Experimental and simulation study on fatigue multi crack fusion of 2195-T8 Al-Li alloy

-

摘要:

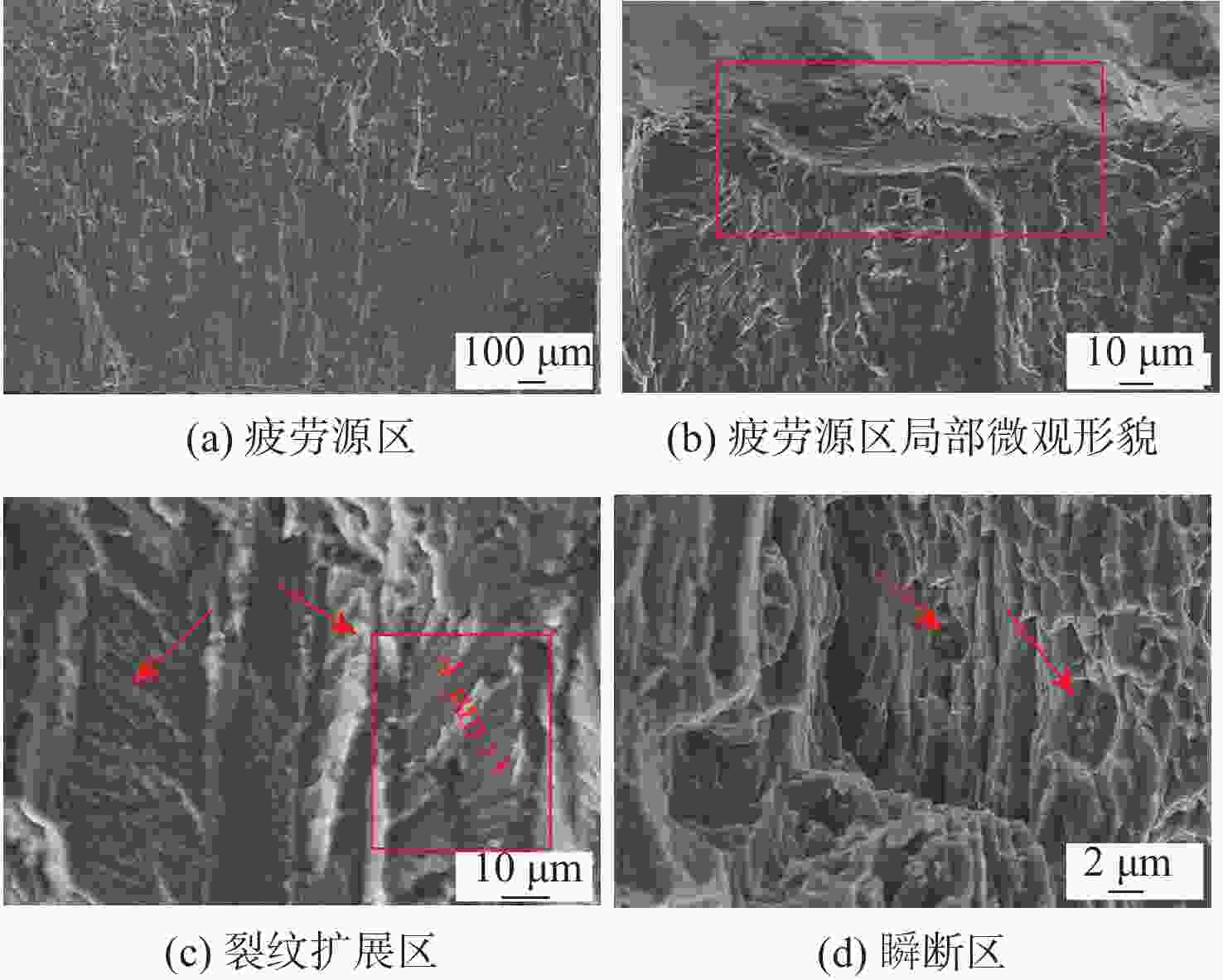

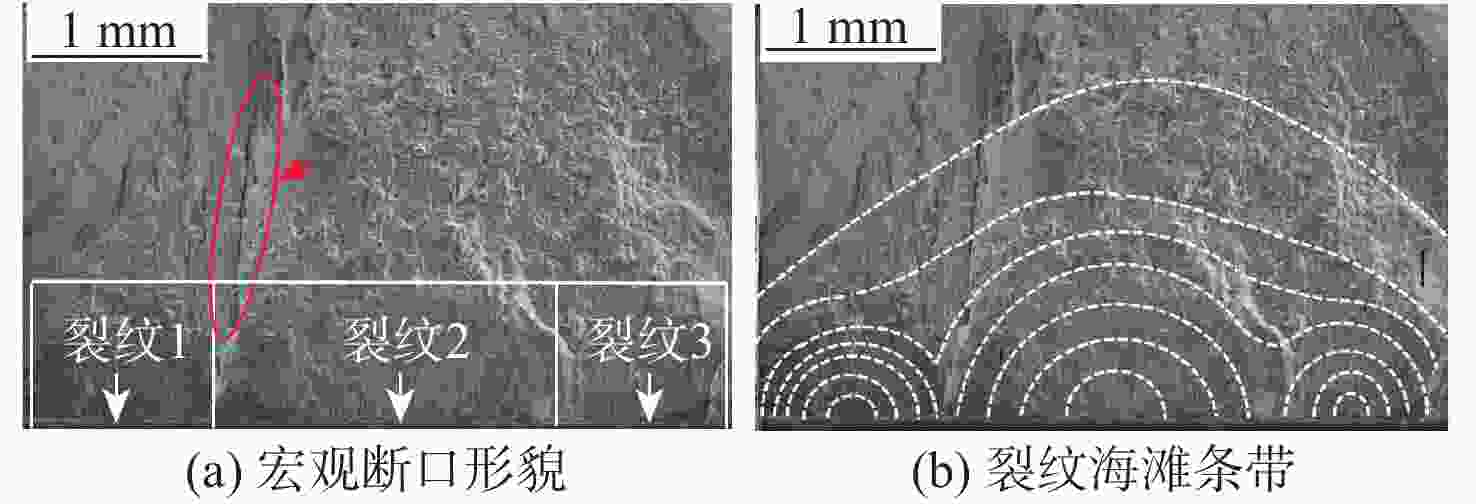

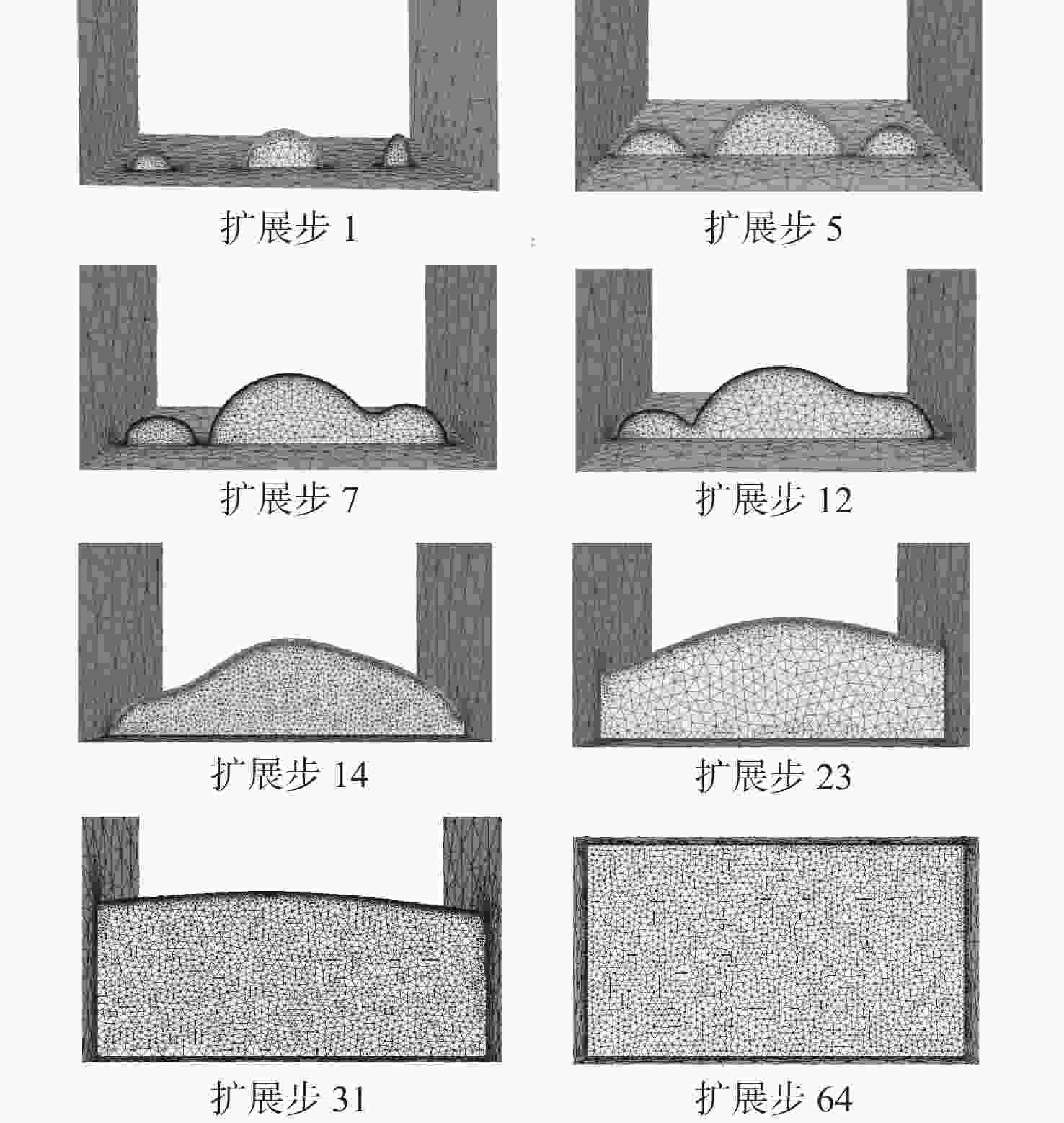

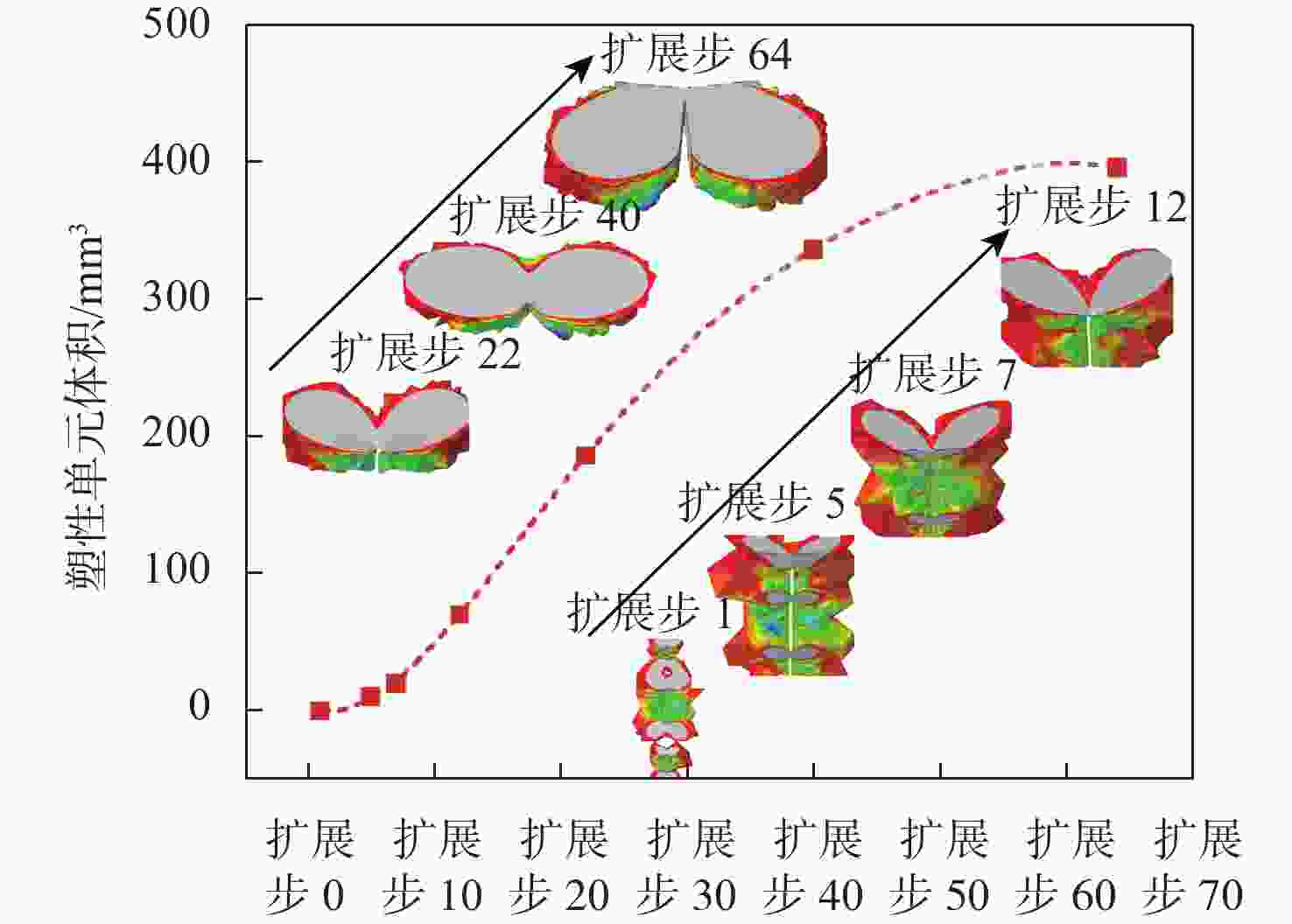

铝锂合金作为航空航天广泛应用的合金材料,其疲劳断裂行为的研究对结构安全性评价具有重要意义。以第三代铝锂合金2195-T8为研究对象,通过恒幅拉-拉疲劳试验和有限元方法对2195-T8 铝锂合金疲劳裂纹扩展行为进行试验与仿真研究。基于断面显微测量与观察,在仿真模型中引入多个初始裂纹,模拟多裂纹的融合扩展过程,获得多裂纹独自扩展、交融时扩展和融合后扩展的规律。结果表明:裂纹融合前,在疲劳循环载荷作用下,裂纹尖端应力强度因子总体上不断增大,塑性区域体积增加区域平缓;当裂纹相互融合时,裂纹面处应力强度因子瞬时增大,远高于其余裂尖数值大小;随着裂纹进一步融合,尖端应力强度因子数值趋于平稳;裂纹完全融合后,到达裂纹快速扩展阶段,塑性区域体积与扩展步数呈正比增加,扩展速率呈现先快后慢的规律,裂纹面交汇融合成新的椭圆形状裂纹面。

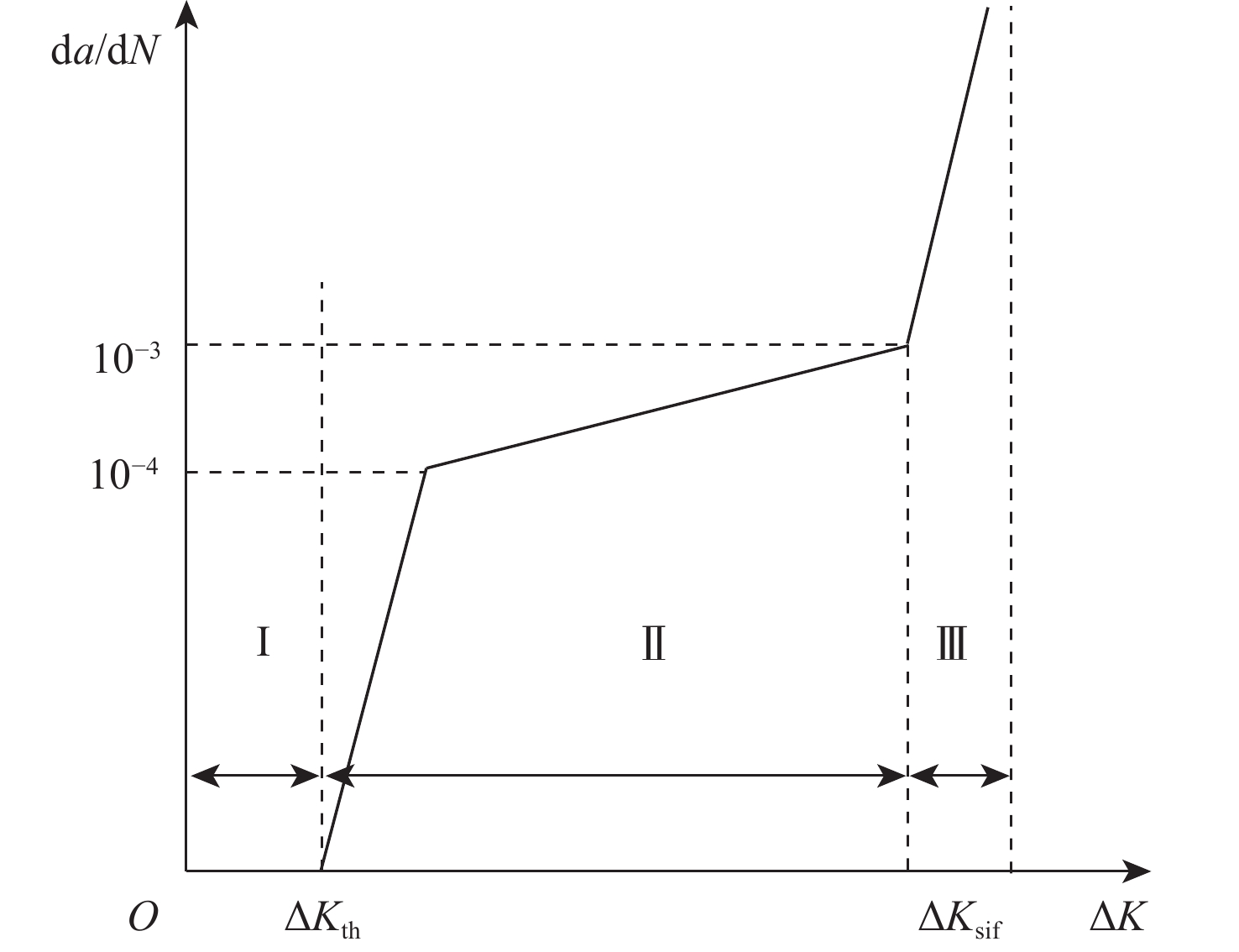

Abstract:As an alloy material widely used in aerospace, the study of fatigue fracture behavior of aluminum-lithium alloy is of great significance to the evaluation of structural safety. The third generation Al-Li alloy 2195-T8 is taken as the research object, and the fatigue crack propagation behavior of 2195-T8 Al-Li alloy is tested and simulated by constant amplitude tensile fatigue test and finite element method. Based on the microscopic measurement and observation of the cross-section, multiple initial cracks were introduced into the simulation model, and then the fusion and propagation process of multiple cracks was simulated. The results show that before crack fusion, under the action of fatigue cyclic load, the value of stress intensity factor at the crack tip increases continuously, and the volume of the plastic region increases gradually; when the cracks fuse with each other, the stress intensity factor at the crack surface increases instantaneously, the stress intensity facto is much higher than the value of the rest of the crack tip. With the further fusion of the crack, the value of the stress intensity factor at the tip tends to be stable; after the crack is completely fused, it reaches the stage of rapid crack expansion, the volume of the plastic region increases in direct proportion to the expansion step, and the growth rate is first fast, then slow; finally, the crack surfaces meet and merge into a new elliptical shape crack surface.

-

Key words:

- fatigue fracture /

- Al-Li alloys /

- crack fusion /

- finite element /

- stress intensity factor

-

表 1 2195-T8铝锂合金的基本力学性能

Table 1. Basic mechanical properties of 2195-T8 AL-Li alloy

抗拉强度

σb/MPa屈服强度

σs/MPa拉伸率

δ/ %弹性模量

E/GPa609.90 583.33 11.4 72.29 -

[1] XU Y, WANG X J, YAN Z T, et al. Corrosion properties of light-weight and high-strength 2195 Al-Li alloy[J]. Chinese Journal of Aeronautics, 2011, 24(5): 681-686. doi: 10.1016/S1000-9361(11)60080-0 [2] 尹嘉明, 马鹏程, 陈永来, 等. 铝锂合金的发展及在运载火箭贮箱的应用[J]. 兵器材料科学与工程, 2020, 43(3): 137-141.YIN J M, MA P C, CHEN Y L, et al. The development of Al-Li alloys and its application in launch vehicle tank[J]. Ordnance Material Science and Engineering, 2020, 43(3): 137-141(in Chinese). [3] 梁准, 张颖晗, 高原, 等. 低温下2219铝合金贮箱焊接缺陷的试验与仿真分析[J]. 强度与环境, 2021, 48(5): 52-57.LIANG Z, ZHANG Y H, GAO Y, et al. Experiment and simulation analysis for weld defected 2219 aluminum alloy tank at low temperature[J]. Structure & Environment Engineering, 2021, 48(5): 52-57(in Chinese). [4] 魏国前, 陈斯雯, 余茜, 等. 焊趾多裂纹的试验与仿真分析[J]. 焊接学报, 2019, 40(11): 75-81.WEI G Q, CHEN S W, YU X, et al. Experimental and simulation study on multiple cracks of weld toe[J]. Transactions of the China Welding Institution, 2019, 40(11): 75-81(in Chinese). [5] 吴鹏飞, 杨邦成, 岳仕航. AA7075-T6 Ⅰ-Ⅱ复合疲劳裂纹扩展研究[J]. 宇航材料工艺, 2022, 52(1): 82-88.WU P F, YANG B C, YUE S H. Experimental study on Ⅰ-Ⅱ mixed-mode fatigue crack growth of AA7075-T6[J]. Aerospace Materials & Technology, 2022, 52(1): 82-88(in Chinese). [6] LI R J, ZHU Y M, FANG W J, et al. Multi-crack interaction and influence on the spherical pressure hull for a deep-sea manned submersible[J]. Journal of Marine Science and Application, 2021, 20(3): 491-503. doi: 10.1007/s11804-021-00223-0 [7] 白树伟, 姜楠, 樊俊玲, 等. 疲劳裂纹扩展前缘形貌分析及数值模拟[J]. 科学技术与工程, 2019, 19(1): 256-260.BAI S W, JIANG N, FAN J L, et al. Morphology analysis and numerical simulation of fatigue crack propagation leading edge[J]. Science Technology and Engineering, 2019, 19(1): 256-260(in Chinese). [8] 赵颖, 黄美, 杨梦灵, 等. 推进剂贮箱金属焊接件疲劳裂纹对应力强度因子影响的数值分析[J]. 航天器环境工程, 2019, 36(3): 247-251.ZHAO Y, HUANG M, YANG M L, et al. Numerical analysis of fatigue crack vs. stress impact factor of metal welded joint for satellite propellant tank[J]. Spacecraft Environment Engineering, 2019, 36(3): 247-251(in Chinese). [9] 徐利辉, 马蒙, 刘维宁, 等. 基于模态叠加法的裂纹板动态应力强度因子计算[C]//第29届全国结构工程学术会议. 北京: 《工程力学》杂志社, 2020: 295-303.XU L H, MA M, LIU W N, et al. Calculation of dynamic stress intensity factor of cracked plate based on modal superposition method [C]//Proceedings of the 29th National Structural Engineering Academic Conference. Beijing: Engineering Mechanics Magazine, 2020: 295-303(in Chinese). [10] AMIRI M, ARCARI A, AIROLDI L, et al. A continuum damage mechanics model for pit-to-crack transition in AA2024-T3[J]. Corrosion Science, 2015, 98: 678-687. doi: 10.1016/j.corsci.2015.06.009 [11] 汪必升, 李毅波, 廖雅诗, 等. 基于扩展有限元模型的动态应力强度因子计算[J]. 中国机械工程, 2019, 30(11): 1294-1301.WANG B S, LI Y B, LIAO Y S, et al. Calculation of dynamic stress intensity factors based on XFEM model[J]. China Mechanical Engineering, 2019, 30(11): 1294-1301(in Chinese). [12] CHEN M X, LI Y B, XIA L Y, et al. Effects of pre-rolling on mechanical properties and fatigue crack growth rate of 2195 Al-Li alloy[J]. Journal of Central South University, 2022, 29(3): 836-847. doi: 10.1007/s11771-022-4969-x [13] 郦正能. 应用断裂力学[M]. 北京: 北京航空航天大学出版社, 2012: 111-112.LI Z N. Applied fracture mechanics[M]. Beihang: Beihang University Press, 2012: 111-112(in Chinese). [14] 岳应娟, 李宁, 陈飞, 等. 埋藏裂纹应力强度因子的有限元分析[J]. 武汉科技大学学报, 2015, 38(2): 125-128.YUE Y J, LI N, CHEN F, et al. Finite element analysis of stress intensity factor of embedding cracks[J]. Journal of Wuhan University of Science and Technology, 2015, 38(2): 125-128(in Chinese). [15] NEWMAN J C JR, RAJU I S. Stress-intensity factors for internal surface cracks in cylindrical pressure vessels[J]. Journal of Pressure Vessel Technology, 1980, 102(4): 342-346. doi: 10.1115/1.3263343 [16] 刘城志, 岳应娟, 陈飞. 一种基于FRANC3D的高压气瓶安全性评定的新方法[J]. 铸造技术, 2012, 33(6): 685-687.LIU C Z, YUE Y J, CHEN F. New method to assess safety of high-pressure cylinder based on FRANC3D[J]. Foundry Technology, 2012, 33(6): 685-687(in Chinese). [17] 艾书民, 于明, 成晓鸣, 等. 基于Franc3D软件的三维裂纹扩展分析与应用[J]. 机械强度, 2018, 40(1): 251-254.AI S M, YU M, CHENG X M, et al. Analysis and application of three-dimensional crack growth based on Franc3D[J]. Journal of Mechanical Strength, 2018, 40(1): 251-254(in Chinese). [18] 蹇海根, 姜锋, 文康, 等. 不同应力下7B04铝合金的疲劳断口[J]. 中南大学学报(自然科学版), 2010, 41(1): 132-137.JIAN H G, JIANG F, WEN K, et al. Fatigue fracture of 7B04 aluminum alloy under different stresses[J]. Journal of Central South University (Science and Technology), 2010, 41(1): 132-137(in Chinese). [19] 占勇, 温建锋, 涂善东, 等. 基于疲劳寿命的共面多裂纹合并准则研究[J]. 压力容器, 2016, 33(2): 1-9.ZHAN Y, WEN J F, TU S D, et al. Combination rules for multiple coplanar cracks based on fatigue life[J]. Pressure Vessel Technology, 2016, 33(2): 1-9(in Chinese). [20] 吴圣川, 李存海, 张文, 等. 金属材料疲劳裂纹扩展机制及模型的研究进展[J]. 固体力学学报, 2019, 40(6): 489-538.WU S C, LI C H, ZHANG W, et al. Research progress on fatigue crack propagation mechanisms and models in metal materials[J]. Journal of Solid Mechanics, 2019, 40(6): 489-538(in Chinese). -

下载:

下载: