-

摘要:

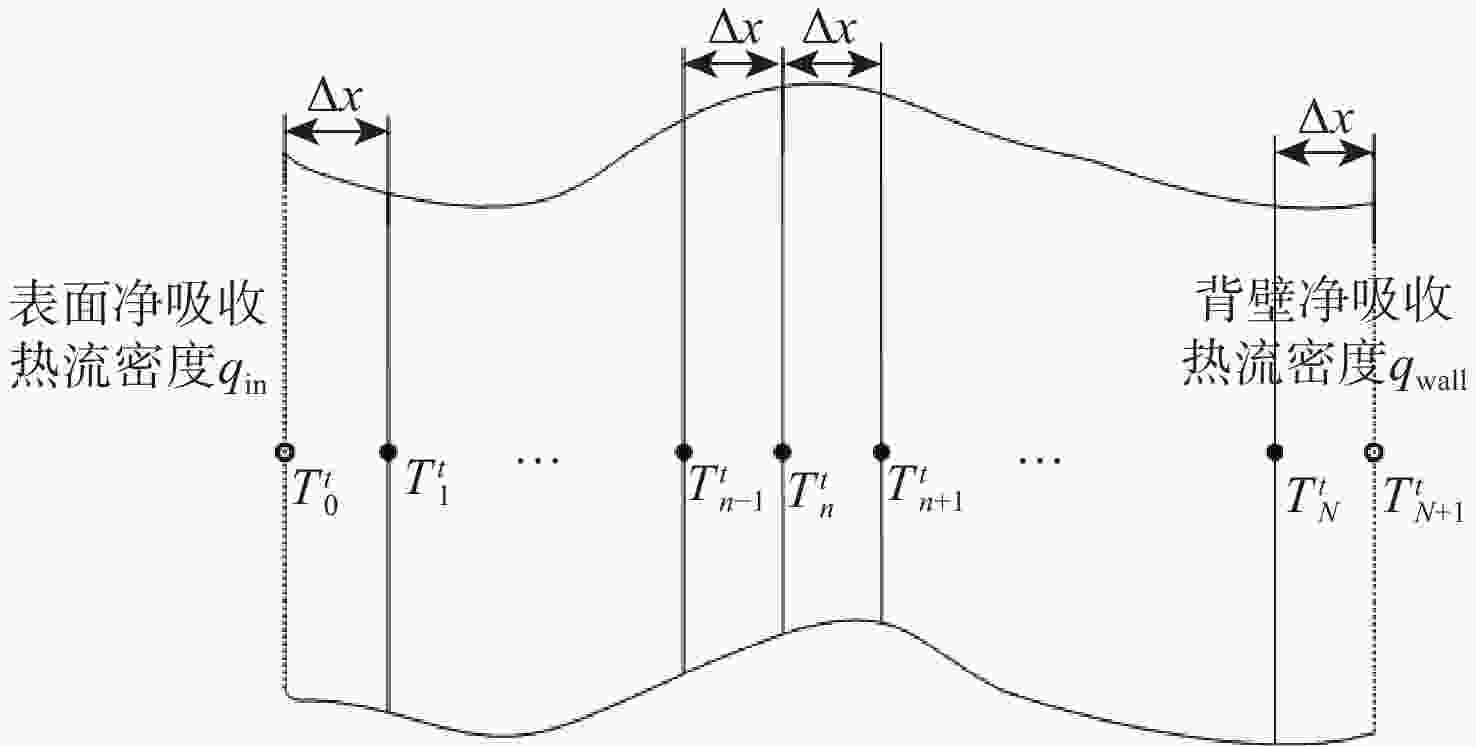

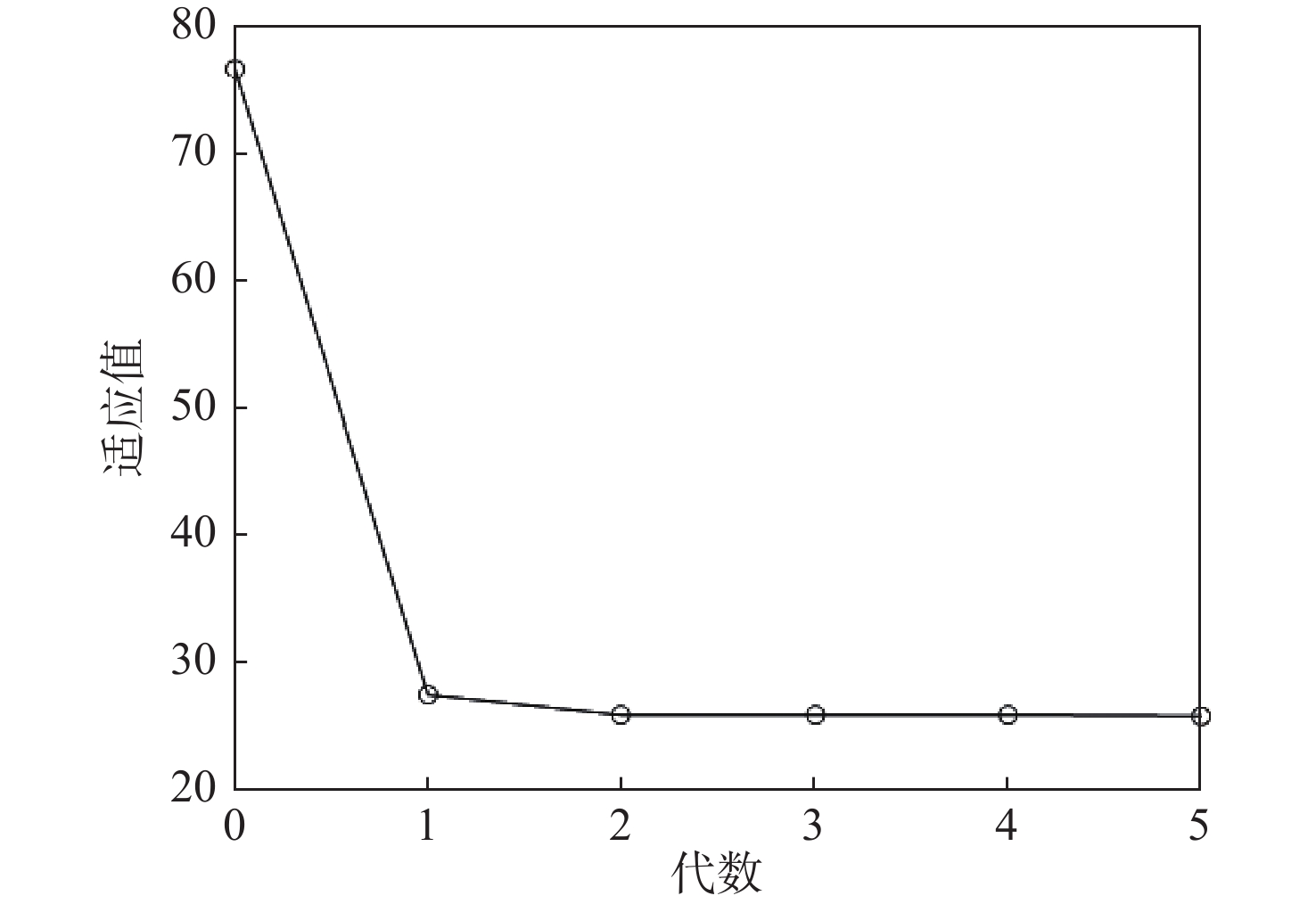

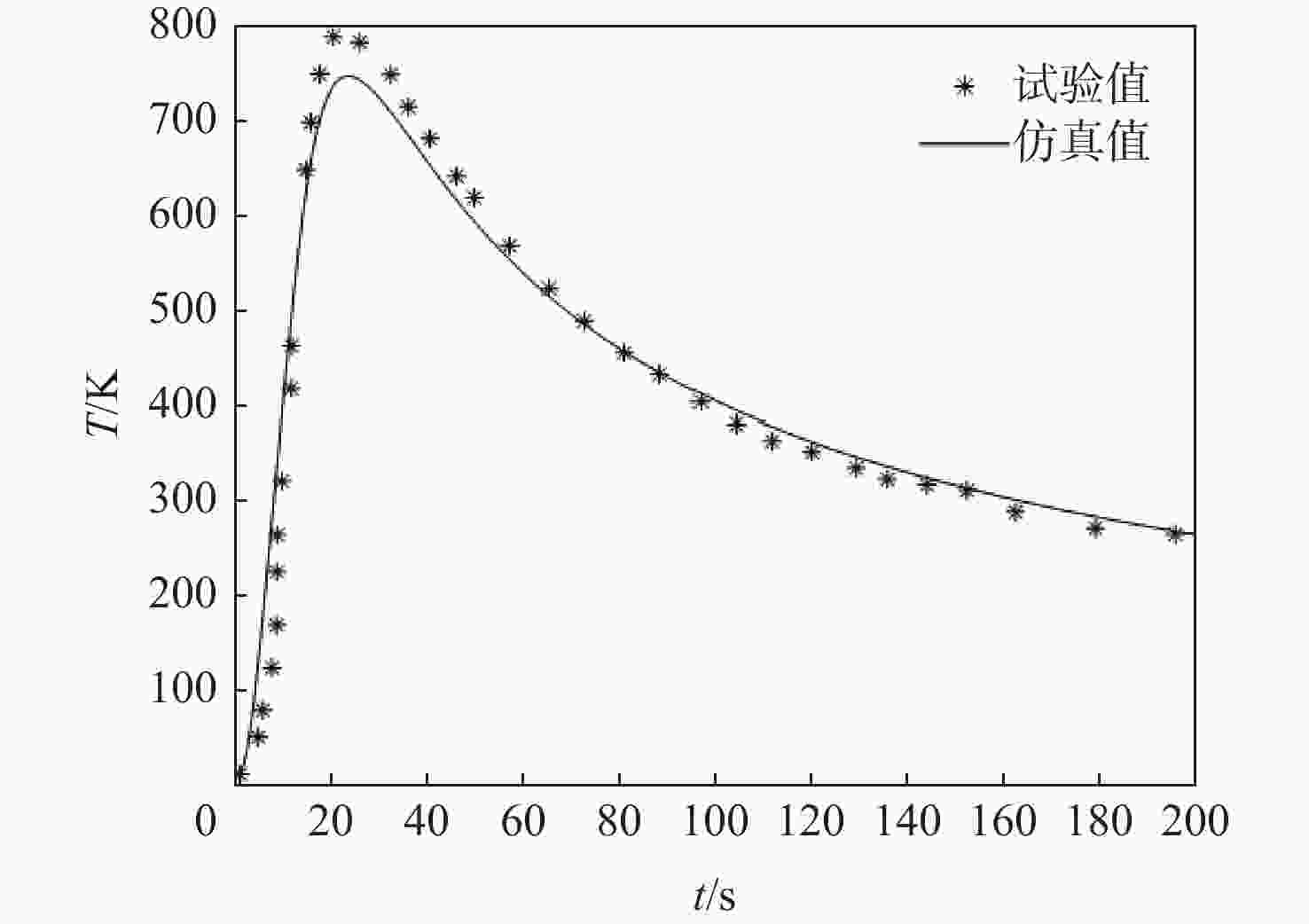

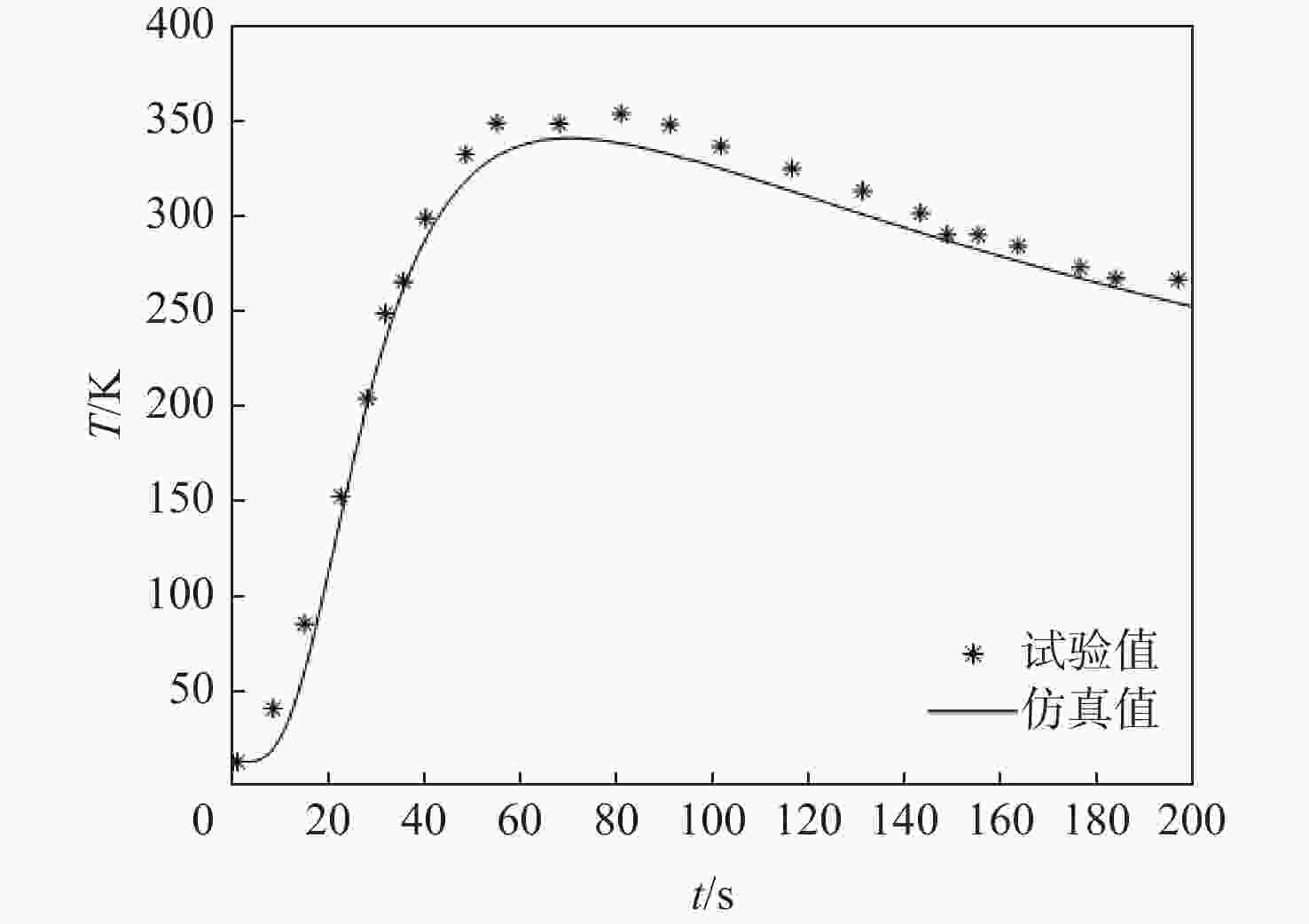

针对碳化材料烧蚀性能参数测量难度大的问题,对基于优化算法的烧蚀性能参数辨识方法进行了研究。根据一维连续模型描述碳化烧蚀材料的内部热响应情况,与公开试验数据进行对比验证,各测量点计算误差均小于15%。采用基函数表征法对材料碳化前后的比热容和导热率进行表征,基函数选取为切比雪夫多项式。根据PICA材料的温度测试试验数据,对材料的热解动力学参数和基函数的待定系数采用遗传算法进行辨识,将辨识得到的材料烧蚀性能参数代入一维连续模型中进行计算,与验证工况下的试验数据进行比对,计算得到的温度曲线平均相对误差小于10%。

Abstract:In response to the difficulty in measuring the ablation performance parameters of thermal protection materials, this paper studies the identification method of ablation performance parameters based on optimization algorithms. The one-dimensional continuous model is used to describe the internal thermal response of carbonization ablation thermal protective materials. Compared with the public experimental data, the calculation error of each measurement point is less than 15%. The basis function characterisation approach uses the Chebyshev polynomial as the basis function to characterize the material’s specific heat capacity and thermal conductivity both before and after carbonization. According to the temperature test experimental data of PICA materials in the public literature, the pyrolysis kinetic parameters of the materials and the undetermined coefficients of the basis function are identified by genetic algorithm, and the parameter identification results are substituted into the one-dimensional continuous model for calculation. Compared with the experimental data in the public literature, the average relative error of the temperature curves under the two verification conditions is less than 10%.

-

表 1 材料性能及初始条件

Table 1. Material properties and initial conditions

材料性能 数值 ${\rho _{\rm{v}}}$/(kg·m−3) 1 810 ${\rho _{\rm{c}}}$/(kg·m−3) 1440 ${\lambda_{\rm{v}}}$/($ {\text{W}} \cdot {{\text{m}}^{ - 1}} \cdot ^\circ {{\text{C}}^{ - 1}} $) $0.804 + 2.76 \times {10^{ - 4}}T$ ${\lambda_{\rm{c}}}$/($ {\text{W}} \cdot {{\text{m}}^{ - 1}} \cdot ^\circ {{\text{C}}^{ - 1}} $) $ \begin{array}{*{20}{c}} \begin{gathered} 0.955 + 8.42 \times {10^{ - 4}}T - 4.07 \times {10^{ - 6}}{T^2} + 5.32 \times {10^{ - 9}}{T^3} \\ \end{gathered} \end{array} $ $ {C_{\rm{v}}} $/(${\text{kJ}} \cdot {\text{k}}{{\text{g}}^{ - 1}} \cdot ^\circ {{\text{C}}^{ - 1}}$) $ 1.089 + 1.09 \times {10^{ - 3}}T $ ${C_{\rm{c}}}$/(${\text{kJ}} \cdot {\text{k}}{{\text{g}}^{ - 1}} \cdot ^\circ {{\text{C}}^{ - 1}}$) $ 0.87 + 1.02 \times {10^{ - 3}}T $ ${C_{\rm{pg}}}$/(${\text{kJ}} \cdot {\text{k}}{{\text{g}}^{ - 1}} \cdot ^\circ {{\text{C}}^{ - 1}}$) 9.63 $\varepsilon $ 0.9 $\sigma $/(${\text{W}} \cdot {{\text{m}}^{ - 2}} \cdot {{\text{K}}^{ - 4}}$) $5.73 \times {10^{ - 8}}$ ${T_0}$/${\text{K}}$ 300 $E$/(${\text{kJ}}\cdot {\mathrm{kmol}}^{-1}$) $2.60 \times {10^5}$ $A$/${{\text{s}}^{ - 1}}$ $1.98 \times {10^{29}}$(剩余率≥0.91),$8.16 \times {10^{18}}$(剩余率<0.91) $m$ 17.33(剩余率≥0.91),6.3(剩余率≥0.91) 表 2 最终时刻不同位置温度对比

Table 2. Temperature comparison of different positions at the final moment

位置/mm 温度/K 相对误差/% 试验值 仿真值 1 1264.8 1295.6 2.44 5 1095.4 1188.4 8.49 10 938.54 1020.6 8.74 29 521.37 594.39 14.00 表 3 试验条件及编号

Table 3. Experimental conditions and numbers

编号 热流密度/

$\left({\text{W}}\cdot\left( {{{\text{m}}^2} \cdot {\text{s}}} \right)^{-1}\right)$持续

时间/s材料

厚度/cm测量

位置/cm1 5.68×106 11 15.24 1.08 2 5.68×106 11 15.24 1.93 3 1.90×107 17 20.32 3.77 4 9.66×106 22 10.16 2.56 -

[1] 朱召贤, 朱小飞, 黄洪勇, 等. 低密度树脂基防热材料研究进展[J]. 中国材料进展, 2019, 38(11): 1086-1092. doi: 10.7502/j.issn.1674-3962.201806008ZHU Z X, ZHU Z F, HUANG H Y, et al. Research progress of low-density resin-based thermal protection materials[J]. Materials China, 2019, 38(11): 1086-1092(in Chinese). doi: 10.7502/j.issn.1674-3962.201806008 [2] 张志成, 潘梅林, 刘初平, 等. 高超声速气动热和热防护[M]. 北京: 国防工业出版社, 2003.ZHANG Z C, PAN M L, LIU C P, et al. Hypersonic aerodynamic thermal and thermal protection[M]. Beijing: National Defense Industry Press, 2003(in Chinese). [3] 张军, 李伟, 方国东, 等. 树脂基防隔热复合材料高温响应分析方法研究进展[J]. 宇航学报, 2020, 41(6): 739-748. doi: 10.3873/j.issn.1000-1328.2020.06.011ZHANG J, LI W, FANG G D, et al. Review of high temperature response analysis of resin matrix thermal protection and insulation composites[J]. Journal of Astronautics, 2020, 41(6): 739-748(in Chinese). doi: 10.3873/j.issn.1000-1328.2020.06.011 [4] 黄娜, 刘亮, 王晓叶. 热重质谱联用技术对酚醛树脂热解行为及动力学研究[J]. 宇航材料工艺, 2012, 42(2): 99-102. doi: 10.3969/j.issn.1007-2330.2012.02.025HUANG N, LIU L, WANG X Y. Pyrolysis and kinetics of phenolic resin by TG-MS analysis[J]. Aerospace Materials & Technology, 2012, 42(2): 99-102(in Chinese). doi: 10.3969/j.issn.1007-2330.2012.02.025 [5] 张莹, 胡宏林, 蒋丽琴, 等. 典型结构钡酚醛树脂热解非等温动力学及热稳定性[J]. 宇航材料工艺, 2021, 51(1): 17-24. doi: 10.12044/j.issn.1007-2330.2021.01.003ZHANG Y, HU H L, JIANG L Q, et al. Non-isothermal pyrolysis kinetic mechanism and thermal stabilization of phenolic resin with different characteristic structure[J]. Aerospace Materials & Technology, 2021, 51(1): 17-24(in Chinese). doi: 10.12044/j.issn.1007-2330.2021.01.003 [6] 时天林, 高丽娟, 何也, 等. 酚醛树脂保温板热解动力学研究[J]. 辽宁科技大学学报, 2021, 44(1): 38-42.SHI T L, GAO L J, HE Y, et al. Study on pyrolysis kinetics of phenolic resin insulation board[J]. Journal of Liaoning University of Science and Technology, 2021, 44(1): 38-42(in Chinese). [7] 王苏, 闫卫锋, 马伟, 等. 酚醛树脂热解的激波管实验[C]//第一届高超声速科技学术会议. 北京: 中国力学学会, 2008: 21-26.WANG S, YAN W F, MA W, et al. Shock tube study on pyrolysis of phenolic resin[C]//Proceedings of the 1st Hypersonic Technology Academic Conference. Beijing: The Chinese Society of Theoretical and Applies Mechanics, 2008: 21-26(in Chinese). [8] 闫卫锋, 王苏, 李帅辉, 等. 酚醛树脂热解产物的激波管研究[C]//第十三届全国激波与激波管会议. 北京: 中国力学学会, 2008: 452-457.YAN W F, WANG S, LI S H, et al. Shock tube study on pyrolysis products of phenolic resin[C]//Proceedings of the 13th National Conference on Shock Waves and Shock Tubes. Beijing: The Chinese Society of Theoretical and Applies Mechanics, 2008: 452-457(in Chinese). [9] 闫卫锋, 王苏, 马伟, 等. 酚醛树脂高温热解的激波管实验研究[J]. 力学学报, 2009, 41(4): 463-468. doi: 10.3321/j.issn:0459-1879.2009.04.003YAN W F, WANG S, MA W, et al. Shock tube study of phenolic resin pyrolysis[J]. Chinese Journal of Theoretical and Applied Mechanics, 2009, 41(4): 463-468(in Chinese). doi: 10.3321/j.issn:0459-1879.2009.04.003 [10] TELEJKO T, MALINOWSKI Z. Application of an inverse solution to the thermal conductivity identification using the finite element method[J]. Journal of Materials Processing Technology, 2004, 146: 145-155. doi: 10.1016/j.jmatprotec.2003.10.006 [11] ZUECO J, ALHAMA F, FERNANDEZ C. Inverse determination of temperature dependent thermal conductivity using network simulation method[J]. Journal of Materials Processing Technology, 2006, 174(1-3): 137-144. [12] CHAR M I, CHANG F P, TAI B C. Inverse determination of thermal conductivity by differential quadrature method[J]. International Communications in Heat and Mass Transfer, 2008, 35: 113-119. doi: 10.1016/j.icheatmasstransfer.2007.06.006 [13] ARDAKANI D M, KHODADAD M. Identification of thermal conductivity and the shape of an inclusion using the boundary elements method and the particle swarm optimization algorithm[J]. Inverse Problems in Science & Engineering, 2009, 17(7): 855-870. [14] 曾建潮, 崔志华. 一种保证全局收敛的PSO算法[J]. 计算机研究与发展, 2004, 41(8): 1333-1338.ZENG J C, CUI Z H. A guaranteed global convergence particle swarm optimizer[J]. Journal of Computer Research and Development, 2004, 41(8): 1333-1338(in Chinese). [15] LIU F B. A hybrid method for the inverse heat transfer of estimating fluid thermal conductivity and heat capacity[J]. International Journal of Thermal Sciences, 2011, 50(5): 718-724. [16] 郭瑾. 树脂基复合材料热解层模型及高温热物性测试研究[D]. 北京: 北京交通大学, 2021.GUO J. Study on measurement of high-temperature thermophysical properties and pyrolysis layer model of polymer matrix composites[D]. Beijing: Beijing Jiaotong University, 2021(in Chinese). [17] MOYER C B, RINDAL R A. An analysis of the coupled chemically reacting boundary layer and the charring ablator: NASA CR-1061[R]. Washington, D.C.: NASA, 1968. [18] 刘骁, 国义军, 刘伟, 等. 碳化材料三维烧蚀热响应有限元计算研究[J]. 宇航学报, 2016, 37(9): 1150-1156.LIU X, GUO Y J, LIU W, et al. Numerical simulation research on three-dimensional ablative thermal response of charring ablators[J]. Journal of Astronautics, 2016, 37(9): 1150-1156(in Chinese). [19] HENDERSON J B, WIEBELT J A, TANT M R. A model for the thermal response of polymer composite materials with experimental verification[J]. Journal of Composite Materials, 1985, 19(6): 579-595. doi: 10.1177/002199838501900608 [20] 孙斌, 于聪, 周王超, 等. NTC热敏电阻特性曲线的拟合方法研究[J]. 中国计量学院学报, 2012, 23(1): 75-79.SUN B, YU C, ZHOU W C, et al. Study on curve fitting methods of NTC thermistor characteristics[J]. Journal of China University of Metrology, 2012, 23(1): 75-79(in Chinese). [21] TRAN H K, JOHNSON C, RASKY D, et al. Phenolic impregnated carbon ablators pica as thermal protection system for discovery missions: NASA TM-110440[R]. Washington, D.C.: NASA, 1997. -

下载:

下载: