Design and on-orbit application of radiator for space optical remote sensor with large aperture

-

摘要:

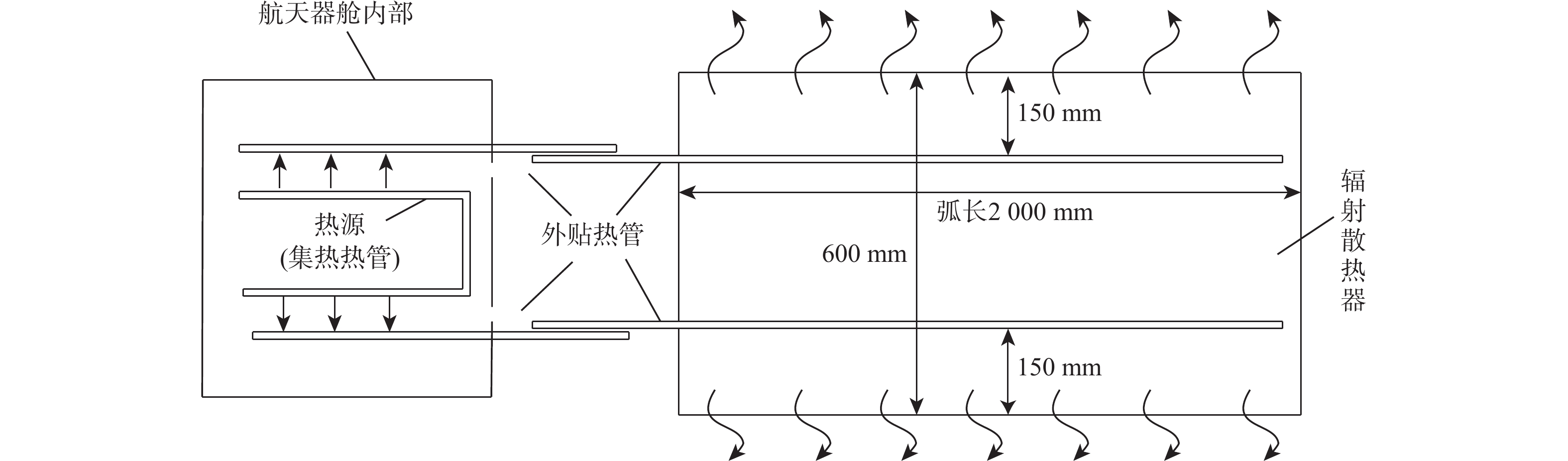

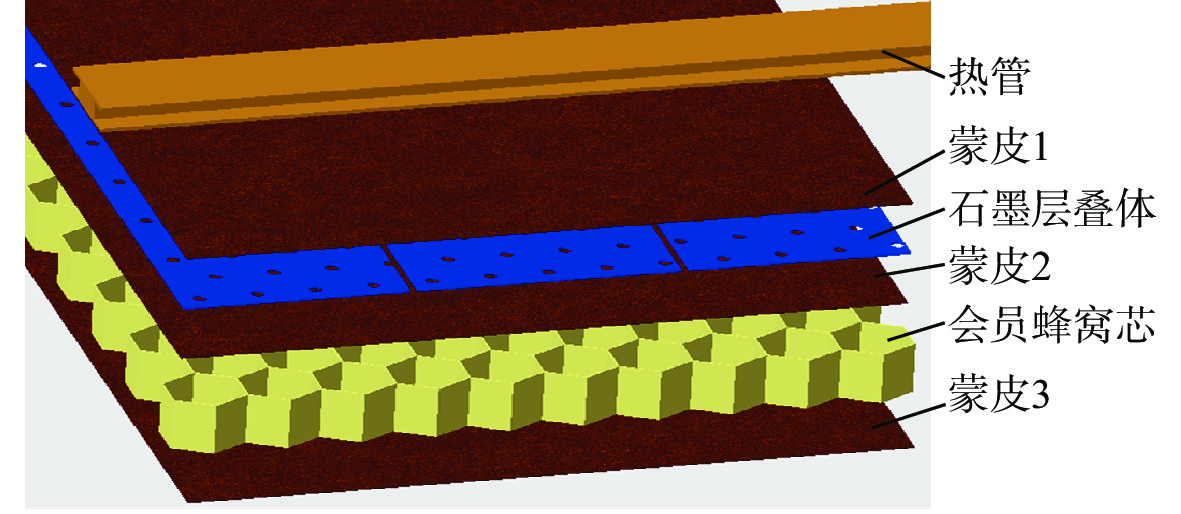

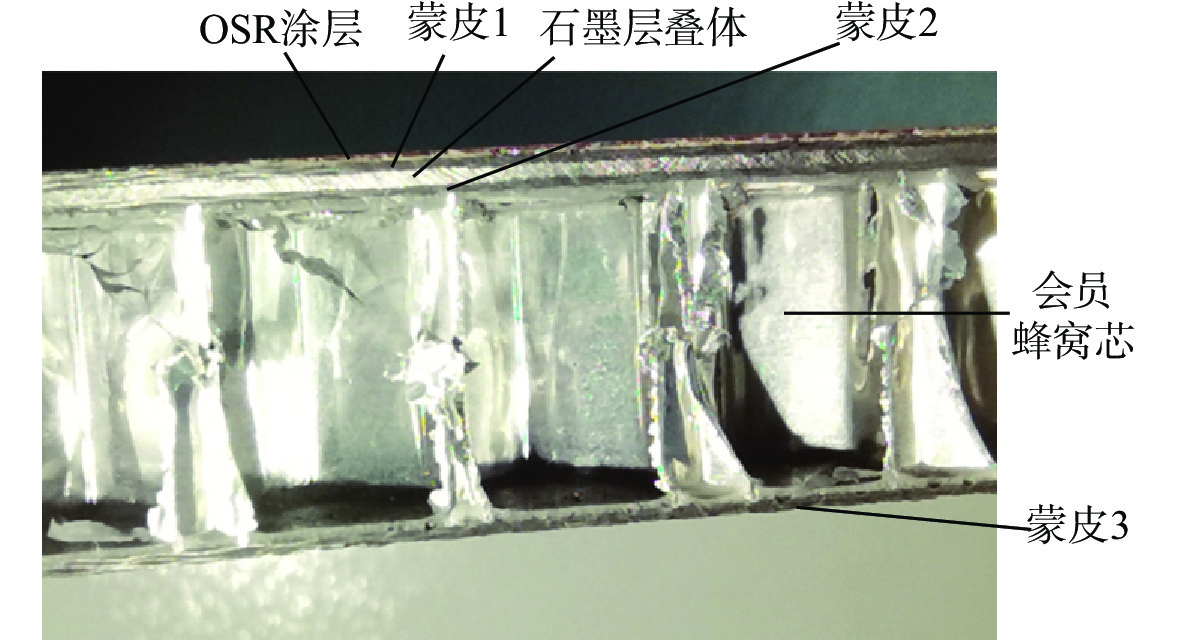

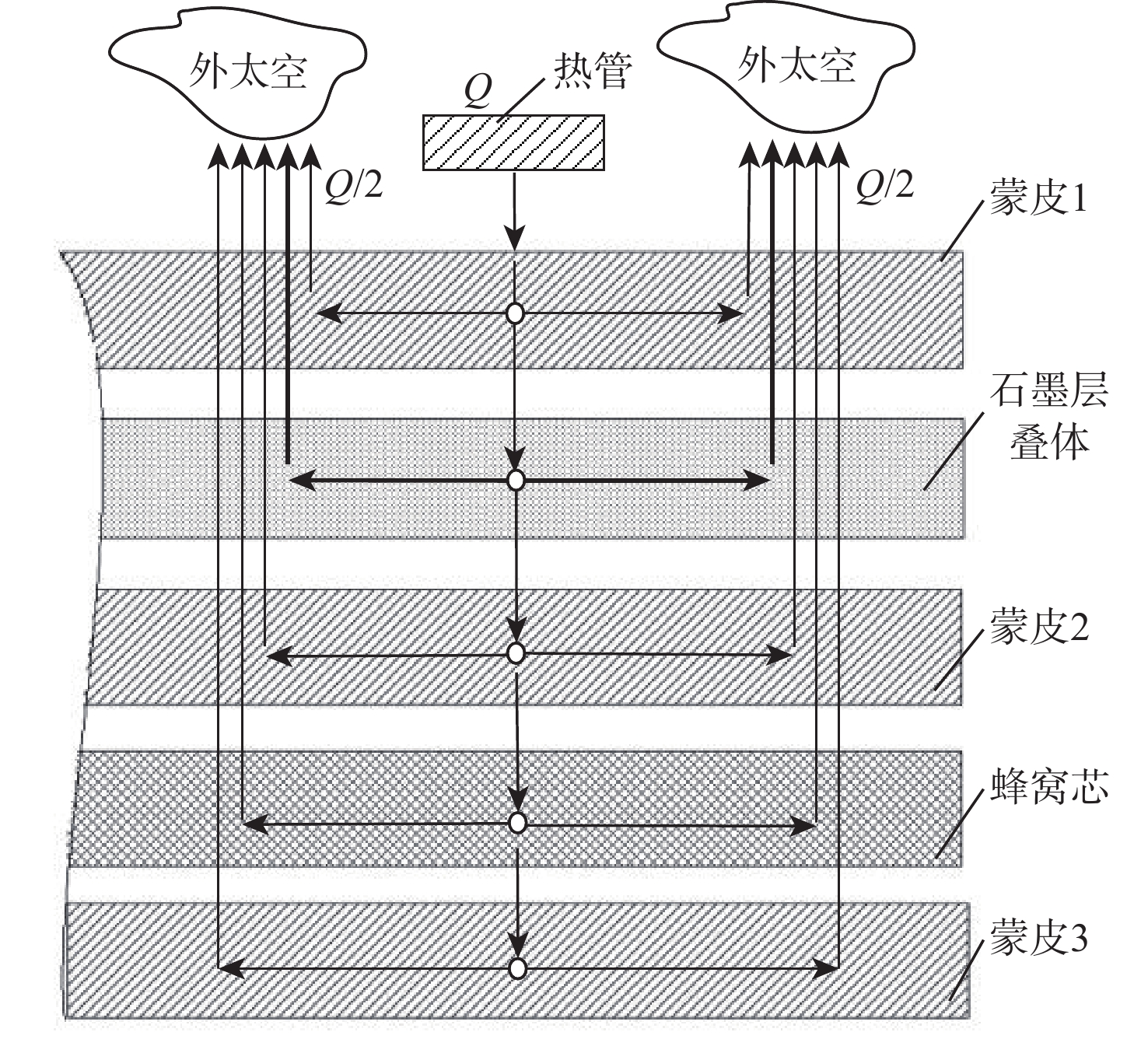

为满足大口径空间光学遥感器高效率、低密度散热的需求,提出一种基于高导热石墨膜的空间辐射散热器。对高导热石墨膜的基础物理性能、结构成分、力学性能、热性能、空间环境适应性等进行较全面的测试分析。将高导热石墨膜与热管、蜂窝板等结合起来解决高导热石墨膜应用中常见的厚度方向导热系数低、力学强度低、硬度低、厚度薄、单块尺寸小的难题。对散热器和2种传统空间辐射散热器进行对比仿真分析,仿真分析结果表明:同等散热能力下,高导热石墨辐射散热器的质量仅为传统铝合金板散热器的约1/3,仅为传统铝蜂窝板辐射散热器的约1/2。通过热平衡实验和在轨飞行应用对散热器的散热性能进行验证,验证结果表明:仿真值与在轨值具有良好的一致性,散热器具有优异的力、热性能及显著的减重优势,可广泛应用于各种航天器的散热及均温。

-

关键词:

- 高导热石墨 /

- 辐射散热器 /

- 大口径空间光学遥感器 /

- 轻量化 /

- 热设计

Abstract:To meet the light-weight and high-efficiency heat dissipation requirements of space optical remote sensors with large aperture, a space radiator based on high thermal conductivity graphite film is proposed for the first time. The basic physical properties, structural composition, mechanical properties, thermal properties and space environment adaptability of the high thermal conductivity graphite film were tested and analyzed. The common disadvantages in the application of high thermal conductivity graphite film, such as low thermal conductivity in the thickness direction, low mechanical strength, low hardness, thin thickness and small single block size, are solved by combining the high thermal conductivity graphite film with heat pipe and honeycomb plate. The high thermal conductivity graphite radiator is simulated and compared with two traditional radiators. The simulation results indicated that under the same heat dissipation capacity, the weight of high thermal conductivity graphite radiator is only about 1/3 of that of traditional aluminum alloy plate radiator, and about 1/2 of that of traditional aluminum honeycomb radiator. The heat dissipation performance of the radiator is verified by heat balance experiment and on-orbit flight application. The verification results show that the simulation values are in good agreement with the on-orbit values. The radiator not only has excellent mechanical and thermal performance, but also has significant weight reduction advantages, and can be widely used in the heat radiation of spacecraft.

-

表 1 石墨膜的主要检测项目及结果

Table 1. Main test items and results of graphite film

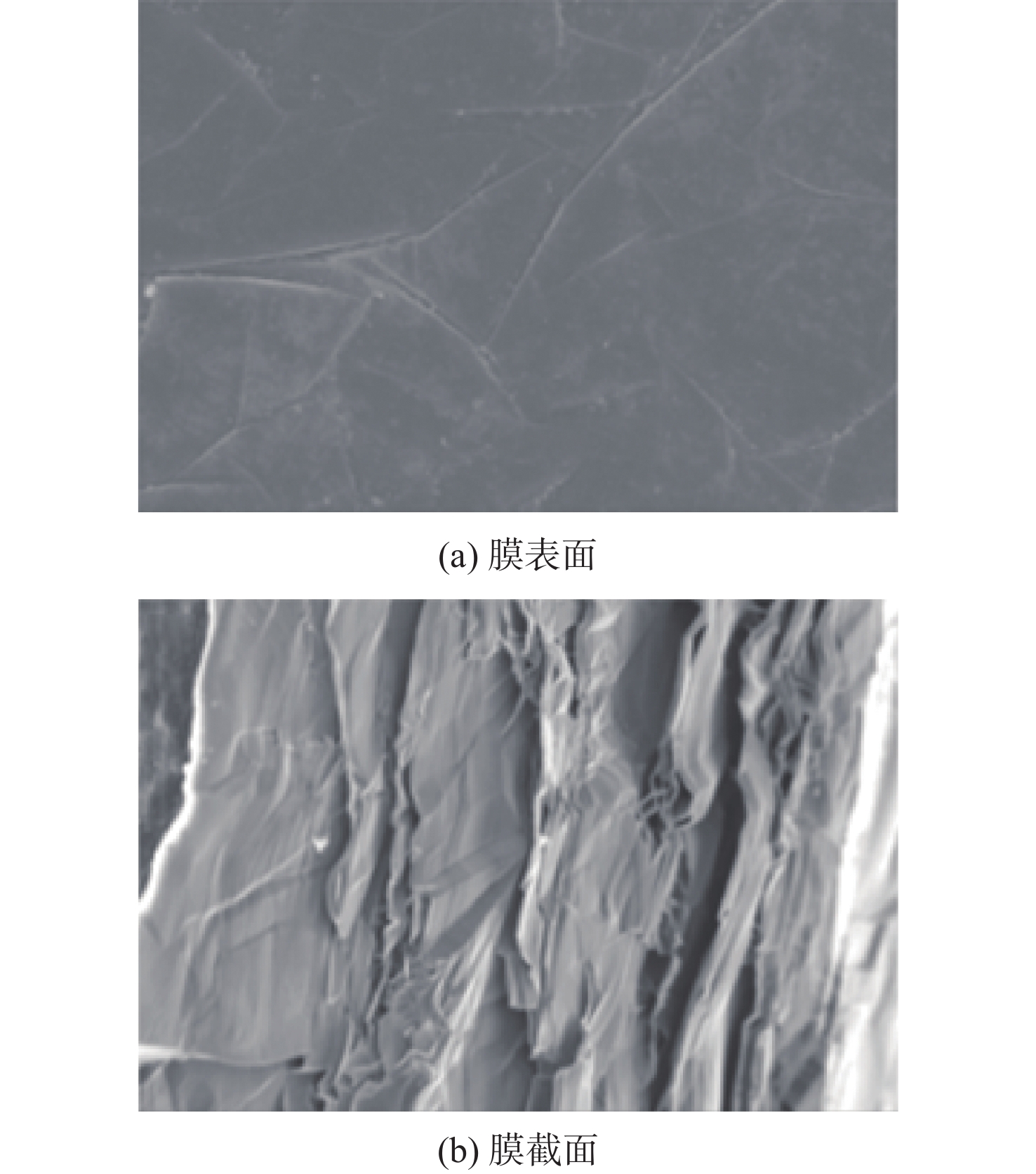

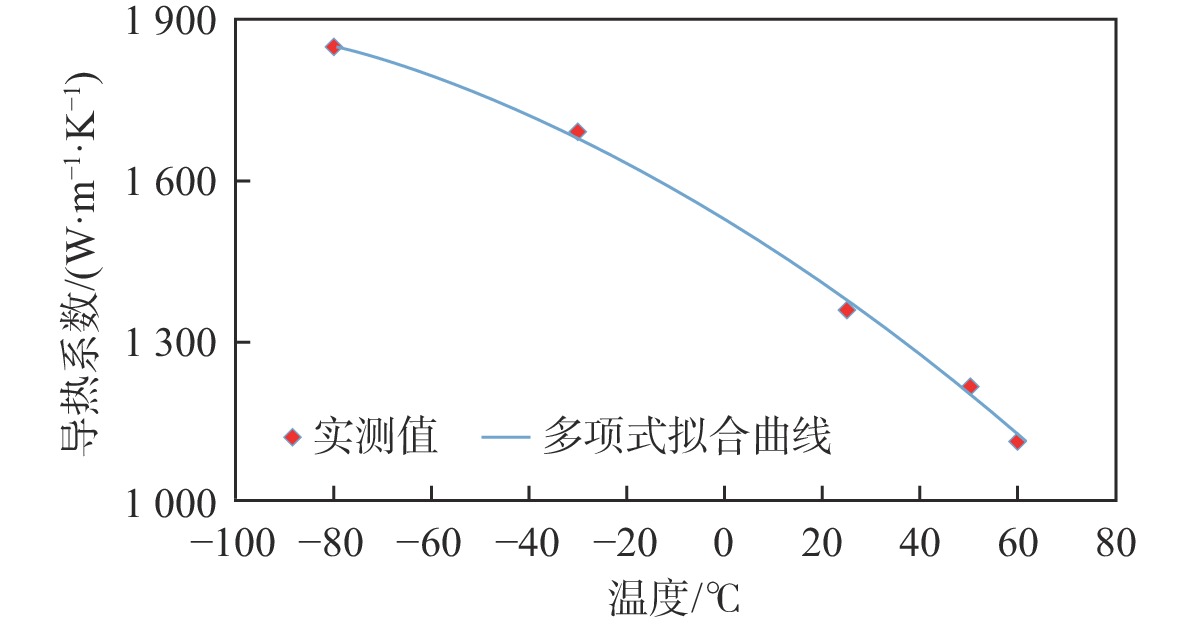

检测项目 测试内容 测试结果 基础物理性能 密度 2000 kg/m3 热稳定性 热失重达到5%时的温度

分别为920 ℃吸水率 ≤0.5% 结构分析 SEM 如图1所示 X射线衍射技术 石墨化度≈100% 拉曼光谱 化学分析 碳含量 99.77% 灰分 0.21% 挥发分 0.02% 力学特性 拉伸强度 40.8 MPa (−80 ℃) 52.8 MPa (室温) 56.7 MPa (+60 ℃) 耐折性 大于21000次 热学性能 比热(常温) 0.85(J·g−1·K−1) 面内导热系数 如图2所示 晶面热膨胀系数 如表2所示 地面环境

适应性湿热环境适应性 试验后无破损,无裂纹,

导热系数平均值保持率

≥95%空间环境

适应性温度冲击环境适应性 试验后无破损,无裂纹,

导热系数平均值保持率

≥95%抗粒子辐照性能,

总剂量9×107 rad(Si)

的辐照试验后无破损,无裂纹,

导热系数平均值保持率

≥95%表 2 不同材料热膨胀系数

Table 2. coefficient of thermal expansion of different materials

材料名称 热膨胀系数 −80 ℃ −50 ℃ 0 ℃ 50 ℃ 高导热石墨 −1.29 −1.54 −1.88 −2.26 碳纤维蒙皮 −0.08 <0.036 表 3 热分析参数

Table 3. Thermal analysis parameters

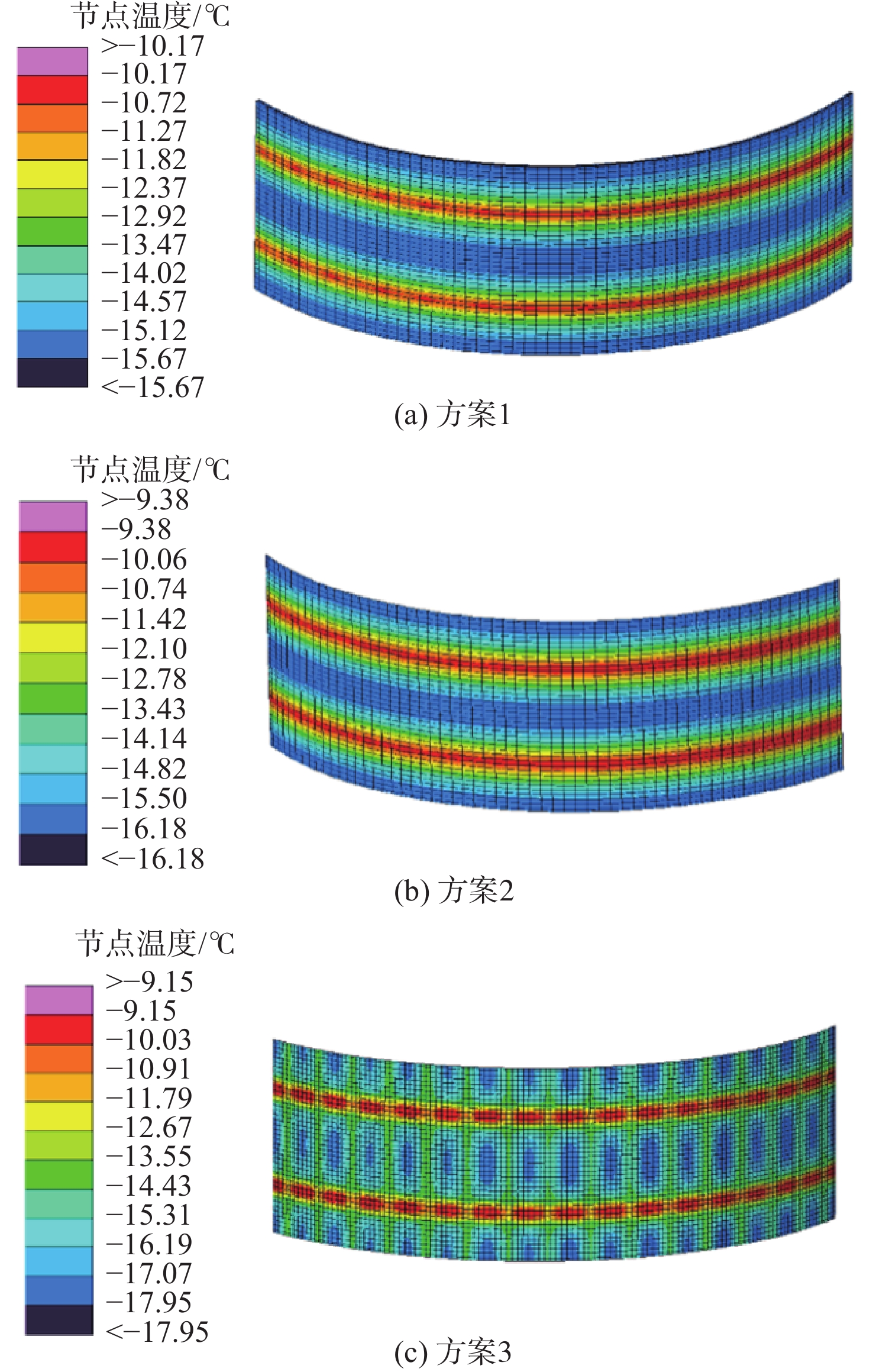

名称 等效导热系数/(W·m−1·K−1) 厚度/mm 密度/(kg·m−3) 石墨层叠体 1350(平面内) 0.34 1 850 2(厚度方向) 碳纤维蒙皮 20(平面内) 0.2 1 430 1(厚度方向) 铝蜂窝芯 1.0(z方向) 10 27 0.6(x方向) 0.5(y方向) 铝板5A06 117 2 700 铝蒙皮 117 0.3 2 700 表 4 不同辐射散热器性能对比

Table 4. Performance comparison of different radiators

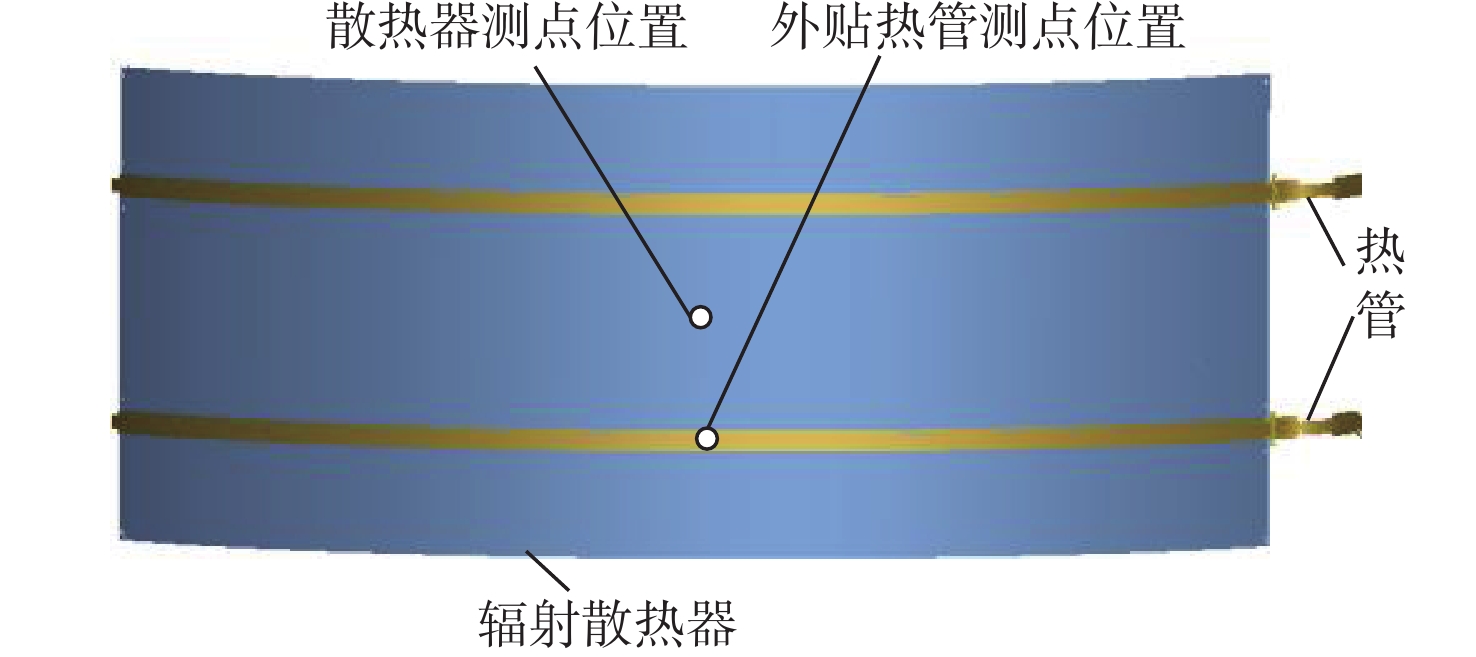

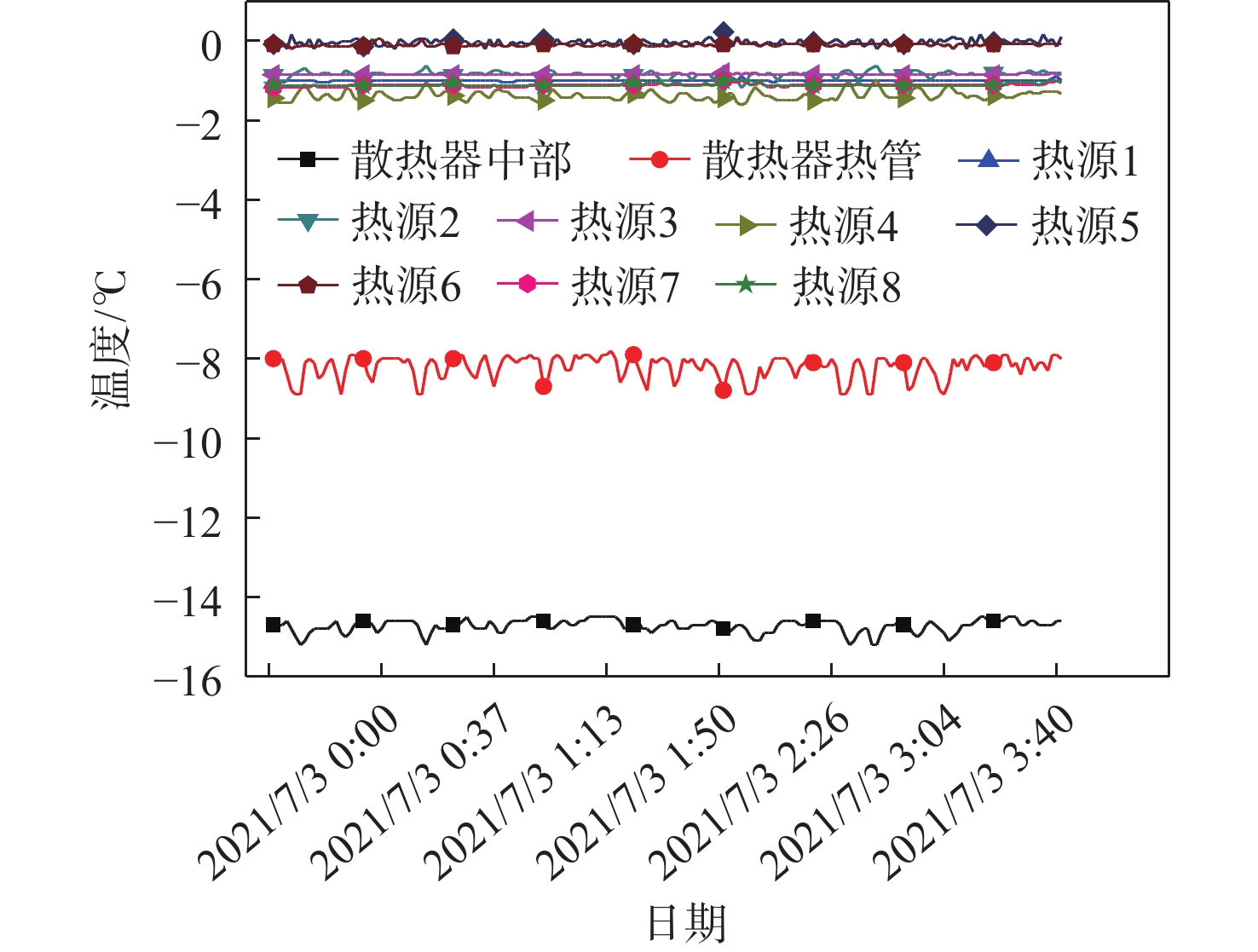

散热器方案 集热热管温度水平/℃ 散热器温度水平/℃ 质量/kg 方案1 −1.5~0.1 −15.7~−10.1 3.4 方案2 −1.5~0.1 −16.2~−9.4 9.1 方案3 −1.5~0.1 −18.0~−9.2 6.3 表 5 辐射散热器不同阶段温度

Table 5. Temperature of radiator in different stages

名称 集热热管平均发热功率/W 集热热管温度/℃ 外贴热管测点温度/℃ 散热器中心测点温度/℃ 外贴热管与散热器

中部测点平均温差/℃仿真值 234 −1.5~−0.1 −9.5~−8.6 −15.8~−15.0 6.35 热平衡试验值 232.2 −1.5~0.3 −8.7~−7.7 −14.9~−14.1 6.3 在轨飞行值 236.4 −1.6~0.2 −8.9~−7.9 −15.3~−14.5 6.5 -

[1] 苗建印, 钟奇, 赵啟伟. 航天器热控制技术[M]. 北京: 北京理工大学出版社, 2018.MIAO J Y, ZHONG Q, ZHAO Q W. Spacecraft thermal control technology[M]. Beijing: Beijing Insititute of Technology Press, 2018 (in Chinese). [2] 赵振明, 鲁盼, 宋欣阳. “高分二号”卫星相机热控系统的设计与验证[J]. 航天返回与遥感, 2015, 36(4): 34-40. doi: 10.3969/j.issn.1009-8518.2015.04.005ZHAO Z M, LU P, SONG X Y. Thermal design and test for high resolution space camera on GF-2 satellite[J]. Spacecraft Recovery & Remote Sensing, 2015, 36(4): 34-40(in Chinese). doi: 10.3969/j.issn.1009-8518.2015.04.005 [3] 孟庆亮, 杨涛, 于志, 等. 空间遥感器用环路热管瞬态数值模拟与在轨验证[J]. 北京航空航天大学学报, 2020, 46(11): 2045-2055. doi: 10.13700/j.bh.1001-5965.2019.0584MENG Q L, YANG T, YU Z, et al. Transient numerical simulation and on-orbit verification of loop heat pipe used for space remote sensor[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2045-2055(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0584 [4] 于峰, 徐娜娜, 赵宇, 等. “高分四号”卫星相机热控系统设计及验证[J]. 航天返回与遥感, 2016, 37(4): 72-79. doi: 10.3969/j.issn.1009-8518.2016.04.010YU F, XU N N, ZHAO Y, et al. Thermal design and test for space camera on GF-4 satellite[J]. Spacecraft Recovery & Remote Sensing, 2016, 37(4): 72-79(in Chinese). doi: 10.3969/j.issn.1009-8518.2016.04.010 [5] CHANG H. Optimization of a heat pipe radiator design[C]//Proceedings of the 19th Thermophysics Conference. Reston: AIAA, 1984. [6] 刘欣, 梁新刚. 太空辐射器传热优化设计及分析[J]. 宇航学报, 2016, 37(5): 605-611.LIU X, LIANG X G. Optimization design and analysis of heat transfer for space radiator[J]. Journal of Astronautics, 2016, 37(5): 605-611(in Chinese). [7] 张学军, 樊延超, 鲍赫, 等. 超大口径空间光学遥感器的应用和发展[J]. 光学精密工程, 2016, 24(11): 2613-2626. doi: 10.3788/OPE.20162411.2613ZHANG X J, FAN Y C, BAO H, et al. Applications and development of ultra large aperture space optical remote sensors[J]. Optics and Precision Engineering, 2016, 24(11): 2613-2626(in Chinese). doi: 10.3788/OPE.20162411.2613 [8] 李宣, 徐勇, 李林霜, 等. 聚酰亚胺基高定向石墨膜的研究进展[J]. 炭素技术, 2015, 34(4): 1-5. doi: 10.14078/j.cnki.1001-3741.2015.04.001LI X, XU Y, LI L S, et al. Research progress of polyimide-based highly oriented graphite films[J]. Carbon Techniques, 2015, 34(4): 1-5(in Chinese). doi: 10.14078/j.cnki.1001-3741.2015.04.001 [9] 张姗姗. 高导热石墨膜增强C/C复合材料的制备与结构性能研究[D]. 北京: 北京化工大学, 2018.ZHANG S S. Preparation and structural properties of C/C composites reinforced by high thermal conductivity graphite films[D]. Beijing: Beijing University of Chemical Technology, 2018 (in Chinese). [10] MA Z K, LIU L, LIAN F, et al. Three-dimensional thermal conductive behavior of graphite materials sintered from ribbon mesophase pitch-based fibers[J]. Materials Letters, 2012, 66(1): 99-101. doi: 10.1016/j.matlet.2011.08.024 [11] 崔正威, 袁观明, 董志军, 高定向导热炭材料的研究进展[J]. 中国材料进展, 2020, 39(6): 450-457.CUI Z W , YUAN G M, DONG Z J . Research progress on carbon materials with high-oriented thermal conductivity[J]. Materials China , 2020, 39(6): 450-457. [12] 童叶龙, 李国强, 余雷, 等. 高热流CCD器件散热与精密控温技术[J]. 航天返回与遥感, 2014, 35(5): 46-53. doi: 10.3969/j.issn.1009-8518.2014.05.007TONG Y L, LI G Q, YU L, et al. Heat dissipation and precise temperature control for high-power CCD assembly[J]. Spacecraft Recovery & Remote Sensing, 2014, 35(5): 46-53(in Chinese). doi: 10.3969/j.issn.1009-8518.2014.05.007 [13] 侯增祺, 胡金刚. 航天器热控制技术: 原理及其应用[M]. 北京: 中国科学技术出版社, 2007: 326-328HOU Z Q, HU J G. Thermal control technology of spacecraft: Principle and application[M]. Beijing: China Science and Technology Press, 2007: 326-328 (in Chinese). [14] 杨世铭, 陶文铨. 传热学[M]. 第4版. 北京: 高等教育出版社, 2006.YANG S M, TAO W Q. Heat transfer[M]. 4th ed. Beijing: Higher Education Press, 2006 (in Chinese). [15] 李玮, 谢宗蕻, 赵剑. 蜂窝芯体面外方向导热系数等效研究[J]. 真空与低温, 2010, 16(3): 162-166.LI W, XIE Z H, ZHAO J. The research on the out-of-plane equivalent thermal conductivity of honeycomb cores[J]. Vacuum and Cryogenics, 2010, 16(3): 162-166(in Chinese). [16] SWANN R T, PTTIMAN C M. Analysis of effective thermal conductivities of Honney core and corrugated core Sandwich Panels: Technical note D-714 [R]. Washington , D. C.: NASA, 1961. 期刊类型引用(1)

1. 王建鹏,郭彤,陈亮,姜文杰,孙晓晨. 基于多目标遗传算法的固定蜂窝板辐射器性能优化. 航天器工程. 2024(04): 34-43 .  百度学术

百度学术其他类型引用(0)

-

下载:

下载:

百度学术

百度学术