-

摘要:

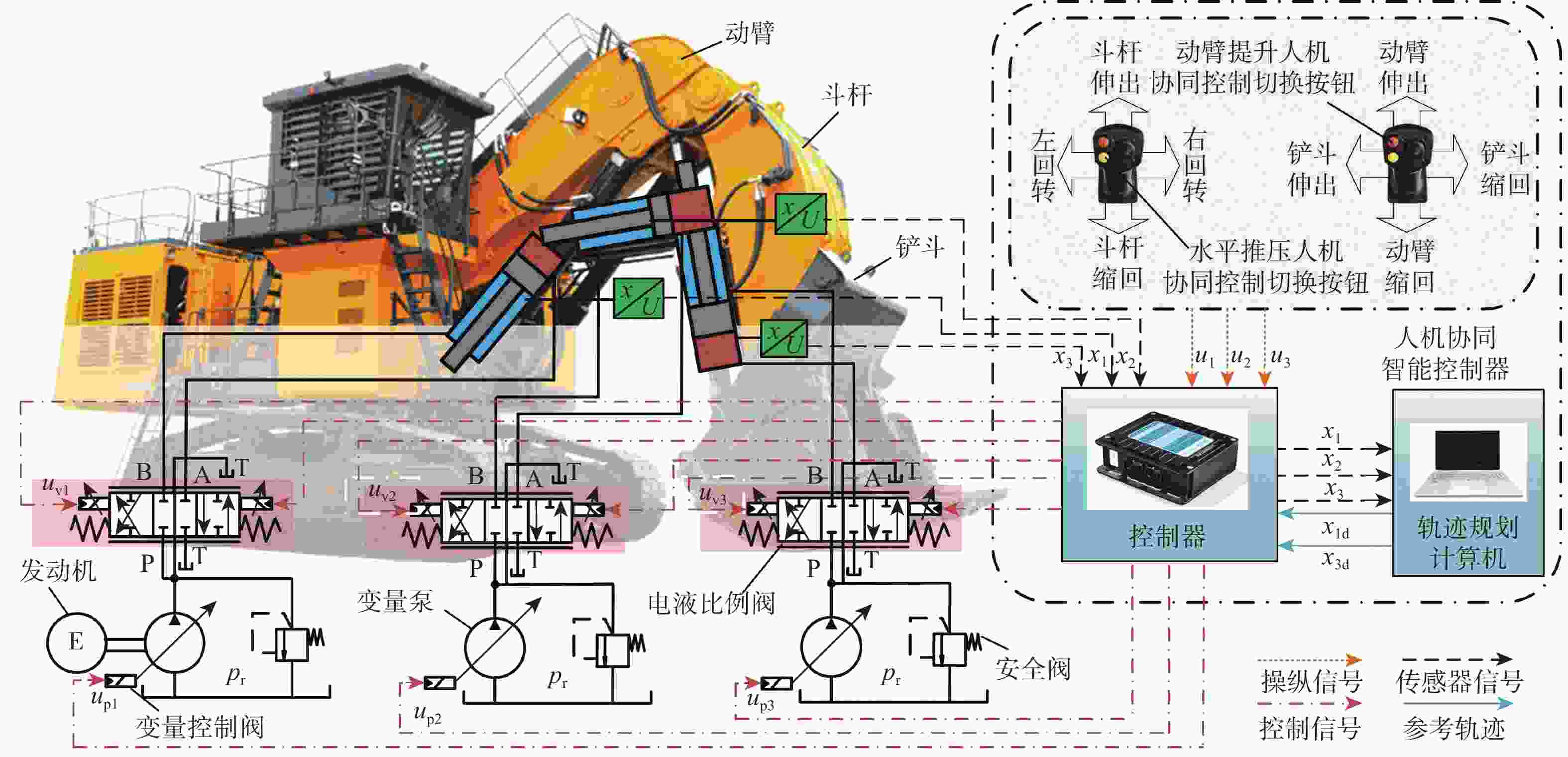

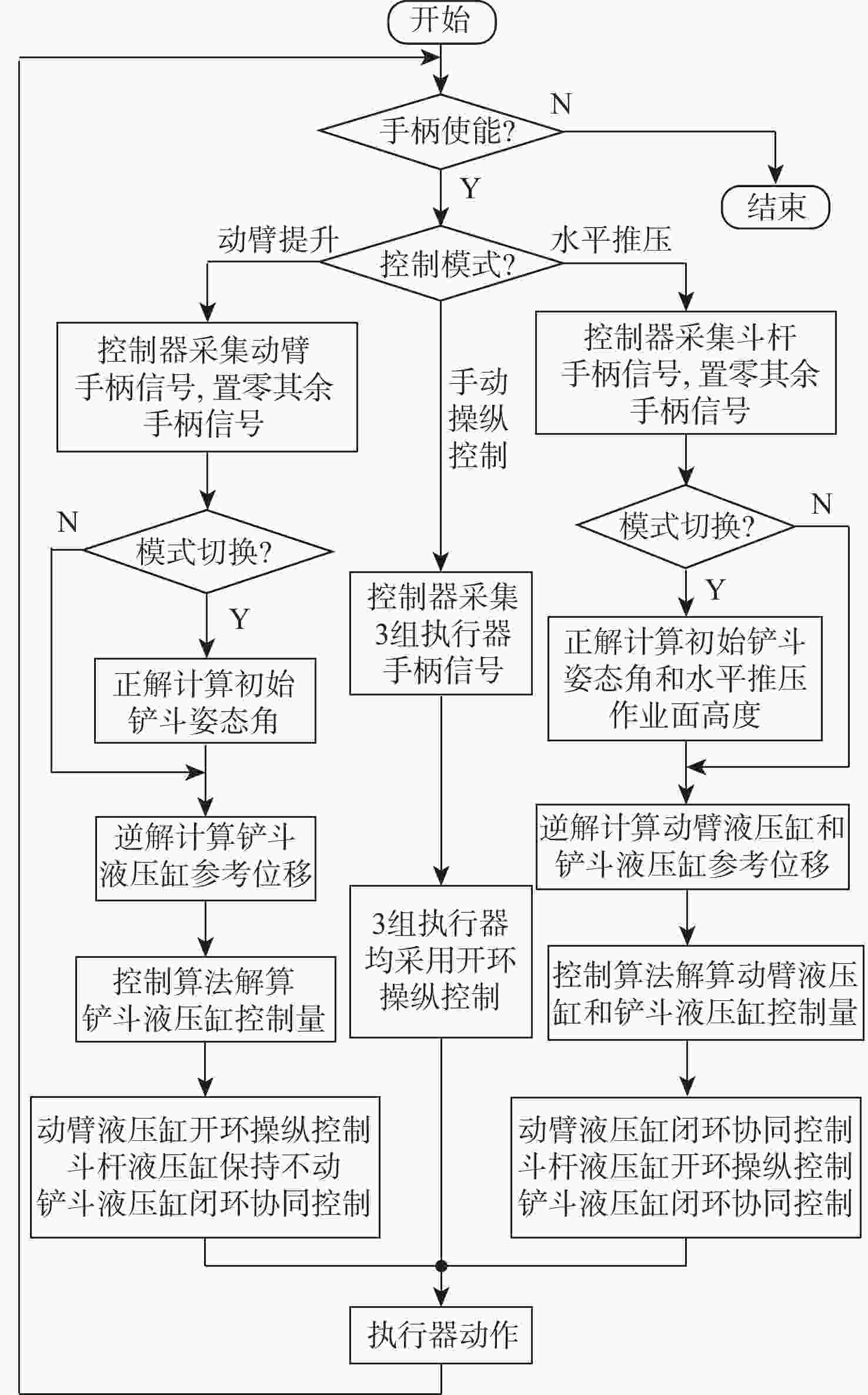

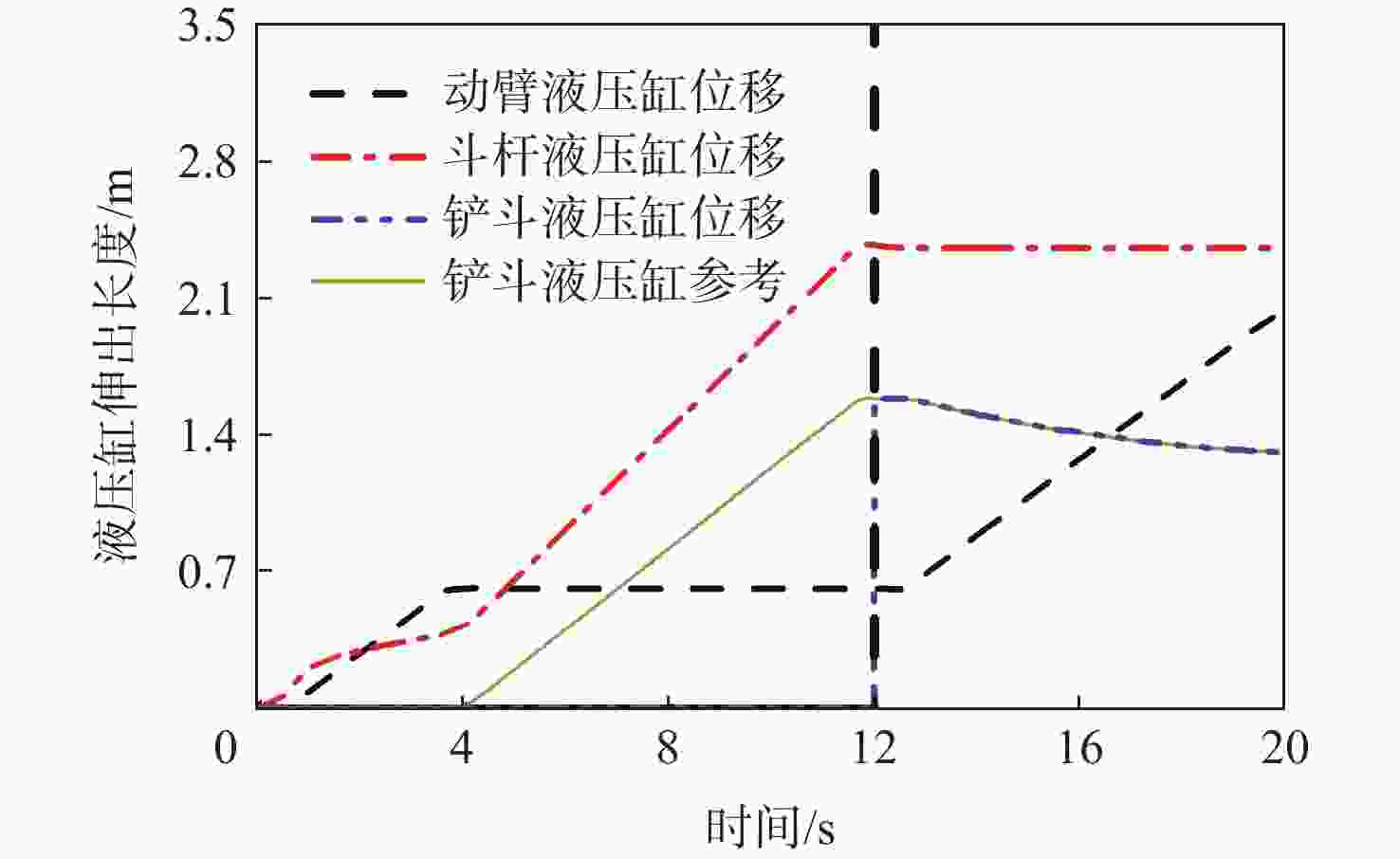

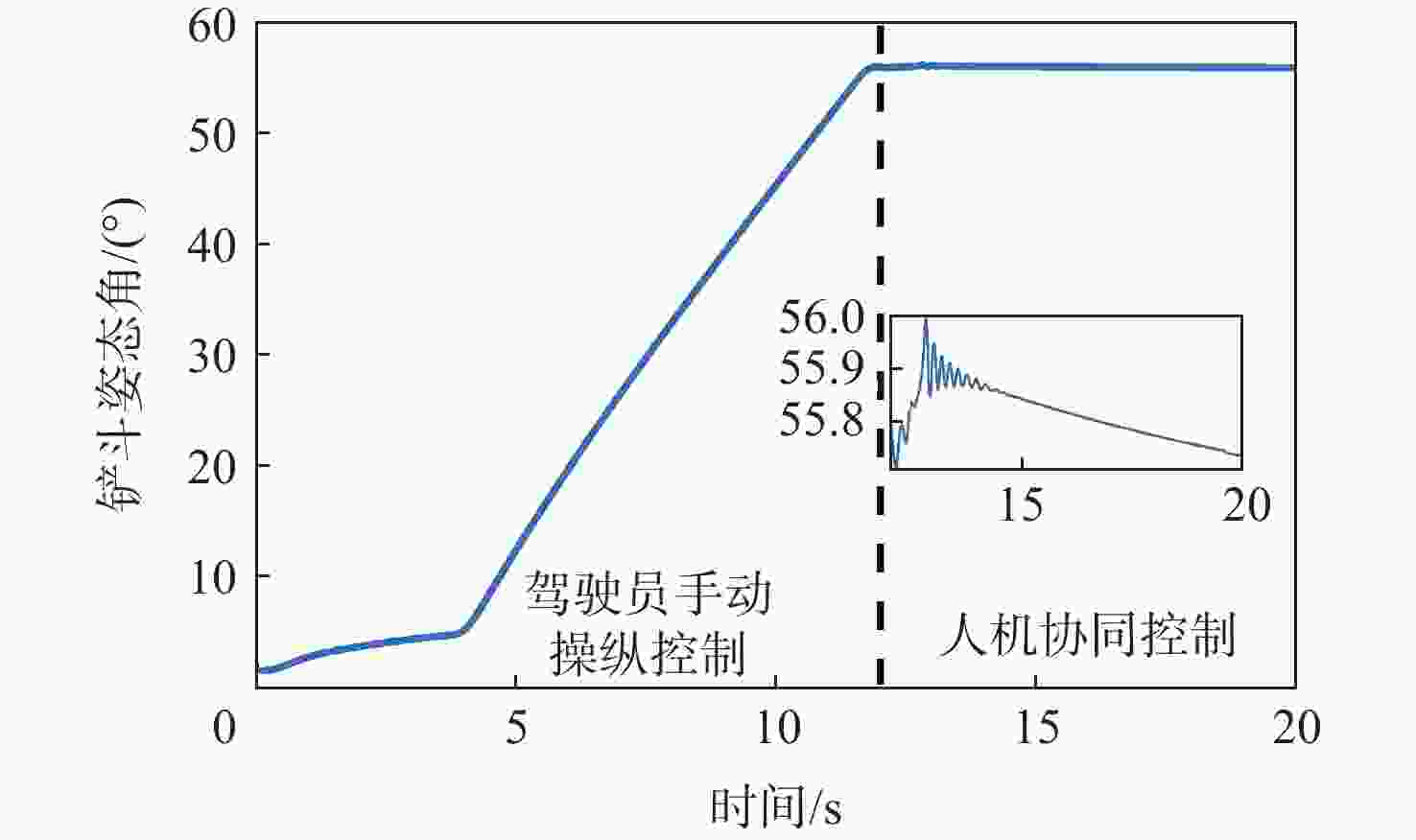

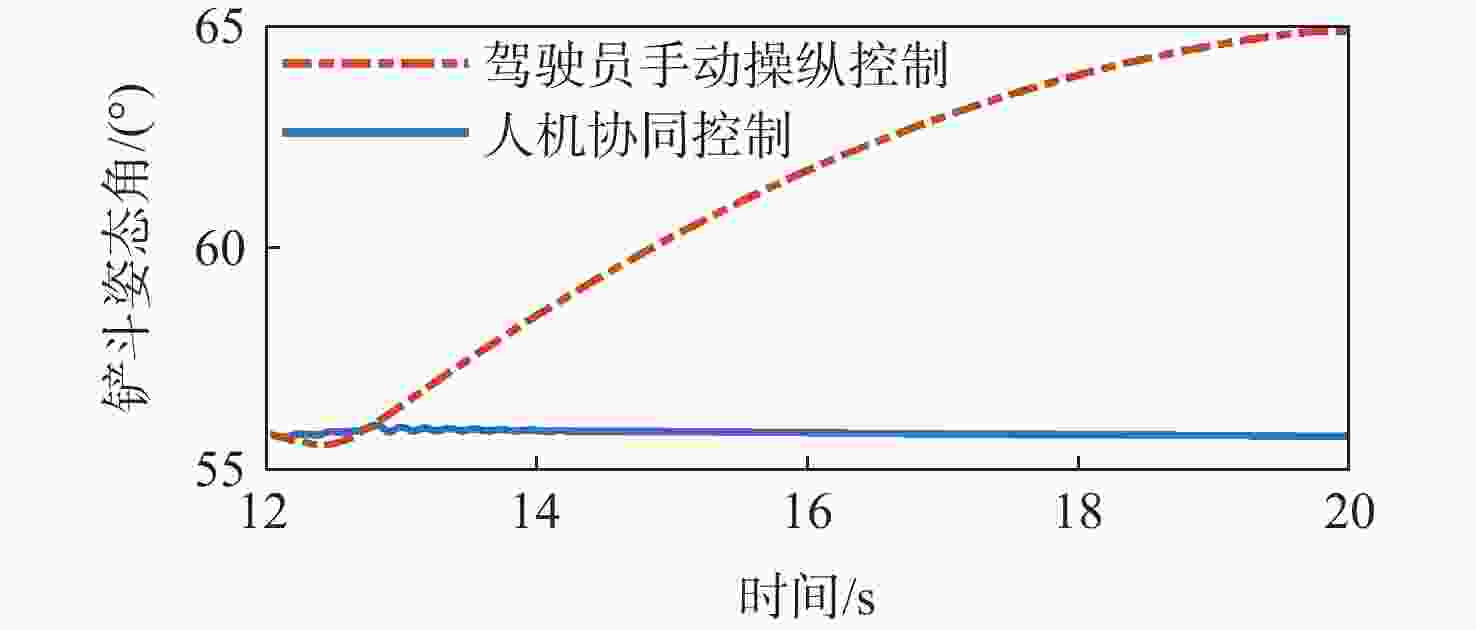

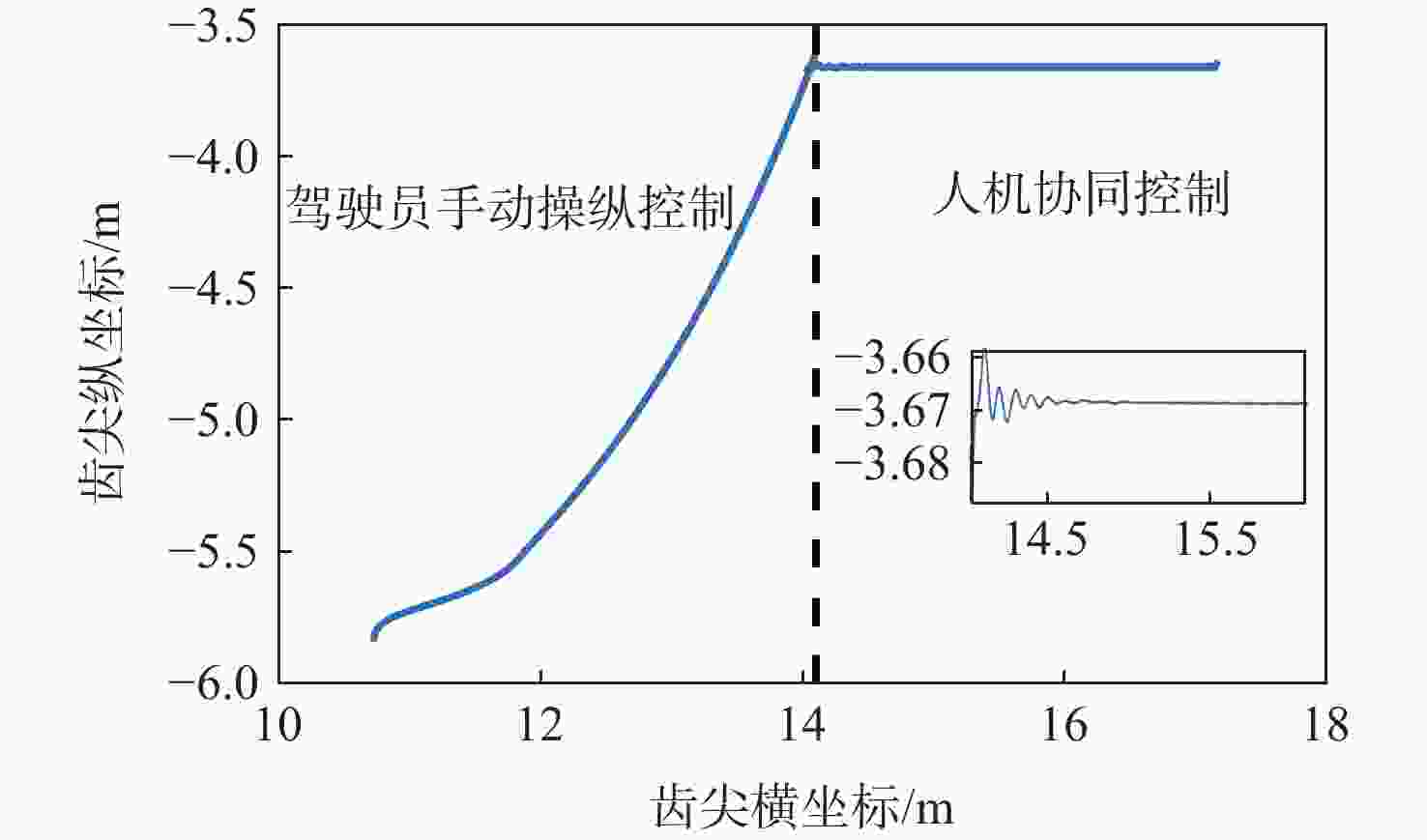

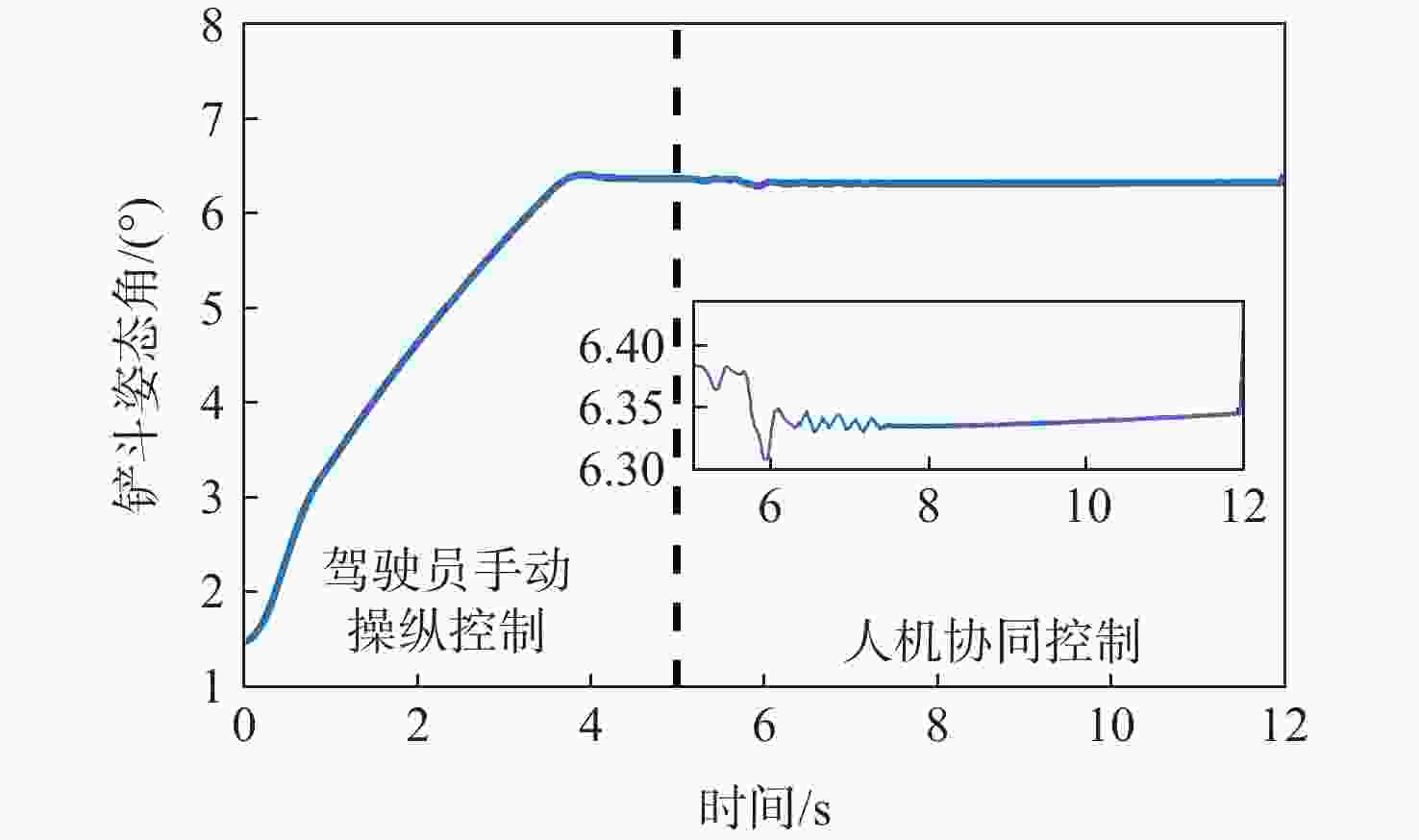

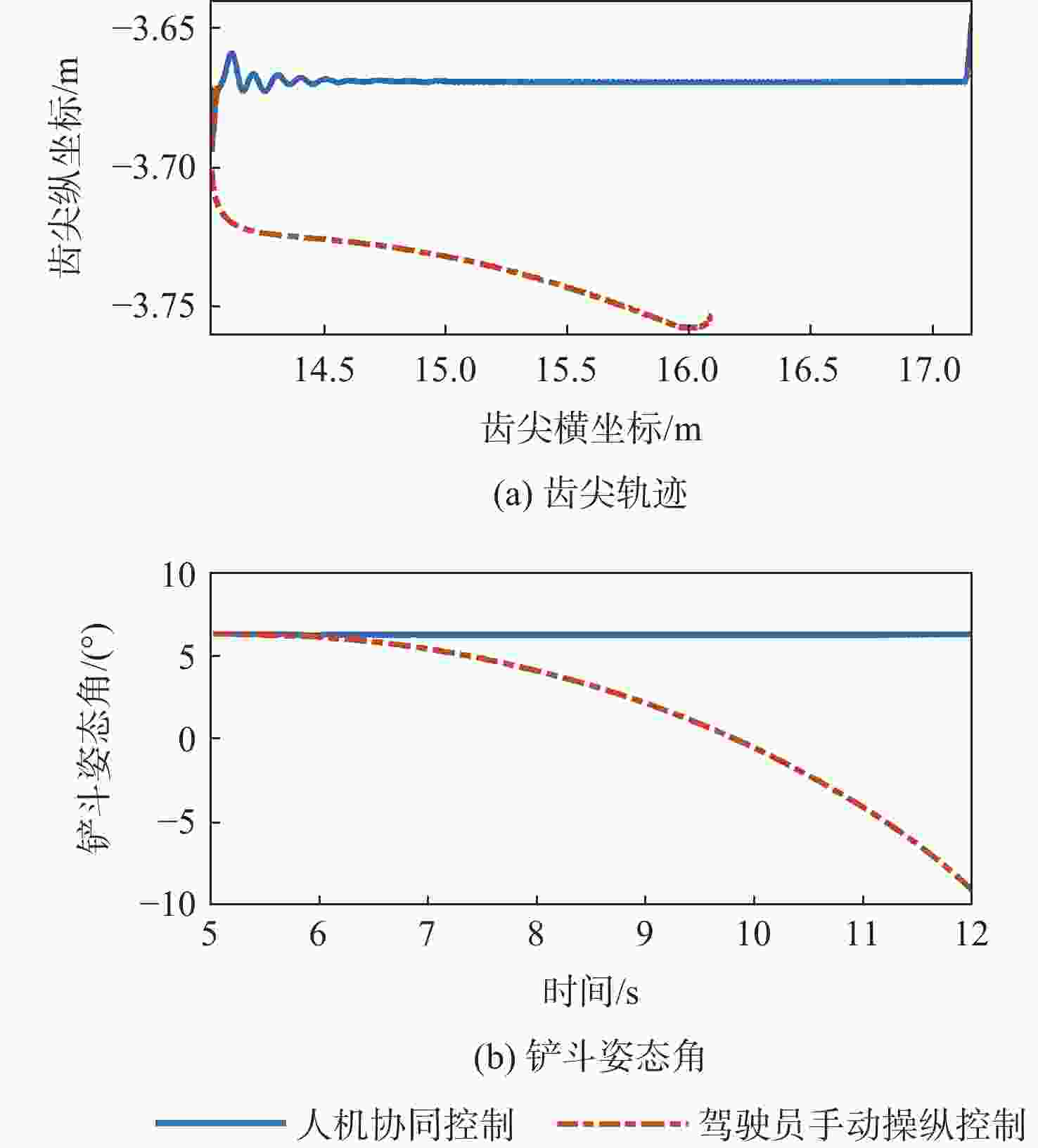

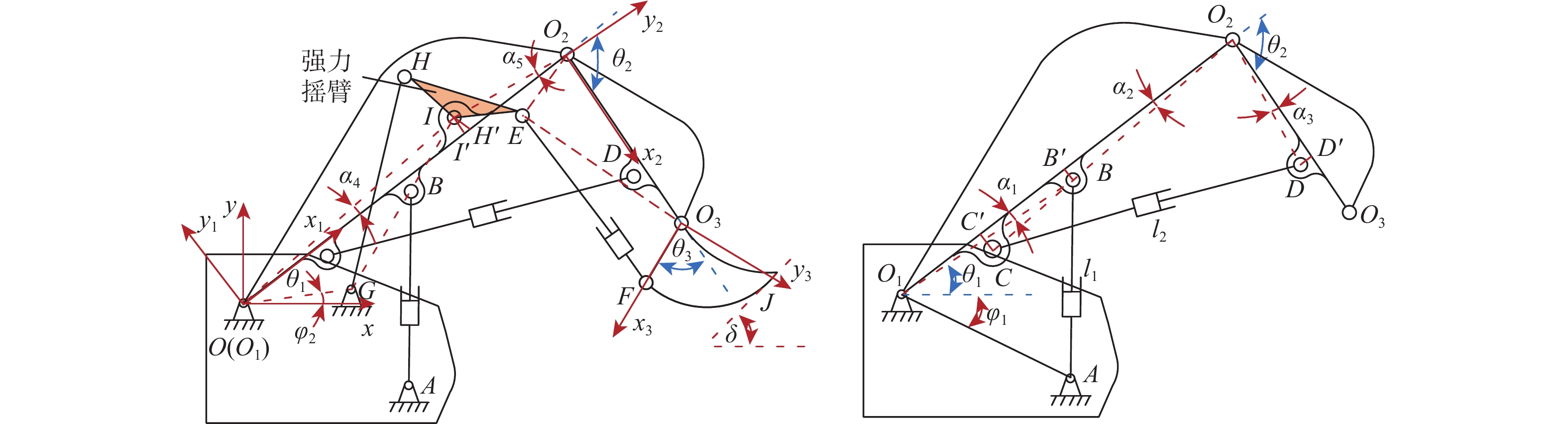

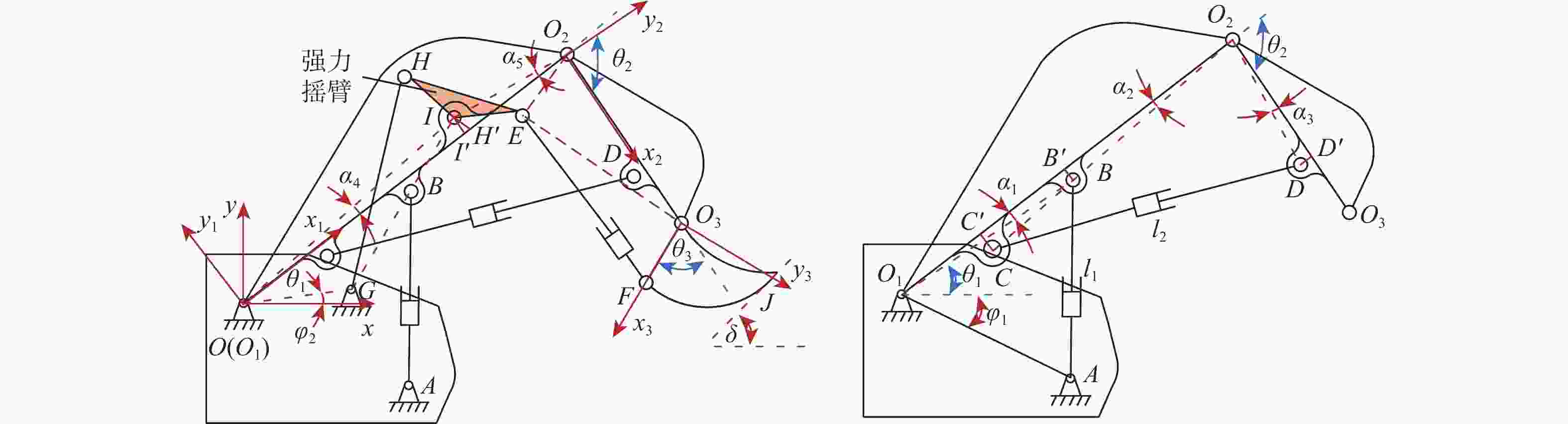

针对矿用正铲液压挖掘机操纵复杂度高的问题,提出了一种通用型人机协同控制方法。对比分析了3种能够降低正铲液压挖掘机操纵复杂度的新型工作装置在动臂提升和水平推压作业模式下的作业性能,结果表明,工作装置创新设计存在机构复杂和作业精度低的问题。基于运动学逆解和切换控制思想,所提方法采用驾驶员手动操纵主要执行机构,其他辅助执行机构根据作业要求约束进行自主协同的策略,在保证作业精度的同时,减小了驾驶员操纵难度。结果表明,所提方法能够降低正铲液压挖掘机在动臂提升和水平推压作业模式下的操纵复杂度,提高作业精度和效率,具有模式切换灵活、通用性强等优点。

Abstract:In view of the high operation complexity of forward shovel hydraulic mining excavators, a general human-machine collaborative control method was proposed. This paper compared the performance of three new working devices which could reduce the operation complexity of the forward shovel hydraulic excavators under the boom lifting and horizontal crowding operation modes. The results show that the innovative design of the working devices has the problems of complex mechanisms and low operation accuracy. The human-machine collaborative control method based on inverse kinematics and switching control adopts the strategy that the driver manually controls the main actuator, and other auxiliary actuators cooperate independently according to the constraints of operation requirements. This not only ensures the operation accuracy but also reduces the operation difficulty of drivers. The research results show that the proposed human-machine collaborative control method can reduce the operation complexity and improve the operation accuracy and efficiency of the forward shovel excavators under the boom lifting and horizontal crowding operation modes. The method has the advantages of flexible mode switching and strong universality.

-

表 1 特殊工况下工作装置作业性能对比

Table 1. Comparison of operation performances of working devices under special working conditions

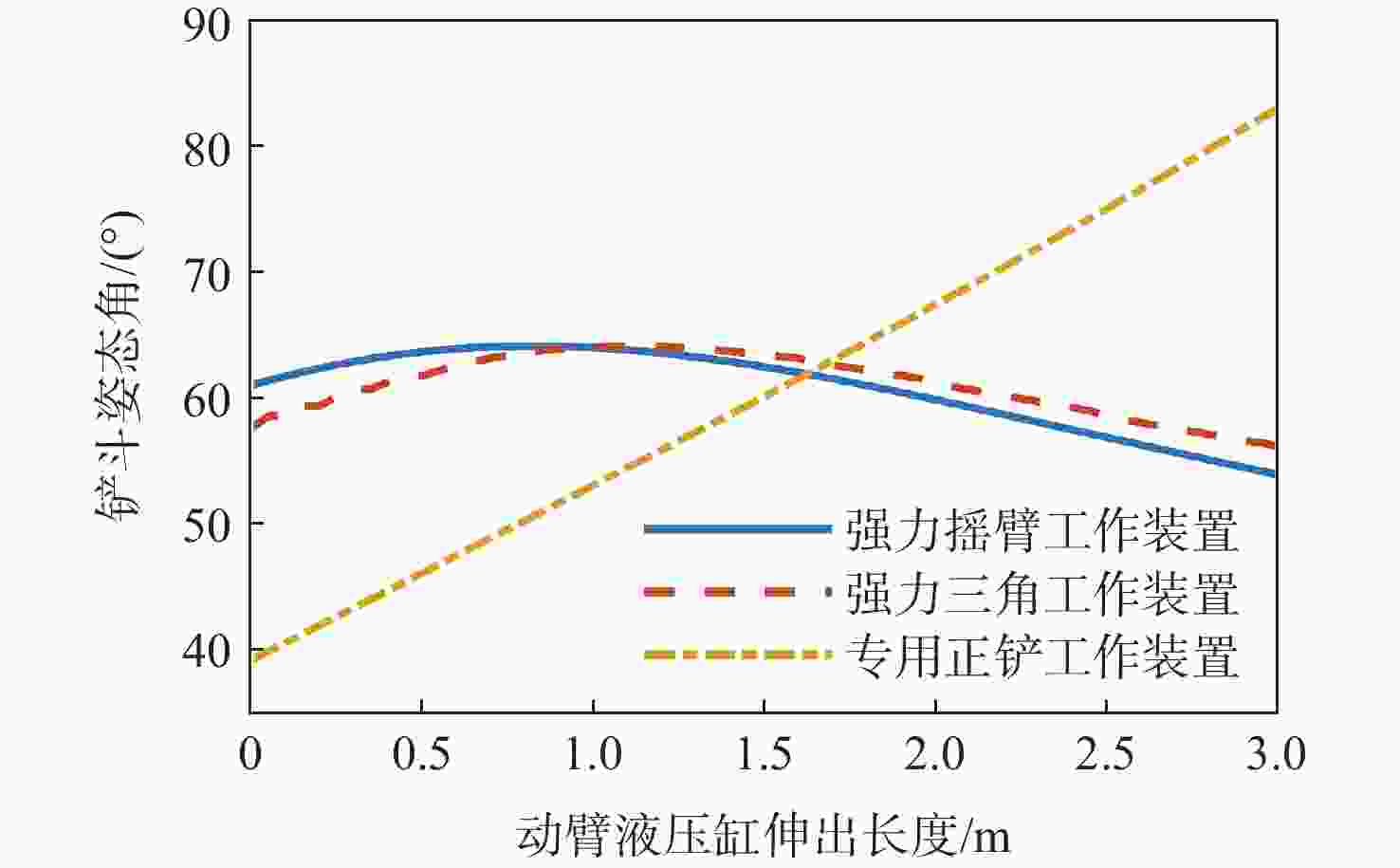

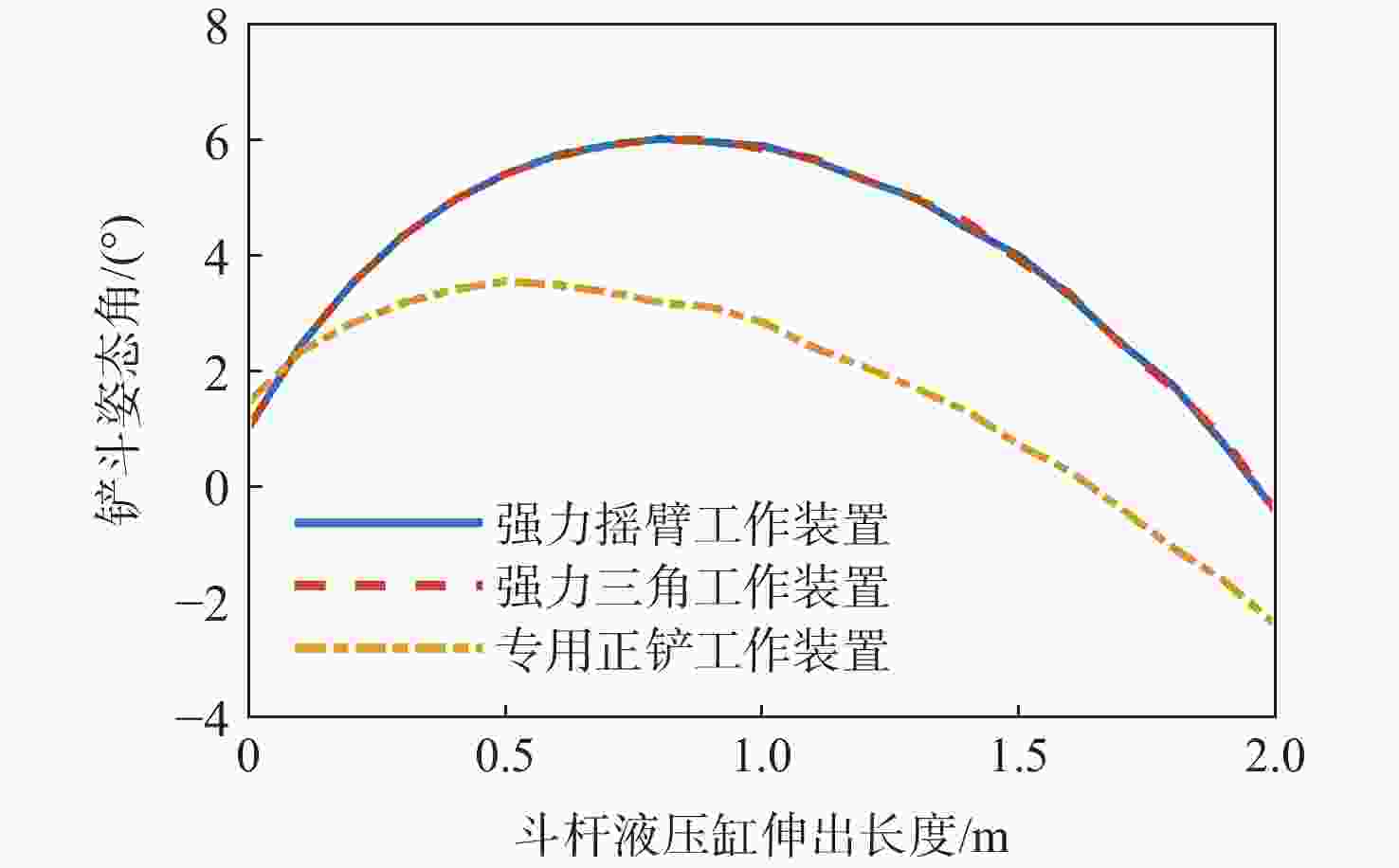

(°) 作业模式 专用正铲姿态角 强力三角姿态角 强力摇臂姿态角 区间 标准差 区间 标准差 区间 标准差 动臂提升 挖掘半径16 m [39.1,82.9] 12.86 [56.1,64.0] 2.45 [53.8,64.0] 3.17 挖掘半径17 m [45.1,88.9] 12.86 [58.3,69.5] 2.90 [62.4,69.5] 2.18 水平推压 作业高度0 m [$ - $2.4,3.6] 1.81 [$ - $0.4,6.0] 1.94 [$ - $0.4,6.0] 1.95 作业高度1 m [$ - $3.7,3.9] 2.36 [$ - $3.3,4.6] 2.21 [$ - $3.3,4.6] 2.21 表 2 各子系统控制参数

Table 2. Control parameters of each subsystem

子系统 kp ki kd 动臂 4 0.5 0.2 斗杆 4 0.5 0.2 铲斗 4 1 0.2 -

[1] HALL A S, MCAREE P R. Robust bucket position tracking for a large hydraulic excavator[J]. Mechanism and Machine Theory, 2005, 40(1): 1-16. doi: 10.1016/j.mechmachtheory.2004.05.005 [2] MITREV R, GRUYCHEV R, POBEGAILO P. CAD/CAE investigation of a large hydraulic mining excavator[J]. Machine Design, 2011, 3(1): 17-22. [3] VLADEANU A, VLADEANU G. The possibilities of the horizontal trajectory realization of the bucket teeth at tri-power excavators[C]//SISOM 2012 and Session of the Commission of Acoustics. Bucharest: SISOM press, 2012: 232-239. [4] 朱丹丹, 曹宇. 强力三角结构液压正铲挖掘机的力学分析[J]. 煤矿机械, 2015, 36(11): 126-127.ZHU D D, CAO Y. Kinematics analysis of triangle structure face-shovel[J]. Coal Mine Machinery, 2015, 36(11): 126-127 (in Chinese). [5] 丁华锋, 曹宇, 杨真真, 等. 基于D-H法的多连杆正铲挖掘机运动学分析与包络图绘制[J]. 燕山大学学报, 2014, 38(3): 197-203. doi: 10.3969/j.issn.1007-791X.2014.03.002DING H F, CAO Y, YANG Z Z, et al. Position kinematics analysis of multi-linkage face-shovel excavator and envelope plotting using D-H method[J]. Journal of Yanshan University, 2014, 38(3): 197-203(in Chinese). doi: 10.3969/j.issn.1007-791X.2014.03.002 [6] LI Y H, MU X Y, FAN R J. Multi-objective optimization and simulation of novel working mechanism for face-shovel excavator[J]. International Journal of Intelligent Robotics and Applications, 2021, 5(1): 1-9. doi: 10.1007/s41315-020-00160-1 [7] FAN R J, LI Y H. An adaptive fuzzy trajectory tracking control via improved cerebellar model articulation controller for electro-hydraulic shovel[J]. IEEE/ASME Transactions on Mechatronics, 2021, 26(6): 2870-2880. doi: 10.1109/TMECH.2021.3094284 [8] QIN T, LI Y H, QUAN L, et al. An adaptive robust impedance control considering energy-saving of hydraulic excavator boom and stick systems[J]. IEEE/ASME Transactions on Mechatronics, 2022, 27(4): 1928-1936. doi: 10.1109/TMECH.2022.3173991 [9] SHI J P, QUAN L, ZHANG X G, et al. Electro-hydraulic velocity and position control based on independent metering valve control in mobile construction equipment[J]. Automation in Construction, 2018, 94: 73-84. doi: 10.1016/j.autcon.2018.06.005 [10] BAO R K, WANG Q F, WANG T. Energy-saving trajectory tracking control of a multi-pump multi-actuator hydraulic system[J]. IEEE Access, 2020, 8: 179156-179166. doi: 10.1109/ACCESS.2020.3027354 [11] LI Y, WANG Q F. Adaptive neural finite-time trajectory tracking control of hydraulic excavators[J]. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2018, 232(7): 909-925. [12] 李勇. 自动作业液压挖掘机的铲斗轨迹控制和回转力矩控制研究[D]. 杭州: 浙江大学, 2019: 79-85.LI Y. Study on bucket traiectorv and swing torque control for the autonomous hydraulic excavator[D]. Hangzhou: Zhejiang University, 2019: 79-85(in Chinese). [13] KIM S, PARK J, KANG S, et al. A robust control approach for hydraulic excavators using μ-synthesis[J]. International Journal of Control, Automation and Systems, 2018, 16(4): 1615-1628. doi: 10.1007/s12555-017-0071-9 [14] LEE C S, BAE J, HONG D. Contour control for leveling work with robotic excavator[J]. International Journal of Precision Engineering and Manufacturing, 2013, 14(12): 2055-2060. doi: 10.1007/s12541-013-0278-5 [15] WANG D Y, ZHENG L J, YU H X, et al. Robotic excavator motion control using a nonlinear proportional-integral controller and cross-coupled pre-compensation[J]. Automation in Construction, 2016, 64: 1-6. doi: 10.1016/j.autcon.2015.12.024 [16] ARAYA H, KAGOSHIMA M. Semi-automatic control system for hydraulic shovel[J]. Automation in Construction, 2001, 10(4): 477-486. doi: 10.1016/S0926-5805(00)00083-2 -

下载:

下载: