Belief reliability modeling for assembly accuracy of spaceborne SAR antenna deployable mechanism

-

摘要:

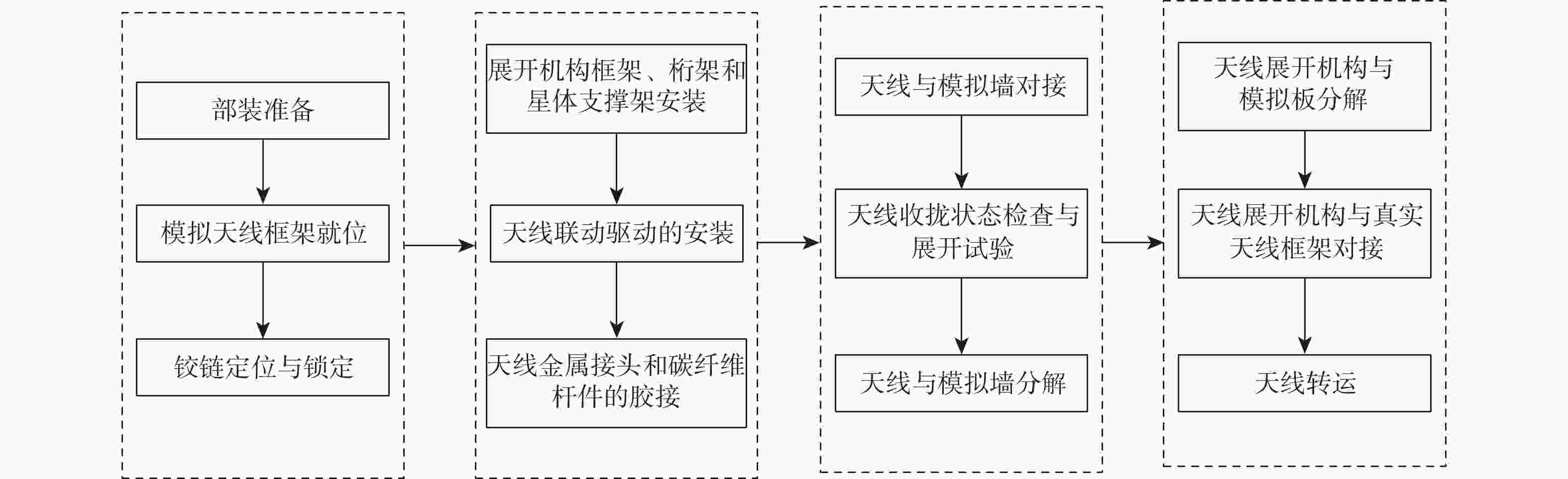

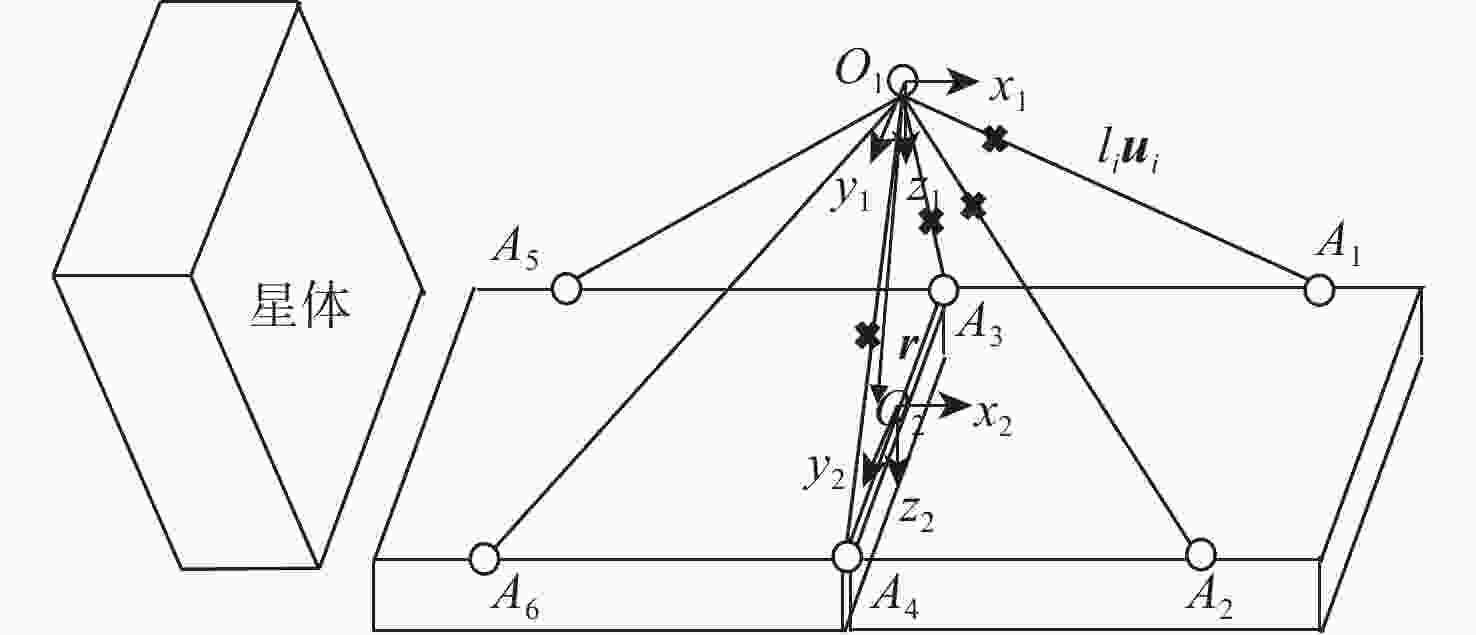

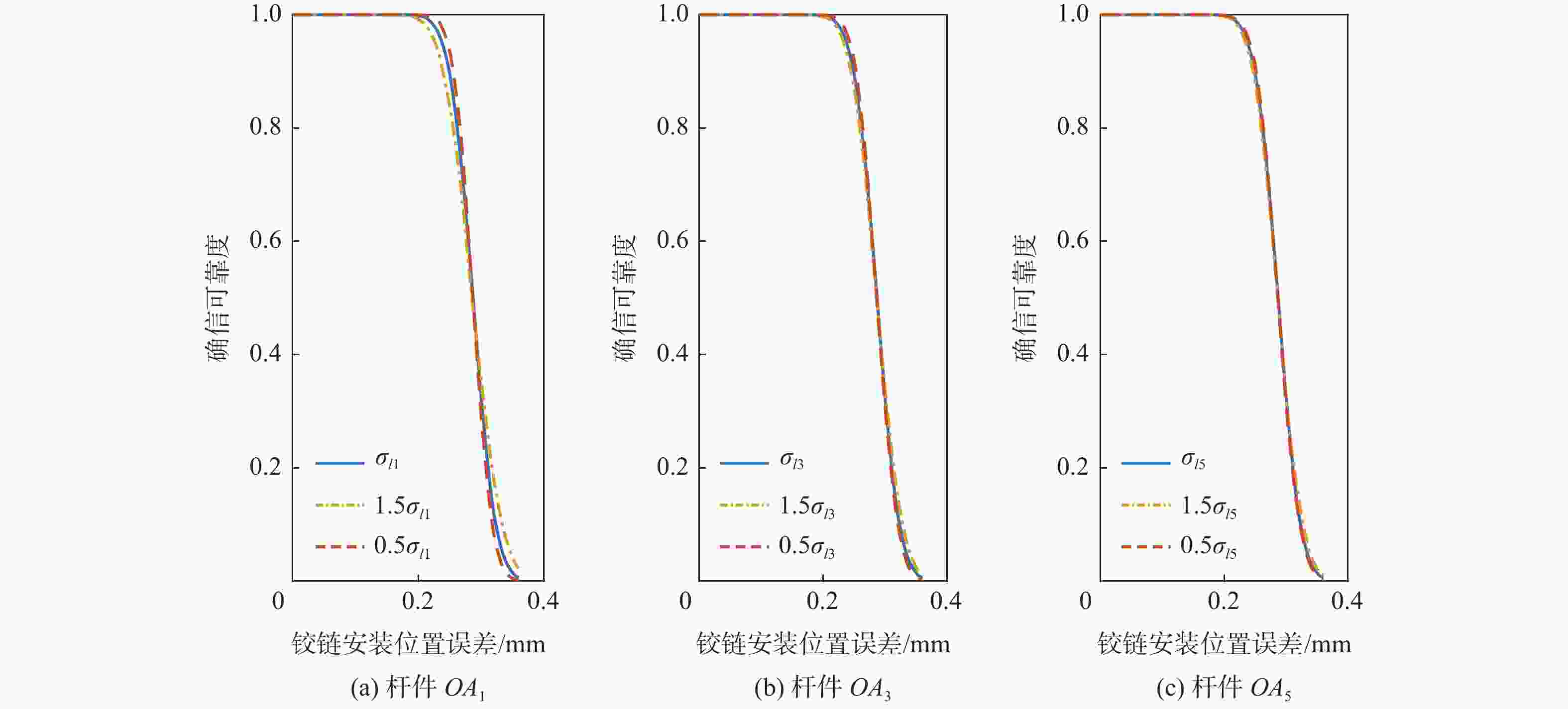

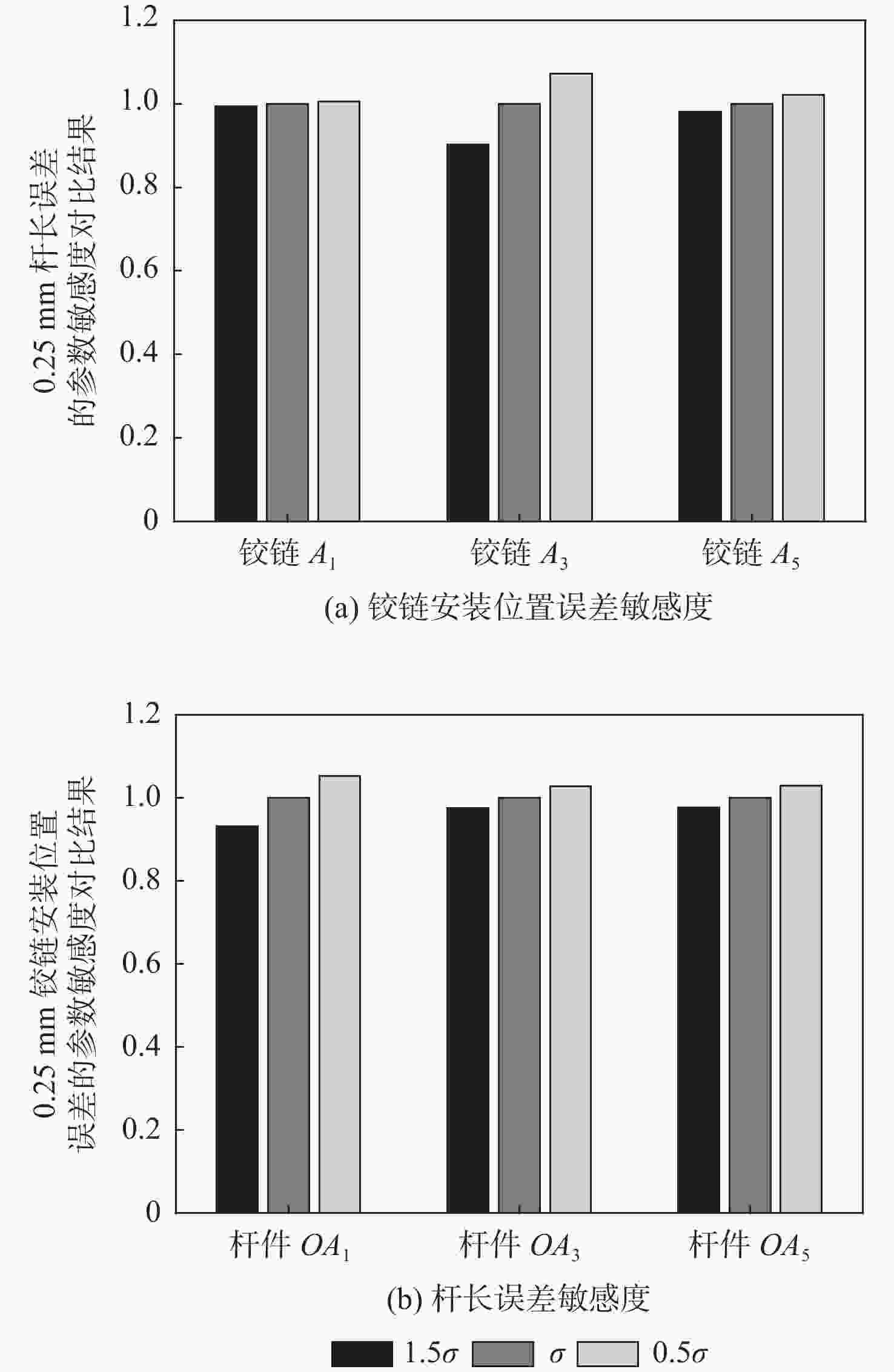

星载合成孔径雷达(SAR)天线展开机构是空间桁架结构,其杆系和铰链的空间位置相互耦合,在装配过程中主要依赖于人工装调,装配精度难以准确控制,装配可靠性直接影响星载SAR天线的服役性能。为此,基于可靠性科学原理,提出星载SAR天线装配精度确信可靠性建模方法。考虑天线装配过程中影响装配精度的内因和外因,确定表征天线展开机构装配精度的性能指标及阈值,建立性能裕量模型。开展多源不确定性分析与量化,构建星载SAR天线展开机构装配精度确信可靠性模型。以某型号星载SAR天线展开机构为研究对象,进行可靠性敏感度分析和验证。研究结果表明:所提方法可为星载SAR天线展开机构装调提供理论指导,有效提高装配精度和效率。

Abstract:The deployable mechanism for a spaceborne synthetic aperture radar (SAR) antenna is a space truss structure, with the rod system and hinge coupled in space. Assembling accuracy is difficult to control precisely during the assembly process, and assembly reliability directly impacts the spaceborne SAR antenna’s service performance. Therefore, based on the principle of reliability science, a precision assurance reliability modeling method for spaceborne SAR antenna ground assembly is proposed in this paper. First, the performance index and threshold indicating the assembly accuracy of the antenna deployable mechanism were established, taking into account both internal and external elements that have an impact on the assembly accuracy in the antenna assembly process. Then, the multi-source uncertainty analysis and quantification were carried out to construct the assembly precision certainty reliability model of the spaceborne SAR antenna deployable mechanism. Finally, the reliability sensitivity analysis and verification of a spaceborne SAR antenna deployable mechanism are carried out. The results show that the proposed method can provide theoretical guidance for the mounting and adjusting of spaceborne SAR antenna deployable mechanism, and effectively improve the assembly accuracy and efficiency.

-

Key words:

- belief reliability /

- antenna deployable mechanism /

- assembly accuracy /

- performance margin /

- uncertainty

-

表 1 某型号星载SAR天线尺寸参数

Table 1. Dimension parameters of an spaceborne SAR antenna of a certain model

mm 参数 数值 A1A2 1 653.73 A1A3 2 162.35 A3A5 1 802.87 OC 2 147.51 OA1 2 335.99 OA3 883.80 OA5 2 007.84 O1O2 901.89 表 2 操作人员造成的测量误差

Table 2. Measurement errors caused by operators

$ {\mu }_{{\Delta p}_{i\_r1}} $/mm $ {\mu }_{{\Delta p}_{i\_r2}} $/mm $ {\sigma }_{{\Delta p}_{i\_r1}}^{2} $/mm $ {\sigma }_{{\Delta p}_{i\_r2}}^{2} $/mm 0 0 0.0222 0.0302 -

[1] MOREIRA A, PRATS-IRAOLA P, YOUNIS M, et al. A tutorial on synthetic aperture radar[J]. IEEE Geoscience and Remote Sensing Magazine, 2013, 1(1): 6-43. doi: 10.1109/MGRS.2013.2248301 [2] WANG R, LOFFELD O, NIES H, et al. Focus FMCW SAR data using the wavenumber domain algorithm[J]. IEEE Transactions on Geoscience and Remote Sensing, 2010, 48(4): 2109-2118. doi: 10.1109/TGRS.2009.2034368 [3] 余德文, 赵强强, 陈飞飞, 等. 利用结构等效转换的空间可展机构装配误差建模与灵敏度分析[J]. 西安交通大学学报, 2019, 53(4): 15-23. doi: 10.7652/xjtuxb201904003YU D W, ZHAO Q Q, CHEN F F, et al. Assembly error modeling and sensitivity analysis for spatial deployable mechanisms with structural equivalent transformation[J]. Journal of Xi’an Jiaotong University, 2019, 53(4): 15-23(in Chinese). doi: 10.7652/xjtuxb201904003 [4] 苏春, 黄漪. 装配误差传递建模及其精度可靠性评估[J]. 中国机械工程, 2017, 28(19): 2359-2364. doi: 10.3969/j.issn.1004-132X.2017.19.014SU C, HUANG Y. Modeling for assembly error propagations and assessments of assembly precision reliability[J]. China Mechanical Engineering, 2017, 28(19): 2359-2364(in Chinese). doi: 10.3969/j.issn.1004-132X.2017.19.014 [5] SZEKELY G S, TEICHERT W H, BRENNER C E, et al. Practical procedures for reliability estimation of spacecraft structures and their components[J]. AIAA Journal, 1998, 36(8): 1509-1515. [6] 张建国, 陈建军, 段宝岩, 等. 基于非概率模型的星载天线展开机构可靠性分析[J]. 西安电子科技大学学报, 2006, 33(5): 739-744.ZHANG J G, CHEN J J, DUAN B Y, et al. Reliability analysis of the deployment mechanism of a large satellite antenna based on the non-probabilistic model[J]. Journal of Xidian University, 2006, 33(5): 739-744(in Chinese) . [7] 刘良. 一种空间折展机构的设计与分析[D]. 南宁: 广西大学, 2020: 1-9.LIU L. Design and analysis of a space deployable and foldable mechanism[D]. Nanning: Guangxi University, 2020: 1-9(in Chinese) . [8] 吴建云, 王春洁, 汪瀚. 基于蒙特卡洛法的卫星天线板展开精度分析[J]. 航天返回与遥感, 2013, 34(6): 89-94. doi: 10.3969/j.issn.1009-8518.2013.06.012WU J Y, WANG C J, WANG H. Accuracy analysis of satellite antenna plate deployment based on Monte Carlo method[J]. Spacecraft Recovery & Remote Sensing, 2013, 34(6): 89-94(in Chinese). doi: 10.3969/j.issn.1009-8518.2013.06.012 [9] 杨玉龙, 关富玲. 可展桁架天线形面精度理论分析[J]. 空间科学学报, 2009, 29(5): 529-533. doi: 10.11728/cjss2009.05.529YANG Y L, GUAN F L. Theoretical analysis of surface error for deployable truss antenna[J]. Chinese Journal of Space Science, 2009, 29(5): 529-533(in Chinese). doi: 10.11728/cjss2009.05.529 [10] 丁建中, 王春洁. 含铰链间隙板式卫星天线展开精度分析[J]. 北京航空航天大学学报, 2016, 42(12): 2625-2631. doi: 10.13700/j.bh.1001-5965.2015.0808DING J Z, WANG C J. Deployment accuracy analysis of planar satellite antenna with joint clearances[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(12): 2625-2631(in Chinese). doi: 10.13700/j.bh.1001-5965.2015.0808 [11] GREENE W H. Effects of random member length errors on the accuracy and internal loads of truss antennas[J]. Journal of Spacecraft & Rockets, 2015, 22(5): 554-559. [12] MOBREM M. Methods of analyzing surface accuracy of large antenna structures due to manufacturing tolerances: AIAA 2023-1453[R]. Reston: AIAA, 2003. [13] HEDGEPETH J M. Influence of fabrication tolerances on the surface accuracy of largeantenna structures[J]. AIAA Journal, 1982, 20(5): 680-686. doi: 10.2514/3.7936 [14] KANG R. Belief reliability theory and methodology[M]. Berlin: Springer, 2021: 60-71. [15] 孙中超, 喻天翔, 崔卫民, 等. 铰链间隙对连杆机构运动精度的重要性测度分析[J]. 中国机械工程, 2014, 25(21): 2874-2879. doi: 10.3969/j.issn.1004-132X.2014.21.007SUN Z C, YU T X, CUI W M, et al. Importance measure analysis of revolute joint clearance about motion accuracy of linkage mechanism[J]. China Mechanical Engineering, 2014, 25(21): 2874-2879(in Chinese). doi: 10.3969/j.issn.1004-132X.2014.21.007 [16] NGUYEN T T, AMTHOR A, AMENT C. High precision laser tracker system for contactless position measurement[C]//Proceedings of the IEEE International Conference on Control System, Computing and Engineering. Piscataway: IEEE Press, 2012: 97-102. [17] 刘建新. 电子经纬仪测角原理及其在航天器检测中的应用[J]. 航天器环境工程, 2007, 24(2): 116-120 . doi: 10.3969/j.issn.1673-1379.2007.02.011LIU J X. Measuring principle of electronic theodolite and its applications in spacecraft inspection[J]. Spacecraft Environment Engineering, 2007, 24(2): 116-120(in Chinese) . doi: 10.3969/j.issn.1673-1379.2007.02.011 [18] LIU B D. Uncertainty theory[M]. Berlin: Springer, 2010: 387-394. [19] LIU Y H. Uncertain random variables: A mixture of uncertainty and randomness[J]. Soft Computing, 2013, 17(4): 625-634. doi: 10.1007/s00500-012-0935-0 [20] LIU Y H. Uncertain random programming with applications[J]. Fuzzy Optimization and Decision Making, 2013, 12(2): 153-169. doi: 10.1007/s10700-012-9149-2 [21] 张清源. 不确定随机系统确信可靠性度量与分析[D]. 北京: 北京航空航天大学, 2020: 77-83.ZHANG Q Y. Certitude reliability measurement and analysis for uncertain stochastic systems[D]. Beijing: Beihang University, 2020: 77-83(in Chinese) . [22] 孙海丽, 姚连璧, 周跃寅, 等. 激光跟踪仪测量精度分析[J]. 大地测量与地球动力学, 2015, 35(1): 177-181. doi: 10.14075/j.jgg.2015.01.040SUN H L, YAO L B, ZHOU Y Y, et al. Analysis of measurement accuracy of laser tracker[J]. Journal of Geodesy and Geodynamics, 2015, 35(1): 177-181(in Chinese). doi: 10.14075/j.jgg.2015.01.040 [23] 钱关旻, 袁榕, 袁祥伟, 等. 电子经纬仪一测回竖直角测角标准偏差测量结果不确定度评定[J]. 中国计量, 2019(8): 108-109. doi: 10.16569/j.cnki.cn11-3720/t.2019.08.034QIAN G M, YUAN R, YUAN X W, et al. Uncertainty in measurement results of standard deviation of angle measurement in vertical angle by electronic theodolite[J]. China Metrology, 2019(8): 108-109(in Chinese) . doi: 10.16569/j.cnki.cn11-3720/t.2019.08.034 -

下载:

下载: