Reliability estimation for aircraft hydraulic pump based on bivariate performance degradation analysis

-

摘要:

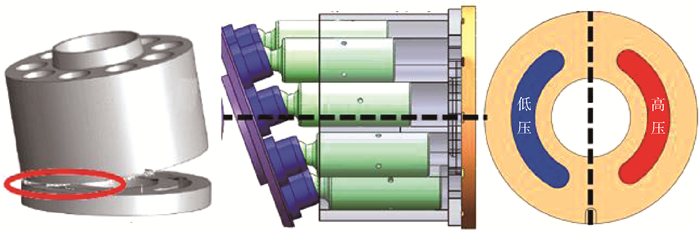

飞机液压泵为飞机操纵、起落架收放和刹车提供高压能源,其安全性和可靠性至关重要。针对飞机液压泵二维退化可靠性评估问题,构建了基于液压泵微观表面混合润滑的转子-配流盘摩擦副和轴尾密封副的摩擦磨损退化模型,基于统一随机过程模型描述2个性能指标的退化规律,利用Copula函数表征二维性能退化的相关关系,使用贝叶斯马尔可夫链蒙特卡罗法得到其考虑二元相关退化模型的未知参数估计,进而对飞机液压泵进行了可靠性评估。通过液压泵回油流量及轴尾密封摩擦力矩2个性能退化指标的实际退化数据,验证了所提出的理论和方法。结果表明,考虑2个性能退化指标相关的退化模型有效提高了可靠性评估及寿命预测精度。

Abstract:An Aircraft hydraulic pump provides high-pressure energy for aircraft manipulation, landing gear retraction and braking. Maintaining its reliability and safety is critical. In this paper, we construct a mixed lubrication wear degradation model based on the micro topography for rotor-valve plate friction pairs and axial pump mechanical seals. The unified stochastic process model is used to describe the degradation process of these two degradation performance indicators, Copula functions are used to describe the dependent relationships between two performance indicators. Bayesian Markov chain Monte Carlo method is used to estimate unknown parameters in the degradation model considering two dependent performance indicators. The results of the estimation are then utilized to conduct reliability evaluations for aircraft hydraulic pumps. The proposed theory and method were verified through real degradation test data of return oil flow for hydraulic pumps and friction torque for mechanical seals. The results show that the degradation model considering two dependent performance indicators can increase the accuracy of reliability estimation and lifetime prediction.

-

表 1 统一随机过程模型定义

Table 1. Definition of unified stochastic process model

模型 α(t) β(t) 维纳过程 μΛ(t) σ2Λ(t) 逆高斯过程 μΛ(t)

伽马过程

表 2 模型中未知参数估计结果

Table 2. Estimation results for unknown parameters in degradation model

性能指标 μ σ q X1 1.189 0.528 1.027 X2 1.098 0.171 9 1.069 注:相关系数θ=0.874 0。 -

[1] 焦宗夏, 孔祥东, 王少萍, 等. 大型飞机电液动力控制与作动系统新体系基础研究[J]. 中国基础科学, 2018, 20(2): 41-47. doi: 10.3969/j.issn.1009-2412.2018.02.006JIAO Z X, KONG X D, WANG S P, et al. Advancements of basic researches on large aircraft of electro-hydraulic power and actuation system new architecture[J]. China Basic Science, 2018, 20(2): 41-47(in Chinese). doi: 10.3969/j.issn.1009-2412.2018.02.006 [2] SHI C, WANG S P, WANG X J, et al. Variable load failure mechanism for high-speed load sensing electro-hydrostatic actuator pump of aircraft[J]. Chinese Journal of Aeronautics, 2018, 31(5): 949-964. doi: 10.1016/j.cja.2018.01.005 [3] 王少萍. 液压泵计算机辅助测试及故障诊断研究[D]. 北京: 北京航空航天大学, 1994.WANG S P. Computer aided test and fault diagnosis to hydraulic pump[D]. Beijing: Beihang University, 1994(in Chinese). [4] GUO S R, CHEN J H, LU Y L, et al. Hydraulic piston pump in civil aircraft: Current status, future directions and critical technologies[J]. Chinese Journal of Aeronautics, 2020, 33(1): 16-30. doi: 10.1016/j.cja.2019.01.013 [5] HUNT T M. Condition monitoring of ship borne hydraulic pump[D]. Bath: University of Bath, 1981. [6] LANGEN H J. Early detection of damage in hydraulic components by measurements of structure-borne sound[J]. Oelhydraul. Pneum, 1981, 25(7): 568-573. [7] IVANTYSYNOVA M, LASAAR R. An investigation into micro- and macrogeometric design of piston/cylinder assembly of swash plate machines[J]. International Journal of Fluid Power, 2004, 5(1): 23-36. doi: 10.1080/14399776.2004.10781181 [8] PELOSI M, IVANTYSYNOVA M. A novel thermal model for the piston/cylinder interface of piston machines[C]//Proceedings of ASME 2009 Dynamic Systems and Control Conference. New York: ASME, 2010: 37-44. [9] PPELOSI M, IVANTYSYNOVA M. Heat transfer and thermal elastic deformation analysis on the piston/cylinder interface of axial piston machines[J]. Journal of Tribology, 2012, 134(4): 041101. doi: 10.1115/1.4006980 [10] KASSEM S A, BAHR M K. Effect of port plate silencing grooves on performance of swash plate axial piston pumps[C]// Current Advances in Mechanical Design and Production Ⅶ. Amsterdam: Elsevier, 2000: 139-148. [11] HONG Y S, LEE S Y, KIM S H, et al. Improvement of the low-speed friction characteristics of a hydraulic piston pump by PVD-coating of TiN[J]. Journal of Mechanical Science and Technology, 2006, 20(3): 358-365. doi: 10.1007/BF02917518 [12] FANG Y, SHIRAKASHI M. Mixed lubrication characteristics between the piston and cylinder in hydraulic piston pump-motor[J]. Journal of Tribology, 1995, 117(1): 80-85. doi: 10.1115/1.2830610 [13] MANRING N D. Friction forces within the cylinder bores of swash-plate type axial-piston pumps and motors[J]. Journal of Dynamic Systems, Measurement, and Control, 1999, 121(3): 531-537. doi: 10.1115/1.2802507 [14] YAMAGUCHI A, MATSUOKA H. A mixed lubrication model applicable to bearing/seal parts of hydraulic equipment[J]. Journal of Tribology, 1992, 114(1): 116-121. doi: 10.1115/1.2920849 [15] KAZAMA T, YAMAGUCHI A. Application of a mixed lubrication model for hydrostatic thrust bearings of hydraulic equipment[J]. Journal of Tribology, 1993, 115(4): 686-691. doi: 10.1115/1.2921694 [16] 诸葛起, 路甬祥. 用振动信号检测柱塞泵松靴故障[J]. 振动、测试与诊断, 1989, 9(3): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCS198903003.htmZHUGE Q, LU Y X. Using vibration signal to detect failure of piston pump's slipper pair[J]. Journal of Vibration, Measurement & Diagnosis, 1989, 9(3): 11-15(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCS198903003.htm [17] 徐兵, 李迎兵, 张斌, 等. 轴向柱塞泵滑靴副倾覆现象数值分析[J]. 机械工程学报, 2010, 46(20): 161-168. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201020028.htmXU B, LI Y B, ZHANG B, et al. Numerical simulation of overturning phenomenon of axial piston pump slipper pair[J]. Journal of Mechanical Engineering, 2010, 46(20): 161-168(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201020028.htm [18] 刘洪, 苑士华, 彭增雄. 轴向柱塞泵滑靴油膜动态仿真[J]. 北京理工大学学报, 2011, 31(11): 1282-1286. https://www.cnki.com.cn/Article/CJFDTOTAL-BJLG201111005.htmLIU H, YUAN S H, PENG Z X. Dynamic simulation of slipper bearings in axial piston pumps[J]. Transactions of Beijing Institute of Technology, 2011, 31(11): 1282-1286(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-BJLG201111005.htm [19] 刘思远, 王闯, 杨梦雪, 等. 斜盘泵滑靴副剧烈磨损过程的动态特性分析[J]. 液压与气动, 2017(1): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ201701001.htmLIU S Y, WANG C, YANG M X, et al. Analysis of dynamic characteristics for severe wear process of swash plate axial piston pump slipper pair[J]. Chinese Hydraulics & Pneumatics, 2017(1): 1-5(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ201701001.htm [20] 杨光琴. 多传感器航空液压系统信息融合故障诊断研究[D]. 北京: 北京航空航天大学, 2003.YANG G Q. Multi-sensors fusion based fault diagnosis of aerial hydraulic system[D]. Beijing: Beihang University, 2003(in Chinese). [21] 张文超. 机载液压泵源健康管理[D]. 北京: 北京航空航天大学, 2008.ZHANG W C. Health management of airborne hydraulic pump[D]. Beijing: Beihang University, 2008(in Chinese). [22] 赵四军. 飞机液压泵源故障预测与健康管理系统关键技术研究[D]. 北京: 北京航空航天大学, 2010.ZHAO S J. Fault prognostics and health management of aircraft hydraulic power supply[D]. Beijing: Beihang University, 2010(in Chinese). [23] 杜隽. 航空液压能源系统动态失效机理与健康管理关键技术研究[D]. 北京: 北京航空航天大学, 2012.DU J. Fault mechanism and health management of aviation hydraulic system[D]. Beijing: Beihang University, 2012(in Chinese). [24] 何兆民. 航空液压泵健康状态识别与故障预测关键技术研究[D]. 北京: 北京航空航天大学, 2014.HE Z M. Health state identification and fault prediction of aircraft hydraulic pump[D]. Beijing: Beihang University, 2014(in Chinese). [25] 卢传奇. 基于分层递进的航空液压系统故障诊断与寿命预测研究[D]. 北京: 北京航空航天大学, 2017.LU C Q. Fault diagnosis and life prediction of aircraft hydraulic system based on hierarchical progression[D]. Beijing: Beihang University, 2017(in Chinese). [26] 贺文涛. 旋转机械密封失效机理与寿命预测研究[D]. 北京: 北京航空航天大学, 2020.HE W T. Failure mechanism and life prediction of rotating machinery seal[D]. Beijing: Beihang University, 2020(in Chinese). [27] MA Z H, WANG S P, LIAO H T, et al. Engineering-driven performance degradation analysis of hydraulic piston pump based on the inverse Gaussian process[J]. Quality and Reliability Engineering International, 2019, 35(7): 2278-2296. [28] CHEN R T, ZHANG C, WANG S P, et al. Reliability estimation of mechanical seals based on bivariate dependence analysis and considering model uncertainty[J]. Chinese Journal of Aeronautics, 2021, 34(5): 554-572. [29] ZHANG C, CHEN R T, BAI G H, et al. Reliability estimation of rotary lip seal in aircraft utility system based on time-varying dependence degradation model and its experimental validation[J]. Chinese Journal of Aeronautics, 2020, 33(8): 2230-2241. [30] 张超. 星载传动机构加速寿命试验理论及评估方法研究[D]. 北京: 北京航空航天大学, 2012.ZHANG C. Accelerated life test and evaluation of spaceborne transmission mechanism[D]. Beijing: Beihang University, 2012(in Chinese). -

下载:

下载: