-

摘要:

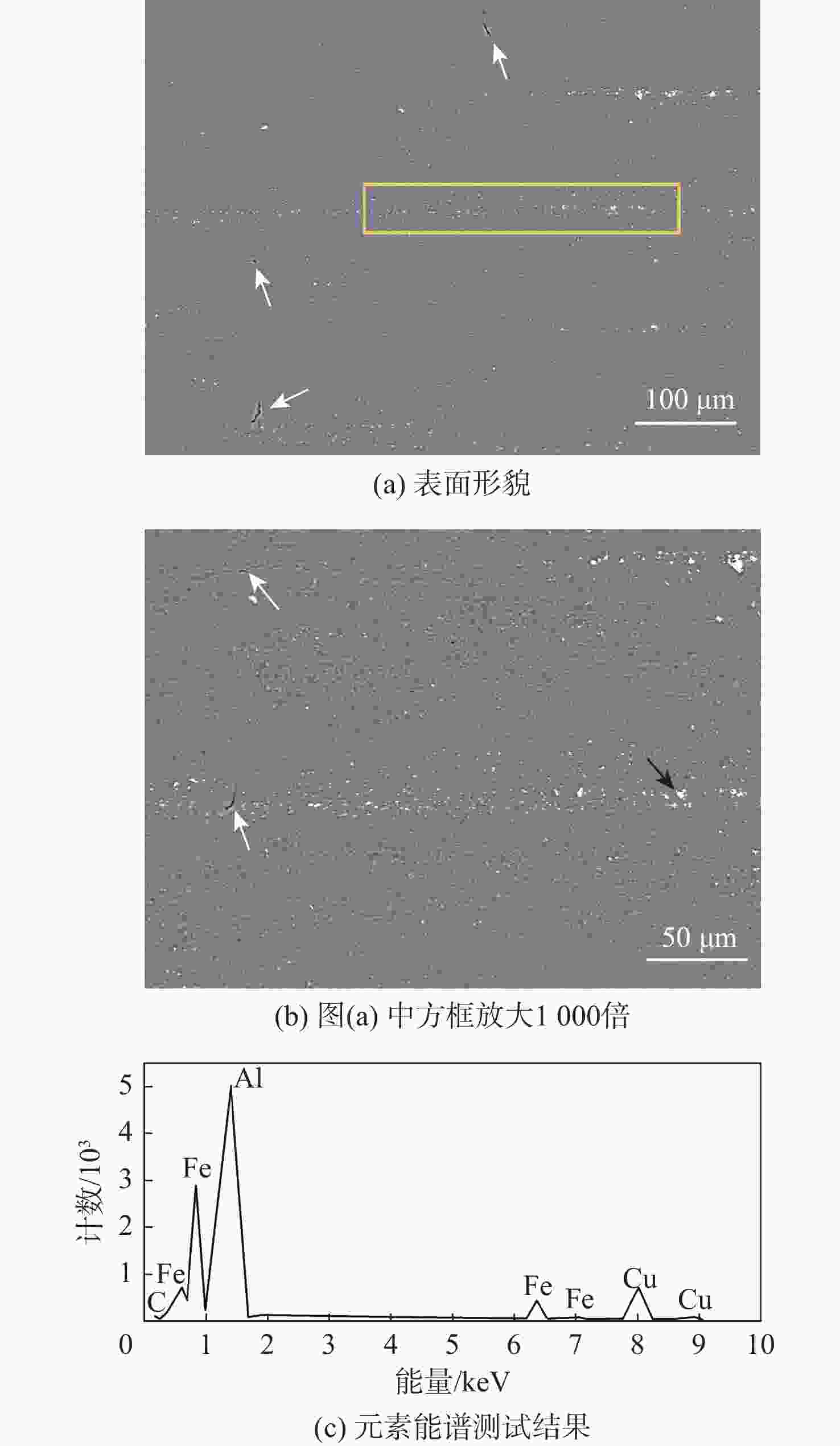

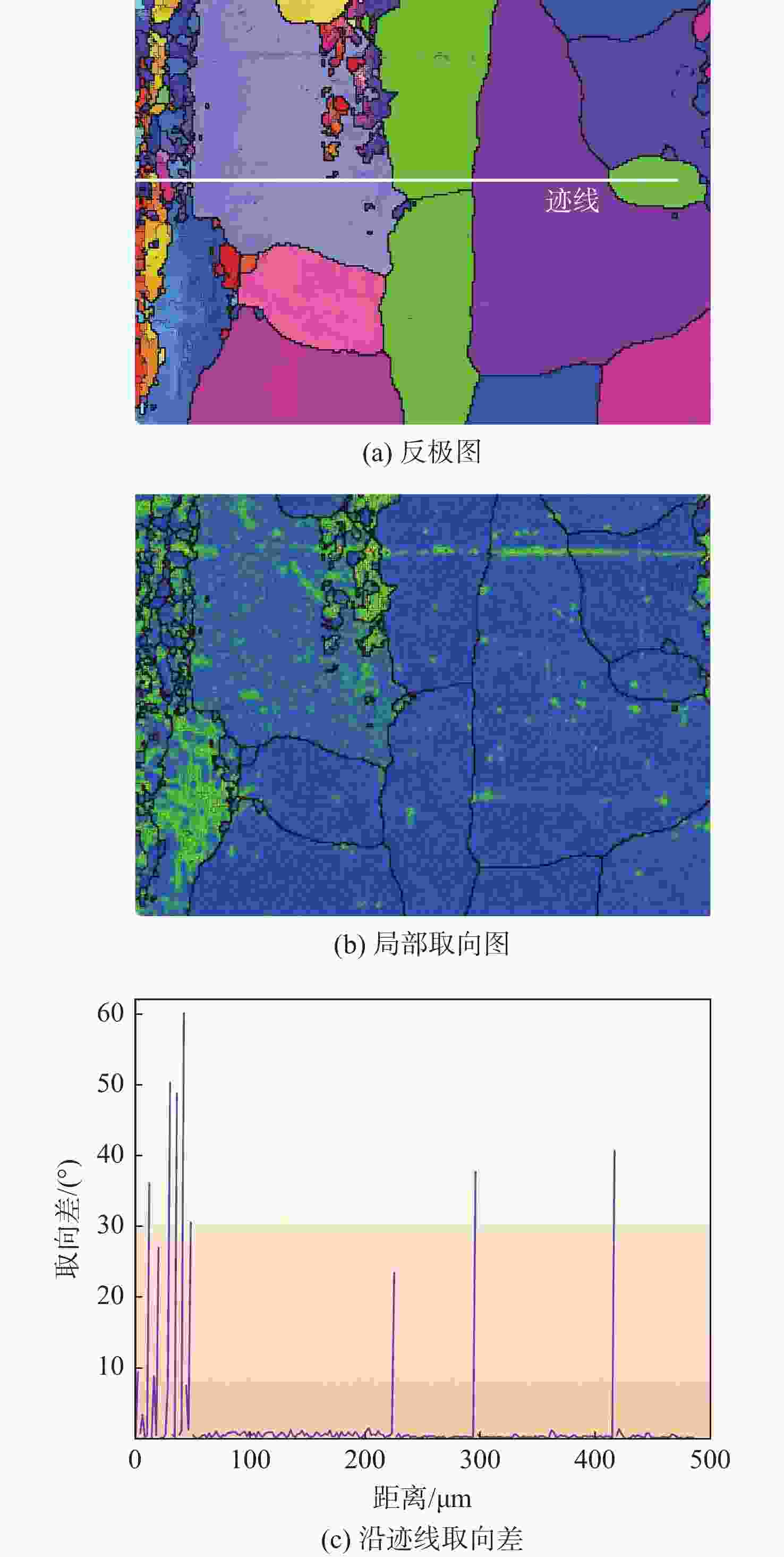

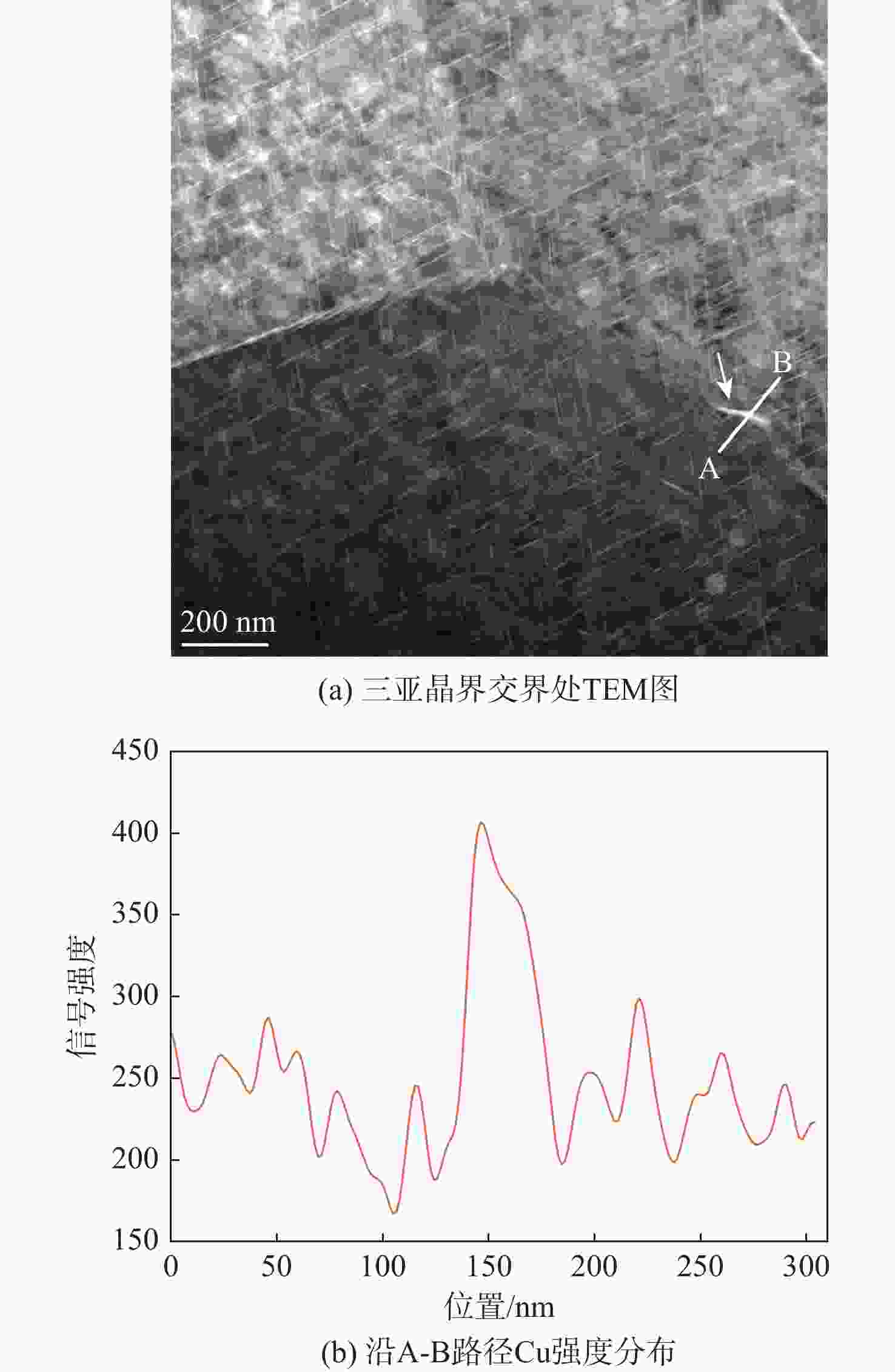

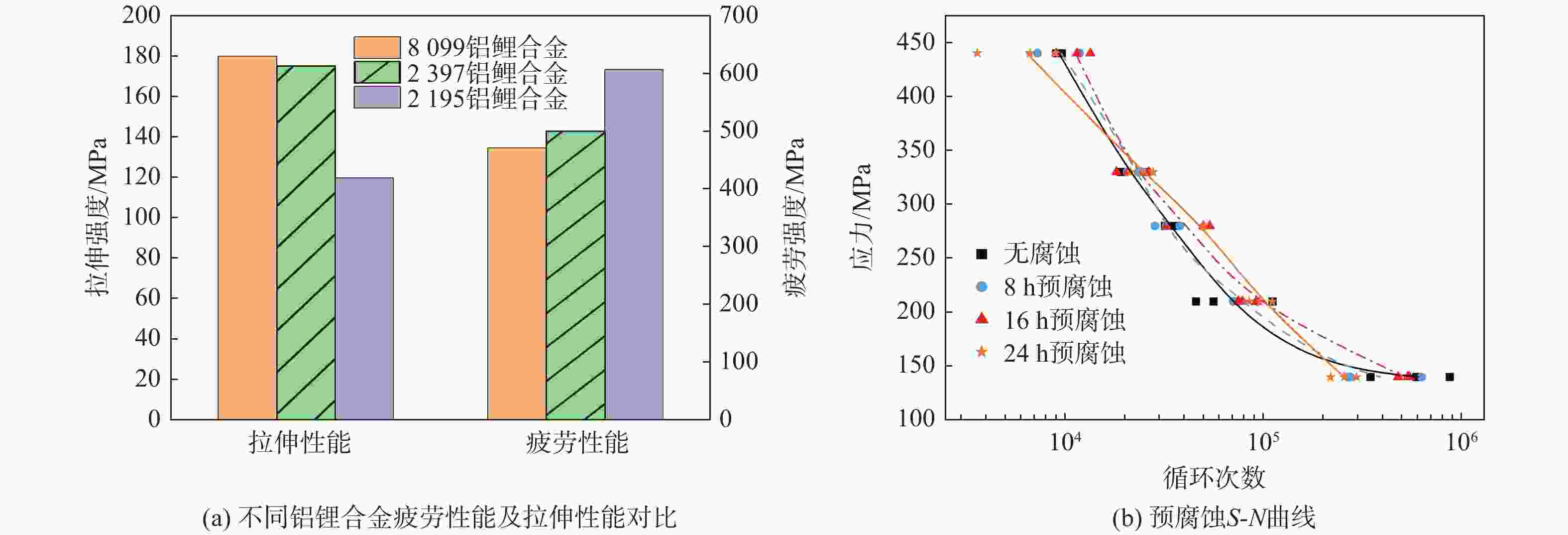

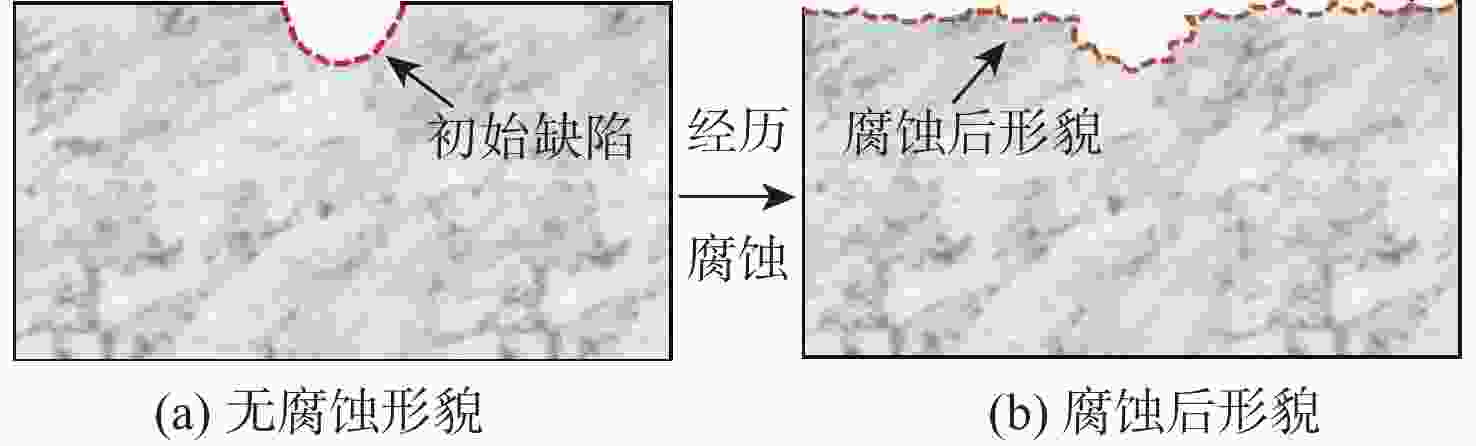

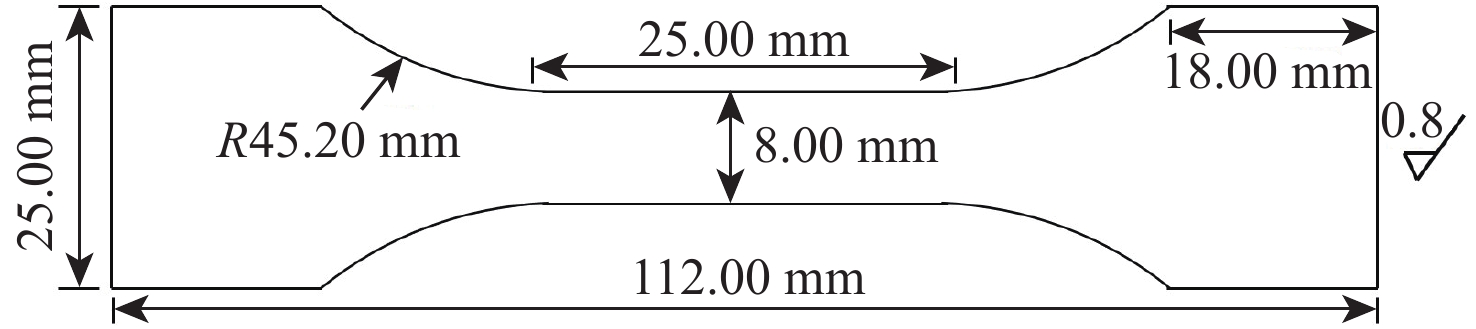

模拟液体导弹贮箱材料和使用特点,进行2195-T8 铝锂合金在30% 硝酸溶液中预腐蚀不同时间后的疲劳试验,利用扫描电子显微镜(SEM)、电子背散射衍射仪(EBSD)及透射电子显微镜(TEM)等显微表征方法,研究了预腐蚀对疲劳性能的影响。结果表明:预腐蚀表面形貌以晶间腐蚀和点蚀为主,在轧制方向上形成条带状腐蚀链,其产生与长条形晶界和金属间粒子连续腐蚀作用相关; 经预腐蚀后,铝锂合金试样在210 ,280,330 MPa中等应力幅下的预腐蚀疲劳寿命较无腐蚀试样有所增加,16 h腐蚀试样寿命提高最为明显,其原因是腐蚀通过将合金表面微裂纹、孔洞等缺陷消除、增加表面粗糙度等方式,降低了应力集中程度,进而延缓了疲劳裂纹萌生。

Abstract:To simulate the material and application characteristics of liquid-missile propellant tanks, fatigue tests were carried out after pre-corrosion in 30% HNO3 for different hours. Effects of pre-corrosion on fatigue properties were investigated by scanning electron microscopy (SEM), transmission electron microscope (TEM), and electron backscatter detector (EBSD) methods. The results show that the surface morphology after corrosion is mainly composed of intergranular corrosion and pitting. Stripped corrosion chains are produced along the rolling direction, which are related with corroded long grain boundaries and intermetallic particles. The fatigue limit values of pre-corroded specimens are lower than those of the uncorroded specimens. The fatigue limit of 16 h corroded specimens is the highest, while the limit of 24 h corroded specimens declines to zero. The fatigue cycles under median stress amplitudes of 210 MPa, 280 MPa and 330 MPa, higher than those of uncorroded specimens, and the increase of 16 h corroded specimens is the most obvious. The enhancement of fatigue cycles attributes to the elimination of microcracks, pores and the improvement of surface roughness through pre-corrosion, which reduces the stress concentration and retards the crack initiation.

-

Key words:

- Al-Li alloys /

- propellant tank /

- pre-corrosion /

- fatigue properties /

- crack initiation

-

表 1 2195-T8铝锂合金力学性能

Table 1. Mechanical properties of 2195-T8 Al-Li alloys

弹性模量

E/GPa屈服强度σs/MPa 极限强度

σb/MPa延伸率/% 72.90 583.33 609.90 11.4 表 2 不同预腐蚀时间下疲劳寿命

Table 2. Fatigue cycles under different pre-corrosion durations

时间/h 应力/MPa 疲劳寿命/次 N50/次 σ 0 140 867558,345447,587392 560449 0.201 210 45680,55923,110945 65687 0.202 280 35504,35196,31748 34106 0.027 330 25535,19844,19068 21299 0.068 440 9027,9630,9322 9323 0.014 8 140 274086,624517,266834 357457 0.209 210 92995,74407,70273 78536 0.064 280 28399,37898,32243 32618 0.063 330 24911,23303,20549 22849 0.042 440 9996,10176,10012 10086 0.004 16 140 543995,476059,533021 516813 0.031 210 92055,74507,78209 81252 0.048 280 49749,53557,42351 48323 0.052 330 20723,18132,26496 21513 0.083 440 9032,11481,13426 11166 0.087 24 140 254628,217528,293901 253439 0.065 210 84543,95573,110622 96328 0.058 280 50236,49204,49803 49746 0.005 330 24163,27778,21368 24296 0.057 440 7611,7926,6660 5988 0.039 -

[1] XU Y, WANG X J, YAN Z T, et al. Corrosion properties of light-weight and high-strength 2195 Al-Li alloy[J]. Chinese Journal of Aeronautics, 2011, 24(5): 681-686. doi: 10.1016/S1000-9361(11)60080-0 [2] LIN Y, ZHENG Z Q, LI S C, et al. Microstructures and properties of 2099 Al-Li alloy[J]. Materials Characterization, 2013, 84: 88-99. doi: 10.1016/j.matchar.2013.07.015 [3] GOEBEL J, GHIDINI T, GRAHAM A J. Stress-corrosion cracking characterisation of the advanced aerospace Al–Li 2099-T86 alloy[J]. Materials Science and Engineering:A, 2016, 673: 16-23. doi: 10.1016/j.msea.2016.07.013 [4] ABD EL-ATY A, XU Y, GUO X Z, et al. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review[J]. Journal of Advanced Research, 2018, 10: 49-67. doi: 10.1016/j.jare.2017.12.004 [5] WANG X H, WANG J H, YUE X, et al. Effect of aging treatment on the exfoliation corrosion and stress corrosion cracking behaviors of 2195 Al–Li alloy[J]. Materials & Design, 2015, 67: 596-605. [6] CHARALAMPIDOU C, DIETZEL W, ZHELUDKEVICH M, et al. Corrosion-induced mechanical properties degradation of Al-Cu-Li (2198-T351) aluminum alloy and the role of side-surface cracks[J]. Corrosion Science, 2021, 183: 109330. doi: 10.1016/j.corsci.2021.109330 [7] MA Y, ZHOU X, HUANG W, et al. Localized corrosion in AA2099-T83 aluminum–lithium alloy: The role of intermetallic particles[J]. Materials Chemistry and Physics, 2015, 161: 201-210. doi: 10.1016/j.matchemphys.2015.05.037 [8] DE SOUSA ARAUJO J V, MILAGRE M X, FERREIRA R O, et al. Exfoliation and intergranular corrosion resistance of the 2198 Al–Cu–Li alloy with different thermomechanical treatments[J]. Materials and Corrosion, 2020, 71(12): 1957-1970. doi: 10.1002/maco.202011839 [9] LIU J H, ZHAO K, YU M, et al. Effect of surface abrasion on pitting corrosion of Al-Li alloy[J]. Corrosion Science, 2018, 138: 75-84. doi: 10.1016/j.corsci.2018.04.010 [10] LEI X W, SAATCHI A, GHANBARI E, et al. Studies on pitting corrosion of Al-Cu-Li alloys part I: Effect of Li addition by microstructural, electrochemical, In-situ, and pit depth analysis[J]. Materials, 2019, 12(10): 1600. [11] ZHONG J, ZHONG S, ZHENG Z Q, et al. Fatigue crack initiation and early propagation behavior of 2A97 Al–Li alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 303-309. doi: 10.1016/S1003-6326(14)63061-2 [12] 薛喜丽, 郑子樵, 胡芳, 等. 时效制度对2A97铝锂合金疲劳裂纹扩展速率的影响[J]. 稀有金属材料与工程, 2016, 45(12): 3319-3324.XUE X L, ZHENG Z Q, HU F, et al. Effect of aging conditions on the fatigue crack propagation rate of 2A97 aluminum-lithium alloy[J]. Rare Metal Materials and Engineering, 2016, 45(12): 3319-3324 (in Chinese). [13] 许罗鹏, 曹小建, 李久楷, 等. 铝锂合金2198-T8高周疲劳性能及其裂纹萌生机理[J]. 稀有金属材料与工程, 2017, 46(1): 83-89.XU L P, CAO X J, LI J K, et al. High cycle fatigue properties and crack initiation mechanisms of Al-Li 2198-T8 alloy[J]. Rare Metal Materials and Engineering, 2017, 46(1): 83-89 (in Chinese). [14] 范雪松, 郑子樵, 张龙, 等. 2397合金高周疲劳性能及裂纹萌生扩展行为[J]. 稀有金属材料与工程, 2017, 46(5): 1327-1333.FAN X S, ZHENG Z Q, ZHANG L, et al. High-cycle fatigue properties and crack initiation and propagation behavior of 2397 alloy[J]. Rare Metal Materials and Engineering, 2017, 46(5): 1327-1333 (in Chinese). [15] TIAN G, JIN G F, ZHANG W, et al. Investigation on electrochemical corrosion characteristics of 2A14 aluminum alloy in nitric acid[J]. Surface Review and Letters, 2017, 24(1): 1850016. [16] LIU D J, TIAN G, JIN G F, et al. Characterization of localized corrosion pathways in 2195-T8 Al–Li alloys exposed to acidic solution[J]. Defence Technology, 2023, 25: 152-165. doi: 10.1016/j.dt.2022.05.004 [17] 刘涛, 高怡斐, 董莉, 等. 金属材料疲劳试验轴向应变控制方法: GB/T 26077—2010[S]. 北京: 中国国家标准化管理委员会, 2011: 5-6.LIU T, GAO Y F, DONG L, et al. Metallic materials-fatigue testing-axial strain-controlled method: GB/T 26077—2010[S]. Beijing:Standardization Administration of China, 2011: 5-6. [18] 高舜之, 何荣年. 金属轴向疲劳试验方法: GB 3075-82[S]. 北京: 冶金部钢铁研究总院, 1982: 7-9.GAO S Z, HE R N. Method of axial force controlled fatigue testing of metals: GB 3075-82[S]. Beijing:Iron and Steel Research Institute of the Ministry of Metallurgy, 1982: 7-9. [19] 刘轩, 刘慧丛, 李卫平, 等. 7075铝合金在不同温度盐水环境中的腐蚀疲劳行为[J]. 航空学报, 2014, 35(10): 2850-2856.LIU X, LIU H C, LI W P, et al. Corrosion fatigue behavior of 7075 aluminum alloy in saline water environment at different temperatures[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(10): 2850-2856 (in Chinese). [20] LUO C, ALBU S P, ZHOU X R, et al. Continuous and discontinuous localized corrosion of a 2xxx aluminum–copper–lithium alloy in sodium chloride solution[J]. Journal of Alloys and Compounds, 2016, 658: 61-70. doi: 10.1016/j.jallcom.2015.10.185 [21] 李劲风, 郑子樵, 李世晨, 等. 2195铝-锂合金晶间腐蚀及剥蚀行为研究[J]. 材料科学与工程学报, 2004, 22(5): 640-643. doi: 10.3969/j.issn.1673-2812.2004.05.005LI J F, ZHENG Z Q, LI S C, et al. Study on intergranular corrosion and exfoliation corrosion behaviors of 2195 Al-Li alloy[J]. Journal of Materials Science and Engineering, 2004, 22(5): 640-643 (in Chinese). doi: 10.3969/j.issn.1673-2812.2004.05.005 [22] 孔祥, 郑子樵, 李劲风, 等. 时效制度对2099铝锂合金力学和应力腐蚀性能的影响[J]. 稀有金属材料与工程, 2016, 45(12): 3271-3277.KONG X, ZHENG Z Q, LI J F, et al. Effects of aging treatment on mechanical and stress corrosion properties of 2099 alloy[J]. Rare Metal Materials and Engineering, 2016, 45(12): 3271-3277 (in Chinese). [23] ZHANG X, ZHOU X, HASHIMOTO T, et al. The influence of grain structure on the corrosion behaviour of 2A97-T3 Al-Cu-Li alloy[J]. Corrosion Science, 2017, 116: 14-21. doi: 10.1016/j.corsci.2016.12.005 [24] HUGHES A E, BOAG A, GLENN A M, et al. Corrosion of AA2024-T3 Part II: Co-operative corrosion[J]. Corrosion Science, 2011, 53(1): 27-39. doi: 10.1016/j.corsci.2010.09.030 [25] LI M C, SEYEUX A, WIAME F, et al. Insights on the Al-Cu-Fe-Mn intermetallic particles induced pitting corrosion of Al-Cu-Li alloy[J]. Corrosion Science, 2020, 176: 109040. doi: 10.1016/j.corsci.2020.109040 [26] SONG H P, LIU C C, ZHANG H, et al. In-situ SEM study of fatigue micro-crack initiation and propagation behavior in pre-corroded AA7075-T7651[J]. International Journal of Fatigue, 2020, 137: 105655. doi: 10.1016/j.ijfatigue.2020.105655 [27] MA M Y, ZHANG J Y, YI D Q, et al. Investigation of high-cycle fatigue and fatigue crack propagation characteristic in 5083-O aluminum alloy[J]. International Journal of Fatigue, 2019, 126: 357-368. doi: 10.1016/j.ijfatigue.2019.05.020 [28] 马少华, 回丽, 周松, 等. 腐蚀环境对预腐蚀铝合金腐蚀疲劳性能的影响[J]. 材料工程, 2015, 43(2): 91-95. doi: 10.11868/j.issn.1001-4381.2015.02.015MA S H, HUI L, ZHOU S, et al. Influence of corrosion environments on corrosion fatigue property of pre-corroded aluminum alloy[J]. Journal of Materials Engineering, 2015, 43(2): 91-95 (in Chinese). doi: 10.11868/j.issn.1001-4381.2015.02.015 [29] 周松, 谢里阳, 回丽, 等. 航空铝合金预腐蚀疲劳寿命退化规律[J]. 东北大学学报(自然科学版), 2016, 37(7): 969-973. doi: 10.3969/j.issn.1005-3026.2016.07.013ZHOU S, XIE L Y, HUI L, et al. Fatigue life degenerating rule of pre-corroded aviation aluminum alloy[J]. Journal of Northeastern University (Natural Science), 2016, 37(7): 969-973 (in Chinese). doi: 10.3969/j.issn.1005-3026.2016.07.013 [30] 佘玲娟, 郑子樵, 钟申, 等. 6156-T62铝合金的高周疲劳性能研究[J]. 稀有金属材料与工程, 2012, 41(7): 1201-1205. doi: 10.3969/j.issn.1002-185X.2012.07.016SHE L J, ZHENG Z Q, ZHONG S, et al. High cycle fatigue performance of 6156-T62 aluminum alloy[J]. Rare Metal Materials and Engineering, 2012, 41(7): 1201-1205 (in Chinese). doi: 10.3969/j.issn.1002-185X.2012.07.016 [31] 章刚, 刘军, 刘永寿, 等. 表面粗糙度对表面应力集中系数和疲劳寿命影响分析[J]. 机械强度, 2010, 32(1): 110-115.ZHANG G, LIU J, LIU Y S, et al. Effect of roughness on surface stress concentration factor and fatigue life[J]. Journal of Mechanical Strength, 2010, 32(1): 110-115 (in Chinese). -

下载:

下载: