Numerical study on coupled heat transfer of rotating disc in centrifugal atomization

-

摘要:

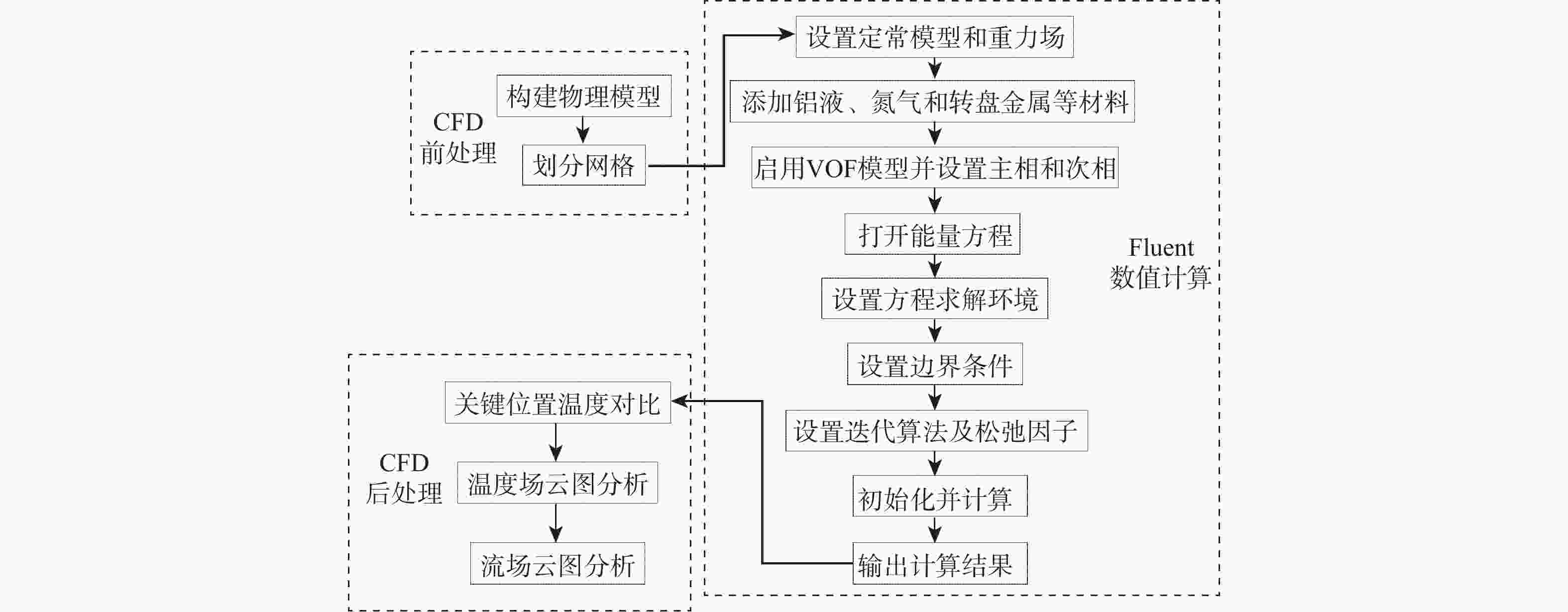

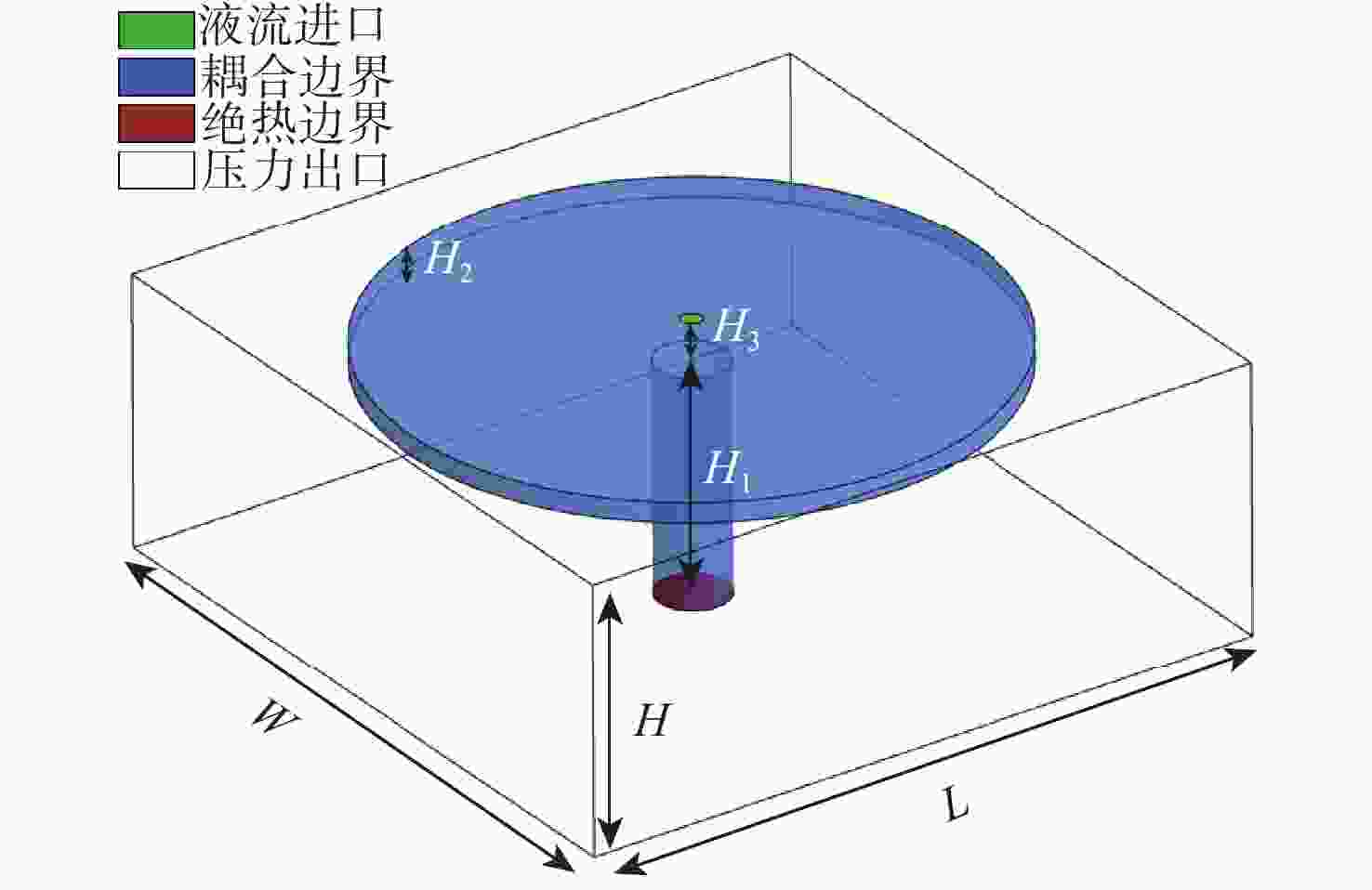

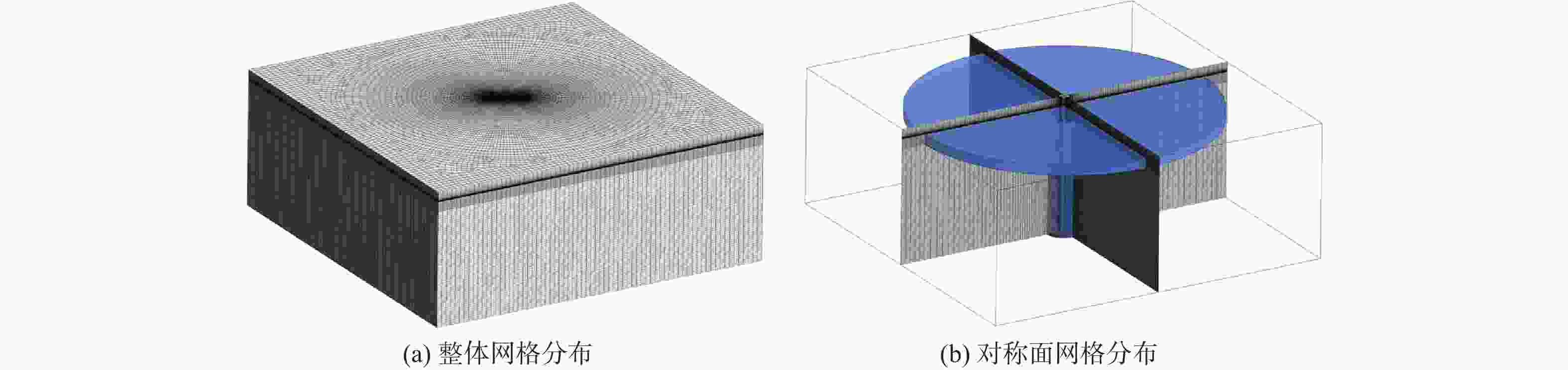

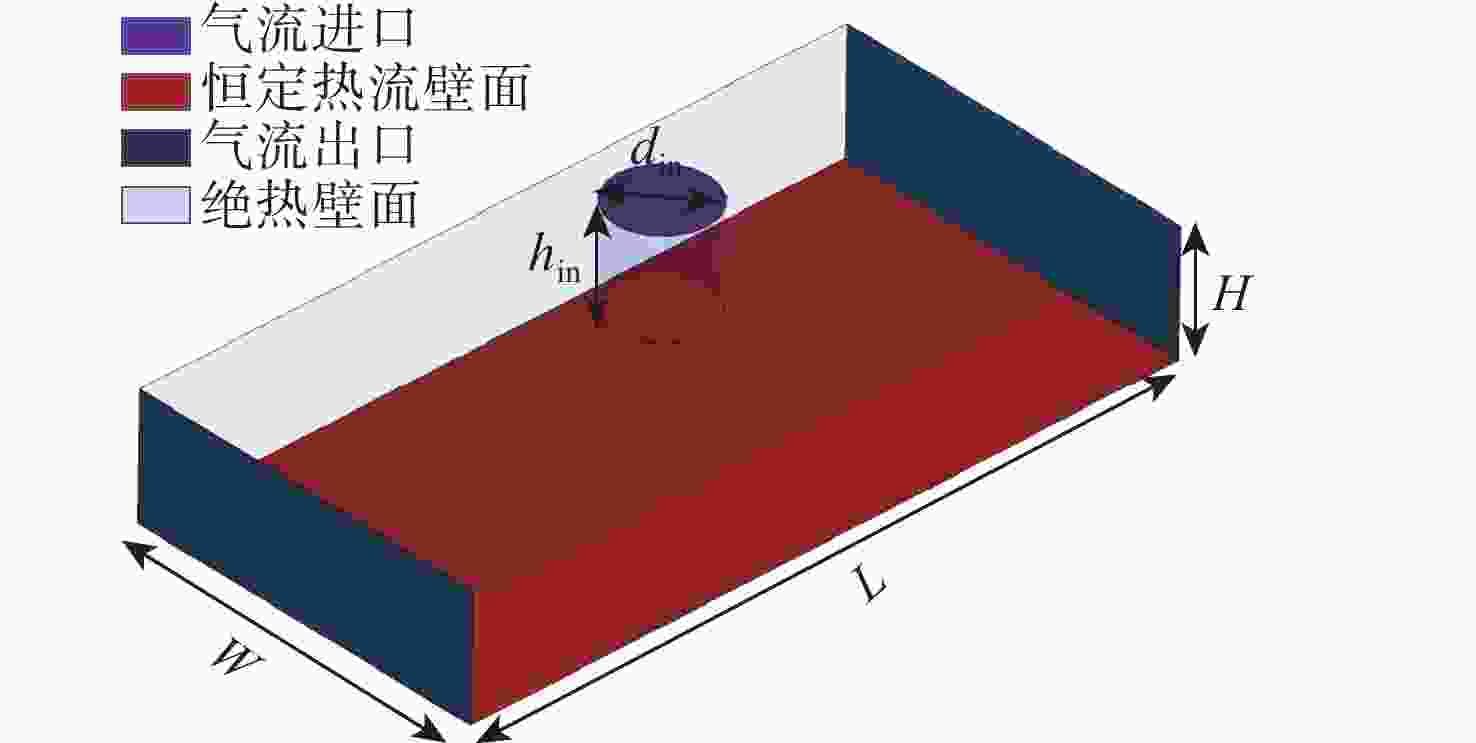

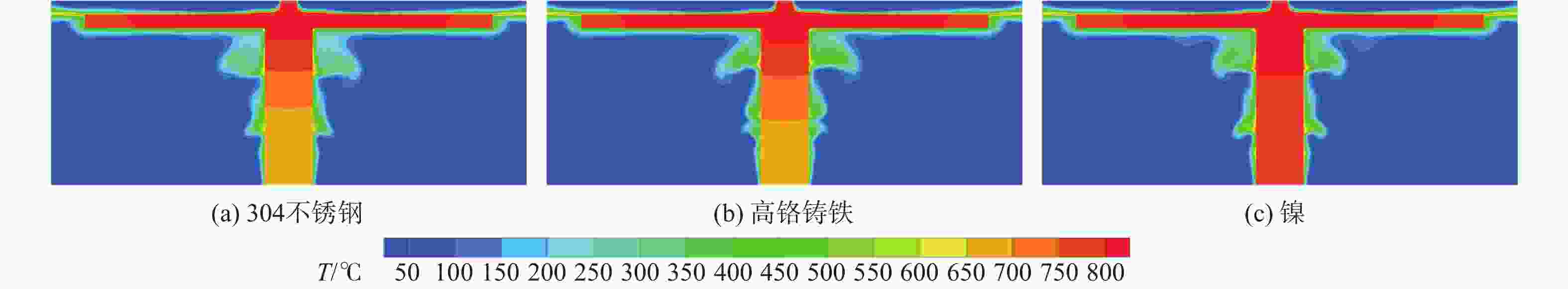

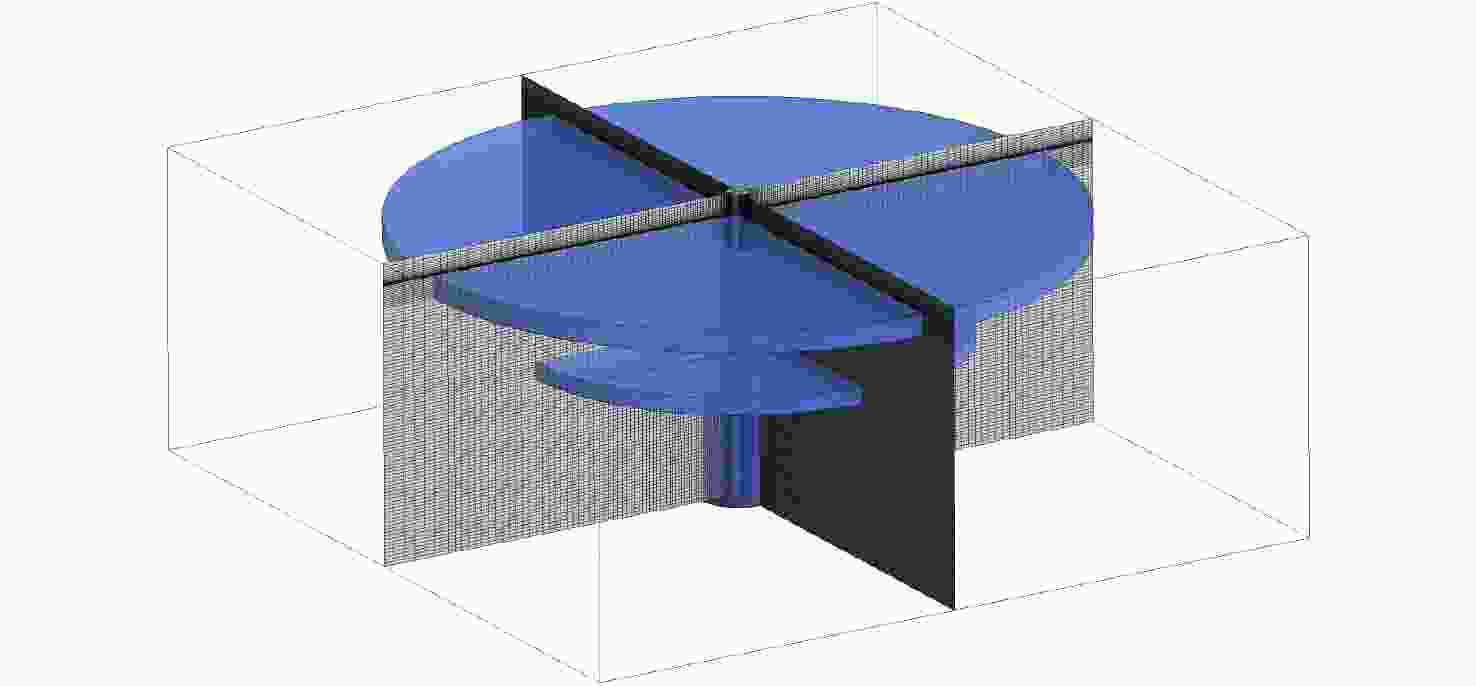

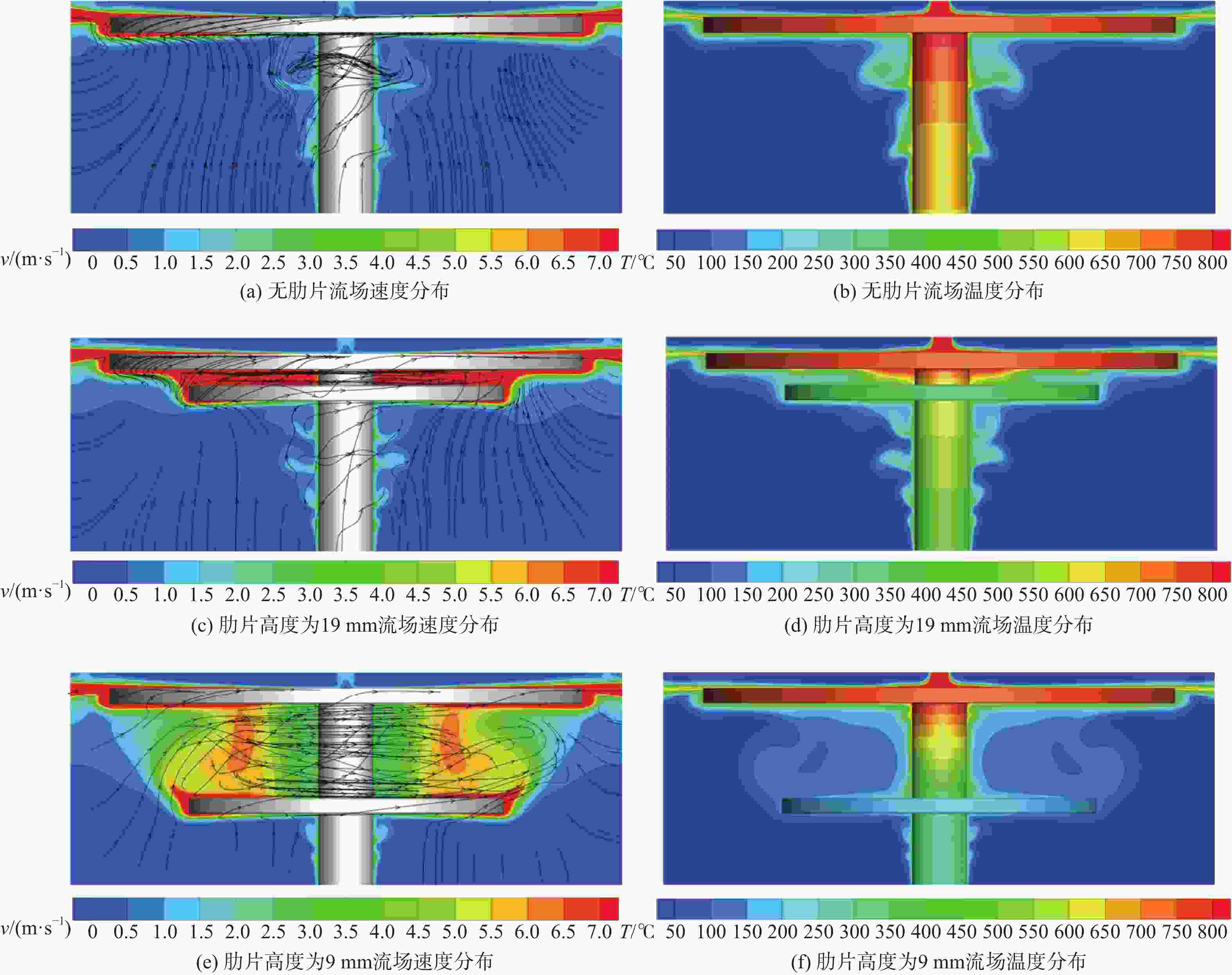

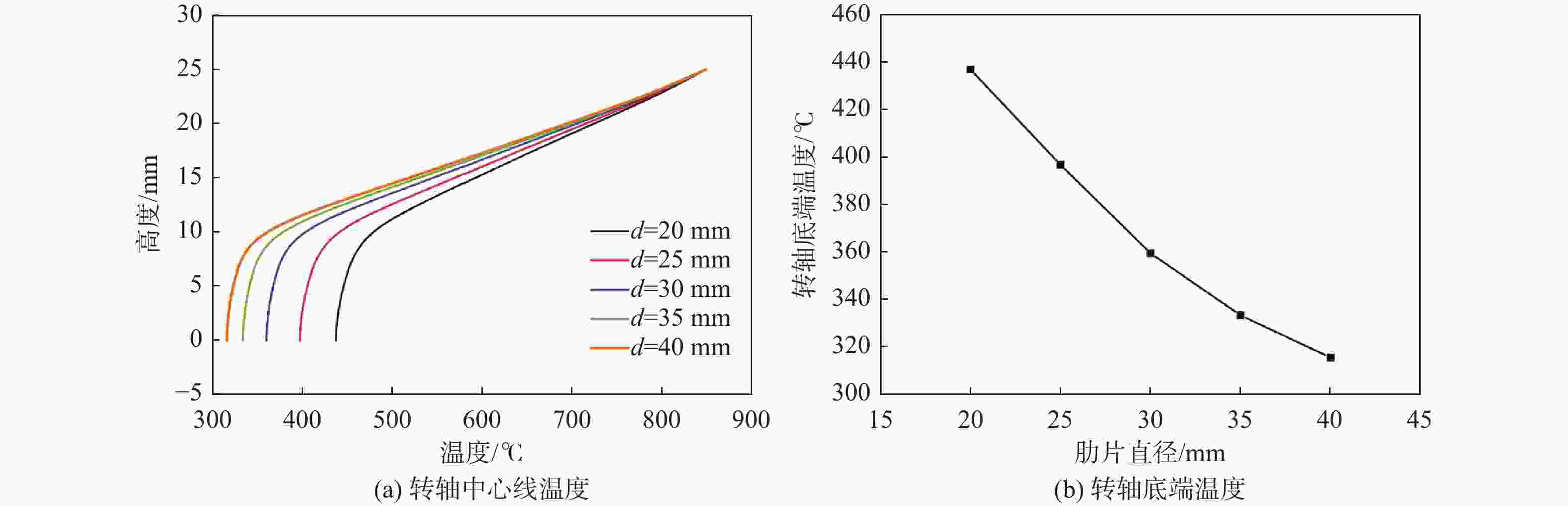

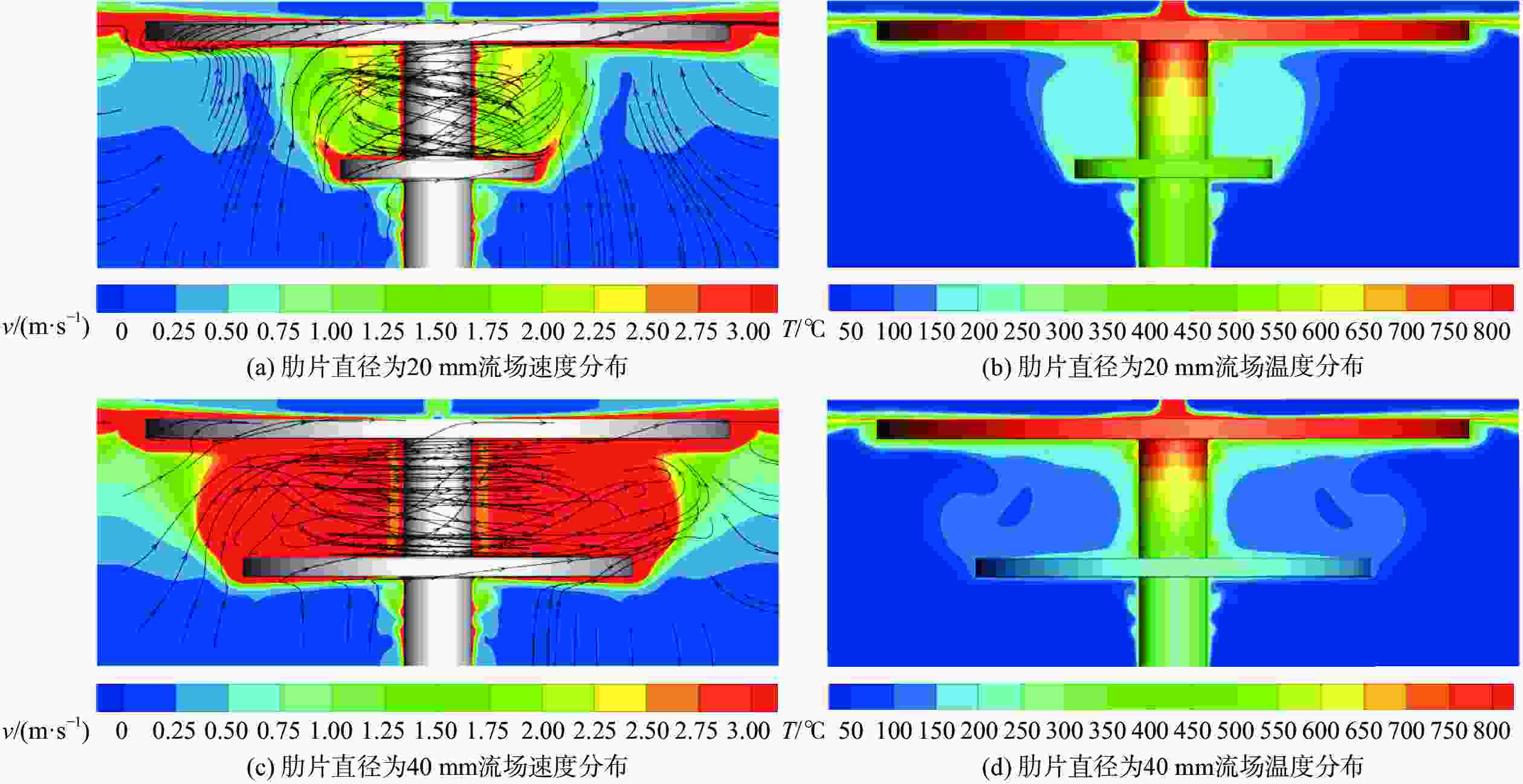

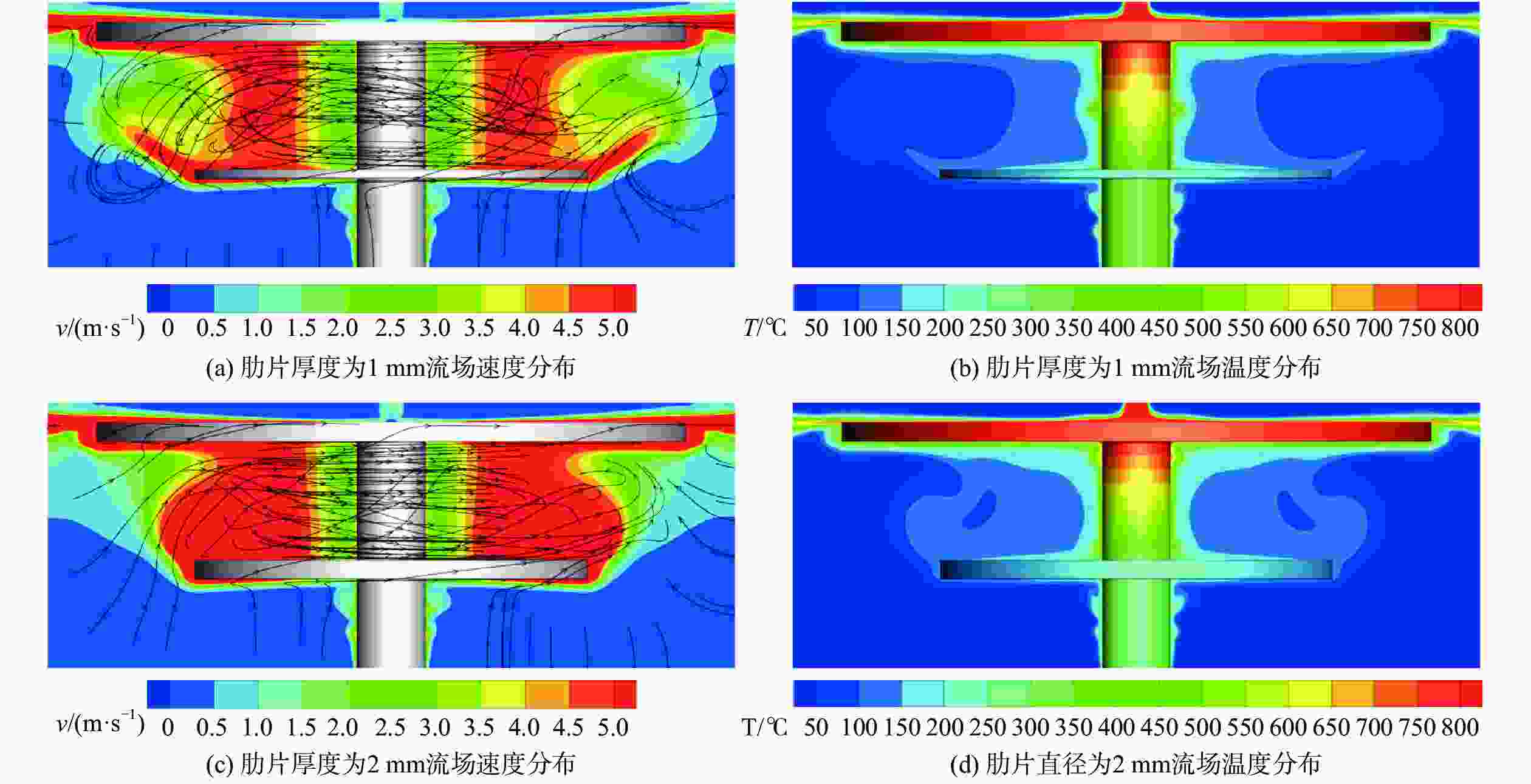

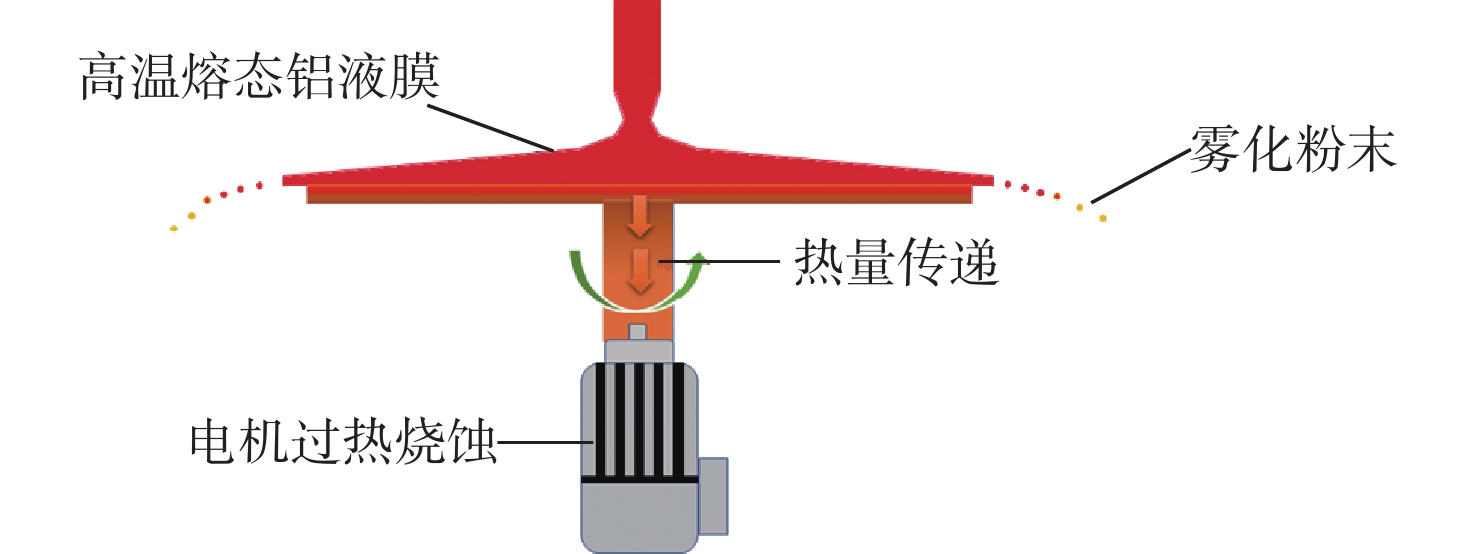

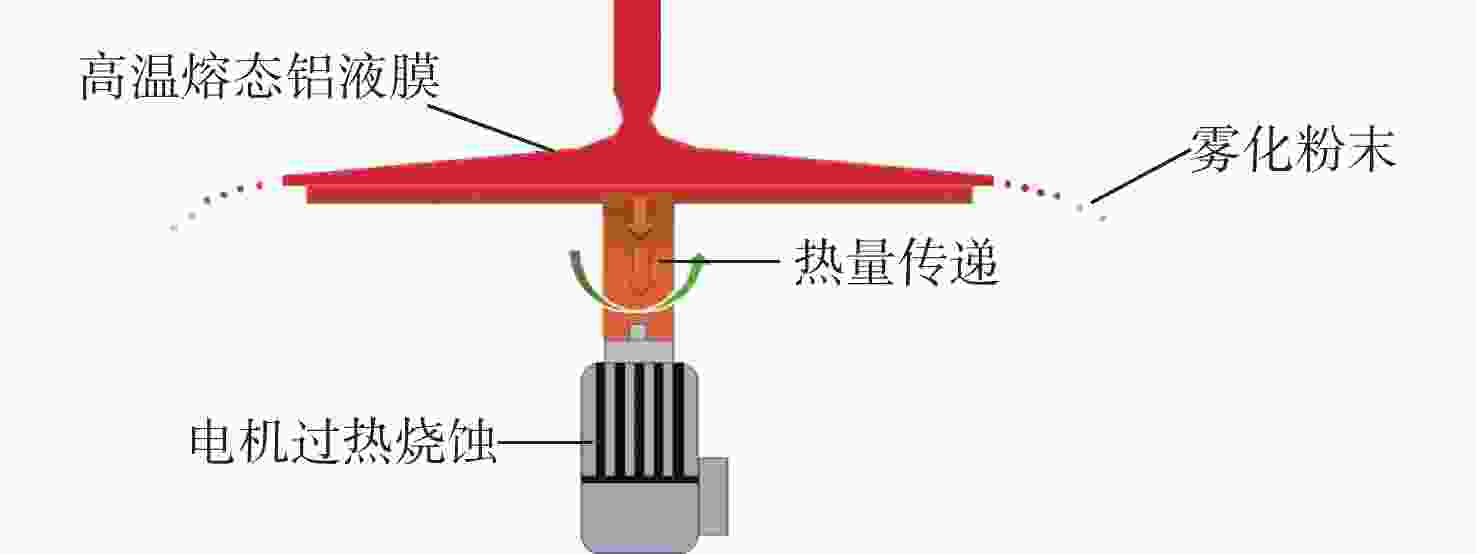

转盘离心雾化是一种制备球形金属粉末的重要方法,在高熔点金属粉末制备中,需要对转盘结构本身和下端的驱动电机进行热防护。采用数值模拟的方法,研究熔融铝液的转盘离心雾化流场模型的耦合传热问题,给出不同材料、不同转盘结构条件下的转盘温度场分布。为提高冷却效率,发展带有肋片的新型转盘热防护结构,分析肋片结构的散热机理,对比不同肋片位置、肋片厚度和肋片直径的热防护效果。研究结果表明:大热容和低导热系数的金属材料转盘的底端温度更低;肋片和转盘之间形成的环形氮气流场是提高转轴散热能力的主要原因;肋片位置越低,直径越大,厚度越厚,转轴底端温度越低,冷却效果越好。

Abstract:Rotating disk atomization is an important method to prepare spherical metal powder. In the preparation of high-melting-point metal powders, by this method, thermal protection is required for both the turntable structure itself and the lower-end driving motor. The coupled heat transfer problem of centrifugal atomization flow field model of molten aluminum was analyzed by numerical simulation, and the temperature field distribution of disk under different materials and disk structures was given. To improve the cooling efficiency, a new type of rotary disk thermal protection structure with fins was developed. The heat dissipation mechanism of the fin structure was analyzed, and the thermal protection effects of different fin positions, fin thickness and fin diameter were compared. The results revealed that the metal rotating shaft with larger specific heat capacity and lower thermal conductivity has lower temperature at its bottom. Moreover, the annular nitrogen flow field formed between the fin and the rotary disk is the main reason to improve the heat dissipation capacity of the rotating shaft. Finally, the lower position the fins, the larger diameter, and the thicker the thickness , the lower the temperature at the bottom of the shaft, resulting in a better cooling effect.

-

Key words:

- rotating disk atomization /

- fluid-heat-solid coupling /

- thermal protection /

- numerical simulation /

- fin

-

密度/(kg·m−3) 比热容/(J·(kg·K)−1) 导热系数/(W·(m·K)−1) 黏性系数/(Pa·s) 标准状态焓值/(kJ·mol−1) 表面张力/(N·m−1) (933$\leqslant $T$\leqslant $1190) (933$\leqslant $T$\leqslant $2327) (933$\leqslant $T$\leqslant $2700) (933$\leqslant $T$\leqslant $1270) 8.66 (933$\leqslant $T$\leqslant $1270) 2667.5−0.311T 1176.8 48.226+0.057T−1.21×10−5T2 1.852×10−4exp(1850.1/T) 1.18−2.4×10−4T 温度/℃ 比热容/(J·(kg·K)−1) 导热系数/(W·(m·K)−1) 25 480 14.8 100 500 15.8 200 530 17.7 300 540 18.8 400 560 20.7 500 570 21.4 600 595 23.5 700 600 24.5 800 620 25.8 900 630 27.5 温度/℃ 导热系数/(W·(m·K)−1) 比热容/(J·(kg·K)−1) 25 426 90 100 480 87 200 547 76 300 700 64 400 536 60 500 535 62 600 540 65 700 557 67 800 574 71 900 590 72.7 温度/℃ 比热容/(J·(kg·K)−1) 导热系数/(W·(m·K)−1) 20 465 54 100 478 50.34 200 519 46.68 300 528 43.02 400 541 39.36 500 558 35.73 600 583 32.04 700 621 29.86 表 5 因素水平确定表

Table 5. Factors to determine level

水平 肋片位置高度/mm 肋片厚度/mm 肋片直径/mm 1 9 1 20 2 14 1.5 30 3 19 2 40 表 6 9种肋片参数搭配下的转轴底端温度

Table 6. Temperature at the bottom of the shaft under 9 different fin parameter combinations

序号 肋片位置高度/

mm肋片厚度/

mm肋片直径/

mm转轴底端温度/

℃1 9 1 20 444.77 2 9 1.5 30 373.74 3 9 2 40 315.63 4 14 1 30 445.02 5 14 1.5 40 387.81 6 14 2 20 499.44 7 19 1 40 510.28 8 19 1.5 20 560.74 9 19 2 30 516.49 表 7 以转轴底端温度为指标的极差分析

Table 7. Range analysis based on temperature at the bottom of rotating shaft

因

素Kmn kmn Rn 水平1 水平2 水平3 水平1 水平2 水平3 1 1134.14 1332.27 1587.51 378.05 444.09 529.17 151.12 2 1400.07 1331.56 1322.29 466.69 440.76 443.85 25.93 3 1504.95 1213.72 1335.25 501.65 445.08 404.57 97.08 -

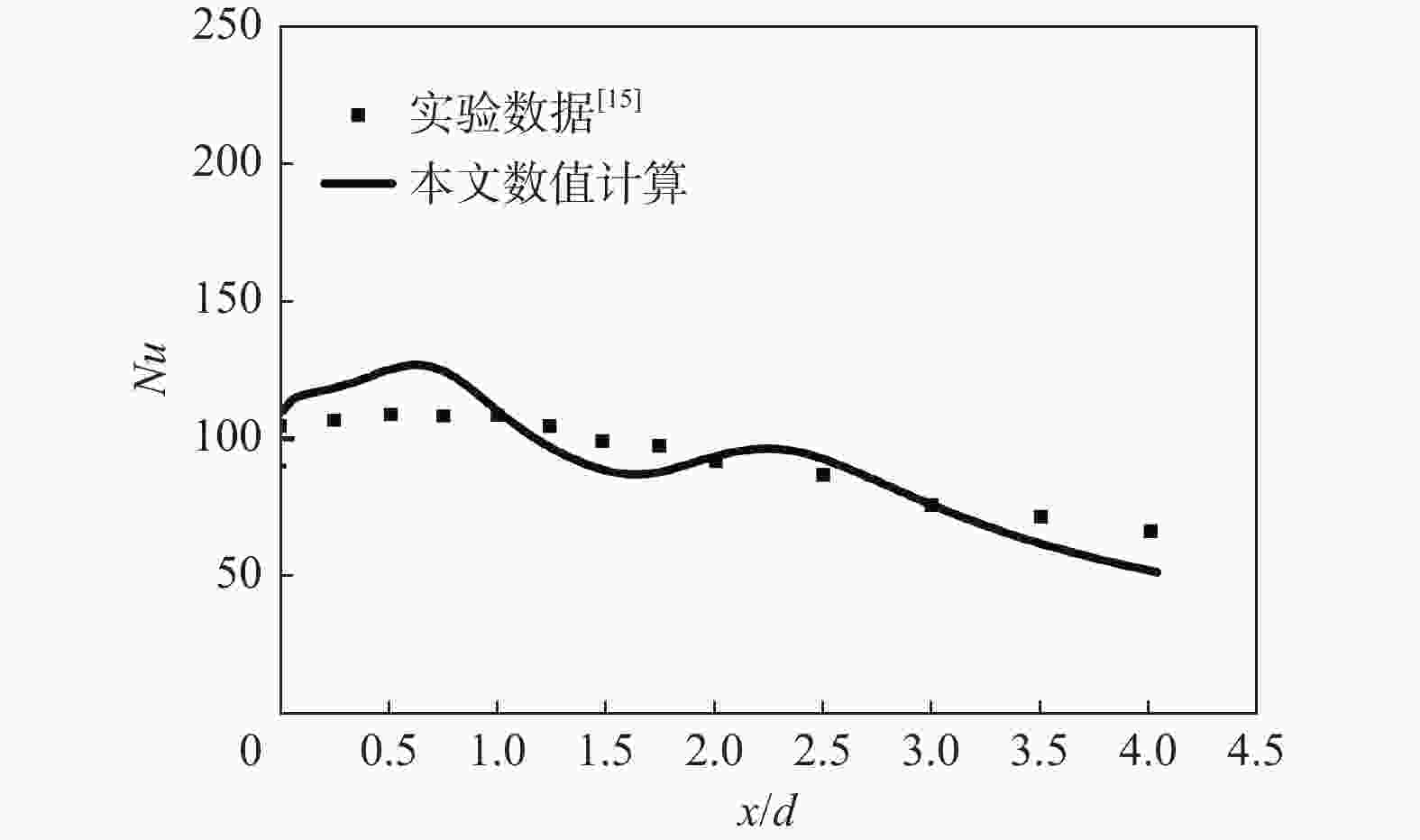

[1] SIMONS M. Additive manufacturing—A revolution in progress? Insights from a multiple case study[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96(1): 735-749. [2] 杨兵, 刘颖. BGA封装技术[J]. 电子与封装, 2003, 3(4): 6-13.YANG B, LIU Y. BGA packaging technology[J]. Electronics & Packaging, 2003, 3(4): 6-13(in Chinese). [3] KIM C K, KIM K H, PARK J M, et al. Development of advanced research reactor fuels using centrifugal atomization technology[J]. Metals and Materials, 1999, 5(2): 149-156. doi: 10.1007/BF03026045 [4] SOVA A, DOUBENSKAIA M, TROFIMOV E, et al. Cold spray of metal powder mixtures: Achievements, issues and perspectives[J]. Transactions of the Indian Institute of Metals, 2021, 74(3): 559-570. doi: 10.1007/s12666-020-02165-7 [5] 高莹, 顾毅, 吴艺辉, 等. 铁锰无磁合金粉的水雾化法生产工艺研究[J]. 粉末冶金技术, 2018, 36(6): 465-469.GAO Y, GU Y, WU Y H, et al. Research on production technology of nonmagnetic Fe-Mn alloy powders by water atomization[J]. Powder Metallurgy Technology, 2018, 36(6): 465-469(in Chinese). [6] 刘英杰, 胡强, 赵新明, 等. 增材制造用高流动性铝合金粉末制备技术研究[J]. 稀有金属材料与工程, 2021, 50(5): 1767-1774.LIU Y J, HU Q, ZHAO X M, et al. Investigation of centrifugal atomization technology of high fluidity aluminium alloy powder for additive manufacturing[J]. Rare Metal Materials and Engineering, 2021, 50(5): 1767-1774(in Chinese). [7] TANG J J, NIE Y, LEI Q, et al. Characteristics and atomization behavior of Ti-6Al-4V powder produced by plasma rotating electrode process[J]. Advanced Powder Technology, 2019, 30(10): 2330-2337. doi: 10.1016/j.apt.2019.07.015 [8] 王建军. 中国雾化制粉技术现状简介[J]. 粉末冶金工业, 2016, 26(5): 1-4.WANG J J. Brief introduction to the present situation of atomization powder technology in China[J]. Powder Metallurgy Industry, 2016, 26(5): 1-4(in Chinese). [9] 杨洪涛, 卢志辉, 孙志杨, 等. 等离子旋转电极雾化制粉设备国内研究现状[J]. 粉末冶金工业, 2021, 31(4): 88-93.YANG H T, LU Z H, SUN Z Y, et al. Domestic research status of plasma rotation electrode process equipment[J]. Powder Metallurgy Industry, 2021, 31(4): 88-93(in Chinese). [10] LABRECQUE C, ANGERS R, TREMBLAY R, et al. Inverted disk centrifugal atomization of AZ91 magnesium alloy[J]. Canadian Metallurgical Quarterly, 1997, 36(3): 169-175. doi: 10.1179/cmq.1997.36.3.169 [11] ÖZTÜRK S, ARSLAN F. Production of rapidly solidified metal powders by water cooled rotating disc atomisation[J]. Powder Metallurgy, 2013, 44(2): 171-176. [12] ÖZTÜRK S, ARSLAN F, ÖZTÜRK B. Effect of process parameters on production of metal powders by water jet cooled rotating disc atomisation[J]. Powder Metallurgy, 2013, 48(2): 163-170. [13] ÖZTÜRK S, ARSLAN F, ÖZTÜRK B. Effect of production parameters on cooling rates of AA2014 alloy powders produced by water jet cooled, rotating disc atomisation[J]. Powder Metallurgy, 2013, 46(4): 342-348. [14] ÖZTÜRK S, USTA G, ÖZTÜRK B. Production of bronze powders by water jet cooled rotating disc atomisation[J]. Powder Metallurgy, 2013, 54(3): 393-399. [15] SAN J Y, SHIAO W Z. Effects of jet plate size and plate spacing on the stagnation Nusselt number for a confined circular air jet impinging on a flat surface[J]. International Journal of Heat and Mass Transfer, 2006, 49(19-20): 3477-3486. doi: 10.1016/j.ijheatmasstransfer.2006.02.055 [16] 夏盛勇, 胡春波. 液态铝和三氧化二铝物性参数计算方法综述[J]. 推进技术, 2019, 40(5): 961-969.XIA S Y, HU C B. Review of physical property calculations of liquid aluminum and alumina[J]. Journal of Propulsion Technology, 2019, 40(5): 961-969(in Chinese). [17] MILLS K C. Recommended values of thermophysical properties for selected commercial alloys[M]. Cambridge: Woodhead, 2002. [18] 范瑞杰. 基于ANSYS的热轧辊蠕变疲劳寿命的预测[D]. 秦皇岛: 燕山大学, 2014: 29-30.FAN R J. The hot roll creep fatigue life prediction based on the ansys platform[D]. Qinhuangdao: Yanshan University, 2014: 29-30(in Chinese). [19] 魏泽辉, 高世杰, 闫素英, 等. 基于极差分析与费用年值法的太阳能-空气源热泵互补供热系统的正交优化[J]. 可再生能源, 2019, 37(8): 1146-1151.WEI Z H, GAO S J, YAN S Y, et al. Orthogonal experimental of the solar heating system assisted with air source heat pump based on annual cost and solar fraction[J]. Renewable Energy Resources, 2019, 37(8): 1146-1151(in Chinese). -

下载:

下载: