Dynamic model by transfer function and parameter determination method of plate fin heat exchanger

-

摘要:

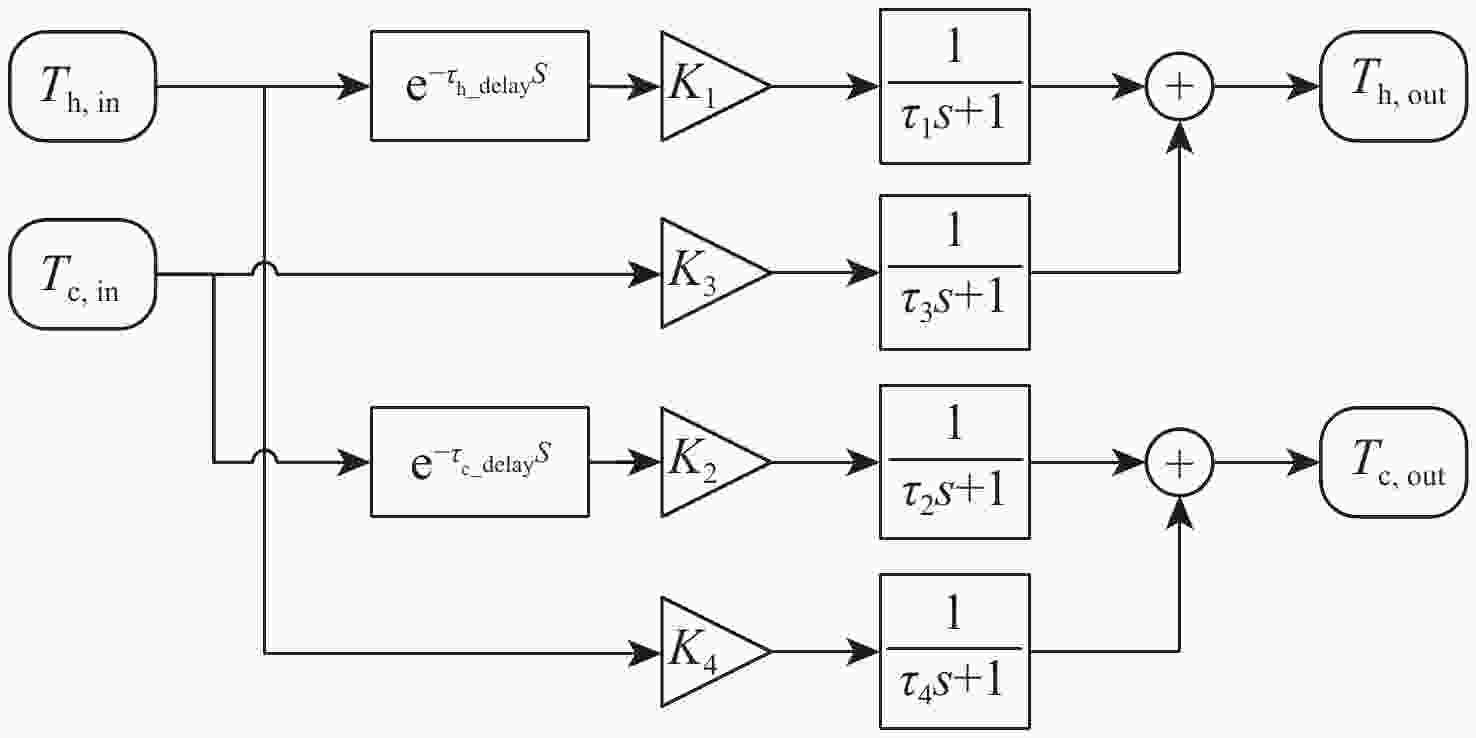

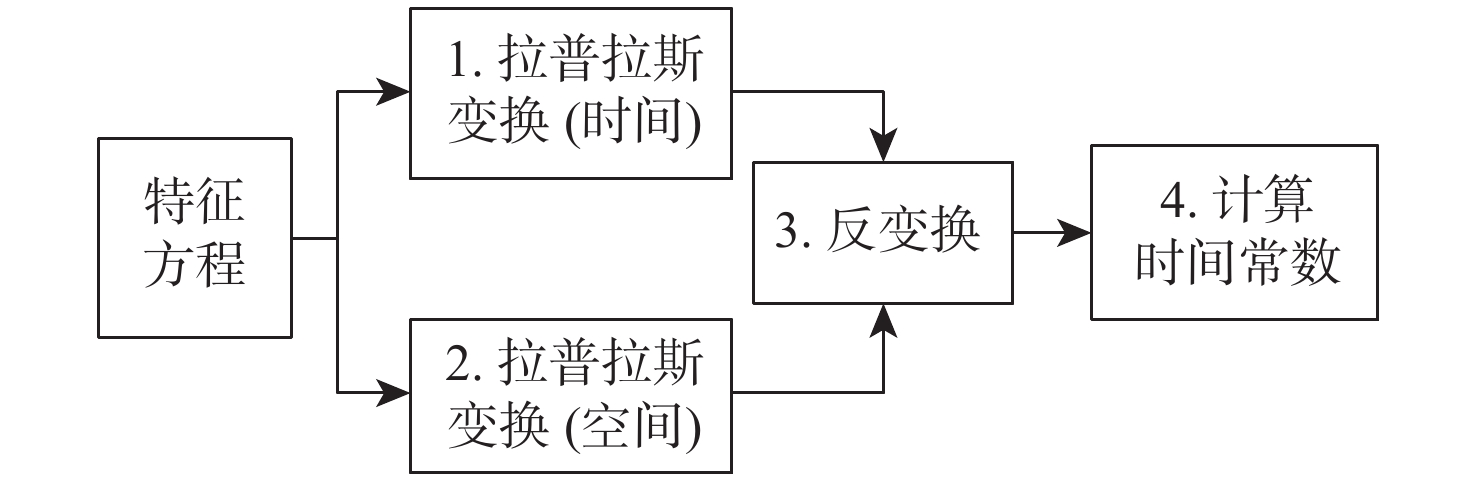

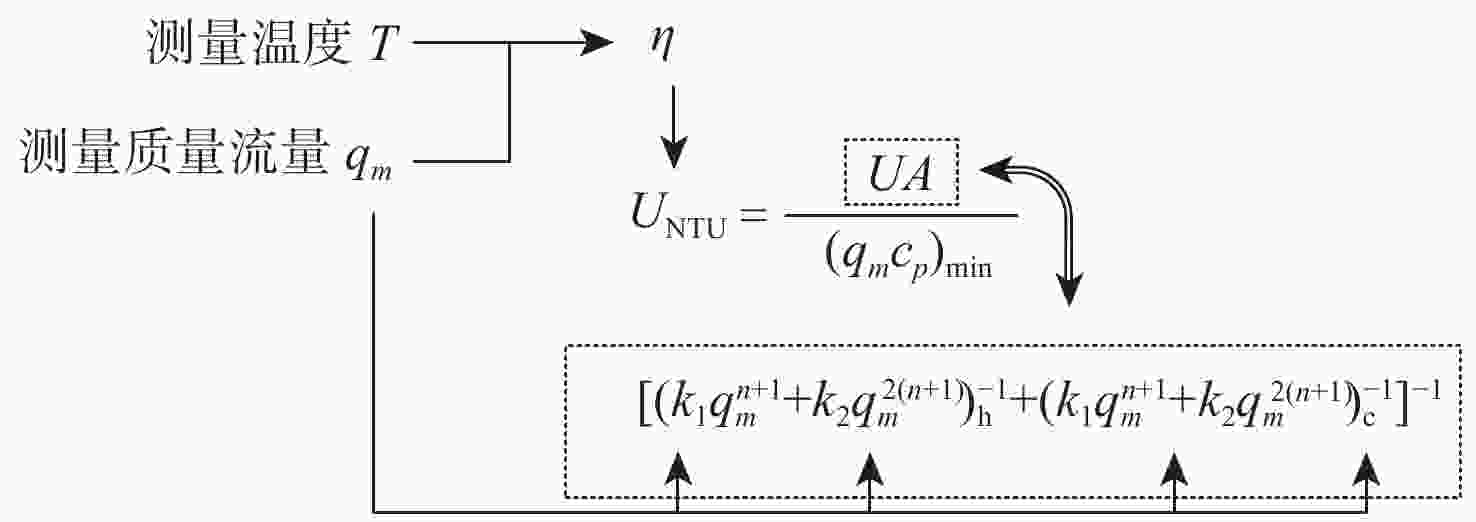

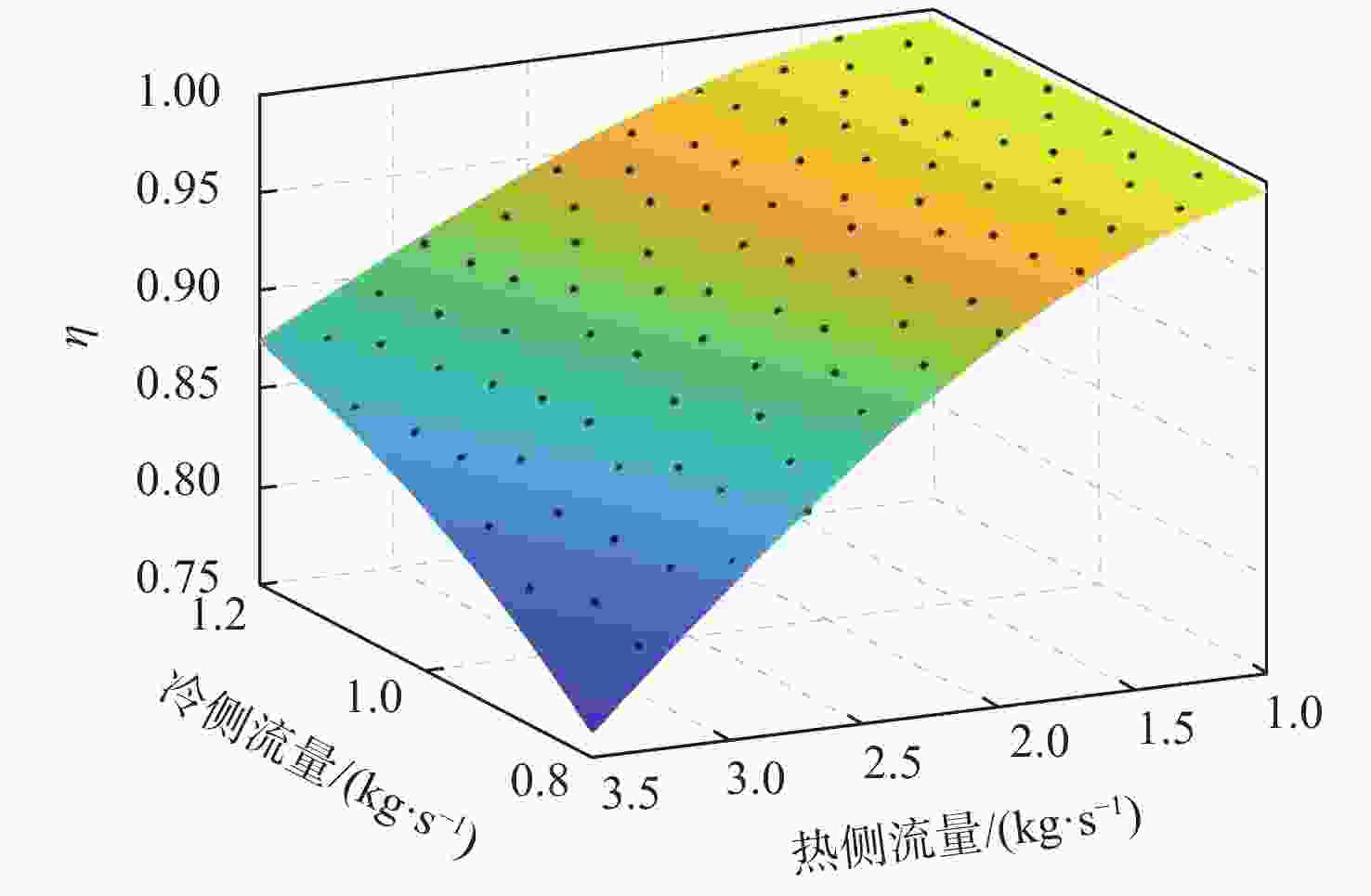

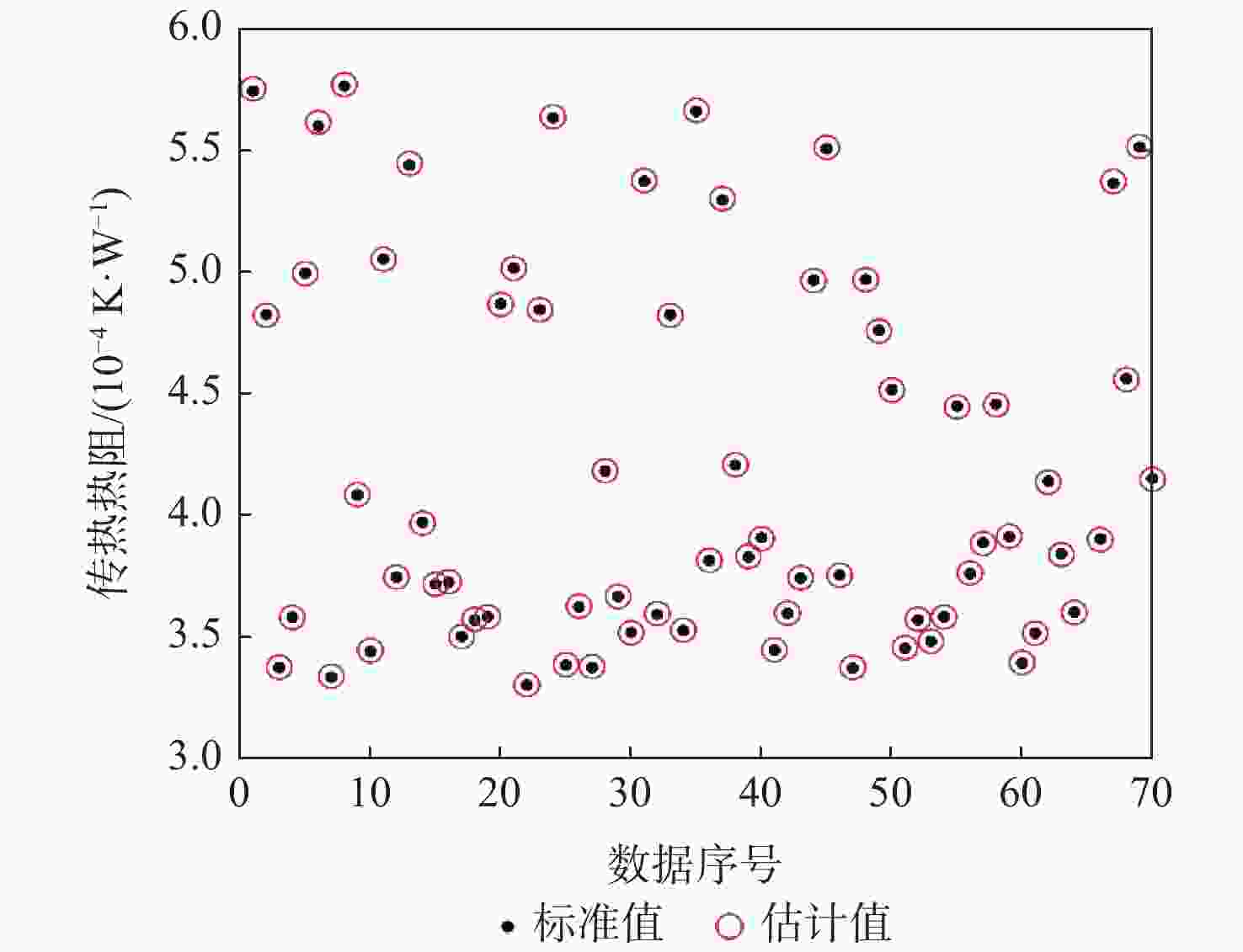

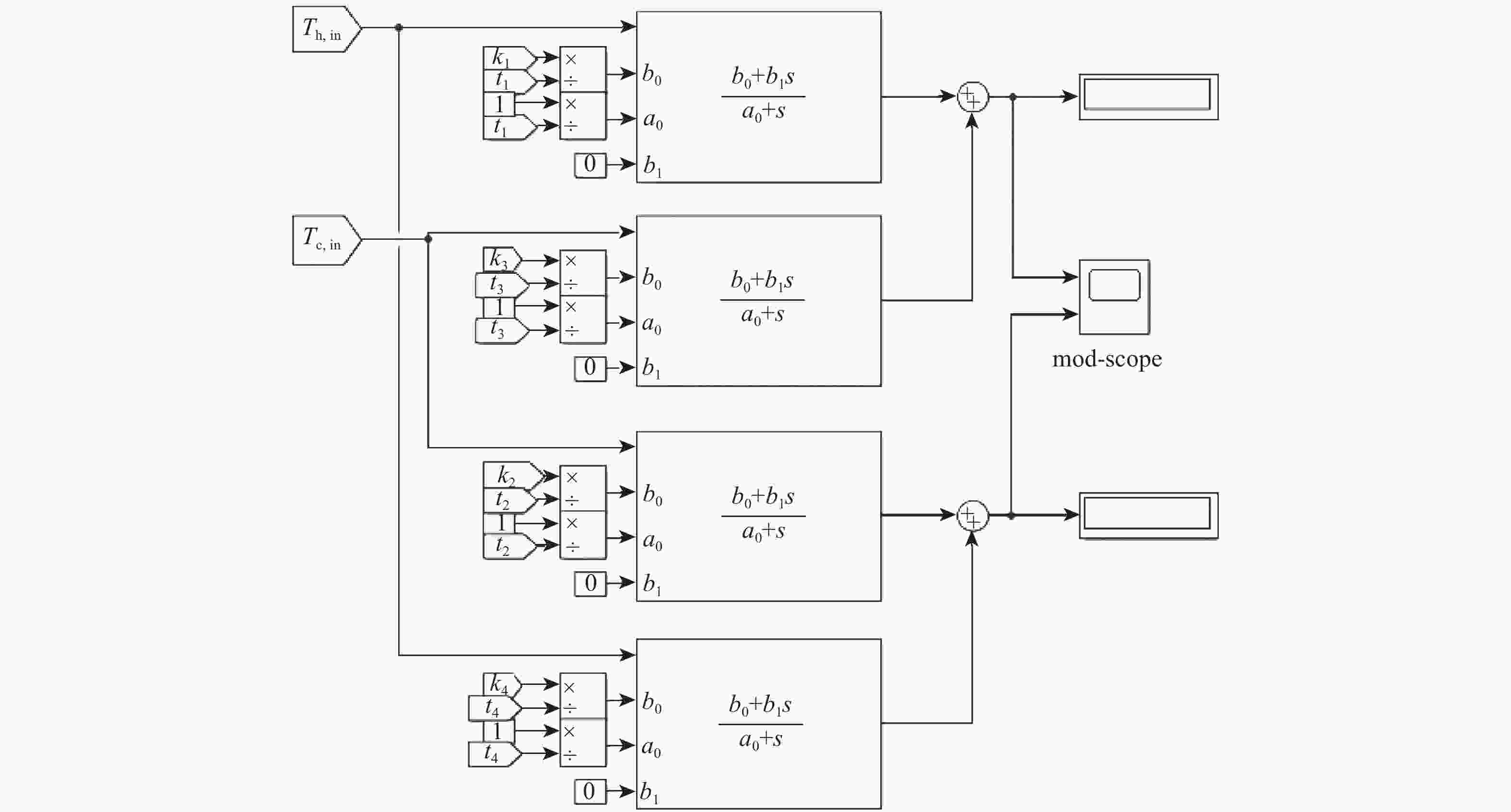

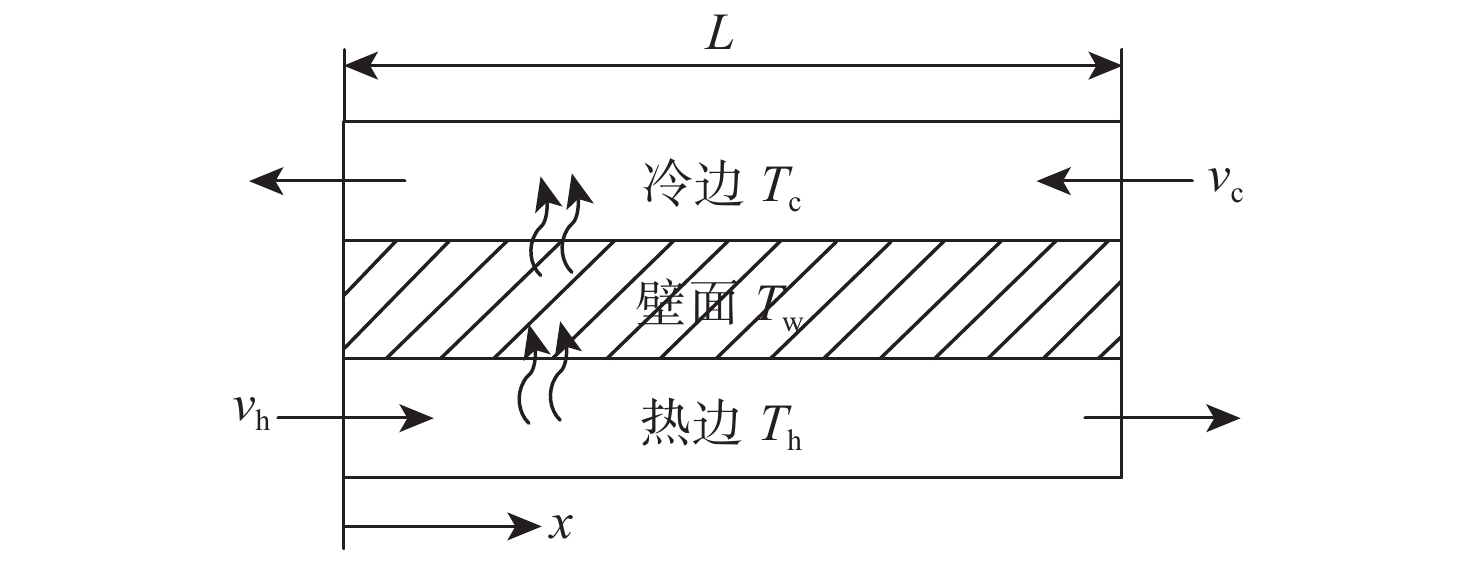

飞机综合环控/热管理系统迫切需要建立快捷高效的换热器动态仿真模型,以满足先进控制系统设计需求。基于此,针对板翅式换热器动态模型,提出一种包含2个延迟环节和4个一阶惯性环节的传递函数矩阵形式,并从换热器机理模型出发,利用拉普拉斯变换推导模型中4个时间常数的计算公式,提出基于换热器效率的传热热阻计算关系式的辨识方法,解决了主要模型参数设置难题。以板翅式换热器为研究对象,在Simulink仿真平台搭建其传递函数动态模型,并与AMESim仿真平台搭建的机理模型进行对比分析,结果显示:2种模型所得空气和冷却水出口温度分别随入口温度和质量流量阶跃变化的动态响应曲线吻合很好,其中,4种工况空气和冷却水出口温度最大稳态偏差分别为0.034 ℃和0.029 ℃,当冷却水入口质量流量阶跃变化时,空气出口温度动态响应相对偏差最大,为9.27%,当空气入口质量流量阶跃变化时,冷却水出口温度动态响应相对偏差最大,为7.03%。

Abstract:A fast and efficient dynamic simulation model of heat exchangers is urgently needed to meet the requirements of the advanced control system design for the integrated environmental control and thermal management system of aircraft. In this paper, a dynamic model by transfer function matrix, composed of two delay links and four first-order inertia links, is proposed for plate-fin heat exchangers. The identification method for the calculation formulas of thermal resistance based on the efficiency of the heat exchanger is given, which solves the issue of setting two key parameters in the model. The calculation formulas of four-time constants in the simplified model are derived according to the mechanism of the heat exchanger by using the Laplace transform. Taking an air-liquid plate-fin heat exchanger as the research object, the new dynamic simulation model is built in Simulink software, and compared with the mechanism model built in AMESim software. The results show that both models have similar dynamic responses of the outlet temperature at both flow sides with step change of inlet temperature or flow rate. Under four working conditions, the highest steady-state variations of the air and cooling water outlet temperatures are 0.034 ℃ and 0.029 ℃, respectively. The maximum dynamic relative deviation of airflow outlet temperature is 9.27% with a step change of the cooling water flow rate. The maximum dynamic relative deviation of cooling water flow outlet temperature is 7.03% with a step change of the airflow rate.

-

Key words:

- heat exchanger /

- dynamic model /

- transfer function matrix /

- time constant /

- thermal resistance

-

表 1 换热器基本结构参数

Table 1. Basic parameters of heat exchanger

冷/热边 翅片间距/mm 翅片高度/mm 翅片厚度/mm 层数 隔板厚度/mm 面板厚度/mm 封条宽度/mm 热边 1.3 2.5 0.15 10 0.6 2 6 冷边 1.3 2.5 0.15 11 0.6 2 6 表 2 AMESim换热器仿真模块参数设置

Table 2. Parameter settings of heat exchanger module in AMESim software

模块 参数 数值 热侧流体流动

传热模块流动系数 0.6 自由流动横截面积/mm2 6 000 换热特征长度/mm 1.5 对流换热面积/m2 9.3046×1/5 翅片面积与总面积之比 0.975 0 翅片效率 0.962 8 换热器体积容积/ L 3.7×1/5 对流传热计算方式 Colburn j因子 j因子表达式j=f(Re) 0.1447Re−0.368 芯体模块 初始温度/℃ 20 流动形式 逆流 芯体质量/kg 9.3069×1/5 冷侧流体流动

传热模块流速计算 等效为孔板 自由流横截面积/mm2 6600 自由流动管径/mm 1.5 最大流动系数 0.99 临界雷诺数 $1000 \sqrt{2} $ 换热器特征长度/mm 1.5 对流换热面积/m2 10.2351×1/5 换热器内部容积/L 4.1×1/5 对流传热计算方式 Colburn j因子 j因子表达式j= f(Re) 0.4722Re−0.536 表 3 仿真工况参数

Table 3. Simulation condition parameters

工况 质量流量/(kg·s−1) 入口温度/℃ 空气侧 冷却水侧 空气侧 冷却水侧 平衡 1.5 0.8 70 10 工况1 阶跃至1.65 0.8 70 10 工况2 1.5 阶跃至0.88 70 10 工况3 1.5 0.8 阶跃至77 10 工况4 1.5 0.8 70 阶跃至14 表 4 2种仿真模型所得出口温度对比

Table 4. Comparison of outlet temperature obtained by two simulation models

工况 标准模型阶跃变化/℃ 稳态偏差/℃ 动态最大偏差/% 动态相对偏差/% 空气出口 冷却水出口 空气出口 冷却水出口 空气出口 冷却水出口 空气出口 冷却水出口 工况1 0.561 2.360 0.023 0.027 0.049 0.270 4.91 7.03 工况2 0.269 2.288 0.034 0.026 0.034 0.101 9.27 2.13 工况3 0.176 3.080 0.020 0.029 0.039 0.310 8.56 4.11 工况4 3.882 2.264 0.026 0.012 0.997 0.197 4.08 2.34 -

[1] WANG J X, LI Y Z, LIU X D, et al. Recent active thermal management technologies for the development of energy-optimized aerospace vehicles in China[J]. Chinese Journal of Aeronautics, 2021, 34(2): 1-27. doi: 10.1016/j.cja.2020.06.021 [2] DEPPEN T O, HEY J E, ALLEYNE A G, et al. A model predictive framework for thermal management of aircraft[C]//Proceedings of the ASME 8th Annual Dynamic Systems and Control Conference. New York: ASME, 2016. [3] ROETZEL W, XUAN Y. Dynamic behaviour of heat exchangers[M]. Southampton: WIT Press/Computational Mechanics Publications, 1999. [4] 冷伟, 房德山, 徐治皋, 等. 对单相换热器集总参数模型动态初始负偏移的机理分析[J]. 热能动力工程, 2001, 16(3): 287-289. doi: 10.3969/j.issn.1001-2060.2001.03.015LENG W, FANG D S, XU Z G, et al. An analysis of the mechanism governing the dynamic and initial negative deviation of a lumped parameter model for a single-phase heat exchanger[J]. Journal of Engineering for Thermal Energy and Power, 2001, 16(3): 287-289(in Chinese). doi: 10.3969/j.issn.1001-2060.2001.03.015 [5] 宋俊虓, 袁修干, 林贵平. 某种叉流板翅式热交换器动态性能的计算[J]. 北京航空航天大学学报, 1999, 25(5): 558-560. doi: 10.3969/j.issn.1001-5965.1999.05.017SONG J X, YUAN X G, LIN G P. Transient performances calculation of a gas-to-gas crossflow heat exchanger[J]. Journal of Beijing University of Aeronautics and Astronautics, 1999, 25(5): 558-560 (in Chinese). doi: 10.3969/j.issn.1001-5965.1999.05.017 [6] 解增忠, 张俊峰, 罗雄麟. 原油换热网络的动态建模与仿真[C]//第九届全国化学工艺年会. 北京: 中国石化出版社, 2005: 1198-1206.XIE Z Z, ZHANG J F, LUO X L. Dynamic modeling and simulation of crude oil heat exchanger networks[C]//Proceedings of the 9th National Chemical Technology Annual Meeting. Beijing: China Petrochemical Press, 2005: 1198-1206(in Chinese). [7] ORAVEC J, BAKOŠOVÁ M, TRAFCZYNSKI M, et al. Robust model predictive control and PID control of shell-and-tube heat exchangers[J]. Energy, 2018, 159: 1-10. doi: 10.1016/j.energy.2018.06.106 [8] CHEN M H, SUN X D, CHRISTENSEN R N, et al. Dynamic behavior of a high-temperature printed circuit heat exchanger: Numerical modeling and experimental investigation[J]. Applied Thermal Engineering, 2018, 135: 246-256. doi: 10.1016/j.applthermaleng.2018.02.051 [9] HEY J E, HODSON S L, YAZAWA K, et al. Experimental characterization of dynamic heat exchanger behavior[J]. International Journal of Heat and Mass Transfer, 2018, 121: 933-942. doi: 10.1016/j.ijheatmasstransfer.2017.12.135 [10] SANGI R, MÜLLER D. Dynamic modelling and simulation of a slinky-coil horizontal ground heat exchanger using Modelica[J]. Journal of Building Engineering, 2018, 16: 159-168. doi: 10.1016/j.jobe.2018.01.005 [11] NASH A L, BADITHELA A, JAIN N. Dynamic modeling of a sensible thermal energy storage tank with an immersed coil heat exchanger under three operation modes[J]. Applied Energy, 2017, 195: 877-889. doi: 10.1016/j.apenergy.2017.03.092 [12] AGARWAL A, B M O, PITSO I. Numerical analysis and performance enhancement of compact heat exchanger using computational fluid dynamics[J]. Journal of Engineering Research, 2021, 9: 15503. [13] GONG M J, PENG M J, ZHU H S. Research of multiple refined degree simulating and modeling for high pressure feed water heat exchanger in nuclear power plant[J]. Applied Thermal Engineering, 2018, 140: 190-207. doi: 10.1016/j.applthermaleng.2018.05.005 [14] FRATCZAK M, NOWAK P, CZECZOT J, et al. Simplified dynamical input-output modeling of plate heat exchangers-case study[J]. Applied Thermal Engineering, 2016, 98: 880-893. doi: 10.1016/j.applthermaleng.2016.01.004 [15] WANG Y R, YOU S J, ZHENG W D, et al. State space model and robust control of plate heat exchanger for dynamic performance improvement[J]. Applied Thermal Engineering, 2018, 128: 1588-1604. doi: 10.1016/j.applthermaleng.2017.09.120 [16] ROMIE F E. Transient response of gas-to-gas crossflow heat exchangers with neither gas mixed[J]. Journal of Heat Transfer, 1983, 105(3): 563-570. doi: 10.1115/1.3245622 [17] WHALLEY R, EBRAHIMI K M. Heat exchanger dynamic analysis[J]. Applied Mathematical Modelling, 2018, 62: 38-50. doi: 10.1016/j.apm.2018.04.024 [18] GVOZDENAC D. Analytical solution of dynamic response of heat exchanger[M]//MITROVIĆ J. Heat exchangers: basics design applications. London: Intechopen, 2012: 53-78. [19] AL-DAWERY S K, ALRAHAWI A M, AL-ZOBAI K M. Dynamic modeling and control of plate heat exchanger[J]. International Journal of Heat and Mass Transfer, 2012, 55(23-24): 6873-6880. doi: 10.1016/j.ijheatmasstransfer.2012.06.094 [20] ZAHID K, PATEL R, MUJTABA I. Development of a dynamic fouling model for a heat exchanger[J]. Chemical Engineering Transactions, 2016, 52: 1135-1140. [21] YIN J, JENSEN M K. Analytic model for transient heat exchanger response[J]. International Journal of Heat and Mass Transfer, 2003, 46(17): 3255-3264. doi: 10.1016/S0017-9310(03)00118-2 [22] GAO T Y, GEER J, SAMMAKIA B. Development and verification of compact transient heat exchanger models using transient effectiveness methodologies[J]. International Journal of Heat and Mass Transfer, 2015, 87: 265-278. doi: 10.1016/j.ijheatmasstransfer.2015.03.091 [23] PEARSON J. EASY5 user guide[Z]. Chicago: Boeing Company, 2005: 265-278. [24] 张一鸣, 袁宁, 陈玉春. 回热循环微燃机中换热器计算模型与仿真研究[J]. 燃气轮机技术, 2012, 25(1): 38-43. doi: 10.3969/j.issn.1009-2889.2012.01.008ZHANG Y M, YUAN N, CHEN Y C. Studies on calculation model and simulation of the heat exchanger in micro-turbine[J]. Gas Turbine Technology, 2012, 25(1): 38-43(in Chinese). doi: 10.3969/j.issn.1009-2889.2012.01.008 -

下载:

下载: