Characterization of influence of fiber arrangement on CFRP induction heating curing process

-

摘要:

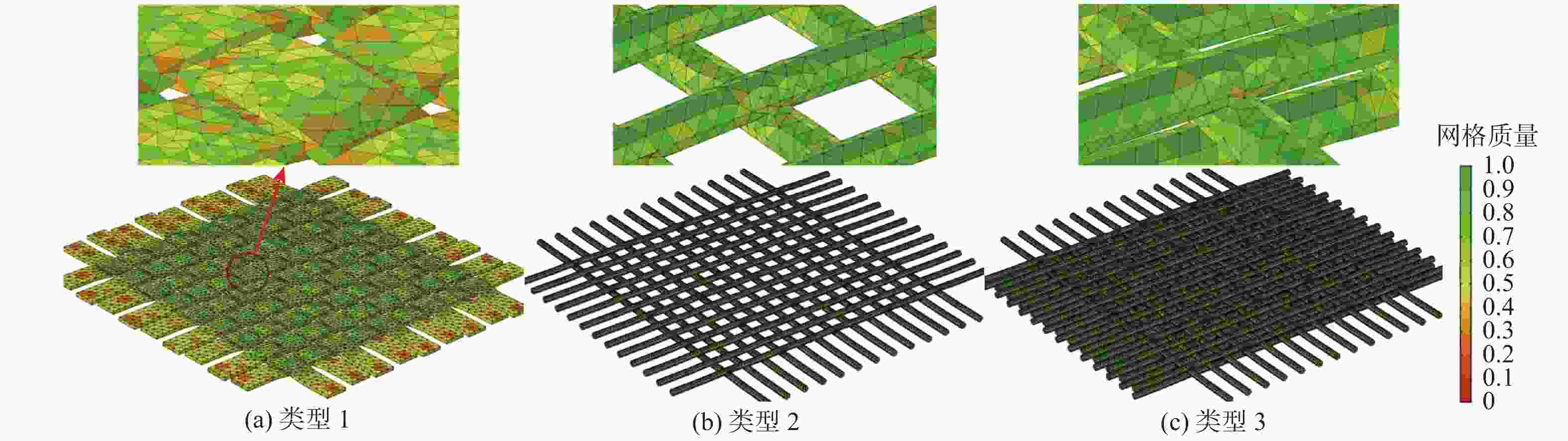

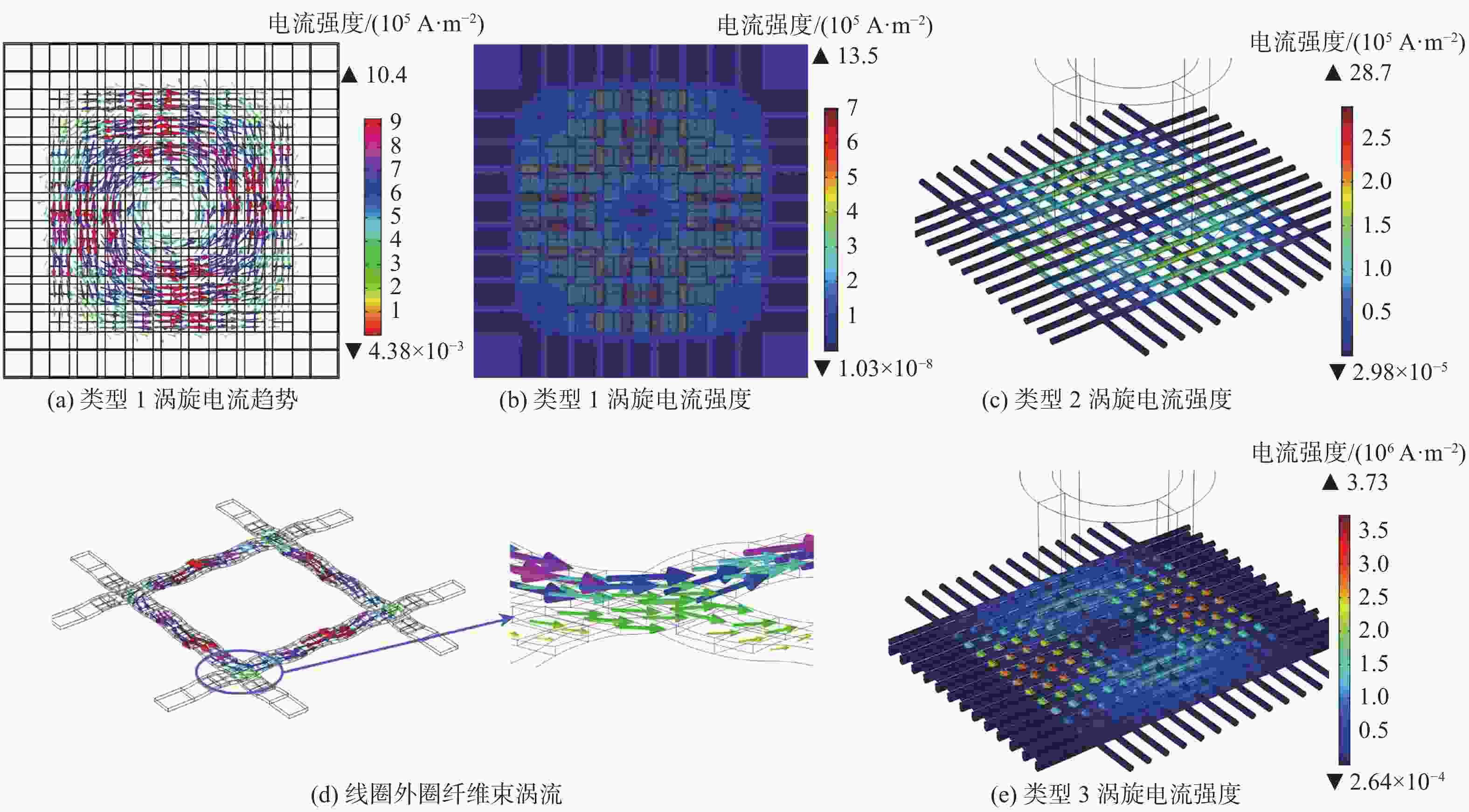

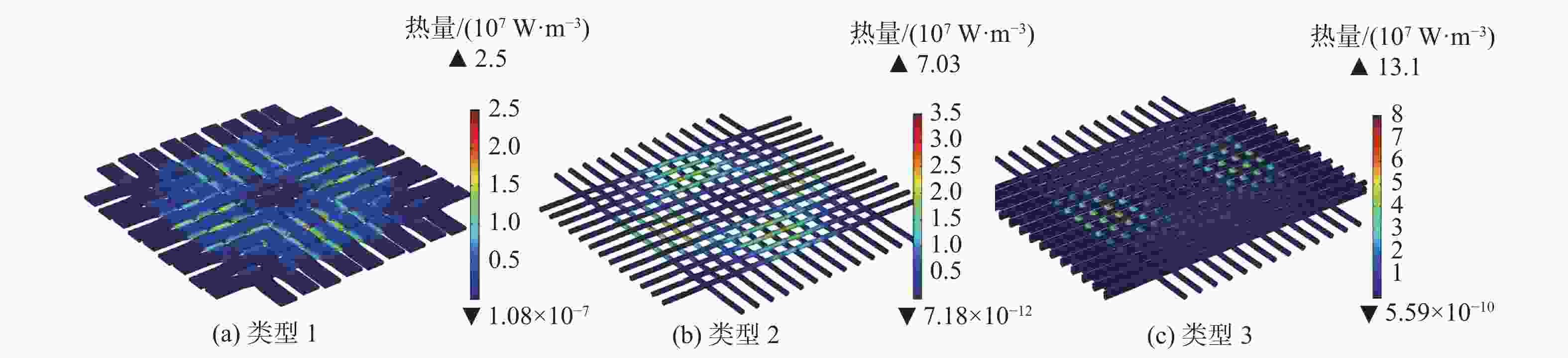

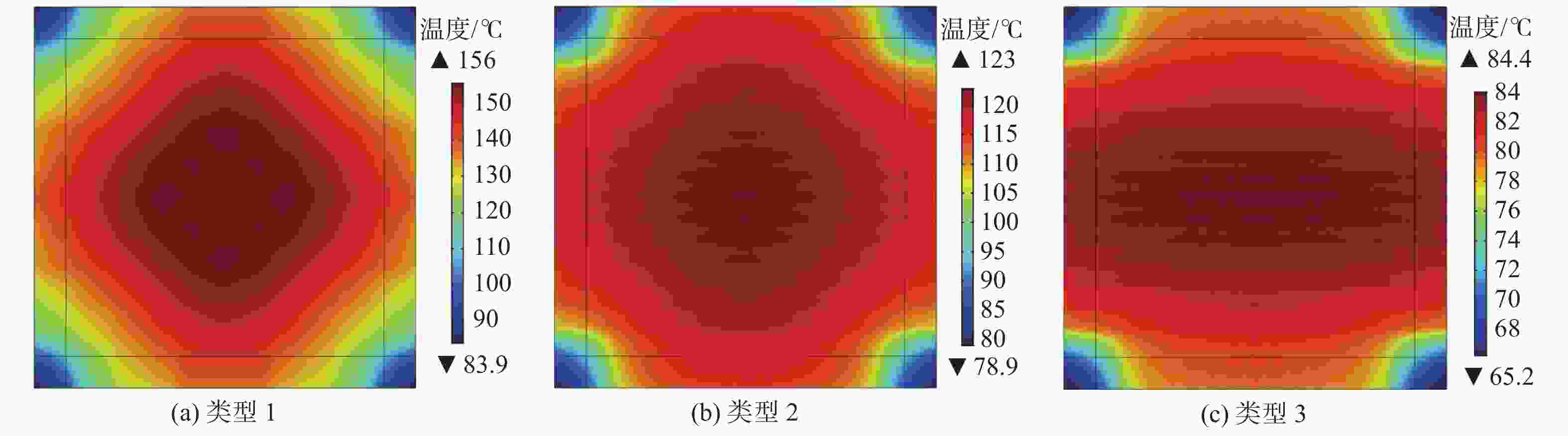

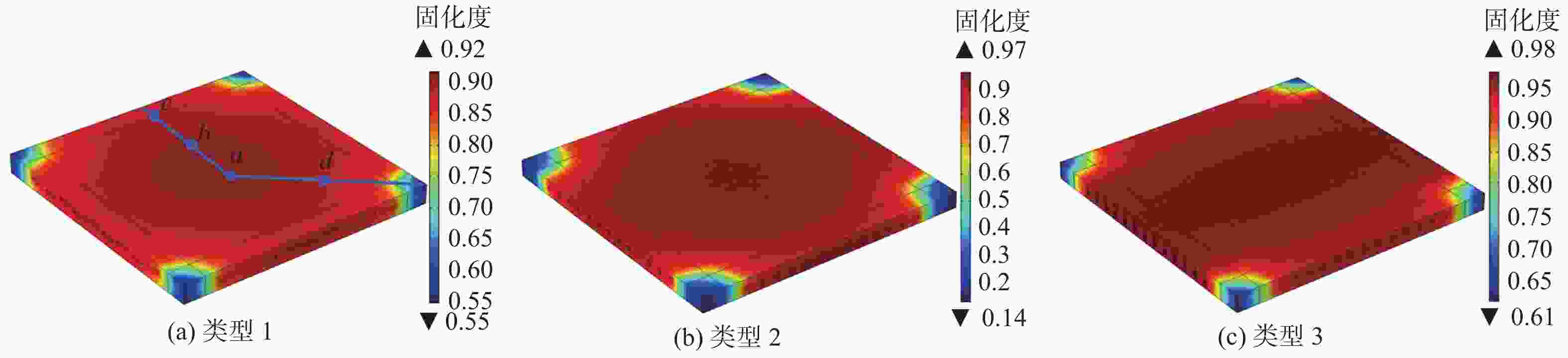

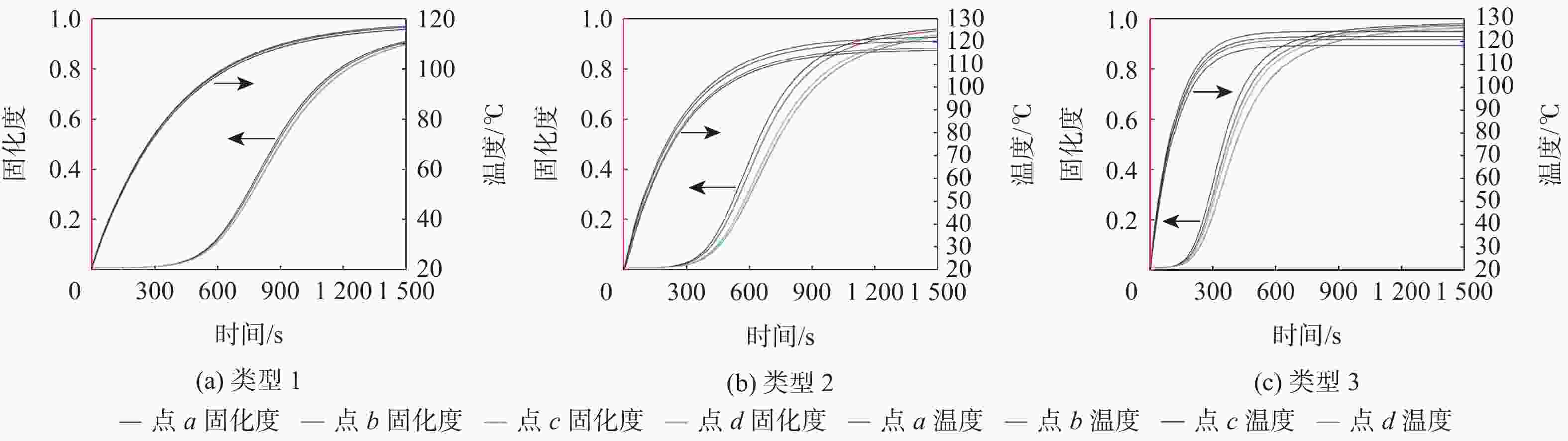

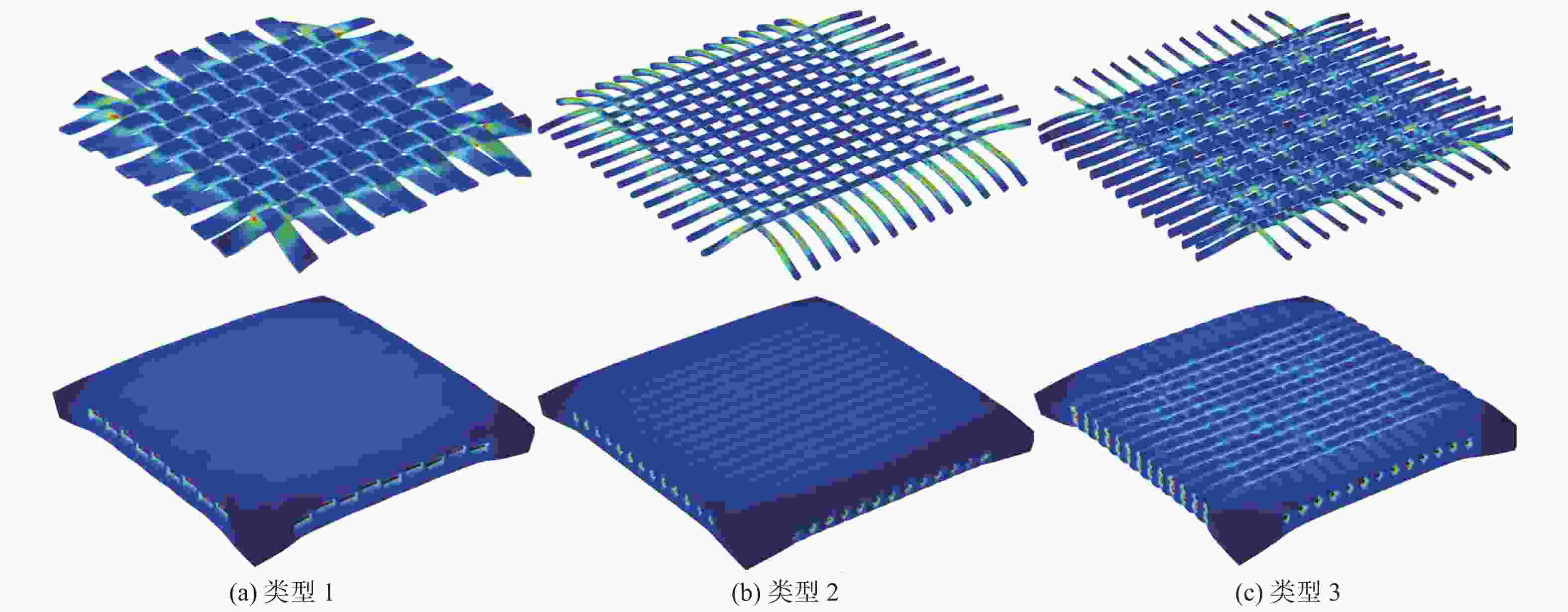

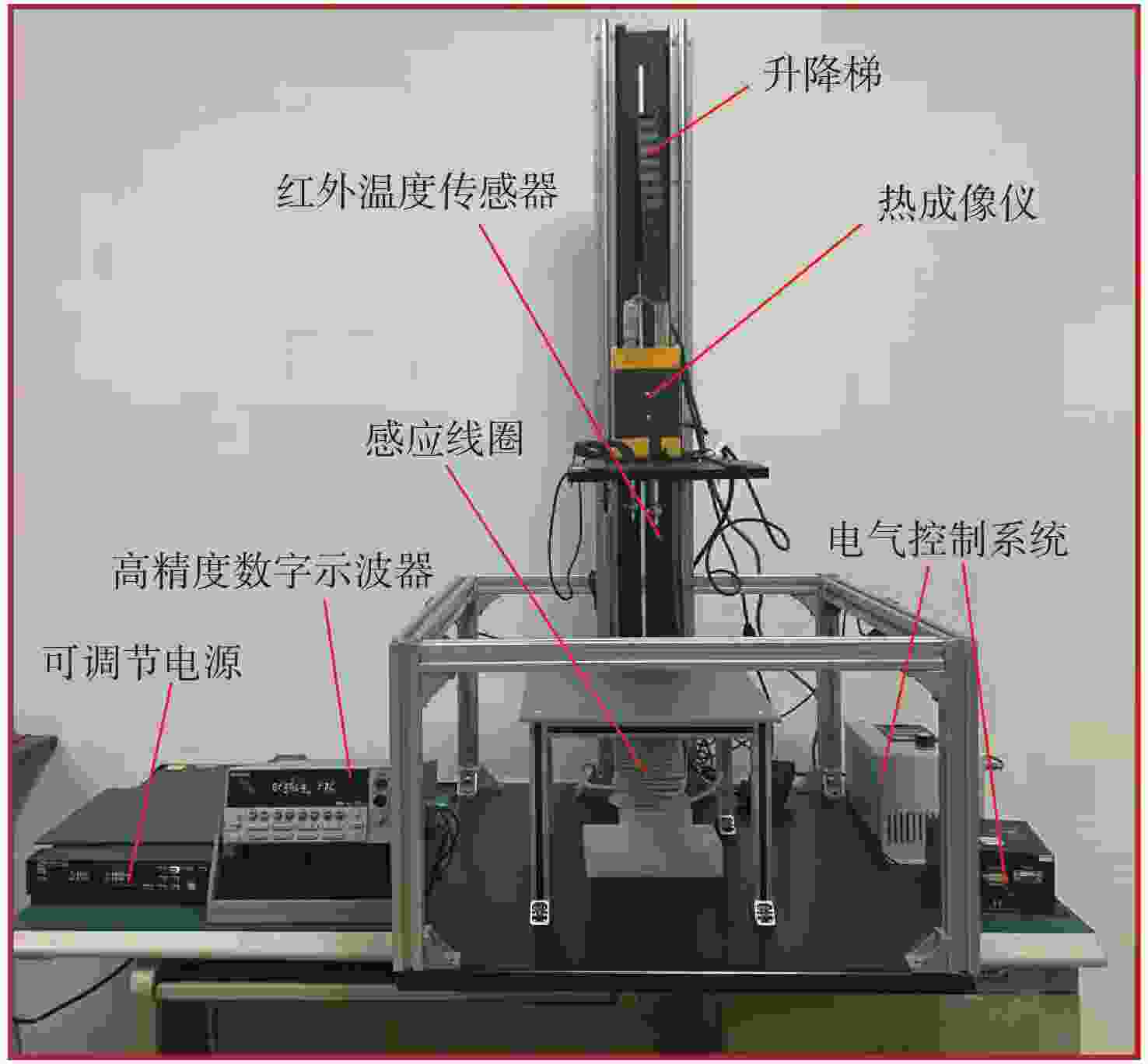

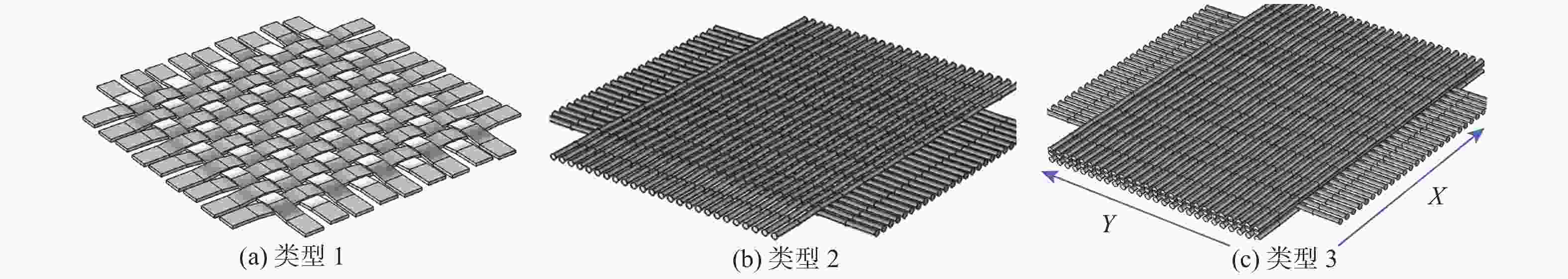

在采用电磁感应加热方式实现碳纤维复合材料(CFRP)加热固化成型的过程中,如何准确表征材料各组成部分的属性参数状态对研究材料加热过程中温度、固化度及应力场分布至关重要。根据纤维实际铺层方式对材料各组成部分进行独立表征,以及碳纤维壳体的等效电-磁-热特性建立了CFRP感应加热有限元细观分析模型,将纤维织构和树脂基体单独建立,实现CFRP在感应加热过程中其内部纤维织构中物理场的变化规律以及对材料整体升温变化规律进行系统分析。通过该模型计算了材料温度、固化度及应力场分布的变化规律,揭示了碳纤维排布对材料感应加热效果的影响,并根据感应加热实验验证了该模型可以准确表征各物理场的分布状态。为研究CFRP在感应加热中各物理场变化规律提供了有效的计算模型和分析方法。

Abstract:In the process of using electromagnetic induction heating to achieve the curing and shaping of carbon fiber reinforced Polymer (CFRP) materials, accurately characterizing the property parameters of the material's various components is of utmost importance in studying temperature, degree of curing, and stress field distribution during the heating process. We have established a finite element microanalysis model for CFRP induction heating based on the actual fiber layup method for independently characterizing the various components of the material and the equivalent electro-magnetic-thermal properties of the carbon fiber shell. This model separates the fiber texture and resin matrix, allowing for a systematic analysis of the changes in physical fields within the internal fiber structure of CFRP during the induction heating process and their effects on the overall temperature variation of the material. Through this model, we have computed the variations in material temperature, degree of curing, and stress field distribution, revealing the influence of carbon fiber arrangement on the effectiveness of induction heating. Furthermore, we have validated the model's ability to accurately represent the distribution states of various physical fields through induction heating experiments. This model provides an effective computational framework and analytical approach for studying the changes in various physical fields during CFRP induction heating.

-

Key words:

- carbon fiber /

- induction heating /

- temperature field /

- degree of cure /

- stress field

-

表 1 材料相关仿真参数

Table 1. Material related simulation parameter

材料 导热系数/(W·(m·K)−1) 比热容/(J·(kg·K)−1) 密度/(kg·m−3) 电导率/(S·m−1) 相对介电常数 相对渗透率 弹性模量/GPa 热膨胀系数/K−1 空气 0 1 1 碳纤维 50 850 1500 6.4×104 1 160 −0.6×10−6 树脂 0.2 1100 1200 1×10−2 3.2 1 1 6×10−5 线圈 8960 6×107 1 1 -

[1] NING F, CONG W, QIU J, et al. Additive manufac-turing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B Engineering, 2015, 80: 369-378. doi: 10.1016/j.compositesb.2015.06.013 [2] SAMBRUNO A, Banon F, SALGUERO J, et al. Study of milling of low thickness thermoplastic carbon fiber composites in function of tool geometry and cutting conditions[J]. The International Journal of Advanced Manufacturing Technology, 2021, 114(7-8): 2515-2526. doi: 10.1007/s00170-021-07050-1 [3] ABLIZ D, YUGANG D. Curing methods for advanced polymer composites-A review[J]. Polymers & Polymer Composites, 2013, 21(6): 101-106. [4] SUN X F, MA S N, LIU H W. Research on properties of carbon fiber/epoxy resin composite material by microwave curing[J]. Rare Metal Materials and Engineering, 2012, 41: 422-424. [5] MENANA H, FELIACHI M. An integro-differential model for 3-D eddy current computation in carbon fiber reinforced polymer composites[J]. IEEE Transactions on Magnetics, 2011, 47(4): 756-763. doi: 10.1109/TMAG.2010.2102770 [6] BAYERL T, DUHOVIC M, MITSCHANG P, et al. The heating of polymer composites by electromagnetic induction-A review[J]. Composites Part A, 2014, 57: 27-40. doi: 10.1016/j.compositesa.2013.10.024 [7] JUN C, JINHAO Q, TOSHIYUKI T. Numerical analysis of correlation between fibre orientation and eddy current testing signals of carbon-fibre reinforced polymer composites[J]. International Journal of Applied Electromagnetics and Mechanics, 2012, 39(1-4): 251-259. doi: 10.3233/JAE-2012-1468 [8] 付天宇, 许家忠, 赵辉, 等. CFRP感应加热线圈中心区域温度场[J]. 复合材料学报, 2021, 38(10): 3314-3322. doi: 10.13801/j.cnki.fhclxb.20201216.001FU T Y, XU J Z, ZHAO H, et al. Temperature field in the central area of CFRP induction heating coil[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3314-3322(in Chinese) . doi: 10.13801/j.cnki.fhclxb.20201216.001 [9] FU T Y, XU J Z, HUI Z. Analysis of induction heating temperature field of plain weave CFRP based on finite element meso model[J]. Applied Composite Materials, 2021, 28(31): 149-163. [10] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review[J]. Advanced Composites and Hybrid Materials, 2019, 2(2): 214-233. doi: 10.1007/s42114-018-0072-z [11] LUNDSTRÖM F, FROGNER K, ANDERSSON M. A method for inductive measurement of equivalent electrical conductivity in thin non-consolidated multilayer carbon fiber fabrics[J]. Composites Part B Engineering, 2017, 140: 204-213. [12] LUNDSTRÖM F, FROGNER K, WIBERG O, et al. Induction heating of carbon fiber composites: Investigation of electric and thermal properties[J]. International Journal of Applied Electromagnetics and Mechanics, 2017, 53: S21-30. doi: 10.3233/JAE-162235 [13] BRUCE K F, ROY L M, JOHN W G. A local theory of heating in cross-ply carbon fiber thermoplastic composites by magnetic induction[J]. Polymer Engineering & Science, 1992, 32(5): 357-369. [14] MITSCHANG P, RUDOLF R, NEITZEL M. Continuous induction welding process, modelling and realisation[J]. Journal of Thermoplastic Composite Materials, 2002, 15(2): 127-153. doi: 10.1177/0892705702015002451 [15] BANERJEE A, AVESTRUZ A T, SURAKITBOVORN K, et al. Uniform single-sided induction heating using multiphase, multi-resonant halbach windings [C]//Applied Power Electronics Conference & Exposition. Piscataway: IEEE Press, 2014: 844-851. [16] FREDRIK L, KENNETH F, MATS A. A numerical model to analyse the temperature distribution in cross-ply CFRP during induction heating[J]. Composites Part B:Engineering, 2020, 202: 108419. doi: 10.1016/j.compositesb.2020.108419 [17] TZENG J T, HSIEH K T. Electromagnetic analysis of composite structures subjected to transient magnetic fields[J]. Journal of Composite Materials, 2019, 54(6): 745-752. [18] RICCIO A, RUSSO A, RAIMONDO A, et al. A numerical/ experimental study on the induction heating of adhesives for composite materials bonding[J]. Materials Today Communications, 2018, 15: 203-213. doi: 10.1016/j.mtcomm.2018.03.008 [19] LIU C W , QU C Y, HAN L, et al. Preparation of carbon fiber-reinforced polyimide composites via in situ induction heating [J]. High Performance Polymers, 2017, 29(9): 263-273. -

下载:

下载: