Ultrasonic longitudinal torsional and low frequency torsional compound vibration tapping experiment

-

摘要:

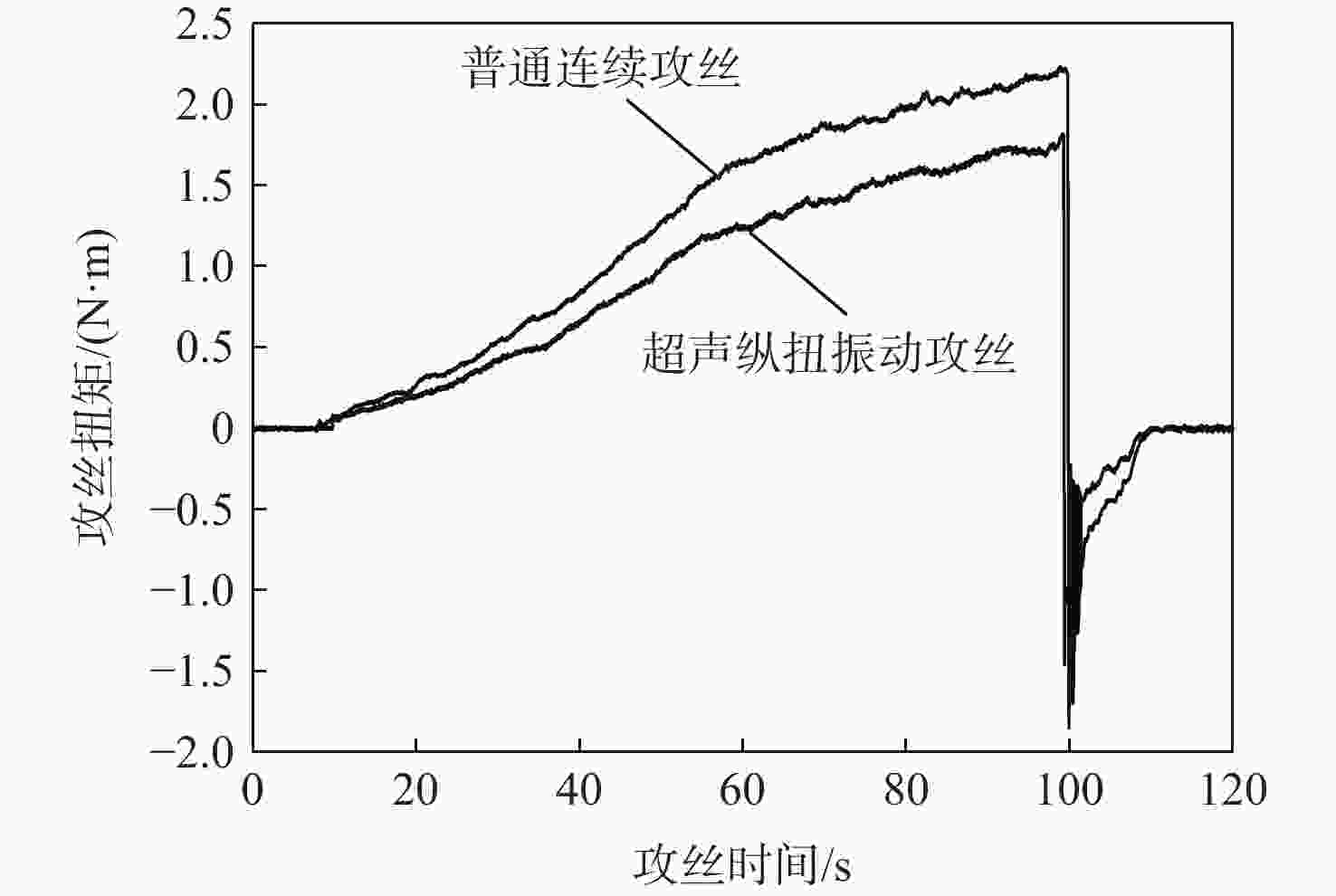

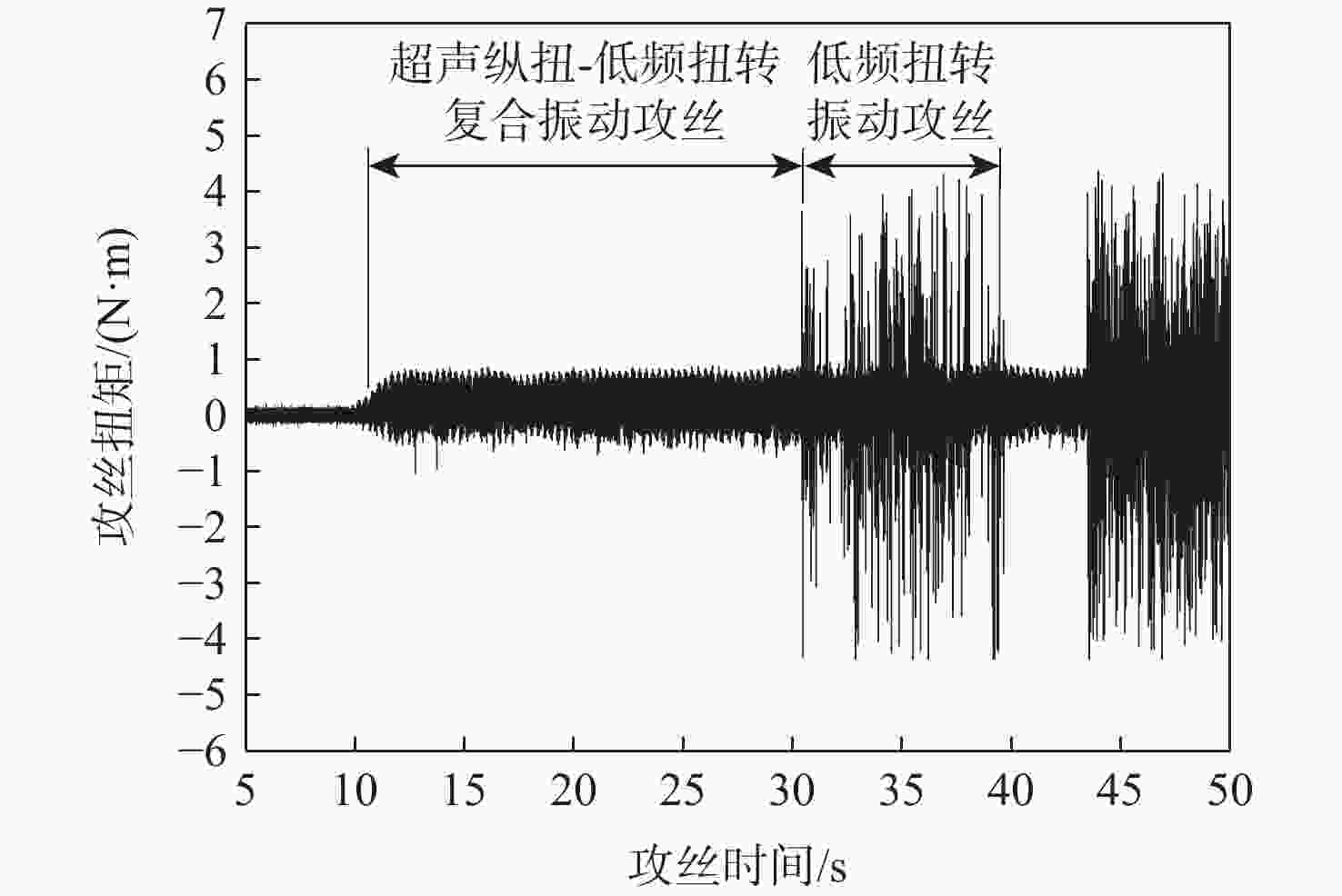

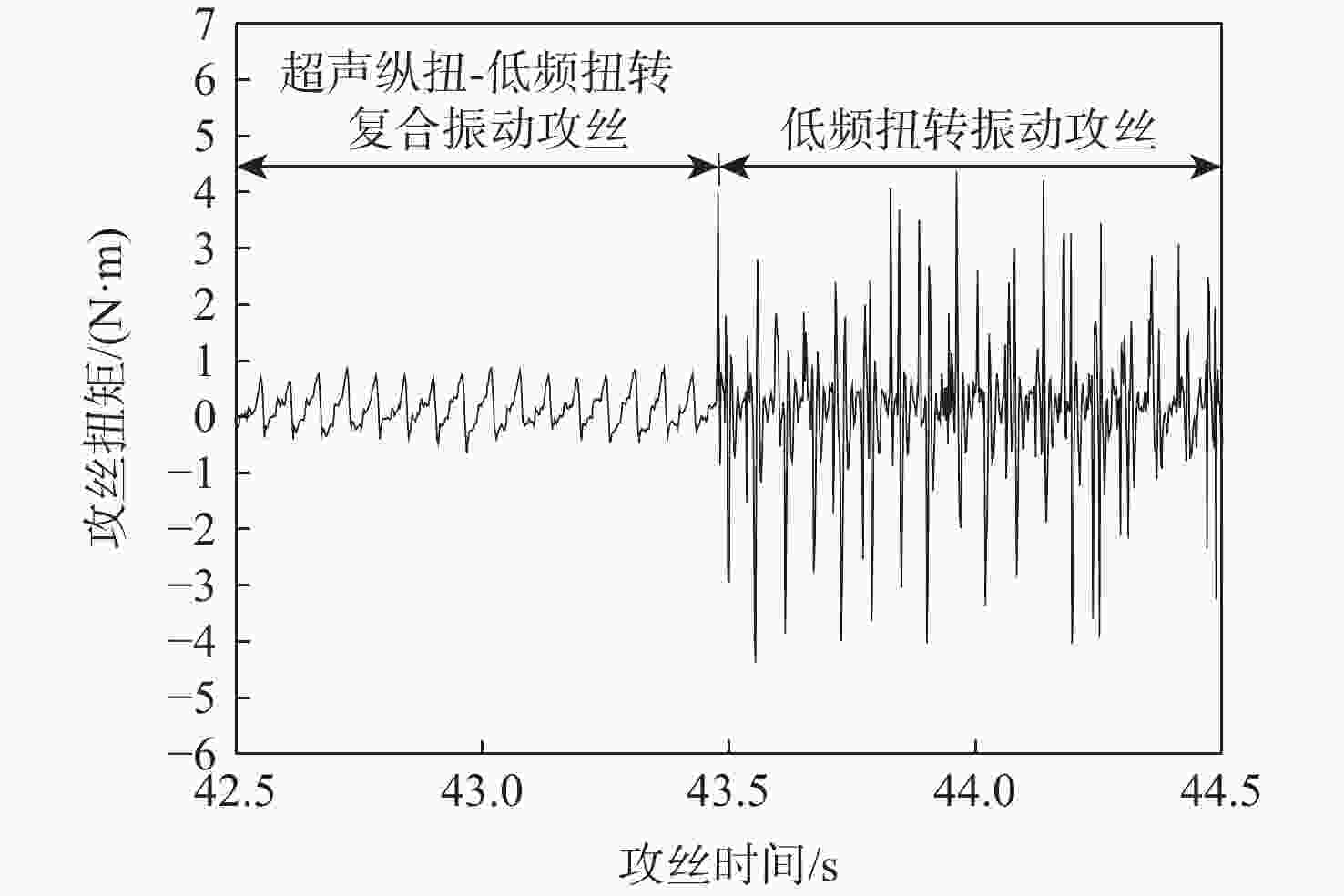

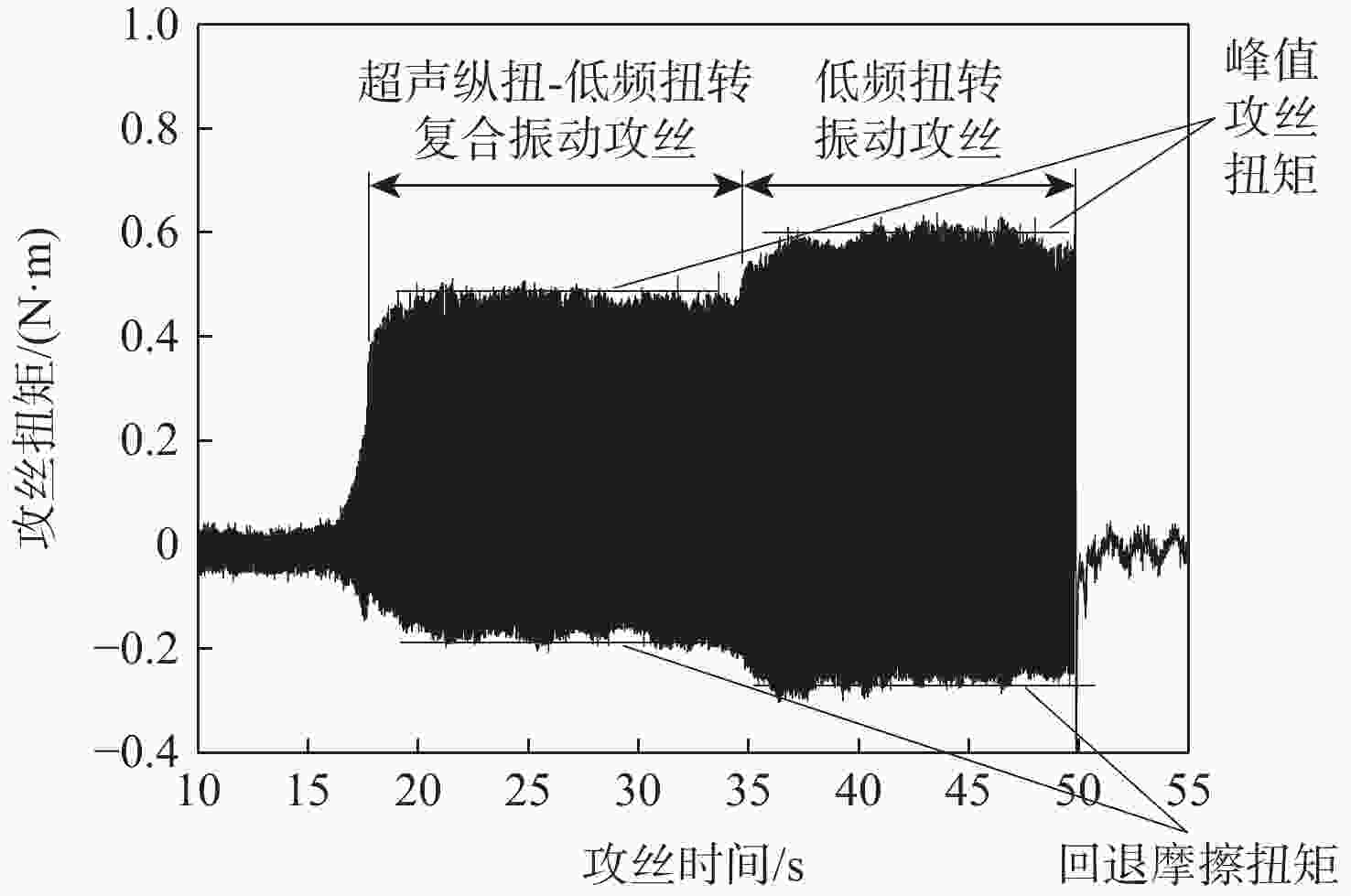

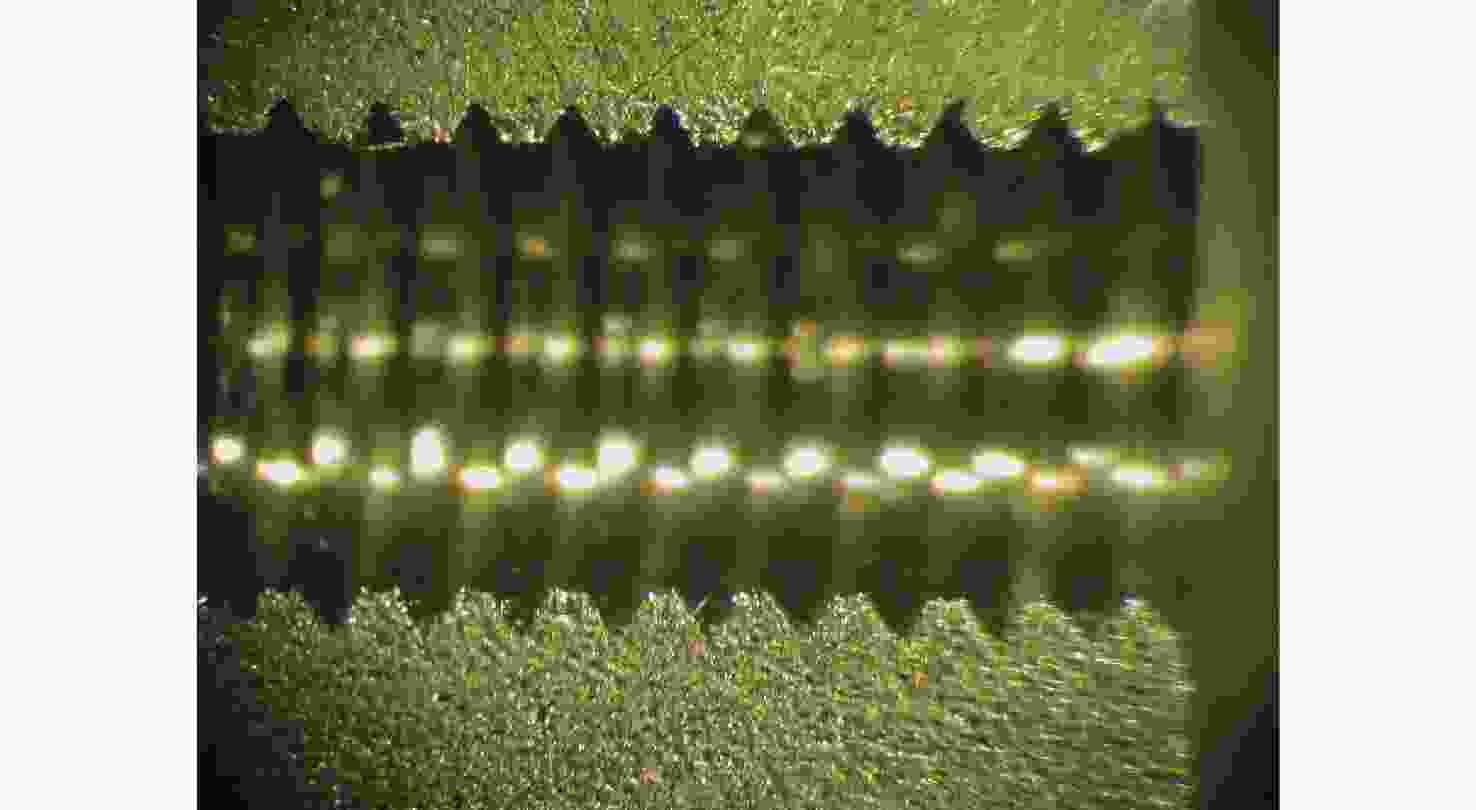

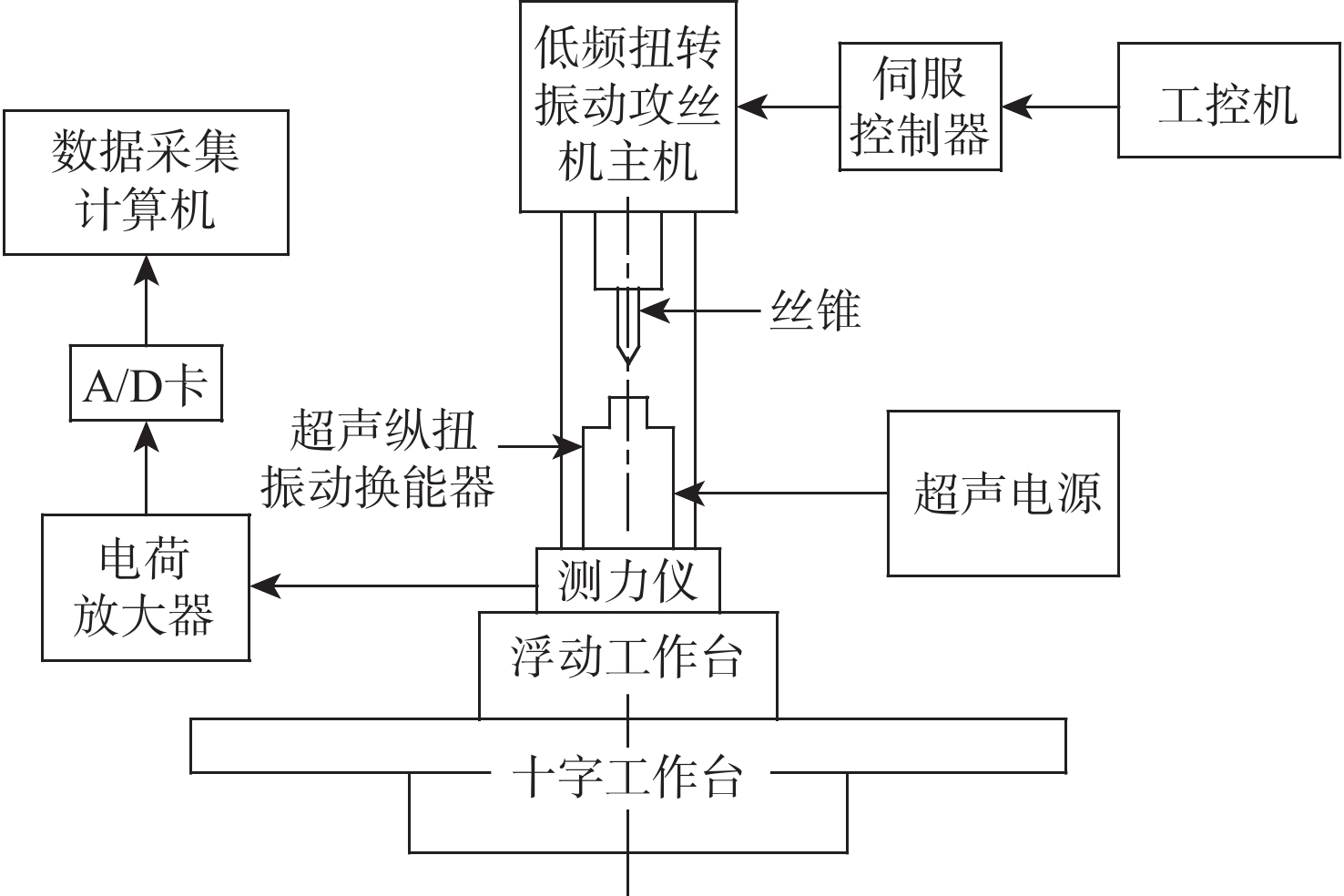

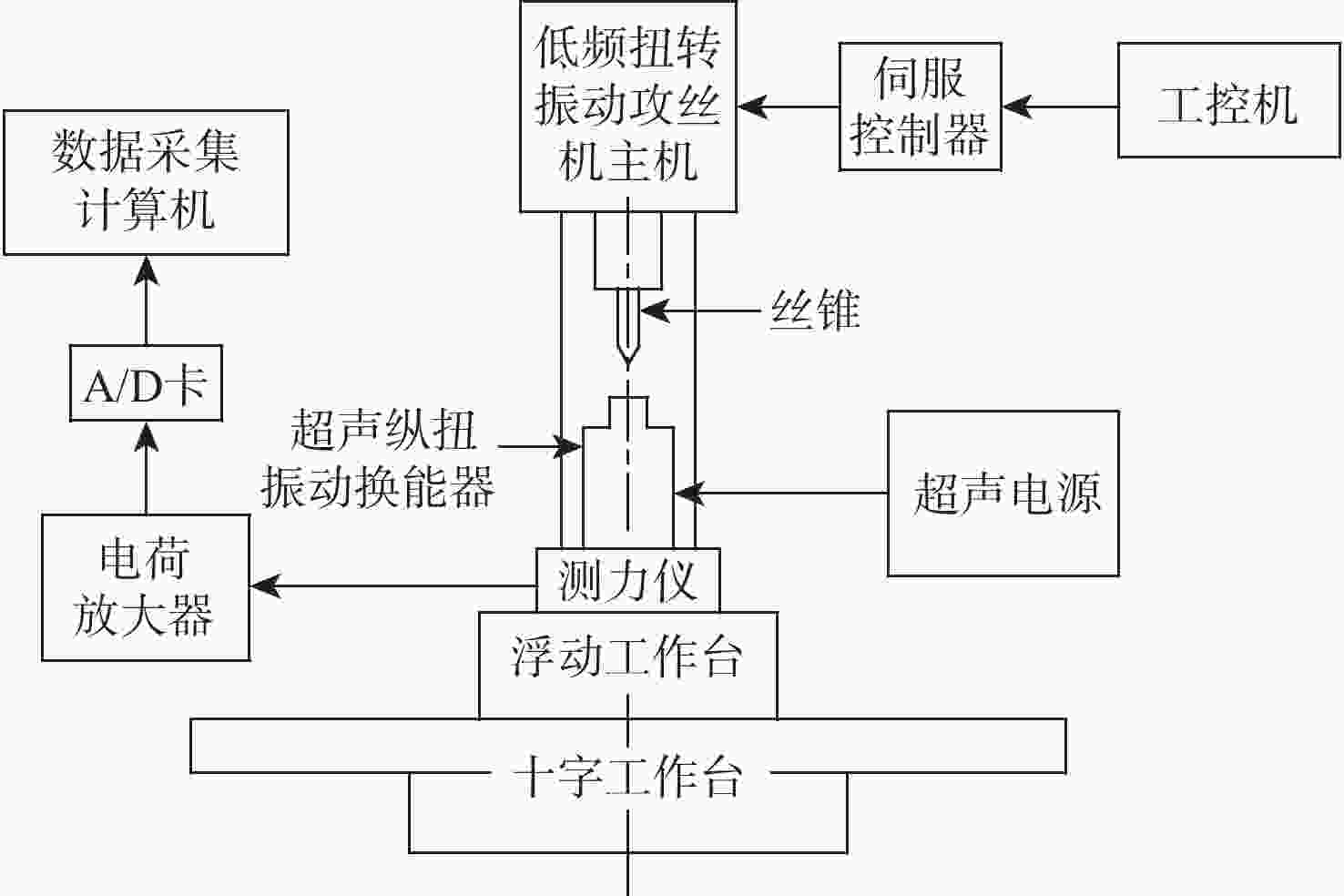

针对钛合金低频扭转振动攻丝效率偏低的问题,提出了超声纵扭-低频扭转复合振动攻丝方法。进行了超声纵扭振动攻丝实验、不同切削液的复合振功攻丝实验和变参数复合振动攻丝实验,研究复合振动攻丝的工艺效果及参数变化的影响规律。实验结果表明:超声纵扭振动增强了切削液的润滑效果,降低了攻丝扭矩,与普通连续攻丝相比,M3螺纹孔的超声纵扭振动攻丝可降低攻丝扭矩约18%;在所选参数范围内,与低频扭转振动攻丝相比,复合振动攻丝最大可降低攻丝扭矩约30%;复合振动攻丝降低攻丝扭矩的效果,随净切削量、主轴转速的增大和回退量的减小而降低。

Abstract:In view of the low efficiency of low frequency torsional vibration tapping of titanium alloy, the ultrasonic longitudinal torsional and low frequency torsional compound vibration tapping method was proposed. To investigate the process effect of compound vibration tapping and the influence rule of parameter change on it, three experiments were conducted in succession: the ultrasonic longitudinal torsional vibration tapping experiment, the compound vibration tapping experiment with different cutting fluids, and the compound vibration tapping experiment with variable parameters. The experimental results show that ultrasonic longitudinal torsional vibration enhances the lubricating effect of the cutting fluid and reduces the tapping torque. Compared with ordinary continuous tapping, the ultrasonic longitudinal torsional vibration tapping of M3 threaded holes can reduce the tapping torque by about 18%. Comparing compound vibration tapping to low frequency torsional vibration tapping, the tapping torque can be reduced by up to approximately 30% within the chosen parameter range. The effect of compound vibration tapping on reducing the tapping torque decreases with the increase of the net cutting amount, the spindle speed, and the decrease of the backward amount.

-

-

[1] 李毅, 赵永庆, 曾卫东. 航空钛合金的应用及发展趋势[J]. 材料导报, 2020, 34(增刊1): 280-282.LI Y, ZHAO Y Q, ZENG W D. Application and development trend of aviation titanium alloy[J]. Materials Reports, 2020, 34(Sup1): 280-282(in Chinese). [2] 原国森, 兖利鹏, 韩艳艳. 钛合金的应用进展[J]. 热加工工艺, 2017, 46(4): 13-16.YUAN G S, YAN L P, HAN Y Y. Application progress of titanium alloy[J]. Hot Working Technology, 2017, 46(4): 13-16(in Chinese). [3] 刘彬, 刘延斌, 杨鑫, 等. TITANIUM 2008: 国际钛工业、制备技术与应用的发展现状[J]. 粉末冶金材料科学与工程, 2009, 14(2): 67-73.LIU B, LIU Y B, YANG X, et al. TITANIUM 2008: Development of international titanium industry, preparation technology and applications[J]. Materials Science and Engineering of Powder Metallurgy, 2009, 14(2): 67-73(in Chinese). [4] 陈志同. 扭转振动机构学及振动攻丝技术研究[D]. 北京: 北京航空航天大学, 2001: 1-9.CHEN Z T. Research on torsional vibration mechanism and vibration tapping technology[D]. Beijing: Beihang University, 2001: 1-9 (in Chinese). [5] ZHANG D Y, CHEN D C. Relief-face friction in vibration tapping[J]. International Journal of Mechanical Sciences, 1998, 40(12): 1209-1222. doi: 10.1016/S0020-7403(98)00002-2 [6] 张利军, 申伟. 钛合金材料攻丝技术的开发[J]. 工具技术, 2015, 49(2): 55-57.ZHANG L J, SHEN W. Research on tapping technology of titanium alloy material[J]. Tool Engineering, 2015, 49(2): 55-57(in Chinese). [7] 隈部淳一郎. 精密加工: 振动切削(基础与应用)[M]. 韩一昆, 薛万夫, 孙祥根, 等, 译. 北京: 机械工业出版社, 1985: 19-147.KUMABE J. Precision machining: Vibration cutting (foundation and application)[M]. HAN Y K, XUE W F, SUN X G, et al, translated. Beijing: China Machine Press, 1985: 19-147(in Chinese). [8] 李祥林, 薛万夫, 张日升. 振动切削及其在机械加工中的应用 [M]. 北京: 北京科学技术出版社, 1985: 5-15.LI X L, XUE W F, ZHANG R S. Vibration cutting and its application in machining[M]. Beijing: Beijing Science and Technology Press, 1985: 5-15(in Chinese). [9] 李光军, 张德远. 难加工材料的低频振动攻丝研究[J]. 中国机械工程, 2004, 15(6): 494-497. doi: 10.3321/j.issn:1004-132X.2004.06.008LI G J, ZHANG D Y. Investigation of low-frequency vibration tapping in diffcult-cutting matierals[J]. China Mechanical Engineering, 2004, 15(6): 494-497(in Chinese). doi: 10.3321/j.issn:1004-132X.2004.06.008 [10] 李光军. 振动攻丝及其监控技术研究[D]. 北京: 北京航空航天大学, 2004: 49-100.LI G J. Research on vibration tapping and its monitoring technology[D]. Beijing: Beihang University, 2004: 49-100(in Chinese) . [11] 韩凤起. 难加工材料低频扭转振动攻丝理论和工艺的研究[D]. 北京: 北京航空航天大学, 2008: 13-108.HAN F Q. Study on theory and technology of vibration tapping of difficult-to-cut materials[D]. Beijing: Beihang University, 2008: 13-108(in Chinese). [12] 刘洋, 韩凤起, 卢慧敏, 等. Al2O3p/Al复合材料振动攻丝螺纹质量研究[J]. 航空精密制造技术, 2008, 44(6): 48-50.LIU Y, HAN F Q, LU H M, et al. Study on thread quality of low-frequency torsional vibration tapping on composite Al2O3p/Al[J]. Aviation Precision Manufacturing Technology, 2008, 44(6): 48-50 (in Chinese). [13] 韩荣第, 殷宝麟, 崔永鹏. 难加工材料小孔振动攻丝试验研究[J]. 哈尔滨工业大学学报, 2008, 40(1): 50-53.HAN R D, YIN B L, CUI Y P. Investigation of small-hole vibration tapping in difficult-to-cut materials[J]. Journal of Harbin Institute of Technology, 2008, 40(1): 50-53(in Chinese). [14] YIN B L, HAN R D. Investigation of the torque characteristics in vibration tapping of hardened steel[J]. International Journal of Machine Tools and Manufacture, 2006, 46(6): 623-630. doi: 10.1016/j.ijmachtools.2005.07.014 [15] 王贵成, 朱金辉, 王磊, 等. 振动方式对攻丝加工效果影响的实验研究[J]. 机械科学与技术, 2008, 27(7): 857-860.WANG G C, ZHU J H, WANG L, et al. Experimental study of the effect of vibration mode on vibratory tapping[J]. Mechanical Science and Technology for Aerospace Engineering, 2008, 27(7): 857-860(in Chinese). [16] 张德远, 刘逸航, 耿大喜, 等. 超声加工技术的研究进展[J]. 电加工与模具, 2019(5): 1-10.ZHANG D Y, LIU Y H, GENG D X, et al. The research progress of ultrasonic machining technology[J]. Electromachining & Mould, 2019(5): 1-10(in Chinese). [17] KUO K L. Experimental investigation of ultrasonic vibration-assisted tapping[J]. Journal of Materials Processing Technology, 2007, 192-193: 306-311. doi: 10.1016/j.jmatprotec.2007.04.033 [18] TSAO C C, KUO K L. Ultrasonic-assisted vibration tapping using taps with different coatings[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: s764-s768. doi: 10.1016/S1003-6326(12)61801-9 [19] PAWAR S, PATIL S, PAWAR P, et al. Effect of axial and torsional vibrations on tapping performance[J]. Applied Mechanics and Materials, 2016, 826: 88-92. doi: 10.4028/www.scientific.net/AMM.826.88 [20] 彭太江, 杨树臣, 杨志刚, 等. 超声波的减摩特性[J]. 吉林大学学报(工学版), 2006, 36(增刊2): 88-90.PENG T J, YANG S C, YANG Z G, et al. Friction-reducing characteristics of ultrasonic wave[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(Sup2): 88-90(in Chinese). [21] 吴博达, 常颖, 杨志刚, 等. 超声振动减摩性能的实验研究及理论分析[J]. 中国机械工程, 2004, 15(9): 813-815.WU B D, CHANG Y, YANG Z G, et al. Experimental study and theoretical analysis on anti-friction capability of ultrasonic vibration[J]. China Mechanical Engineering, 2004, 15(9): 813-815(in Chinese). [22] 常颖, 彭太江, 阚君武, 等. 超声振动对摩擦系数影响的试验研究[J]. 压电与声光, 2003, 25(6): 511-513.CHANG Y, PENG T J, KAN J W, et al. Experiment study on the influence on friction-factor by ultrasonic vibration[J]. Piezoelectrics & Acoustooptics, 2003, 25(6): 511-513(in Chinese). -

下载:

下载: