A machine learning based method for lithium-ion battery state of health classification and prediction

-

摘要:

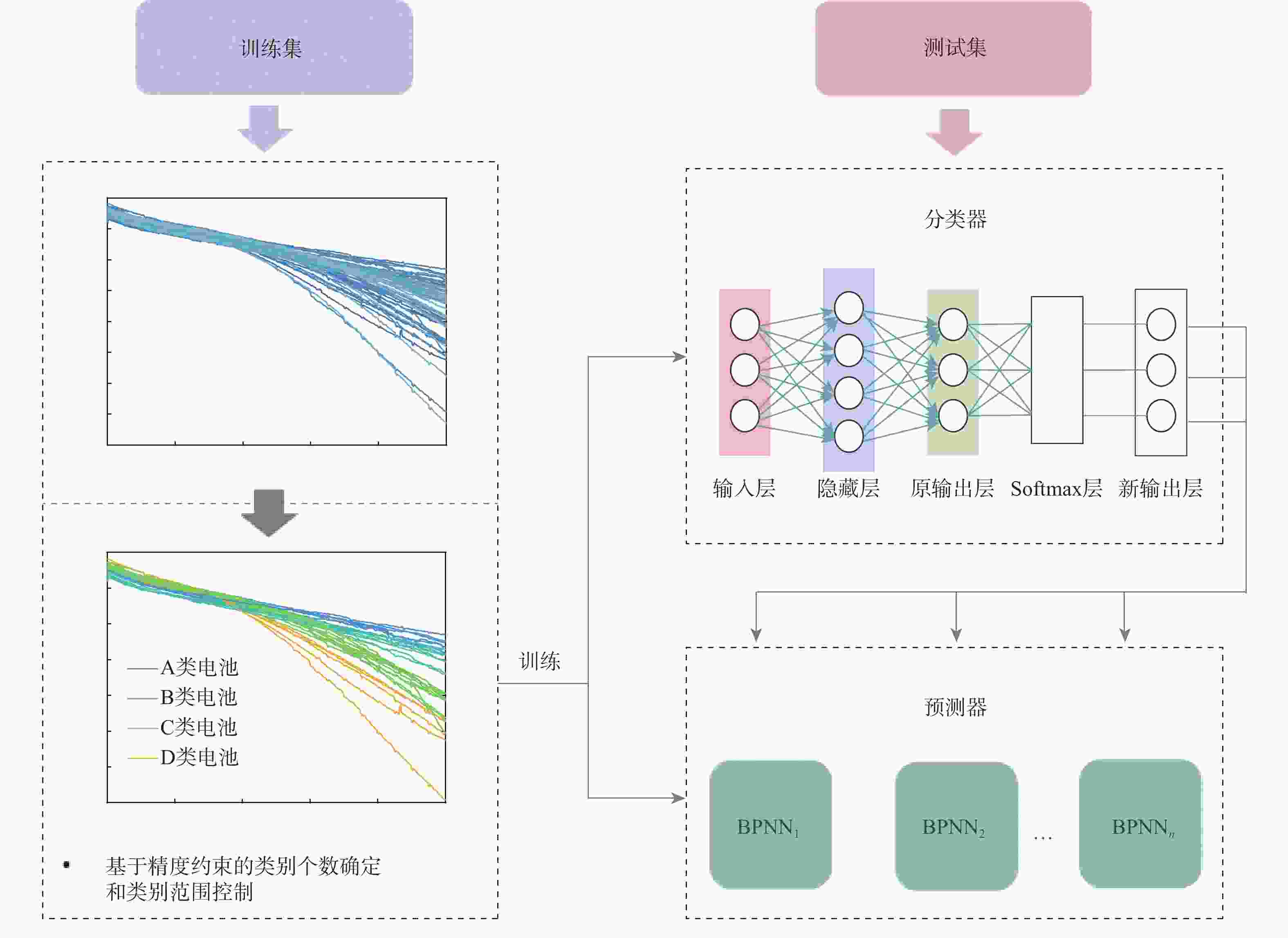

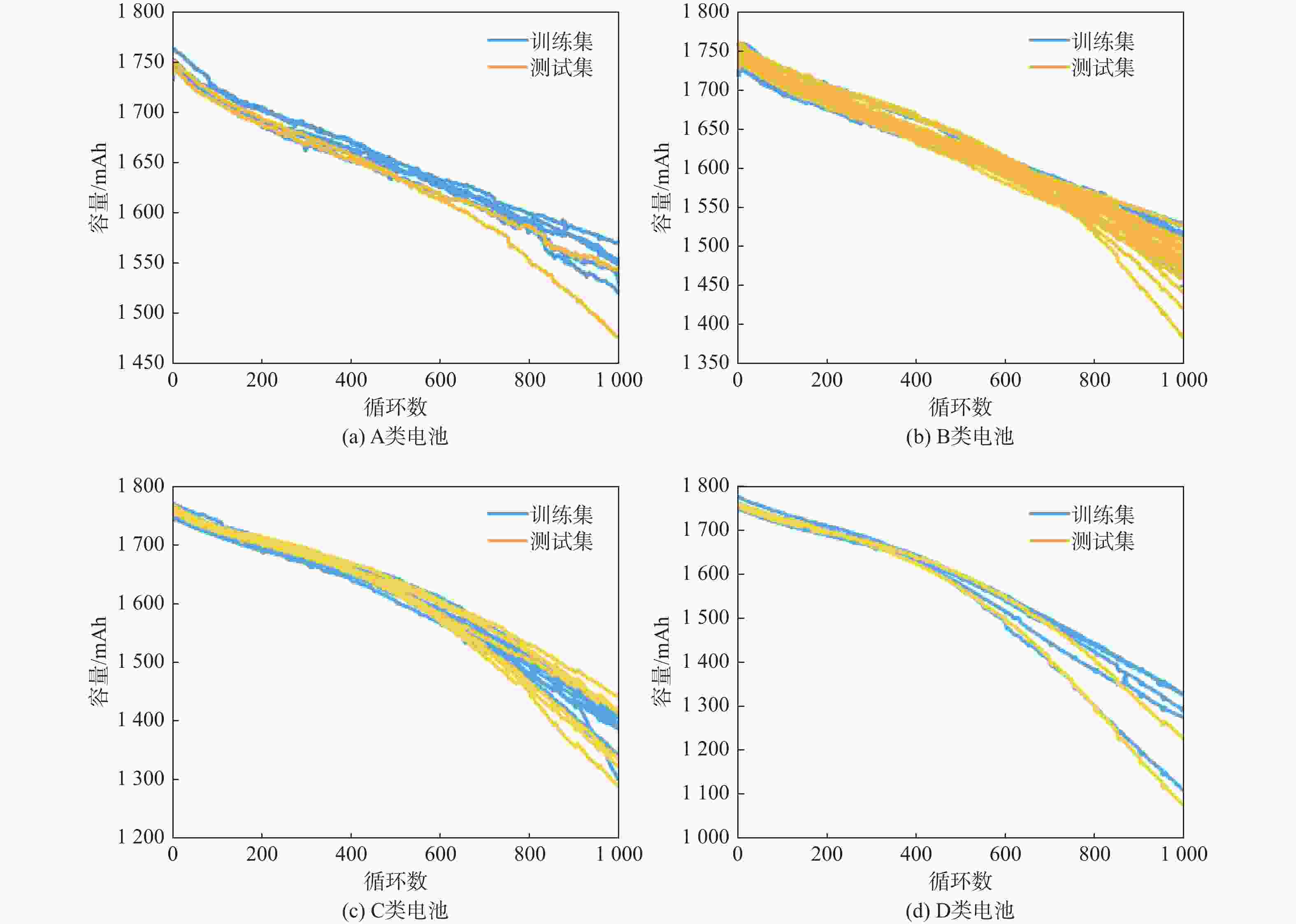

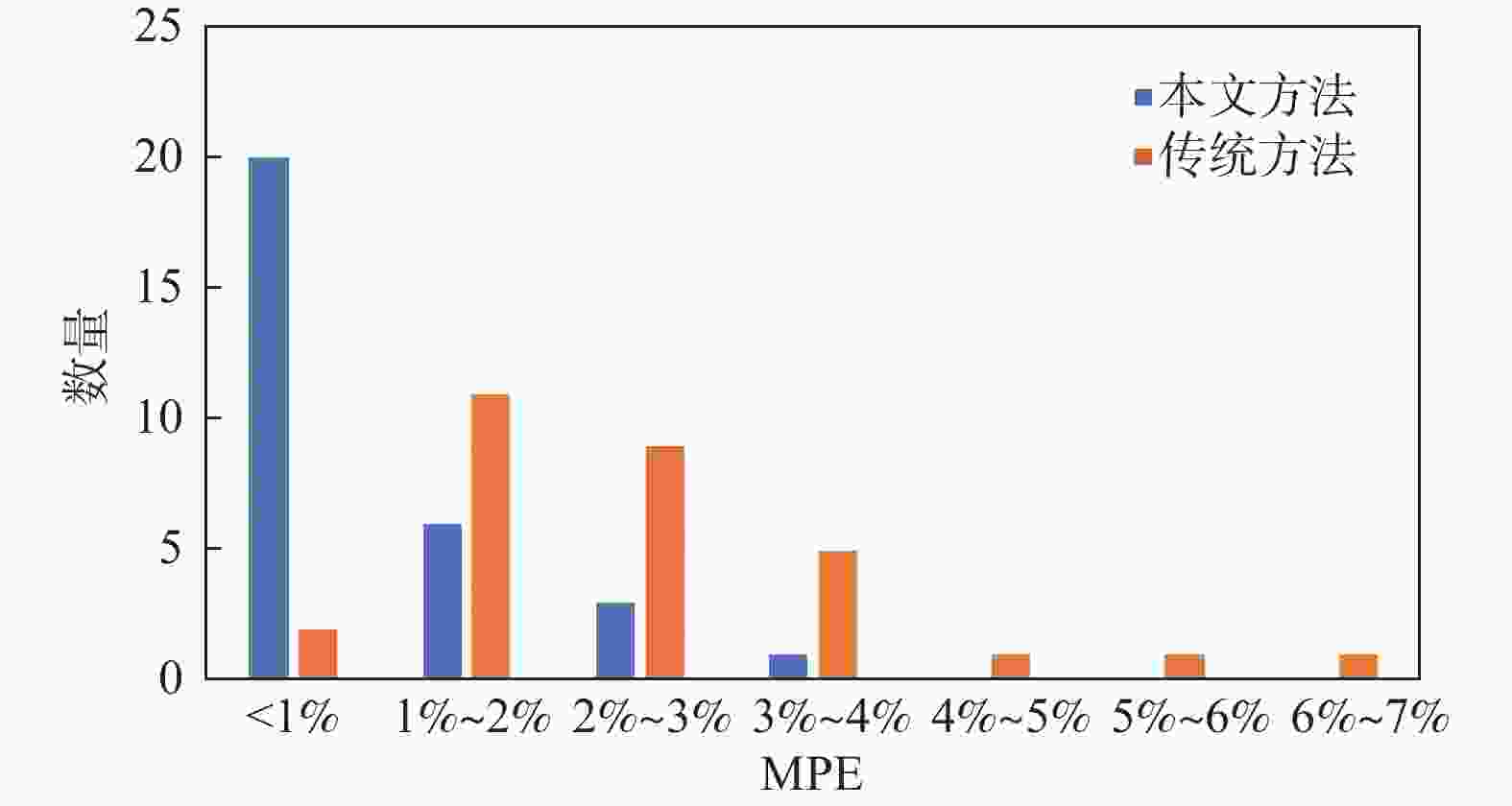

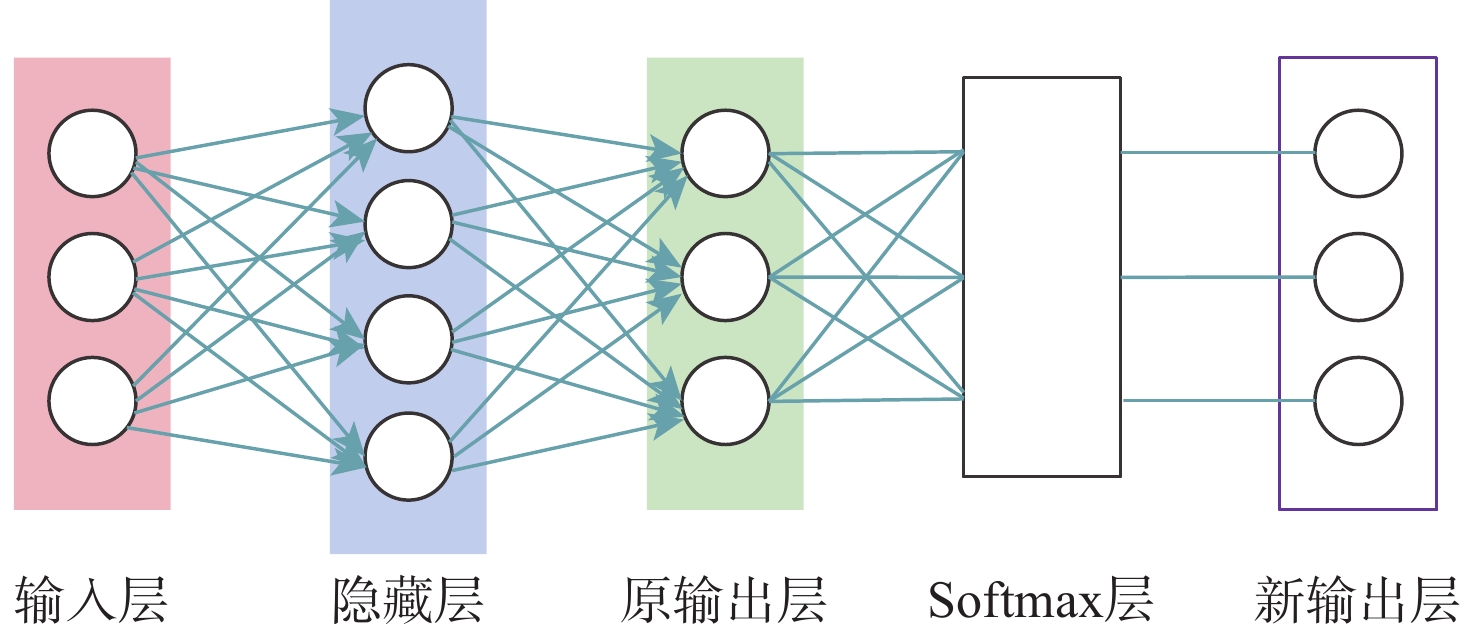

对锂离子电池进行准确的健康状态(SOH)预测是电池应用中的一项关键技术。由于锂离子电池内部复杂的电化学反应体系,多样的失效机理及生产差异,锂离子电池的退化往往呈现出较大的分散性,为锂离子电池SOH的准确预测造成了较大的困难。为此,提出一种基于机器学习的锂离子电池SOH分类与预测方法,基于精度约束,利用双子群优化算法确定训练集数据合适的类别个数及类别范围;基于Softmax分类模型根据锂离子电池早期退化数据进行SOH分类,使得退化趋势较为接近的电池被分为一类;对每一类电池分别利用神经网络构建其SOH预测模型,从而减小锂离子电池数据的大分散性的影响,提升锂离子电池的SOH预测精度。所提方法相比传统方法预测误差降低了34%以上,验证了所提方法的有效性和优越性。

Abstract:Accurate state of health (SOH) prediction for lithium-ion batteries is a key technology in battery applications. However, because of the varied failure modes, complicated electrochemical systems, and production variations, the degradation of lithium-ion batteries frequently exhibits high dispersion, making it challenging to precisely forecast the SOH of the lithium-ion battery. To solve this problem, this paper proposes a machine learning-based method for classifying and predict the SOH of lithium-ion batteries. First, based on the accuracy constraints, the double subgroup optimization algorithm is used to determine the appropriate number of categories and category ranges for the training set data. Then, based on the Softmax classification model, lithium-ion batteries are classified according to the early-cycle data, so that the batteries with a similar degradation trend are divided into one class. To limit the impact of data dispersion and increase forecast accuracy, the SOH prediction model for each kind of battery is built using a backpropagation neural network. Compared with the traditional method, the prediction error of the proposed method is reduced by more than 34%, which verifies the effectiveness and superiority of proposed method.

-

表 1 本文方法与传统方法预测误差对比

Table 1. Comparison of prediction errors between proposed method and traditional method

方法 MPE/% MPEE/% RMSE 本文方法 0.96 2.74 17.45 传统方法 2.33 4.19 41.15 -

[1] DUNN B, KAMATH H, TARASCON J M. Electrical energy storage for the grid: A battery of choices[J]. Science, 2011, 334(6058): 928-935. doi: 10.1126/science.1212741 [2] NYKVIST B, NILSSON M. Rapidly falling costs of battery packs for electric vehicles[J]. Nature Climate Change, 2015, 5(4): 329-332. doi: 10.1038/nclimate2564 [3] RACCUGLIA P, ELBERT K C, ADLER P D F, et al. Machine-learning-assisted materials discovery using failed experiments[J]. Nature, 2016, 533(7601): 73-76. doi: 10.1038/nature17439 [4] GAO L J, LIU S Y, DOUGAL R A. Dynamic lithium-ion battery model for system simulation[J]. IEEE Transactions on Components and Packaging Technologies, 2002, 25(3): 495-505. doi: 10.1109/TCAPT.2002.803653 [5] NISHI Y. Lithium-ion secondary batteries: Past 10 years and the future[J]. Journal of Power Sources, 2001, 100(1-2): 101-106. doi: 10.1016/S0378-7753(01)00887-4 [6] BURNS J C, KASSAM A, SINHA N N, et al. Predicting and extending the lifetime of Li-ion batteries[J]. Journal of the Electrochemical Society, 2013, 160(9): A1451-A1456. doi: 10.1149/2.060309jes [7] BAUMHÖFER T, BRÜHL M, ROTHGANG S, et al. Production caused variation in capacity aging trend and correlation to initial cell performance[J]. Journal of Power Sources, 2014, 247: 332-338. doi: 10.1016/j.jpowsour.2013.08.108 [8] DAI H D, ZHAO G C, LIN M Q, et al. A novel estimation method for the state of health of lithium-ion battery using prior knowledge-based neural network and Markov chain[J]. IEEE Transactions on Industrial Electronics, 2019, 66(10): 7706-7716. doi: 10.1109/TIE.2018.2880703 [9] BARRÉ A, DEGUILHEM B, GROLLEAU S, et al. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications[J]. Journal of Power Sources, 2013, 241: 680-689. doi: 10.1016/j.jpowsour.2013.05.040 [10] LYU C, LAI Q Z, GE T F, et al. A lead-acid battery’s remaining useful life prediction by using electrochemical model in the particle filtering framework[J]. Energy, 2017, 120: 975-984. doi: 10.1016/j.energy.2016.12.004 [11] PASTOR-FERNÁNDEZ C, UDDIN K, CHOUCHELAMANE G H, et al. A comparison between electrochemical impedance spectroscopy and incremental capacity-differential voltage as Li-ion diagnostic techniques to identify and quantify the effects of degradation modes within battery management systems[J]. Journal of Power Sources, 2017, 360: 301-318. doi: 10.1016/j.jpowsour.2017.03.042 [12] DONG G Z, CHEN Z H, WEI J W, et al. Battery health prognosis using Brownian motion modeling and particle filtering[J]. IEEE Transactions on Industrial Electronics, 2018, 65(11): 8646-8655. doi: 10.1109/TIE.2018.2813964 [13] HU C, JAIN G, TAMIRISA P, et al. Method for estimating capacity and predicting remaining useful life of lithium-ion battery[J]. Applied Energy, 2014, 126: 182-189. doi: 10.1016/j.apenergy.2014.03.086 [14] BATZEL T D, SWANSON D C. Prognostic health management of aircraft power generators[J]. IEEE Transactions on Aerospace and Electronic Systems, 2009, 45(2): 473-482. doi: 10.1109/TAES.2009.5089535 [15] SEPASI S, GHORBANI R, LIAW B Y. Inline state of health estimation of lithium-ion batteries using state of charge calculation[J]. Journal of Power Sources, 2015, 299: 246-254. doi: 10.1016/j.jpowsour.2015.08.091 [16] XU F, YANG F F, FEI Z C, et al. Life prediction of lithium-ion batteries based on stacked denoising autoencoders[J]. Reliability Engineering & System Safety, 2021, 208: 107396. [17] WEI J W, DONG G Z, CHEN Z H. Remaining useful life prediction and state of health diagnosis for lithium-ion batteries using particle filter and support vector regression[J]. IEEE Transactions on Industrial Electronics, 2018, 65(7): 5634-5643. doi: 10.1109/TIE.2017.2782224 [18] HU J N, HU J J, LIN H B, et al. State-of-charge estimation for battery management system using optimized support vector machine for regression[J]. Journal of Power Sources, 2014, 269: 682-693. doi: 10.1016/j.jpowsour.2014.07.016 [19] WANG D, MIAO Q, PECHT M. Prognostics of lithium-ion batteries based on relevance vectors and a conditional three-parameter capacity degradation model[J]. Journal of Power Sources, 2013, 239: 253-264. doi: 10.1016/j.jpowsour.2013.03.129 [20] YOU G W, PARK S, OH D. Diagnosis of electric vehicle batteries using recurrent neural networks[J]. IEEE Transactions on Industrial Electronics, 2017, 64(6): 4885-4893. doi: 10.1109/TIE.2017.2674593 [21] ZHANG Y Z, XIONG R, HE H W, et al. Long short-term memory recurrent neural network for remaining useful life prediction of lithium-ion batteries[J]. IEEE Transactions on Vehicular Technology, 2018, 67(7): 5695-5705. doi: 10.1109/TVT.2018.2805189 [22] HU X S, JIANG J C, CAO D P, et al. Battery health prognosis for electric vehicles using sample entropy and sparse Bayesian predictive modeling[J]. IEEE Transactions on Industrial Electronics, 2015, 63(4): 2645-2656. [23] ZHANG Y Z, XIONG R, HE H W, et al. Lithium-ion battery remaining useful life prediction with BOX–COX transformation and Monte Carlo simulation[J]. IEEE Transactions on Industrial Electronics, 2019, 66(2): 1585-1597. doi: 10.1109/TIE.2018.2808918 [24] WAAG W, FLEISCHER C, SAUER D U. Critical review of the methods for monitoring of lithium-ion batteries in electric and hybrid vehicles[J]. Journal of Power Sources, 2014, 258: 321-339. doi: 10.1016/j.jpowsour.2014.02.064 [25] LIU Z B, SUN G Y, BU S H, et al. Particle learning framework for estimating the remaining useful life of lithium-ion batteries[J]. IEEE Transactions on Instrumentation and Measurement, 2017, 66(2): 280-293. doi: 10.1109/TIM.2016.2622838 [26] 李栋. 智慧水务应用架构设计与关键技术研究[D]. 西安: 西北工业大学, 2019: 106-111.LI D. Smart water application architecture design and key technology research[D]. Xi’an: Northwestern Polytechnical University, 2019: 106-11(in Chinese). [27] MORRIS G M, GOODSELL D S, HALLIDAY R S, et al. Automated docking using a Lamarckian genetic algorithm and an empirical binding free energy function[J]. Journal of Computational Chemistry, 1998, 19(14): 1639-1662. doi: 10.1002/(SICI)1096-987X(19981115)19:14<1639::AID-JCC10>3.0.CO;2-B [28] PAN W T. A new fruit fly optimization algorithm: Taking the financial distress model as an example[J]. Knowledge-Based Systems, 2012, 26: 69-74. doi: 10.1016/j.knosys.2011.07.001 [29] RAO R V, SAVSANI V J, VAKHARIA D P. Teaching-learning-based optimization: A novel method for constrained mechanical design optimization problems[J]. Computer-Aided Design, 2011, 43(3): 303-315. doi: 10.1016/j.cad.2010.12.015 -

下载:

下载: