Optimization method of thermo-elastic lattice structure based on surrogate models of microstructures

-

摘要:

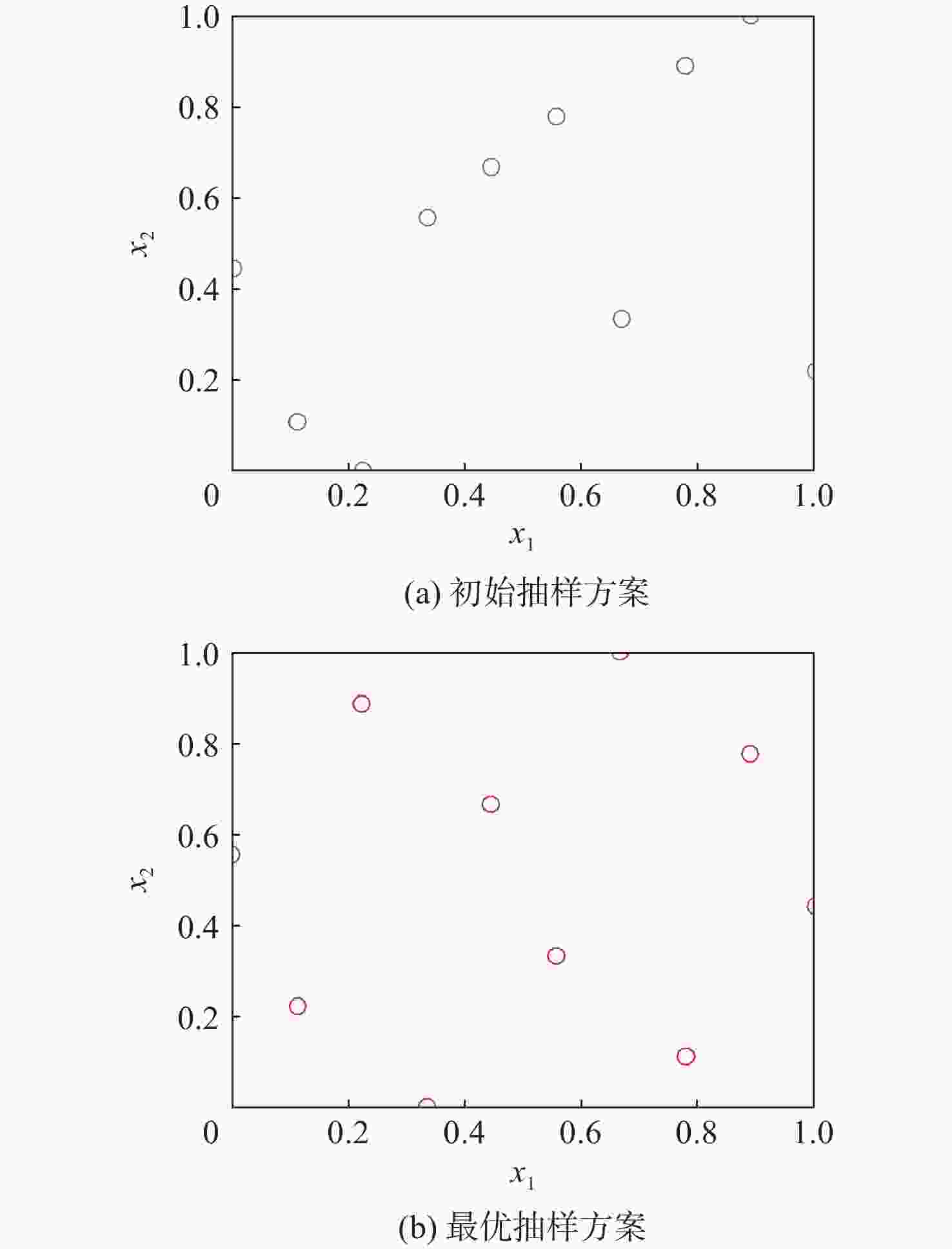

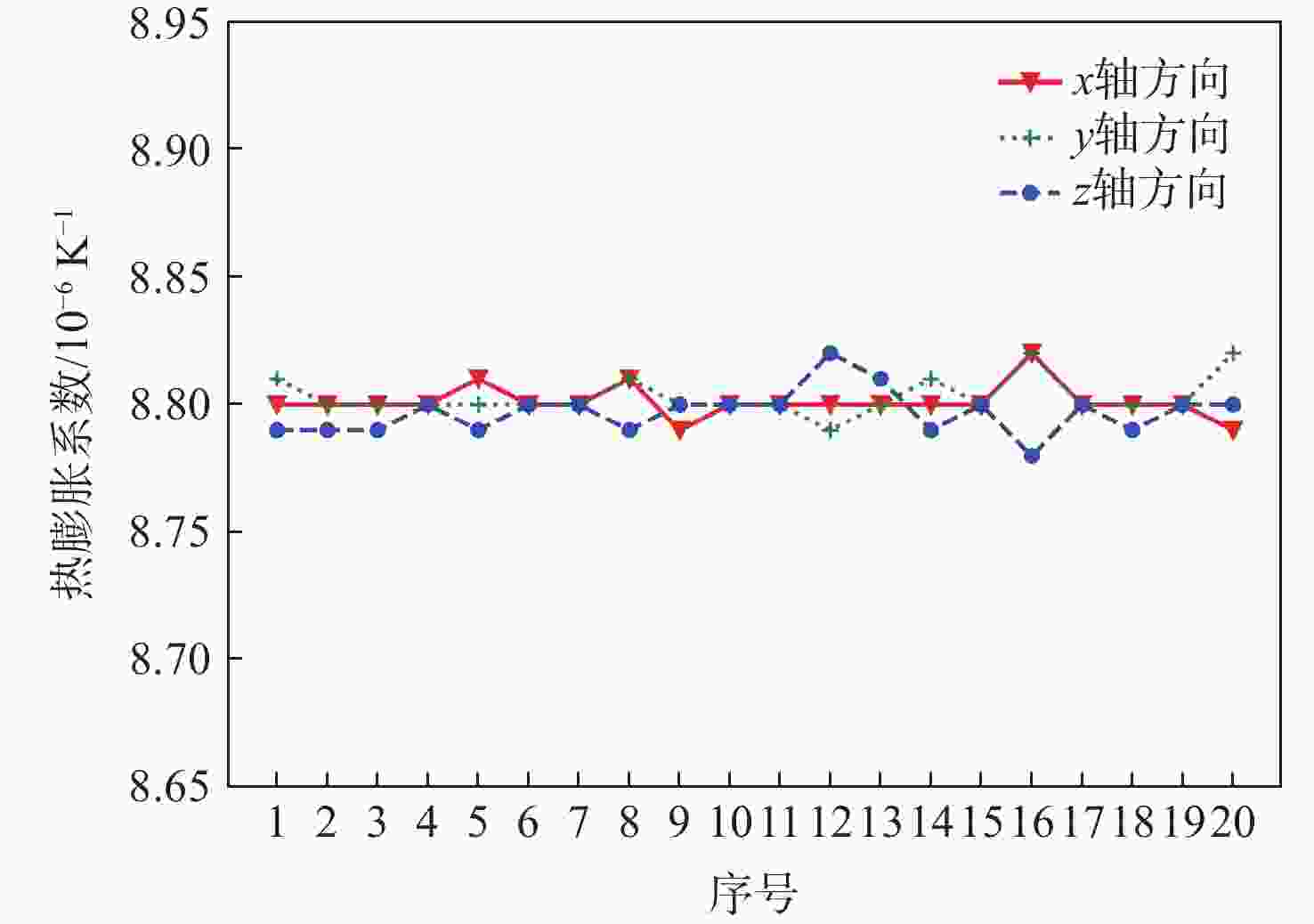

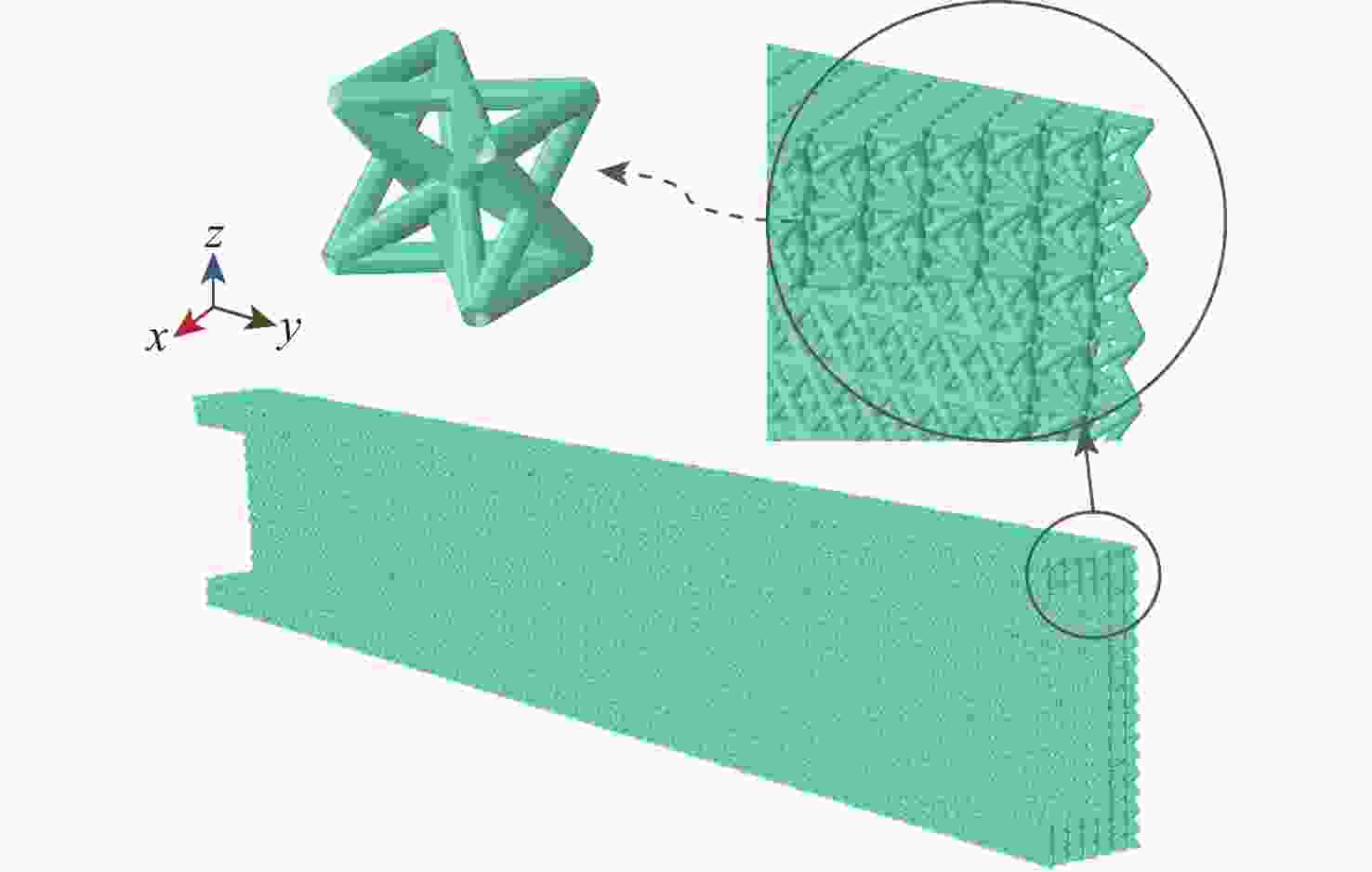

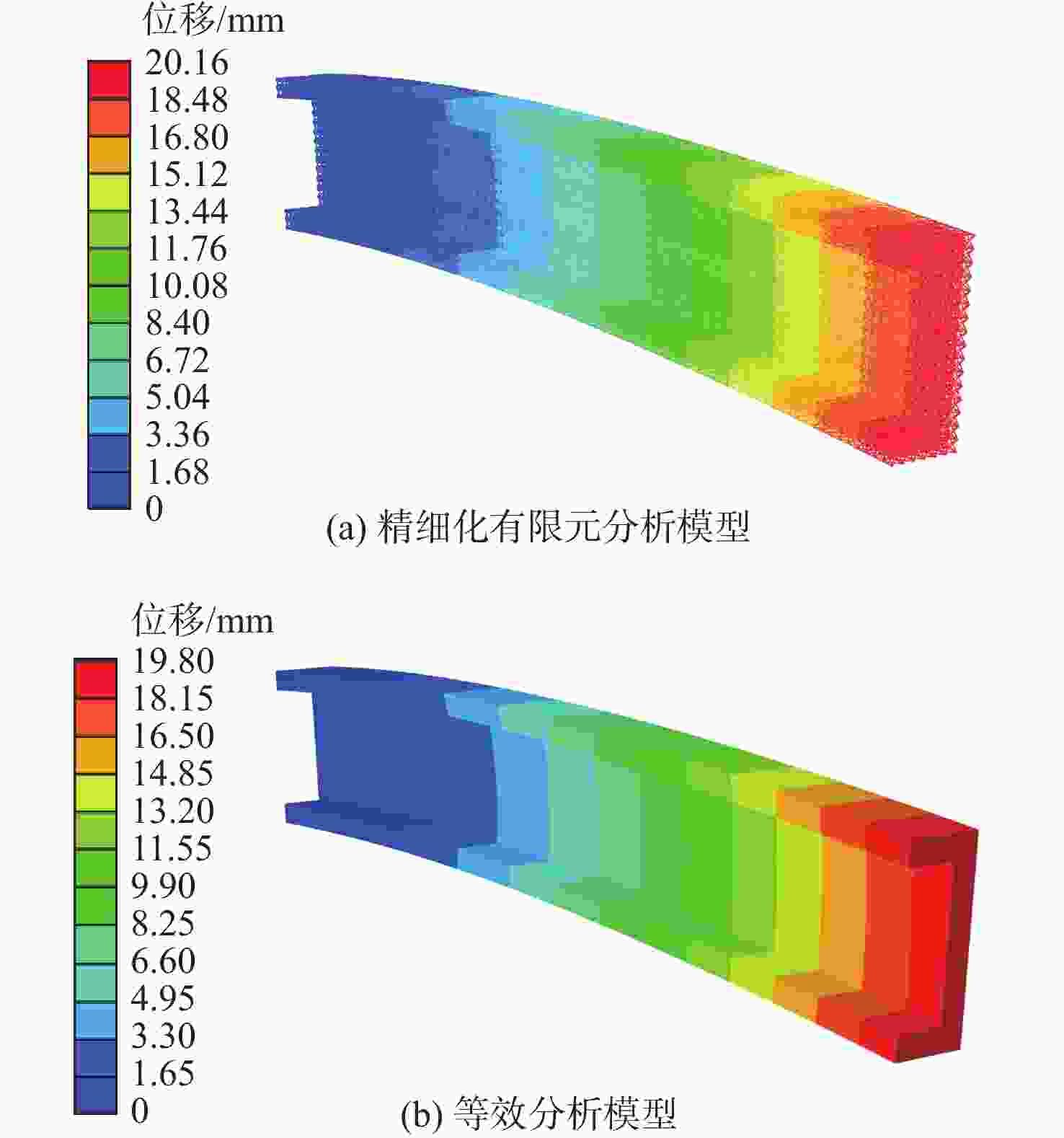

三维点阵材料是一种具有多尺度特性的新型轻质多功能材料,其有千变万化的微结构和高孔隙率,通过设计其细观尺度特征可以获得优良的宏观性能。为了发挥材料与结构的最大设计潜力,提出一种热弹性点阵结构优化方法。在材料细观研究尺度上,实现了三维点阵材料等效热弹性性能预测,利用周期性边界条件下的代表体元法进行数值求解,利用径向基函数代理模型构建细观结构和宏观材料性能的数学关系,并进行了预测误差验证,证明了所提方法具有良好的精确度。在结构宏观研究尺度上,建立了以等效材料填充的结构优化模型,考虑了热力载荷作用,以单胞等效性能代理模型作为材料插值模型,提出最小应变能热弹性点阵结构优化数学模型。在典型三维算例中得到了细观结构变密度分布的优化结果,结构热刚度在一定体积约束下显著提高,证明了所提方法的有效性。

Abstract:Lattice material is a new type of lightweight and multifunctional material, which has a variety of microstructures and high porosity. Excellent macroscopic properties can be obtained by designing its mesoscale features. To maximize the design potential of materials and structures, an optimization method for the thermo-elastic lattice structure is proposed. As for mesoscale material research, the effective thermo-elastic properties prediction of three-dimensional lattice materials is implemented. Relevant coefficients are solved using the idea of the representative volume method under periodic boundary conditions. Surrogate models are constructed to build the relationship between macroscopic responses and microstructures, and are proved to have good accuracy through error verification tests. As for macroscale material research, a structural optimization model filled with equivalent materials is established. Considering the thermal and mechanical loads, a mathematical model for structural optimization of thermo-elastic lattice structure with minimum strain energy is proposed using the surrogate models of effective properties as the material interpolation schemes. The result of an optimal spatially varying metamaterial is obtained in a typical three-dimensional structure example, and the thermal stiffness of the structure is improved under a certain volume constraint, demonstrating the effectiveness of the optimization method.

-

表 1 TC4材料基本属性

Table 1. Properties of TC4 material

密度$\rho $ /

(kg·mm−3)泊松比$\mu $ 弹性模量E/

MPa热膨胀系数$\alpha $/

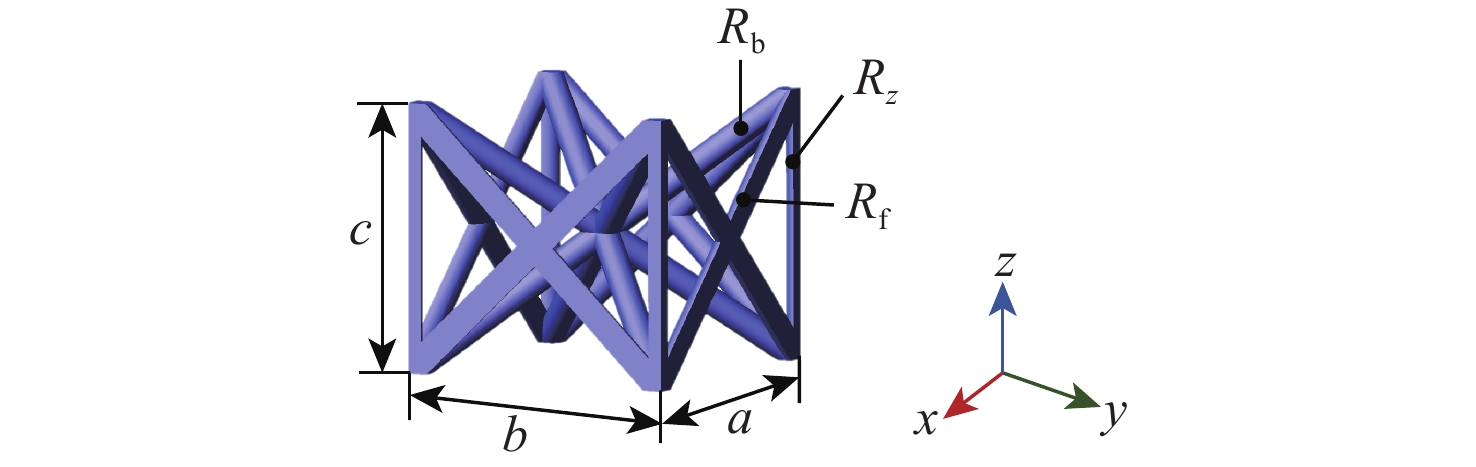

(10−6·K−1)4.43×10−6 0.30 115000 8.8 表 2 单胞等效热弹性系数计算方法

Table 2. Calculation method of effective thermal-elastic properties of lattice cells

宏观

应力载荷

施加等效热弹性性能 $\sigma _x^0$ ${F_x}( B)$ ${E_x} = \dfrac{ {\sigma _x^0} }{ {\varepsilon _x^0} } = \dfrac{ { {F_x}{a^2} } }{ { {V_{\text{c} } }{u_B} } },\;{\mu _{xy} } = - \dfrac{ {\varepsilon _y^0} }{ {\varepsilon _x^0} } = - \dfrac{ { { { {v_D} } / b} } }{ { { { {u_B} } /a} } },\;{\mu _{x{\textit{z} } } } = - \dfrac{ {\varepsilon _{\textit{z} }^0} }{ {\varepsilon _x^0} } = - \dfrac{ { { { {w_E} }/ c} } }{ { { { {u_B} } / a} } }$ $\sigma _y^0$ ${F_y}( D )$ ${E_y} = \dfrac{ {\sigma _y^0} }{ {\varepsilon _y^0} } = \dfrac{ { {F_y}{b^2} } }{ { {V_{\text{c} } }{v_D} } },\;{\mu _{yx} } = {\mu _{xy} },\;{\mu _{y{\textit{z} } } } = - \dfrac{ {\varepsilon _{\textit{z} }^0} }{ {\varepsilon _y^0} } = - \dfrac{ { { { {w_E} } /c} } }{ { { { {v_D} } / b} } }$ $\sigma _{\textit{z}}^0$ ${F_{\textit{z} } }( E )$ ${E_{\textit{z} } } = \dfrac{ {\sigma _{\textit{z} }^0} }{ {\varepsilon _{\textit{z} }^0} } = \dfrac{ { {F_{\textit{z} } }{c^2} } }{ { {V_{\text{c} } }{w_E} } },\;{\mu _{ {\textit{z} }x} } = {\mu _{x{\textit{z} } } },\;{\mu _{ {\textit{z} }y} } = {\mu _{y{\textit{z} } } }$ $\tau _{xy}^0$ ${F_y}( B )$ ${G_{xy}} = \dfrac{{\tau _{xy}^0}}{{\gamma _{xy}^0}} = \dfrac{{{F_y}{a^2}}}{{{V_{\text{c}}}{v_B}}}$ $\tau _{y{\textit{z}}}^0$ ${F_{\textit{z} } }( D )$ ${G_{y{\textit{z}}}} = \dfrac{{\tau _{y{\textit{z}}}^0}}{{\gamma _{y{\textit{z}}}^0}} = \dfrac{{{F_{\textit{z}}}{b^2}}}{{{V_{\text{c}}}{w_D}}}$ $\tau _{{\textit{z}}x}^0$ ${F_x}( E )$ ${G_{{\textit{z}}x}} = \dfrac{{\tau _{{\textit{z}}x}^0}}{{\gamma _{{\textit{z}}x}^0}} = \dfrac{{{F_x}{c^2}}}{{{V_{\text{c}}}{u_E}}}$ $\sigma _{{\text{th}}}^0$ $\Delta T$ ${\alpha _x} = \dfrac{ {\varepsilon _x^0} }{ {\Delta T} } = \dfrac{ { {u_B} } }{ {a\Delta T} },\;{\alpha _y} = \dfrac{ {\varepsilon _y^0} }{ {\Delta T} } = \dfrac{ { {v_D} } }{ {b\Delta T} },\;{\alpha _{\textit{z} } } = \dfrac{ {\varepsilon _{\textit{z} }^0} }{ {\Delta T} } = \dfrac{ { {w_E} } }{ {c\Delta T} }$ 表 3 单胞等效性能代理模型测试误差

Table 3. Test error of surrogate model of effective properties for lattice cells

输出变量 相对误差${\varepsilon '_{{\text{RMSE}}}}$/% ${E_1}{\text{, }}{E_2}$ 0.86 ${E_3}{\text{ }}$ 1.84 ${\mu _{12}}{\text{ }}$ 3.88 ${\mu _{13}}{\text{, }}{\mu _{23}}$ 3.29 ${G_{13}}{\text{, }}{G_{23}}$ 0.85 ${G_{12}}{\text{ }}$ 1.40 ${V_{\text{f}}}$ 0.23 表 4 算例参数设置

Table 4. Parameter settings in the example

上翼缘温升/

K下翼缘温升/

K机械载荷/

MPa初始半径/

mm体积分数

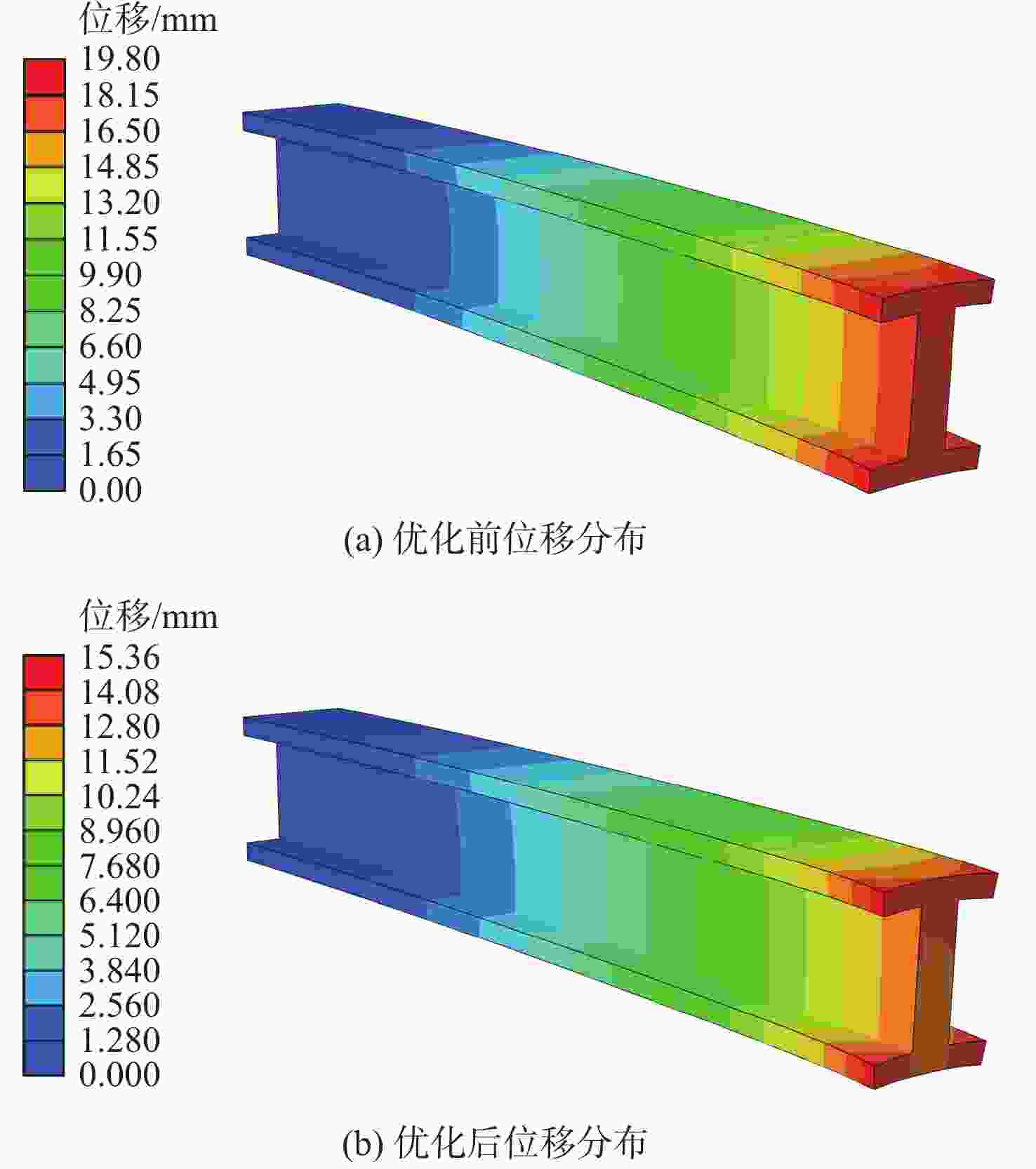

约束/%$350$ ${\text{10}}$ $0.5$ $1.8$ $26.3$ 表 5 点阵填充工字悬臂梁优化前后对比分析

Table 5. Comparative analysis before and after structural optimization of lattice filled I-shaped cantilever beam

优化时间 ${S_{\max }}{\text{/MPa}}$ ${U_{\max }}{\text{/mm}}$ ${S_{{\text{web}}}}{\text{/MPa}}$ ${U_{{\text{web}}}}{\text{/mm}}$ 优化前 $19.34$ $19.8$ $1.92$ $5.8$ 优化后 $15.75$ $15.4$ $1.55$ $3.9$ -

[1] 杨亚政, 杨嘉陵, 曾涛, 等. 轻质多孔材料研究进展[J]. 力学季刊, 2007, 28(4): 503-516. doi: 10.3969/j.issn.0254-0053.2007.04.001YANG Y Z, YANG J L, ZENG T, et al. Progress in research work of light materials[J]. Chinese Quarterly of Mechanics, 2007, 28(4): 503-516(in Chinese). doi: 10.3969/j.issn.0254-0053.2007.04.001 [2] WANG X W, WEI K, WANG K Y, et al. Effective thermal conductivity and heat transfer characteristics for a series of lightweight lattice core sandwich panels[J]. Applied Thermal Engineering, 2020, 173: 115205. doi: 10.1016/j.applthermaleng.2020.115205 [3] LU T J, VALDEVIT L, EVANS A G. Active cooling by metallic sandwich structures with periodic cores[J]. Progress in Materials Science, 2005, 50(7): 789-815. doi: 10.1016/j.pmatsci.2005.03.001 [4] RODRIGUES H, FERNANDES P. A material based model for topology optimization of thermoelastic structures[J]. International Journal for Numerical Methods in Engineering, 1995, 38(12): 1951-1965. doi: 10.1002/nme.1620381202 [5] GAO T, ZHANG W H. Topology optimization involving thermo-elastic stress loads[J]. Structural and Multidisciplinary Optimization, 2010, 42(5): 725-738. doi: 10.1007/s00158-010-0527-5 [6] PEDERSEN P, PEDERSEN N L. Strength optimized designs of thermoelastic structures[J]. Structural and Multidisciplinary Optimization, 2010, 42(5): 681-691. doi: 10.1007/s00158-010-0535-5 [7] WU J, SIGMUND O, GROEN J P. Topology optimization of multi-scale structures: A review[J]. Structural and Multidisciplinary Optimization, 2021, 63(3): 1455-1480. doi: 10.1007/s00158-021-02881-8 [8] NOOR A K. Continuum modeling for repetitive lattice structures[J]. Applied Mechanics Reviews, 1988, 41(7): 285-296. doi: 10.1115/1.3151907 [9] BABUŠKA I, GLOWINSKI R, LIONS J L. Homogenization approach in engineering[C]//Computing Methods in Applied Sciences and Engineering. Berlin: Springer, 1976: 137-153. [10] TANG S F, HUANG F H, LIANG J, et al. Multi-scale analysis for thermo-elasticity properties of composite materials with small periodic configuration[J]. Key Engineering Materials, 2007, 334-335: 25-28. doi: 10.4028/www.scientific.net/KEM.334-335.25 [11] CHENG G D, CAI Y W, XU L. Novel implementation of homogenization method to predict effective properties of periodic materials[J]. Acta Mechanica Sinica, 2013, 29(4): 550-556. doi: 10.1007/s10409-013-0043-0 [12] 李鑫. 基于渐近均匀化方法的创新数值实现方法的点阵夹层结构热弹性分析[D]. 大连: 大连理工大学, 2019.LI X. Thermoelastic analysis of lattice sandwich structures based on novel implementation of asymptotic homogenization method[D]. Dalian: Dalian University of Technology, 2019 (in Chinese). [13] SUN C T, VAIDYA R S. Prediction of composite properties from a representative volume element[J]. Composites Science and Technology, 1996, 56(2): 171-179. doi: 10.1016/0266-3538(95)00141-7 [14] 张超, 许希武, 严雪. 纺织复合材料细观力学分析的一般性周期性边界条件及其有限元实现[J]. 航空学报, 2013, 34(7): 1636-1645.ZHANG C, XU X W, YAN X. General periodic boundary conditions and their application to micromechanical finite element analysis of textile composites[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(7): 1636-1645(in Chinese). [15] WANG L, CAI Y R, LIU D L. Multiscale reliability-based topology optimization methodology for truss-like microstructures with unknown-but-bounded uncertainties[J]. Computer Methods in Applied Mechanics and Engineering, 2018, 339: 358-388. doi: 10.1016/j.cma.2018.05.003 [16] 阎军, 程耿东, 刘书田, 等. 周期性点阵类桁架材料等效弹性性能预测及尺度效应[J]. 固体力学学报, 2005, 26(4): 421-428. doi: 10.3969/j.issn.0254-7805.2005.04.007YAN J, CHENG G D, LIU S T, et al. Prediction of equivalent elastic properties of truss materials with periodic microstructure and the scale effects[J]. Acta Mechanica Solida Sinica, 2005, 26(4): 421-428(in Chinese). doi: 10.3969/j.issn.0254-7805.2005.04.007 [17] XIA Z H, ZHANG Y F, ELLYIN F. A unified periodical boundary conditions for representative volume elements of composites and applications[J]. International Journal of Solids and Structures, 2003, 40(8): 1907-1921. doi: 10.1016/S0020-7683(03)00024-6 [18] 杨素霞. 热弹性点阵结构多尺度并发优化设计[D]. 大连: 大连理工大学, 2014.YANG S X. Multi-scale concurrent optimization design of thermoelastic lattice structures[D]. Dalian: Dalian University of Technology, 2014 (in Chinese). [19] XU B, HUANG X, ZHOU S W, et al. Concurrent topological design of composite thermoelastic macrostructure and microstructure with multi-phase material for maximum stiffness[J]. Composite Structures, 2016, 150: 84-102. doi: 10.1016/j.compstruct.2016.04.038 [20] WATTS S, ARRIGHI W, KUDO J, et al. Simple, accurate surrogate models of the elastic response of three-dimensional open truss micro-architectures with applications to multiscale topology design[J]. Structural and Multidisciplinary Optimization, 2019, 60(5): 1887-1920. doi: 10.1007/s00158-019-02297-5 [21] WANG C, ZHU J H, ZHANG W H, et al. Concurrent topology optimization design of structures and non-uniform parameterized lattice microstructures[J]. Structural and Multidisciplinary Optimization, 2018, 58(1): 35-50. doi: 10.1007/s00158-018-2009-0 [22] WANG C, GU X J, ZHU J H, et al. Concurrent design of hierarchical structures with three-dimensional parameterized lattice microstructures for additive manufacturing[J]. Structural and Multidisciplinary Optimization, 2020, 61(3): 869-894. doi: 10.1007/s00158-019-02408-2 [23] WHITE D A, ARRIGHI W J, KUDO J, et al. Multiscale topology optimization using neural network surrogate models[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 346: 1118-1135. doi: 10.1016/j.cma.2018.09.007 [24] LI S G, WONGSTO A. Unit cells for micromechanical analyses of particle-reinforced composites[J]. Mechanics of Materials, 2004, 36(7): 543-572. doi: 10.1016/S0167-6636(03)00062-0 [25] LIEM R P, MADER C A, MARTINS J R R A. Surrogate models and mixtures of experts in aerodynamic performance prediction for aircraft mission analysis[J]. Aerospace Science and Technology, 2015, 43: 126-151. doi: 10.1016/j.ast.2015.02.019 -

下载:

下载: