Residual thickness detection of pipeline based on electromagnetic ultrasonic shear wave

-

摘要:

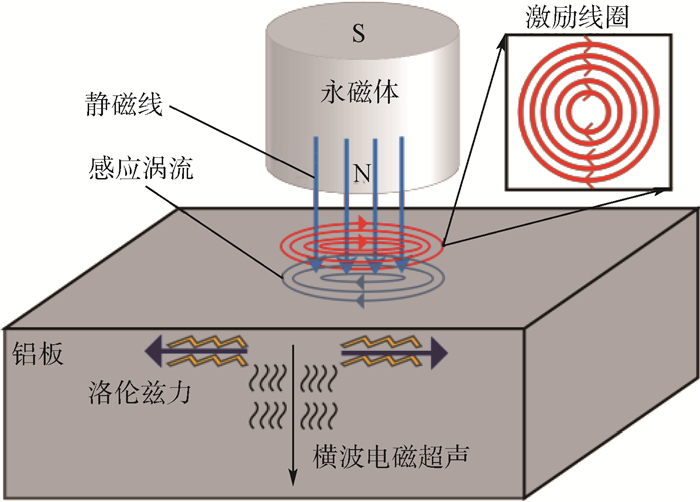

为实现管道剩余厚度的精确检测,设计了一种基于电磁超声横波的非接触式管道厚度检测系统。采用自研的电磁超声大功率激励源与换能器产生测厚横波,并由接收器对回波电压信号进行实时滤波和处理,得到铝制管道的精确剩余厚度。针对电磁超声回波的小信号和低信噪比对激励线圈参数进行优化,在此基础上对横波声束在圆形管道界面辐射特性进行分析。根据换能器线圈匝数、线圈宽度分别为回波信号峰峰值和信噪比的最大影响因子,设计优化后检测换能器并实现了误差小于0.2%的剩余厚度检测。

Abstract:To accurately detect the residual thickness of pipeline, a non-contact pipeline thickness detection system based on the electromagnetic ultrasonic shear wave was designed. The system adopts a self-developed electromagnetic ultrasonic high-power excitation source and a transducer to generate shear wave, and the receiver is used to filter and process the echo voltage signal in real-time to obtain the accurate residual thickness of the aluminum pipe. The excitation coil parameters were optimized to improve the small-signal and low signal-to-noise ratio of the receiving signal. On this basis, the beam radiation of shear waves propagating within the pipe was analyzed. Based on the fact that the number of turns of the coil and the width of the coil are the majority influence factors to the peak-to-peak value of the echo signal and the SNR respectively, the transducer is designed and the residual thickness detection accuracy with the error less than 0.2% is achieved.

-

表 1 电磁超声换能器参数优化范围

Table 1. Electromagnetic acoustic tranolucer parameter optimization range

线圈匝数 线圈宽度/mm 线圈间距/mm 4 0.2 0.8 6 0.4 1.0 8 0.6 1.2 表 2 横波电磁超声换能器参数正交测试阵列

Table 2. Shear wave electromagnetic acoustic transducer parameter orthogonal test array

试验号 线圈匝数 线圈宽度/mm 线圈间距/mm 峰峰值/mV 信噪比/dB 1 4 0.2 1.0 0.285 8 14.218 2 6 0.2 0.8 0.243 9 15.095 3 8 0.2 1.2 0.144 4 9.768 4 4 0.4 0.8 0.316 7 15.559 5 6 0.4 1.2 0.193 1 18.129 6 8 0.4 1.0 0.172 0 15.657 7 4 0.6 1.2 0.243 9 15.458 8 6 0.6 1.0 0.213 5 16.682 9 8 0.6 0.8 0.197 7 18.603 表 3 正交试验结果分析

Table 3. Analysis of orthogonal experiment results

分析因子 对峰峰值影响 对信噪比影响 Kcn1 2.8×10-4 15.08 Kcn2 2.2×10-4 16.64 Kcn3 1.7×10-4 14.68 Rcn 1.1×10-4 1.96 Kω1 2.2×10-4 13.03 Kω2 2.3×10-4 16.45 Kω3 2.2×10-4 16.91 Rω 8.9×10-6 3.89 Kl1 2.5×10-4 16.42 Kl2 2.2×10-4 15.52 Kl3 1.9×10-4 14.45 Rl 5.9×10-5 1.97 -

[1] YOSHIDA M, ASANO T. A new method to measure the oxide layer thickness on steels using electromagnetic acoustic resonance[J]. Journal of Nondestructive Evaluation, 2003, 22: 11-19. doi: 10.1023/A:1025776030607 [2] HOBBIS A, ARULESWARAN A. Non-contact thickness and profile measurements of rolled aluminium strip using EMAT[C]//AIP Conference, 2006, 820: 1772-1779. [3] PARRA-RAAD J, KHALILI P, CEGLA F. Shear waves with orthogonal polarisations for thickness measurement and crack detection using EMATs[J]. NDT & E International, 2020, 111: 1-7. [4] 王相豪. 电磁超声测厚系统的设计与实现[D]. 哈尔滨: 哈尔滨工程大学, 2018: 63-69.WANG X H. Design and realization of electromagnetic ultrasonic thickness measurement system[D]. Harbin: Harbin Engineering University, 2018: 63-69(in Chinese). [5] 唐志峰, 孙兴涛, 张鹏飞, 等. 集测厚与导波检测于一体的复合式电磁超声换能器研究[J]. 仪器仪表学报, 2020, 41(9): 98-109. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB202009011.htmTANG Z F, SUN X T, ZHANG P F, et al. Research on composite electromagnetic ultrasonic transducer integrating thickness measurement and guided wave detection[J]. Chinese Journal of Scientific Instrument, 2020, 41(9): 98-109(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB202009011.htm [6] 孙峥, 李永虔, 杨金旭, 等. 管道内检测电磁超声在线测厚装置[J]. 中国测试, 2017, 43(2): 69-72. https://www.cnki.com.cn/Article/CJFDTOTAL-SYCS201702014.htmSUN Z, LI Y W, YANG J X, et al. Thickness gauging equipment for ILI of pipelines using EMATs[J]. China Measurement & Test, 2017, 43(2): 69-72(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-SYCS201702014.htm [7] 黄松岭, 王坤, 赵伟. 电磁超声导波理论与应用[M]. 北京: 清华大学出版社, 2013: 2-29.HUANG S L, WANG K, ZHAO W. Theory and application electromagnetic ultrasonic guided wave[M]. Beijing: Tsinghua University Press, 2013: 2-29(in Chinese). [8] RIBICHINI R, NAGY P, OGI H. The impact of magnetostriction on the transduction of normal bias field emats[J]. NDT & E International, 2012, 51: 8-15. [9] MIRKHANI K, CHAGGARES C, MASTERSON C, et al. Optimal design of EMAT transmitters[J]. NDT & E International, 2004, 37(3): 181-193. [10] JIA X J, QI O Y. Optimal design of point-focusing shear vertical wave electromagnetic ultrasonic transducers based on orthogonal test method[J]. IEEE Sensors Journal, 2018, 18(19): 8064-8073. [11] YUAN W, LIU Z, LI Y, et al. Comparative analysis of emat receiving process between ferromagnetic and nonferromagnetic materials[C]//2019 IEEE International Ultrasonics Symposium (IUS). Piscataway: IEEE Press, 2019: 611-614. [12] KANG L, DIXON S, WANG K C, et al. Enhancement of signal amplitude of surface wave EMATs based on 3D simulation analysis and orthogonal test method[J]. Ndt & E International, 2013, 59: 11-17. [13] HUANG S L, ZHAO W, ZHANG Y S, et al. Study on the lift-off effect of EMAT[J]. Sensors and Actuators A: Physical, 2009, 153(2): 218-221. [14] 唐旭明, 阳能军, 李平. 电磁超声横波换能器中永磁体的建模与优化[J]. 无损探伤, 2017, 41(6): 17-22. https://www.cnki.com.cn/Article/CJFDTOTAL-WSTS201706005.htmTANG X M, YANG N J, LI P. Modeling method and optimum design of permanent magnet in elctromagnetic acoustic shear wave transduceers[J]. NDT, 2017, 41(6): 17-22(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-WSTS201706005.htm [15] PENG J, DONG F, XU Q, et al. Orthogonal test design for optimization of supercritical fluid extraction of daphnoretin, 7-methoxy-daphnoretin and 1, 5-diphenyl-1-pentanone from Stellera chamaejasme L. and subsequent isolation by high-speed counter-current chromatography[J]. Journal of Chromatography A, 2006, 1135(2): 151-157. [16] AUGUSTYNIAK M, USAREK Z. Finite element method applied in electromagnetic NDTE: A review[J]. Journal of Nondestructive Evaluation, 2016, 35(3): 1-15. [17] DAVID J, CHEEKE N. Fundamentals and applications of ultrasonic waves[M]. 2nd ed. Boca Raton: CRC Press, 2010: 76-90. -

下载:

下载: