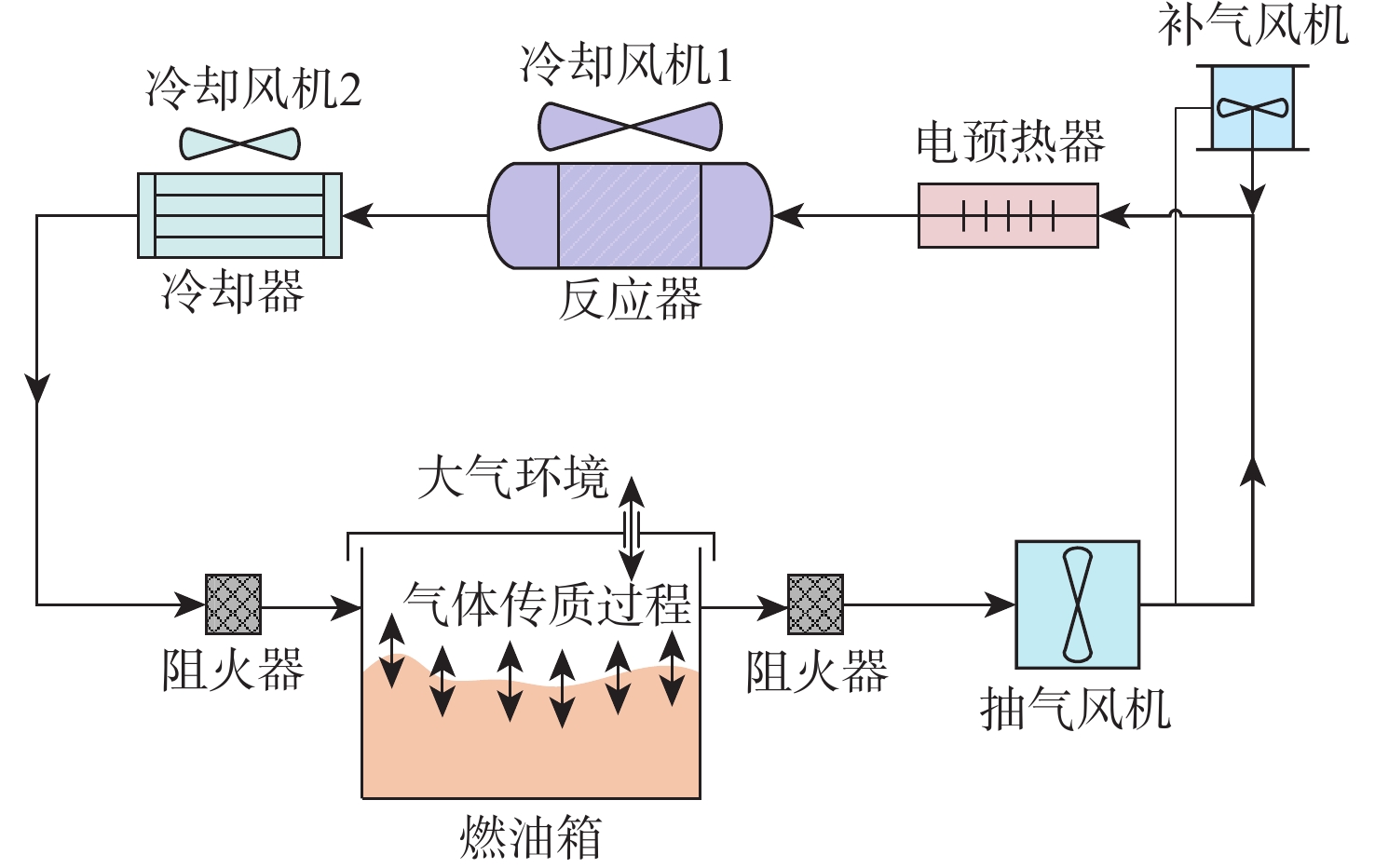

温度是燃油箱耗氧惰化系统适航符合性验证过程中重要指标。基于MATLAB Simulink软件,建立了飞机燃油箱耗氧型惰化系统油箱部件的传质传热模型,并验证其可靠性。在此基础上,分析了惰化系统抽气流量和出口温度对飞机燃油箱气相空间节点温度和燃油节点温度的影响。结果表明:所建立的飞机燃油箱传质传热模型具有较高的可靠性;随着惰化系统抽气流量的增加和惰化系统出口温度的升高,气相空间节点温度随之升高但对燃油节点温度影响不明显。

Abstract:The temperature serves as a crucial indicator in the airworthiness compliance verification process of the fuel tank inerting system. Using MATLAB Simulink software, a mass and heat transfer model was established and validated for analyzing the behavior of gas phase space nodes and fuel nodes' temperatures within an aircraft's fuel tank inerting system under varying conditions such as different gas extraction flow rates or outlet temperatures. The results demonstrate that this developed model exhibits high reliability when applied to analyze thermal characteristics inside an aircraft's fuel tank during its operation with different operating parameters.

-

Key words:

- aircraft fuel tank /

- oxygen-consuming inerting /

- thermal model /

- heat and mass transfer /

- airworthiness

-

-

[1] LANGTON R, CLARK C, HEWITT M, et al. Aircraft fuel systems [M]. New York: John Wiley and Sons, 2010: 225-237. [2] Federal Aviation Administration. Fuel tank flammability minimization: 25.981-2A[S]. Washington, D. C.: Federal Register, 2008. [3] Federal Aviation Administration. Transport airplane fuel tank system design review, flammability reduction, and maintenance and inspection requirements: 21-78, 25-102[S]. Washington, D. C.: Federal Register, 2005: 13. [4] Federal Aviation Administration. Reduction of fuel tank system flammability in transport category airplanes: 25-125[S]. Washington, D. C.: FederalRegister, 2008: 14-15. [5] GUPTA A. Fuel tank flammability reduction and inerting system and methods thereof: US9016078[P]. 2015-04-28. [6] DOMAN D B. Fuel flow topology and control for extending aircraft thermal endurance[J]. Journal of Thermophysics and Heat Transfer, 2018, 32(1): 35-50. doi: 10.2514/1.T5142 [7] 张斌. 民用飞机燃油箱系统热模型分析研究[J]. 民用飞机设计与研究, 2013(1): 23-26.ZHANG B. Research on the thermal model analysis of civil aircraft fuel tank system[J]. Civil Aircarft Design & Research, 2013(1): 23-26(in Chinese). [8] 郭军亮. 民用飞机燃油箱热特性数值仿真[J]. 航空计算技术, 2013, 43(1): 65-68.GUO J L. Numerical simulation on fuel tank thermal characters for civil aircraft[J]. Aeronautical Computing Technique, 2013, 43(1): 65-68(in Chinese). [9] 吕亚国, 任国哲, 刘振侠, 等. 飞机燃油箱热分析研究[J]. 推进技术, 2015, 36(1): 61-67. doi: 10.13675/j.cnki.tjjs.2015.01.009LV Y G, REN G Z, LIU Z X, et al. Thermal analysis of fuel tank for aircraft[J]. Journal of Propulsion Technology, 2015, 36(1): 61-67(in Chinese). doi: 10.13675/j.cnki.tjjs.2015.01.009 [10] 彭孝天, 冯诗愚, 任童, 等. 飞行包线下燃油箱耗氧型惰化系统性能研究[J]. 北京航空航天大学学报, 2021, 47(8): 1565-1570.PENG X T, FENG S Y, REN T, et al. Performance of oxygen-consuming catalytic inerting system of fuel tank under flight envelope[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(8): 1565-1570(in Chinese). [11] 刘夙春, 邱献双. 一种新型的飞机油箱催化惰化系统[J]. 航空科学技术, 2011, 22(4): 27-29.LIU S C, QIU X S. A new fuel tank catalytically inerting system[J]. Aeronautical Science & Technology, 2011, 22(4): 27-29(in Chinese). [12] 谢辉辉, 冯诗愚, 彭孝天, 等. 耗氧型惰化系统反应器性能理论研究[J]. 北京航空航天大学学报, 2019, 45(11): 2312-2319.XIE H H, FENG S Y, PENG X T, et al. Theoretical of reactor performance in oxygen consumption based inerting system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(11): 2312-2319(in Chinese). [13] JOHNSON R W, ZAKI R, YATES S F. Advanced carbon dioxide fuel tank inerting system: US 7628965[P]. 2009-12-08. [14] 陶文铨. 传热学[M]. 5版. 北京: 高等教育出版社, 2019.TAO W Q. Heat transfer[M]. 5th ed. Beijing: Higher Education Press, 2019 (in Chinese). [15] 康振烨, 刘振侠, 任国哲, 等. 基于MATLAB/Simulink的飞机燃油箱内燃油温度仿真计算[J]. 推进技术, 2014, 35(1): 62-69.KANG Z Y, LIU Z X, REN G Z, et al. Simulation and calculation of fuel temperature in aircraft fuel tank based on MATLAB/Simulink[J]. Journal of Propulsion Technology, 2014, 35(1): 62-69(in Chinese). [16] 王晨臣, 潘俊, 王洋洋, 等. 抽吸气流量对催化惰化系统性能影响[J]. 北京航空航天大学学报, 2022, 48(7): 1183-1189.WANG C C, PAN J, WAMG Y Y, et al. Effect of suction flow rate on performance of catalytic inerting system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2022, 48(7): 1183-1189(in Chinese). -

下载:

下载: