Function oriented belief reliability design and optimization of new torsion spring electrical connectors

-

摘要:

新产品正向设计需综合考虑新结构工艺、多设计变量、复杂工作环境的影响,并合理量化不确定性影响,评估可靠性水平,从而在源头上确保高可靠性。基于确信可靠性理论,研究了基于性能裕量的确信可靠性正向设计优化方法。提出了面向新型扭簧电连接器研发的确信可靠性正向设计优化基本流程,包括设计变量初值优选、性能裕量建模、不确定性量化和确信可靠性分析与优化4部分。以某新型扭簧电连接器的正向设计为例,基于正交实验、响应面建模和模拟退火启发式优化等方法实现了多维离散-连续变量及其不确定性作用下的优化设计。

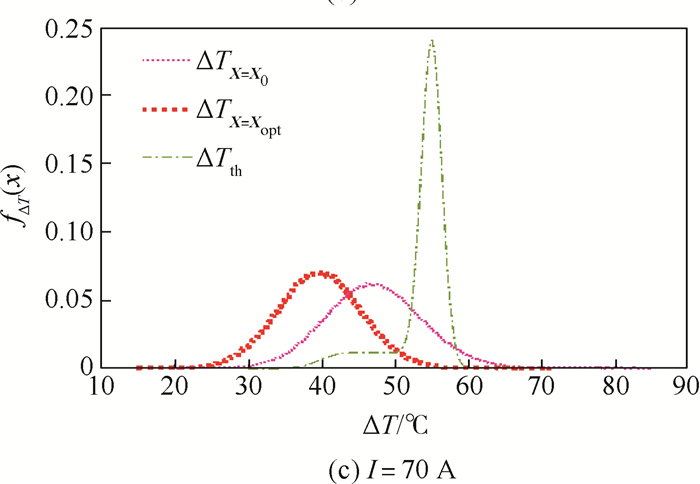

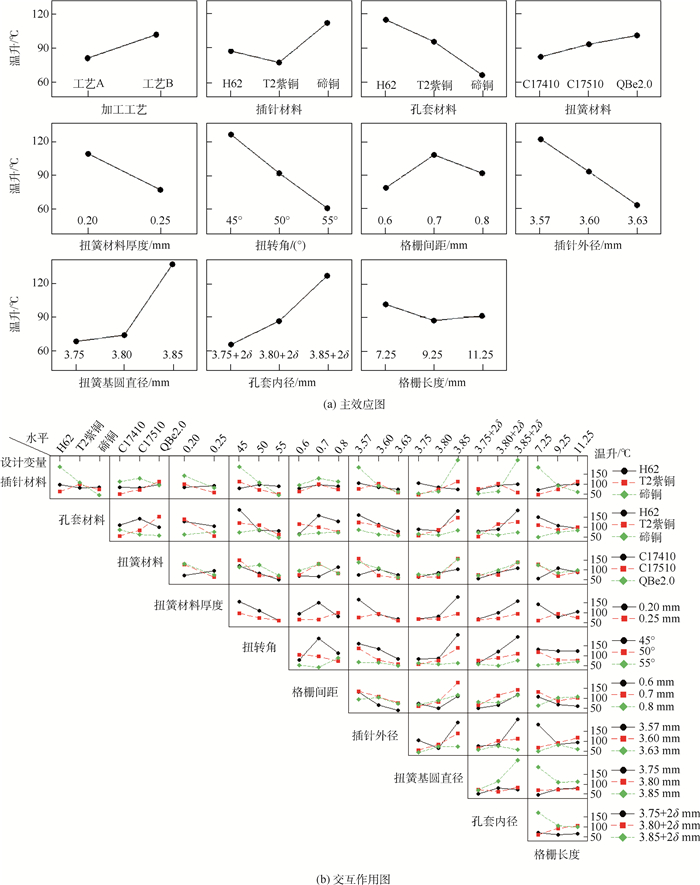

Abstract:To evaluate reliability of new products, function-oriented design should comprehensively consider the influence of new structure and technology, multiple design variables, and complex working environments, and reasonably quantify uncertainty effects. This will ensure high reliability from the original design. Based on the belief reliability theory, this study investigates a performance margin-based and function-oriented method for belief reliability design and optimization. The basic procedure of the function-oriented reliability design is proposed for the development of new torsion spring electrical connectors, which includes four steps, i.e., initial value selection of design variables, performance margin modeling, uncertainty quantification, and reliability analysis and optimization. This procedure is exemplified in the design and development of a new type of torsion spring electrical connector. The optimal design of multidimensional discrete-continuous variables under the influence of their uncertainties is realized based on orthogonal experiments, response surface modeling, and simulated annealing heuristic optimization.

-

表 1 内因变量分析

Table 1. Analysis of endogenous variables

序号 影响因素 变量类型 水平数 水平 1 加工工艺 D 2 工艺A、工艺B 2 粗糙度Ra D 3 0.8、1.6、3.2 3 镀层材料 D 3 金、银、镍 4 插针材料 D 3 T2紫铜、碲铜、H62 5 孔套材料 D 3 T2紫铜、碲铜、H62 6 扭簧材料 D 3 C17410、C17510、QBe2.0 7 扭簧材料厚度δ D 2 0.2 mm、0.25 mm 8 扭转角θ C 3 45°、50°、55° 9 格栅间距s C 3 0.6 mm、0.7 mm、0.8 mm 10 插针外径dp C 3 3.57 mm、3.60 mm、3.63 mm 11 扭簧基圆直径ds C 3 3.75 mm、3.80 mm、3.85 mm 12 孔套内径dh C 3 2δ+{3.75, 3.80, 3.85} mm 13 格栅长度l C 3 7.25 mm、9.25 mm、11.25 mm 表 2 确定最优设计变量初值

Table 2. Determination of optimal initial values

序号 内因变量 数值特征 初步优选水平 是否变更 水平变更 1 加工工艺 D 工艺A √ 工艺B 2 粗糙度Ra D 0.8 3 镀层材料 D 金 4 插针材料 D T2 5 孔套材料 D 碲铜 6 扭簧材料 D C17410 7 扭簧材料厚度δ D 0.2 mm 8 扭转角θ C 55° √ 65 mm 9 格栅间距s C 0.6 mm 10 插针外径dp C 3.63 mm √ 3.57 mm 11 扭簧基圆直径ds C 3.75 mm 12 孔套内径dh C 2δ+3.75 mm √ 4.2 mm 13 格栅长度l C 7.25 mm 表 3 响应面采样点

Table 3. Sampling points of response surface

变量 采样边界 -1 1 扭转角θ/(°) 55 75 格栅间距s/mm 0.5 0.9 插针外径dp/mm 3.57 3.60 扭簧基圆直径ds/mm 3.75 3.80 孔套内径dh/mm 4.2 4.25 格栅长度l/mm 5.25 9.25 电流Ii2/A2 1 600 4 900 环境温度Te/℃ -40 150 表 4 随机变量的分布

Table 4. Distribution of random variables

变量 分布 均值μ 标准差σ 随机扰动ε Φε 0 5.35℃ 扭簧基圆直径ds Φds μds 0.001 mm 扭转角θ Φθ μθ 4° 孔套内径dh Φdp μdp 0.01 mm 格栅间距s Φs μs 0.01 mm 电流Ii ΦI μI 0.05μI/3 A 环境温度Te ΦTe μTe 5/3℃ 温升阈值ΔTth ΦΔTth E[ΔTth(I, Te)]

表 5 确信可靠度优化结果

Table 5. Results of belief reliability optimization

变量 取值范围 正向设计优化 初值X0 优化值Xopt 扭簧基圆直径ds/mm [3.75, 3.80] 3.75 3.773 扭转角θ/(°) [55,75] 65 73.87 孔套内径dh/mm [4.20, 4.25] 4.2 4.202 格栅间距s/mm [0.5, 0.9] 0.6 0.5 确信可靠度理论值R 0.978 5 0.994 7 -

[1] 李志萍. 电动汽车传导式充电接口关键技术研究[D]. 成都: 电子科技大学, 2014: 18-21.LI Z P. Research on key techniques of conductive charge coupler of electric vehicle[D]. Chengdu: University of Electronic Science and Technology of China, 2014: 18-21(in Chinese). [2] 吴珊珊. 电动汽车充电连接器的热性能研究[D]. 北京: 北京邮电大学, 2020: 4-7.WU S S. Study on thermal performance of electric vehicle connectors[D]. Beijing: Beijing University of Posts and Telecommunications, 2020: 4-7(in Chinese). [3] 王世娇, 陈文华, 钱萍, 等. 航天电连接器的可靠性设计建模[J]. 机械工程学报, 2017, 53(10): 180-186.WANG S J, CHEN W H, QIAN P, et al. Reliability design model of aerospace electrical connector[J]. Journal of Mechanical Engineering, 2017, 53(10): 180-186(in Chinese). [4] 汪日超, 张伟, 徐佳济, 等. 电连接器接触件结构分析与结构参数优化设计[J]. 机械制造与自动化, 2021, 50(3): 136-139.WANG R C, ZHANG W, XU J J, et al. Structural ansysis of electrical connector contacts and optimization design of structural parameters[J]. Machine Building & Automation, 2021, 50(3): 136-139(in Chinese). [5] 关凌宇. 线簧连接器的特性研究[D]. 北京: 北京邮电大学, 2018: 25-28.GUAN L Y. Research on the characteristics of wire spring connector[D]. Beijing: Beijing University of Posts and Telecommunications, 2018: 25-28(in Chinese). [6] KYEONG S, PECHT M. Electrical connectors[M]. New York: Wiley, 2020: 173-196. [7] 田楠. 连接器不同触点材料滑动接触特性及可靠性分析[D]. 北京: 北京邮电大学, 2019: 11-15.TIAN N. Sliding contact characteristics and reliability analysis of different contact materials of connector[D]. Beijing: Beijing University of Posts and Telecommunications, 2019: 11-15(in Chinese). [8] 凌三强, 徐乐, 付饶, 等. 基于稳健性设计原理的接触件插拔力质量一致性优化方法[J]. 机械工程学报, 2017, 53(4): 190-197.LING S Q, XU L, FU R, et al. Optimization method of quality consistency for insertion force of electrical contact based on robust design principle[J]. Journal of Mechanical Engineering, 2017, 53(4): 190-197(in Chinese). [9] WANG R Y, XU L J, ZHOU Y L. A systematic approach for the reliability evaluation of electric connector[J]. Journal of Electrical and Computer Engineering, 2021, 2021: 5514674. [10] JENSEN H A, SEPULVEDA J G. Structural optimization of uncertain dynamical systems considering mixed-design variables[J]. Probabilistic Engineering Mechanics, 2011, 26(2): 269-280. doi: 10.1016/j.probengmech.2010.08.005 [11] ZHU N, ZHAI G F, GUO Z Y. Research on contact reliability design of electrical connector contact[C]//2019 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE). Piscataway: IEEE Press, 2019: 155-160. [12] 康锐. 确信可靠性理论与方法[M]. 北京: 国防工业出版社, 2020: 26-29.KANG R. Belief reliability theory and methodology[M]. Beijing: National Defense Industry Press, 2020: 26-29(in Chinese). [13] 张清源, 文美林, 康锐, 等. 基于确信可靠性的功能、性能与裕量分析方法[J]. 系统工程与电子技术, 2021, 43(5): 1413-1419.ZHANG Q Y, WEN M L, KANG R, et al. Function, performance and margin analysis method based on belief reliability[J]. Systems Engineering and Electronics, 2021, 43(5): 1413-1419(in Chinese). [14] 范梦飞, 曾志国, 康锐. 基于确信可靠度的可靠性评价方法[J]. 系统工程与电子技术, 2015, 37(11): 2648-2653. doi: 10.3969/j.issn.1001-506X.2015.11.34FAN M F, ZENG Z G, KANG R. An approach to measure reliability based on belief reliability[J]. Systems Engineering and Electronics, 2015, 37(11): 2648-2653(in Chinese). doi: 10.3969/j.issn.1001-506X.2015.11.34 [15] 李泊远, 康锐, 余丽. 基于概率测度的确信可靠性建模与分析方法[J]. 系统工程与电子技术, 2021, 43(7): 1995-2004.LI B Y, KANG R, YU L. Belief reliability modelling and analysis method based on the probability measure[J]. Systems Engineering and Electronics, 2021, 43(7): 1995-2004(in Chinese). [16] 陈文彬, 李晓阳, 童邦安, 等. 谐波减速器的传动效率确信可靠性建模与分析[J]. 振动工程学报, 2022, 35(1): 237-245.CHEN W B, LI X Y, TONG B G, et al. Belief reliability modeling and analysis for transmission efficiency of harmonic gear[J]. Journal of Vibration Engineering, 2022, 35(1): 237-245(in Chinese). [17] 李晓阳. 加速退化试验——不确定性量化与控制[M]. 北京: 国防工业出版社, 2022: 25-26.LI X Y. Accelerated degradation testing: Quantification and control of uncertainties[M]. Beijing: National Defense Industry Press, 2022: 25-26(in Chinese). [18] 汪天宇. 大功率连接器的可靠性研究与设计[D]. 北京: 北京邮电大学, 2021: 1-7.WANG T Y. Research and reliability design of high power connector[D]. Beijing: Beijing University of Posts and Telecommunications, 2021: 1-7(in Chinese). [19] USCAR. Performance specification for automotive electrical connector systems: SAE/USCAR-2 Rev. 7[S]. Warrendale: SAE International, 2020: 22-26. [20] 陈孟, 黄庆, 翁羽, 等. 自然对流换热系数计算方法研究[C]//第十七届全国反应堆结构力学会议, 2012: 217-221.CHEN M, HUANG Q, WENG Y, et. al. The computational method for heat transfer film coefficient of nature convection[C]//Proceedings of the 17th National Conference on Reactor Structural Mechanics, 2012: 217-221(in Chinese). [21] 王静. 高强度正交表的构造及D-最优增广设计[D]. 上海: 上海师范大学, 2021: 1-5.WANG J. Construction of orthogonal arrays with high strength and D-optimal augmented designs[D]. Shanghai: Shanghai Normal University, 2021: 1-5(in Chinese). [22] KAYMAZ I, MCMAHON C A. A response surface method based on weighted regression for structural reliability analysis[J]. Probabilistic Engineering Mechanics, 2005, 20(1): 11-17. [23] HUANG X Z, LIU Y, ZHANG Y M, et al. Reliability analysis of structures using stochastic response surface method and saddlepoint approximation[J]. Structural and Multidisciplinary Optimization, 2017, 55(6): 2003-2012. [24] IEC. Appliance couplers for household and similar general purposes-Part 1: General requirements: IEC 60320-1 ED4[S]. Geneva: IEC, 2021: 36-38, 68-71. [25] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 电动汽车传导充电用连接装置第1部分: 通用要求: GB/T 20234.1—2015[S]. 北京: 中国标准出版社, 2016: 3-10.General administration of quality supervision, inspection and quarantine, China national standardization administration committee. Connection set of conductive charging for electric vehicles-Part 1: General requirements: GB/T 20234.1—2015[S]. Bejing: China Standard Press, 2016: 3-10(in Chinese). -

下载:

下载: