-

摘要:

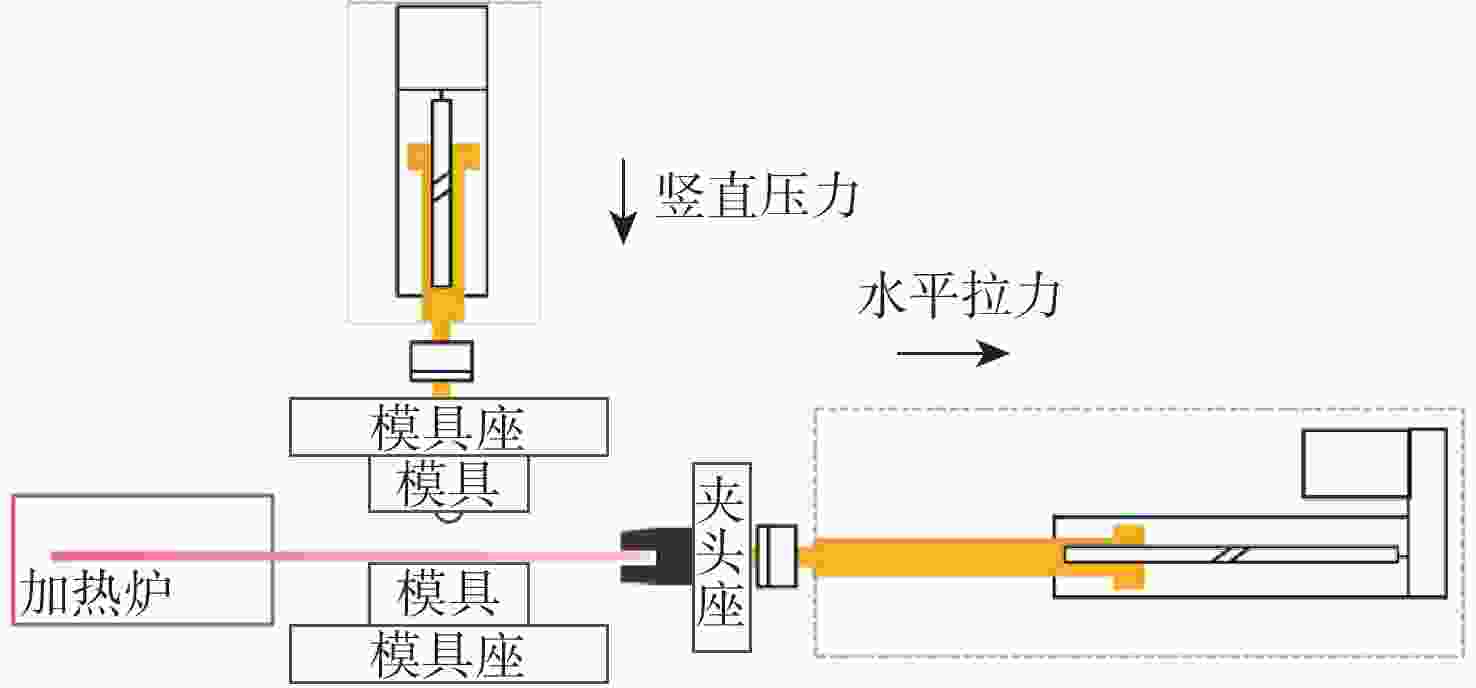

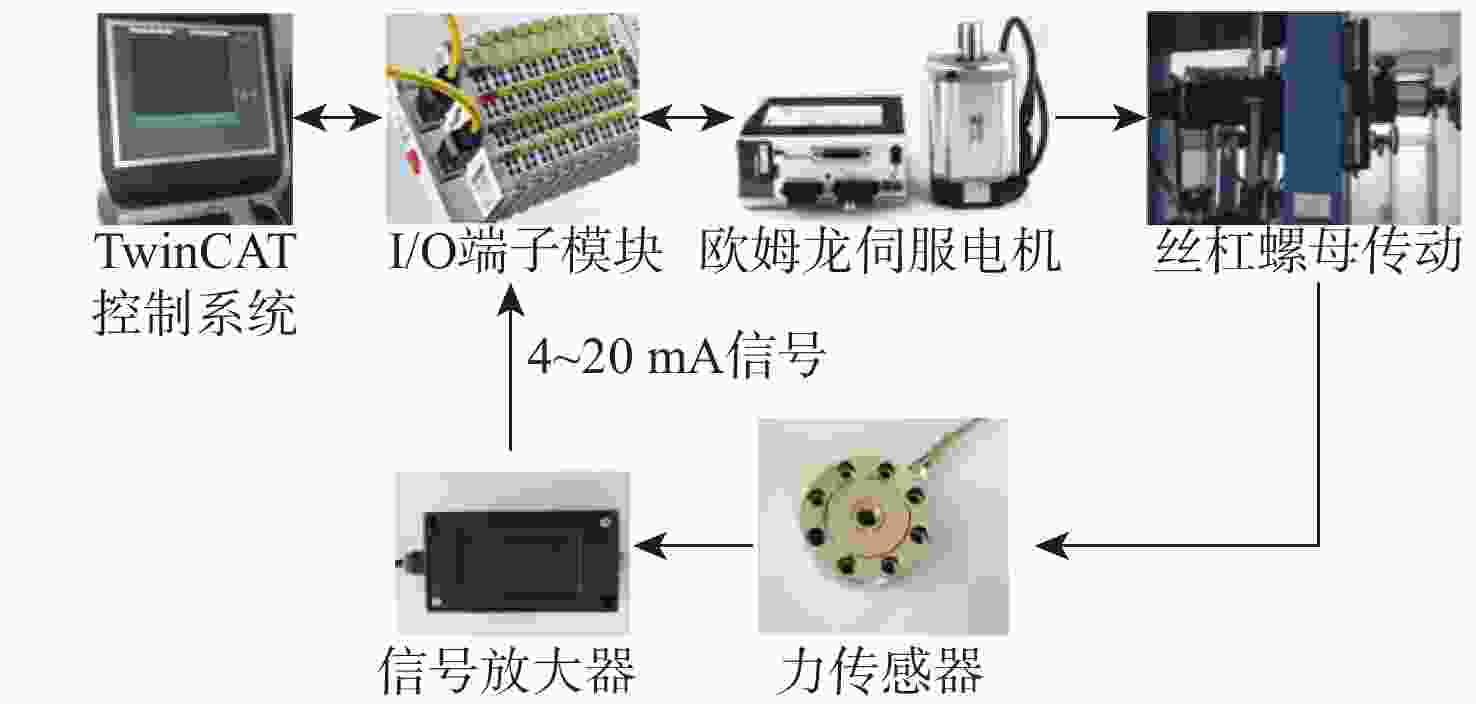

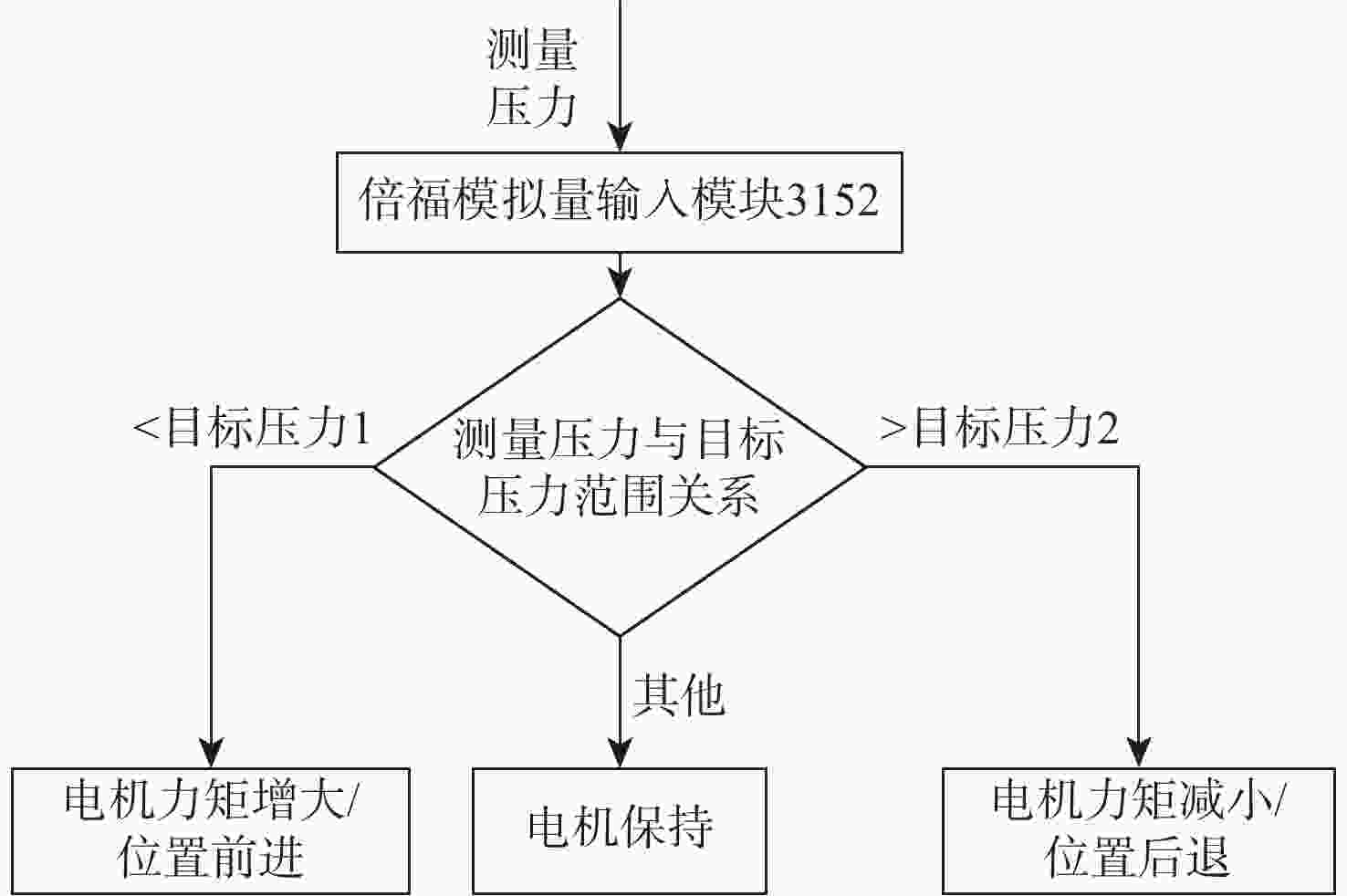

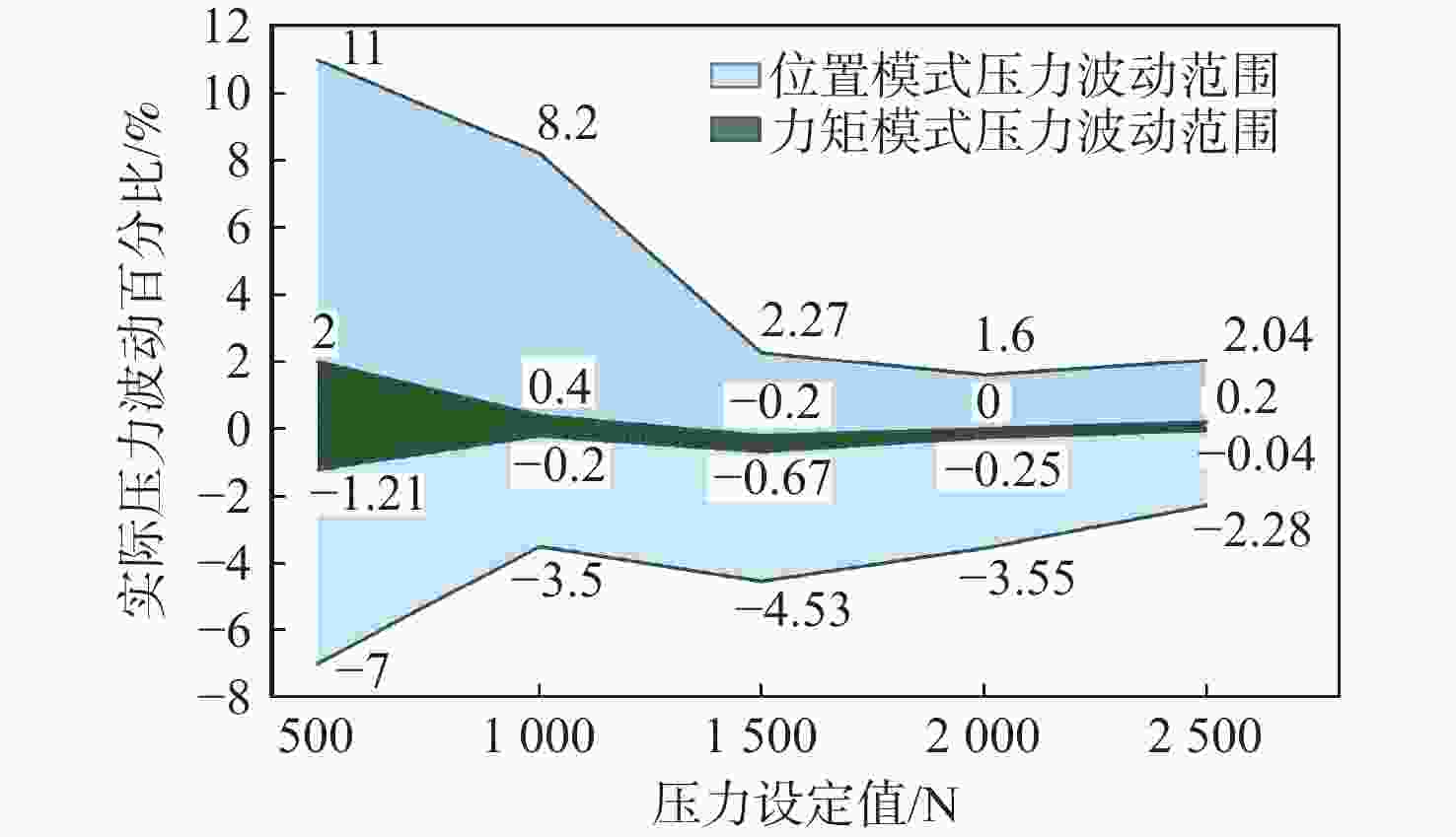

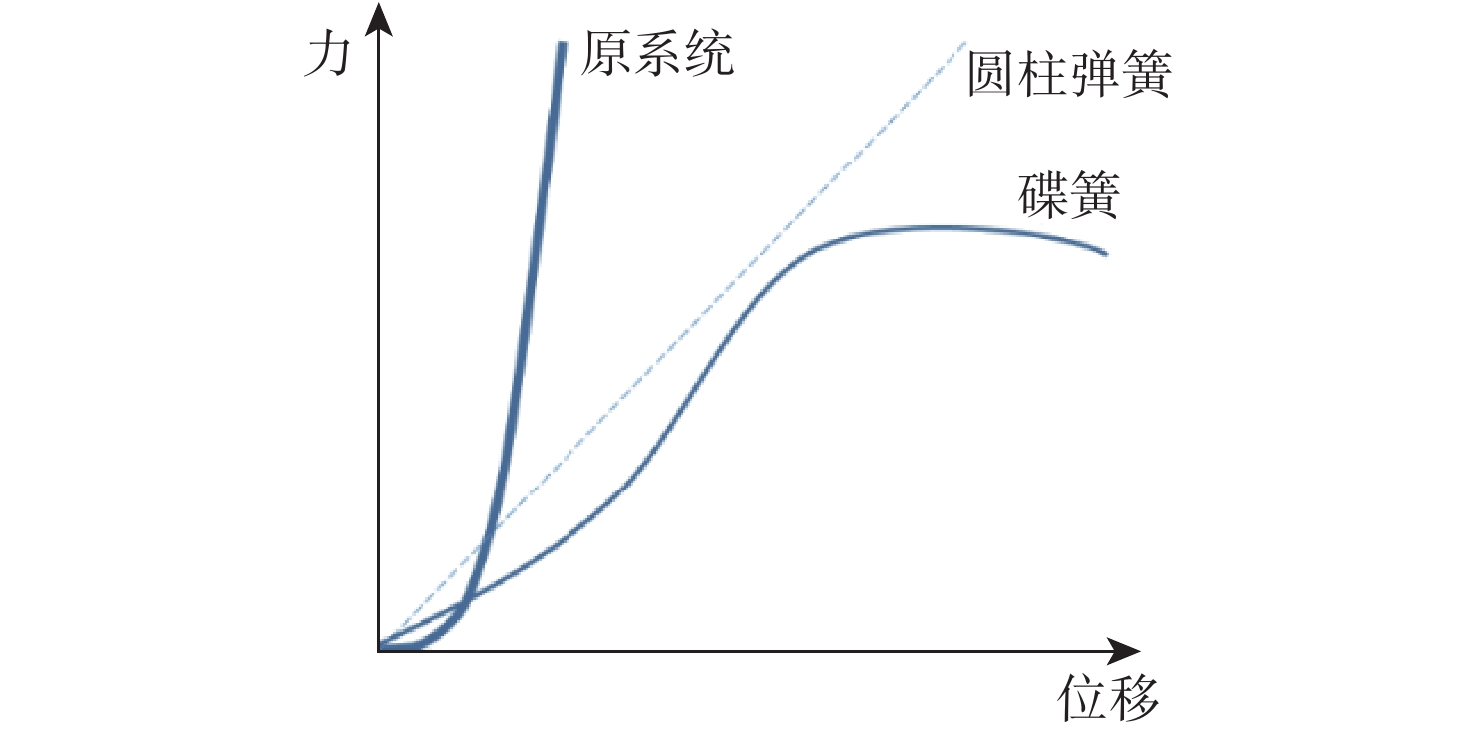

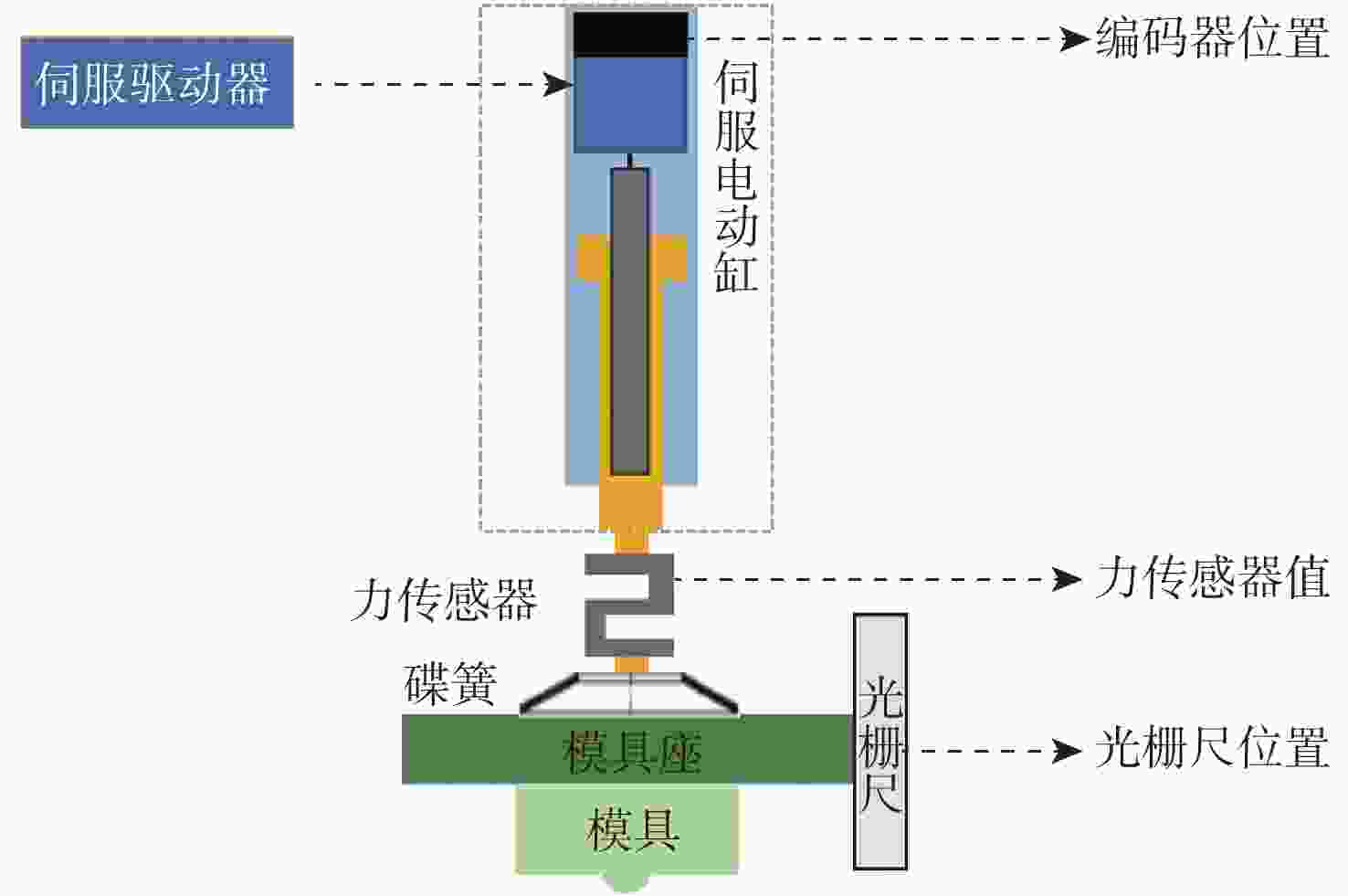

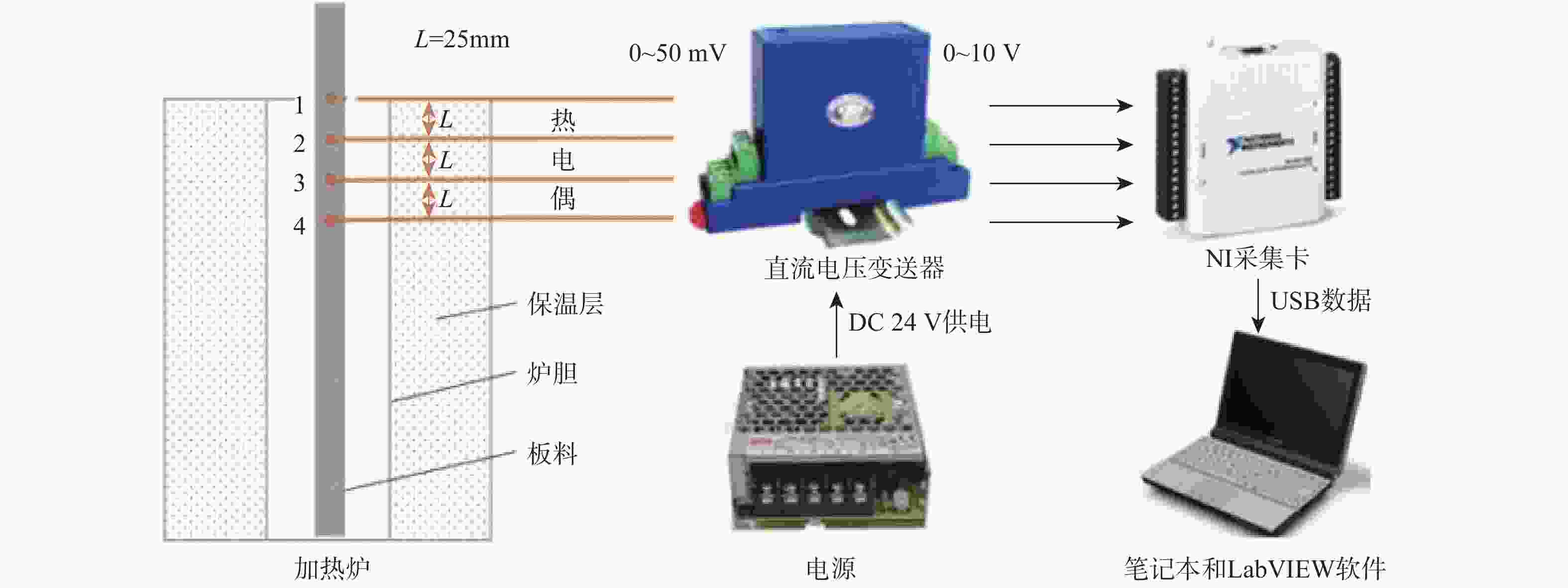

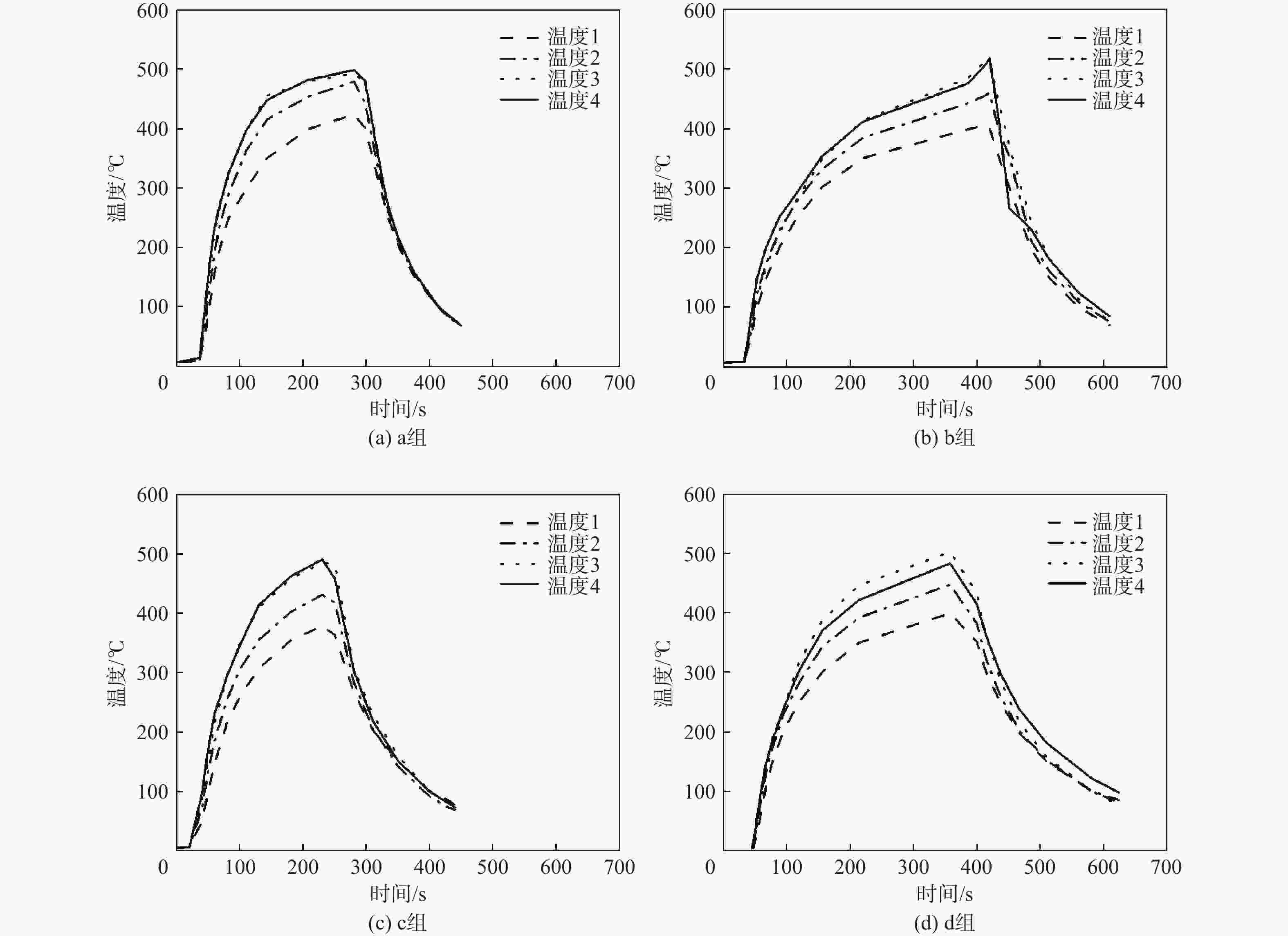

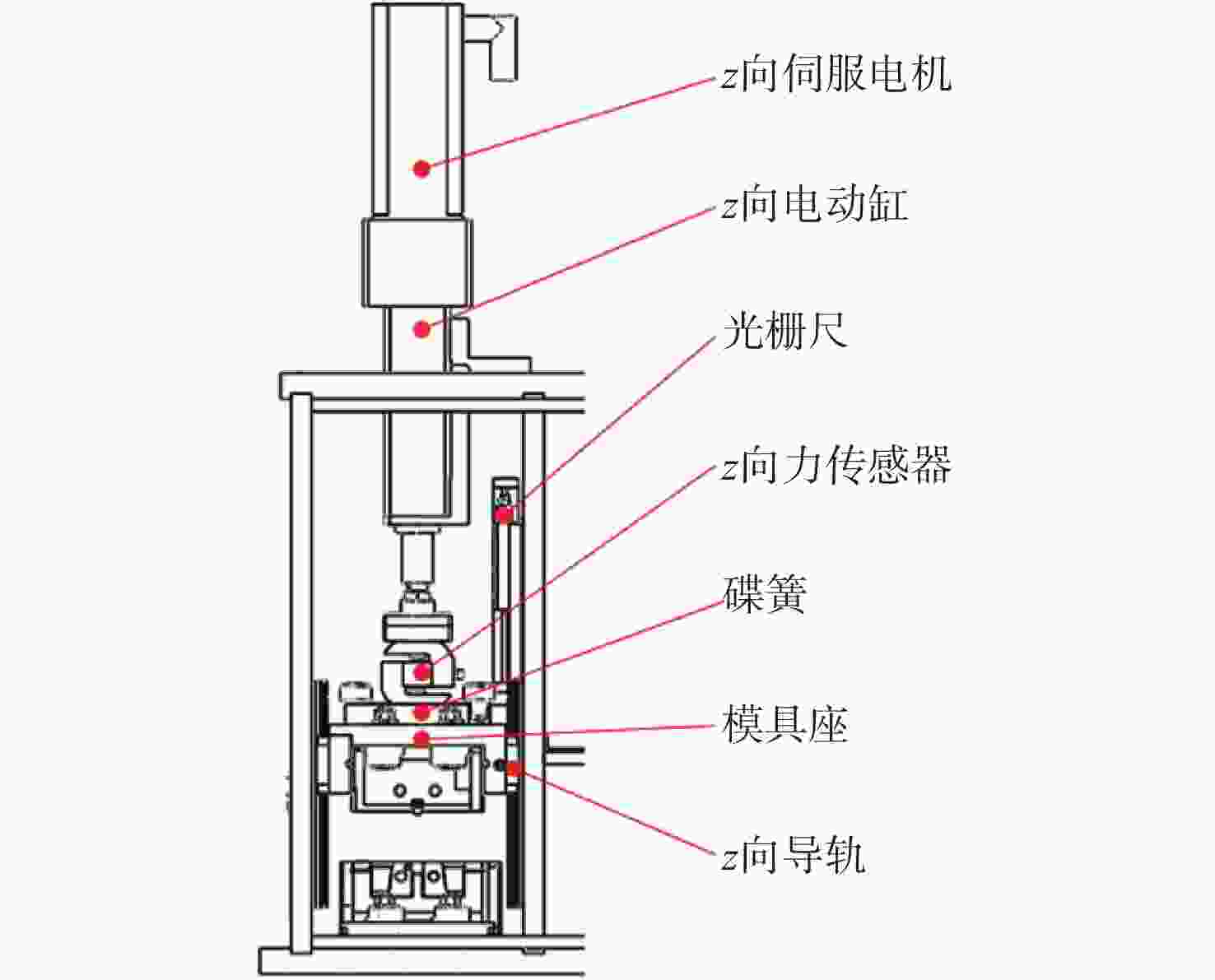

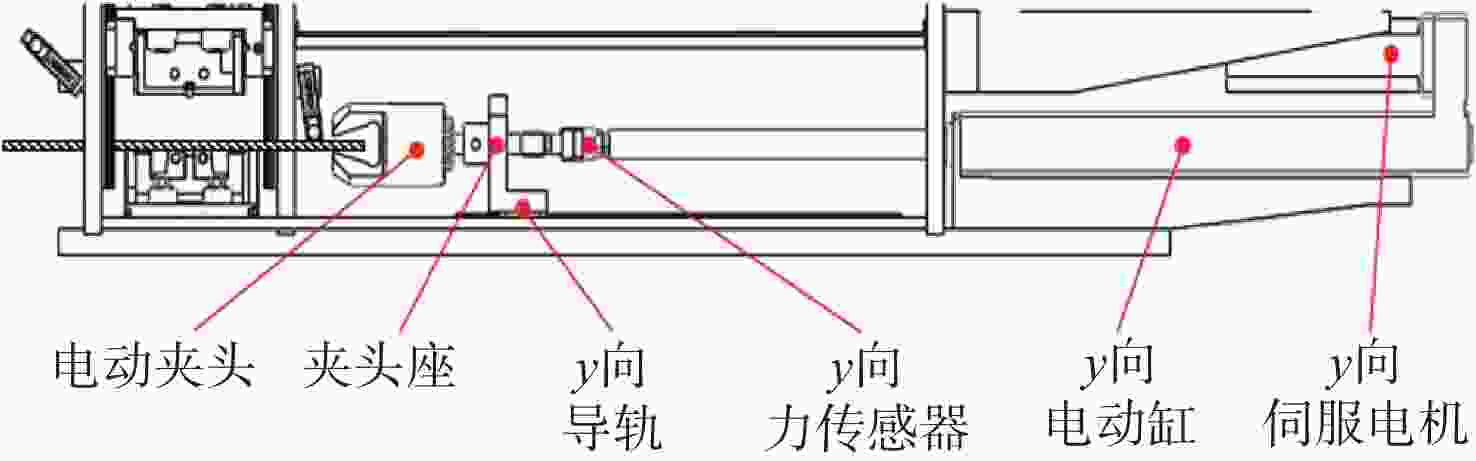

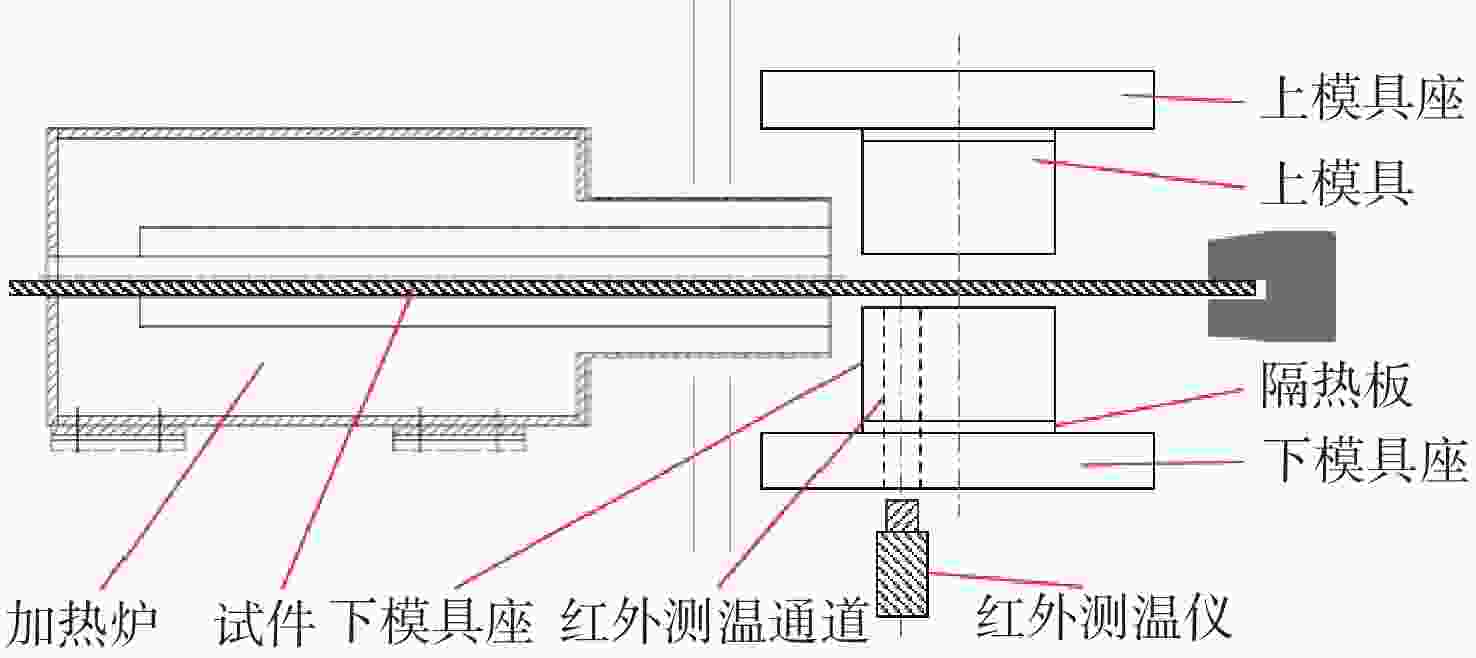

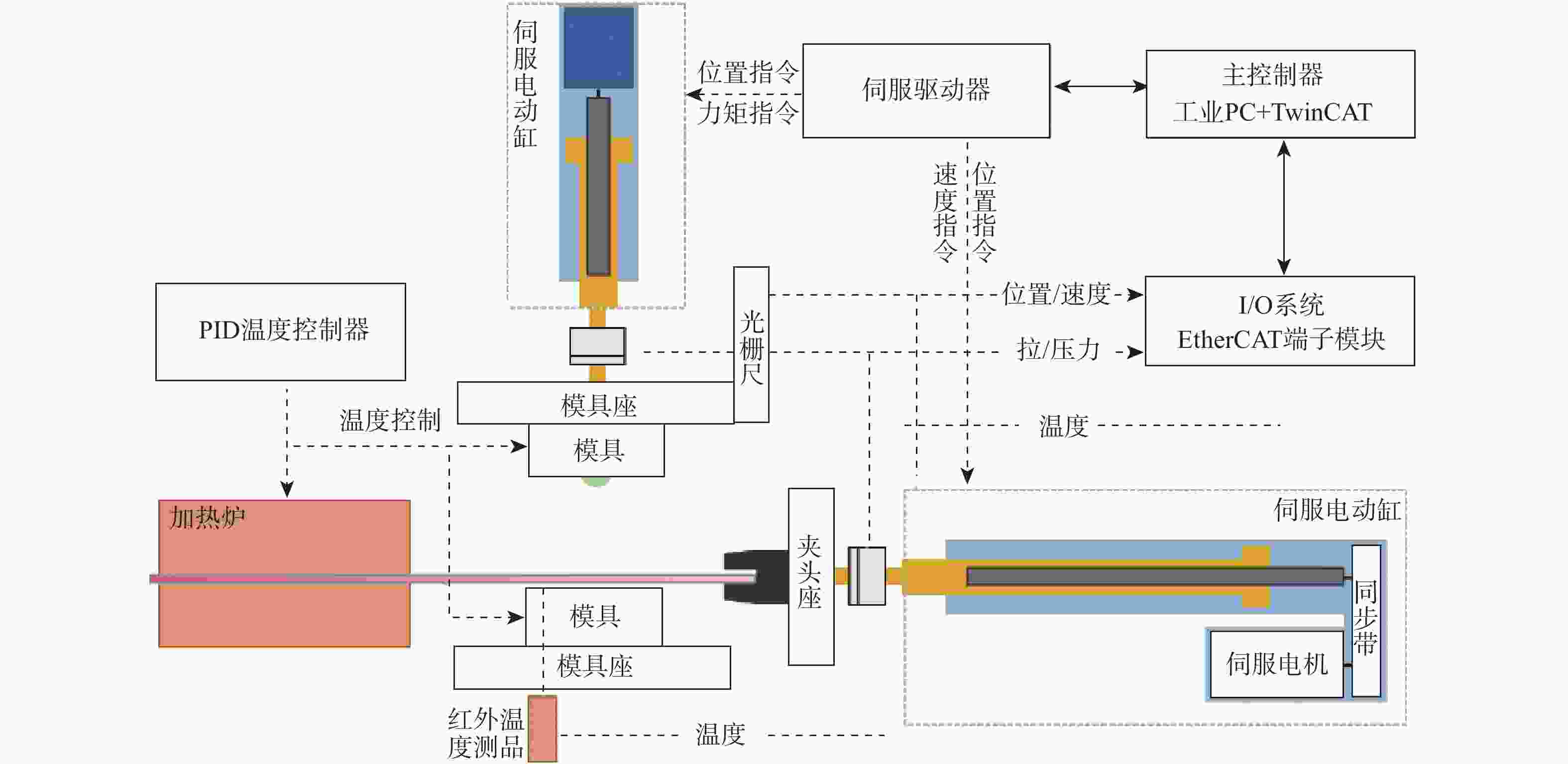

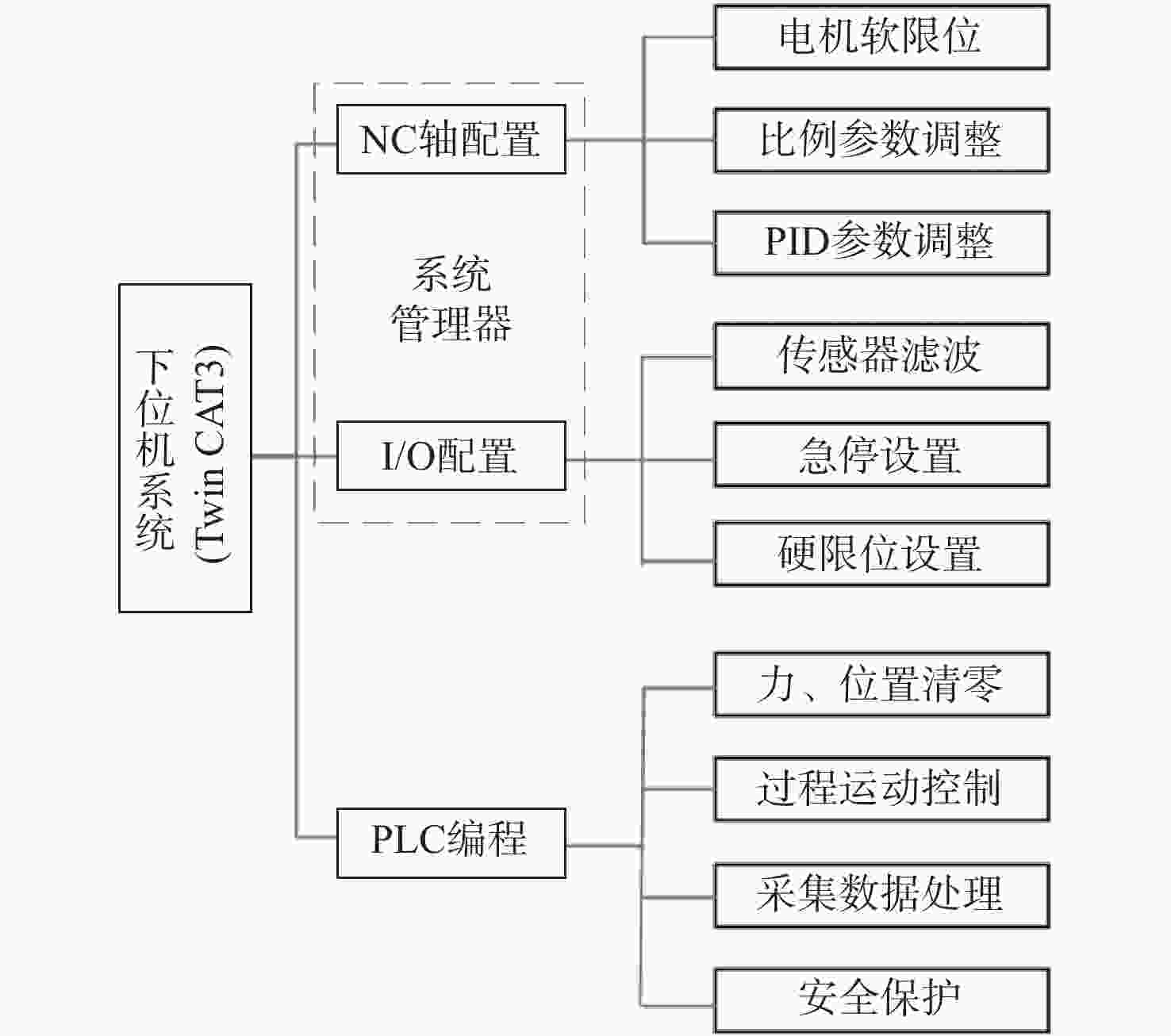

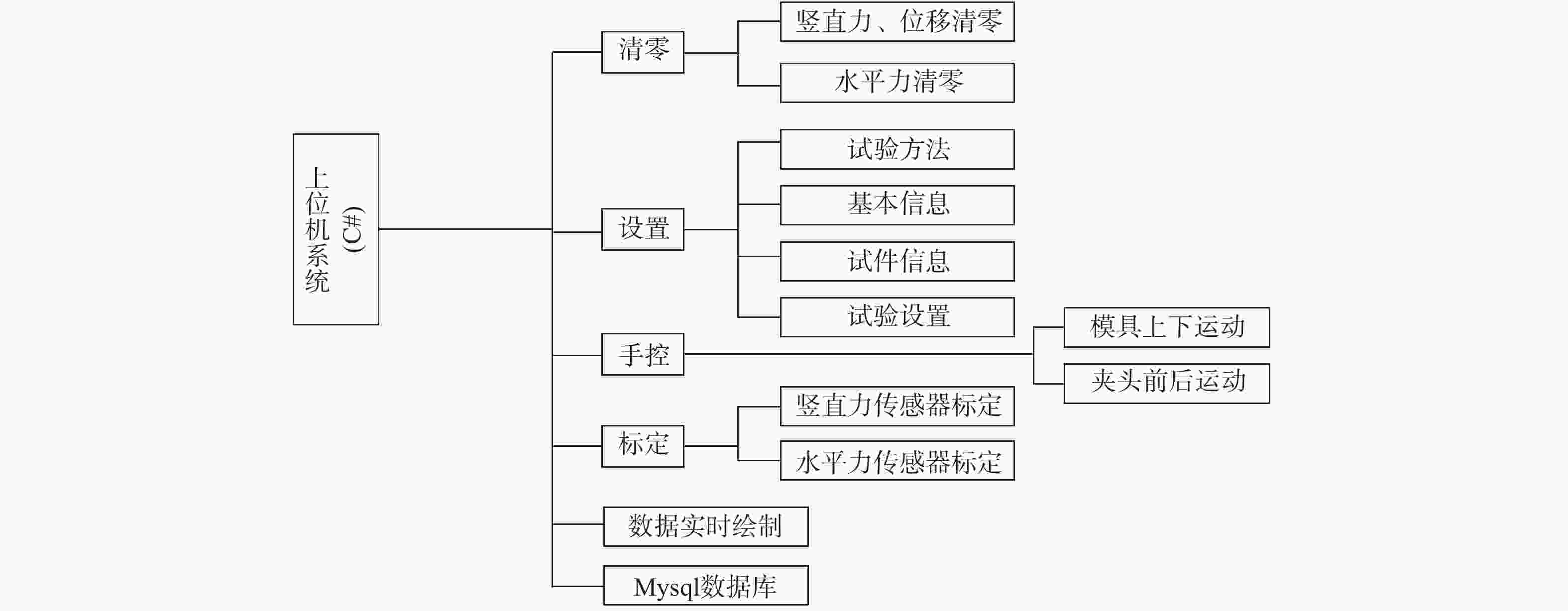

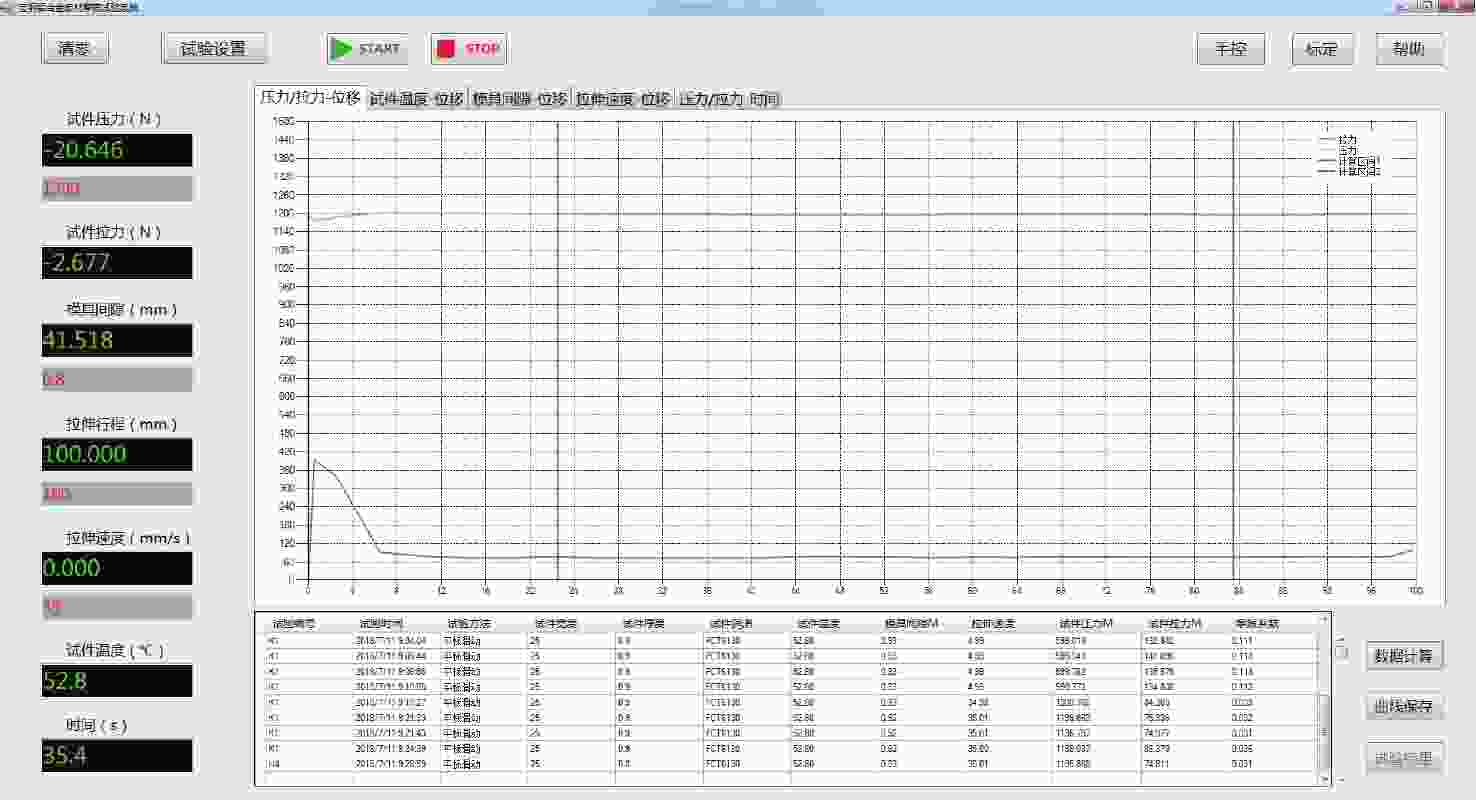

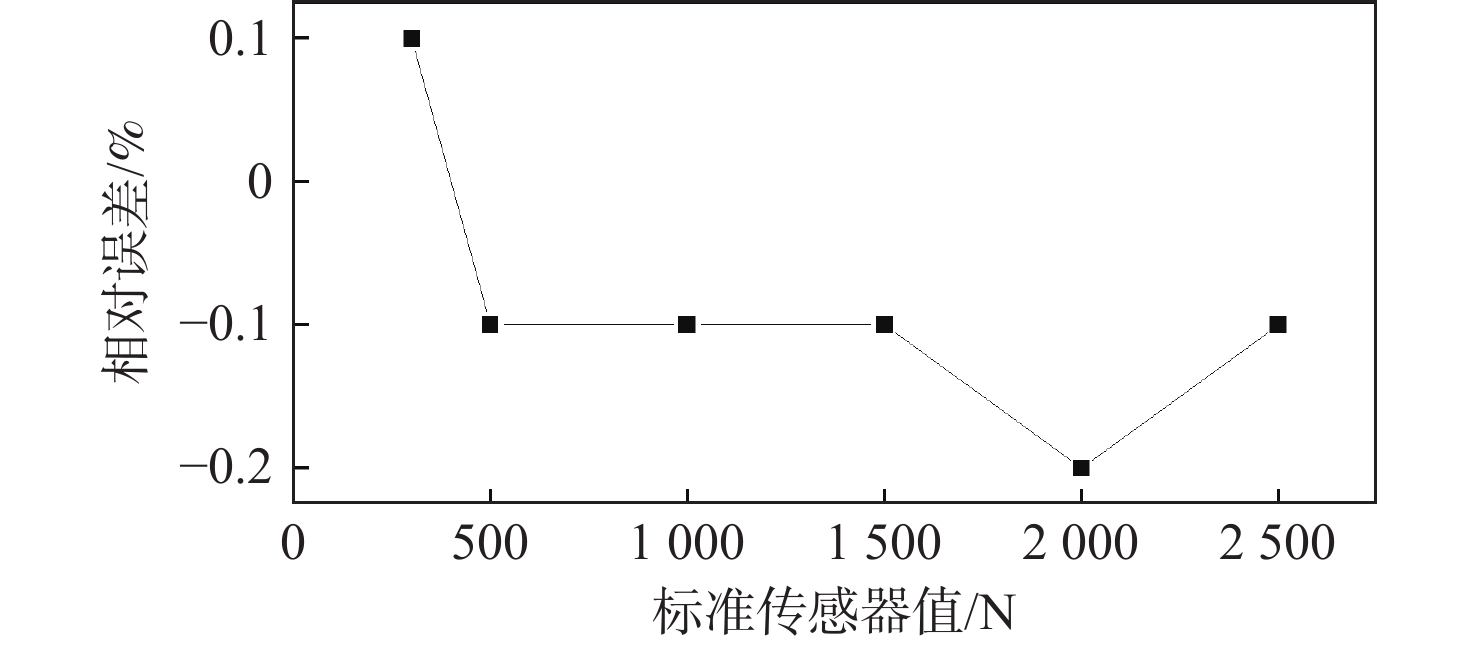

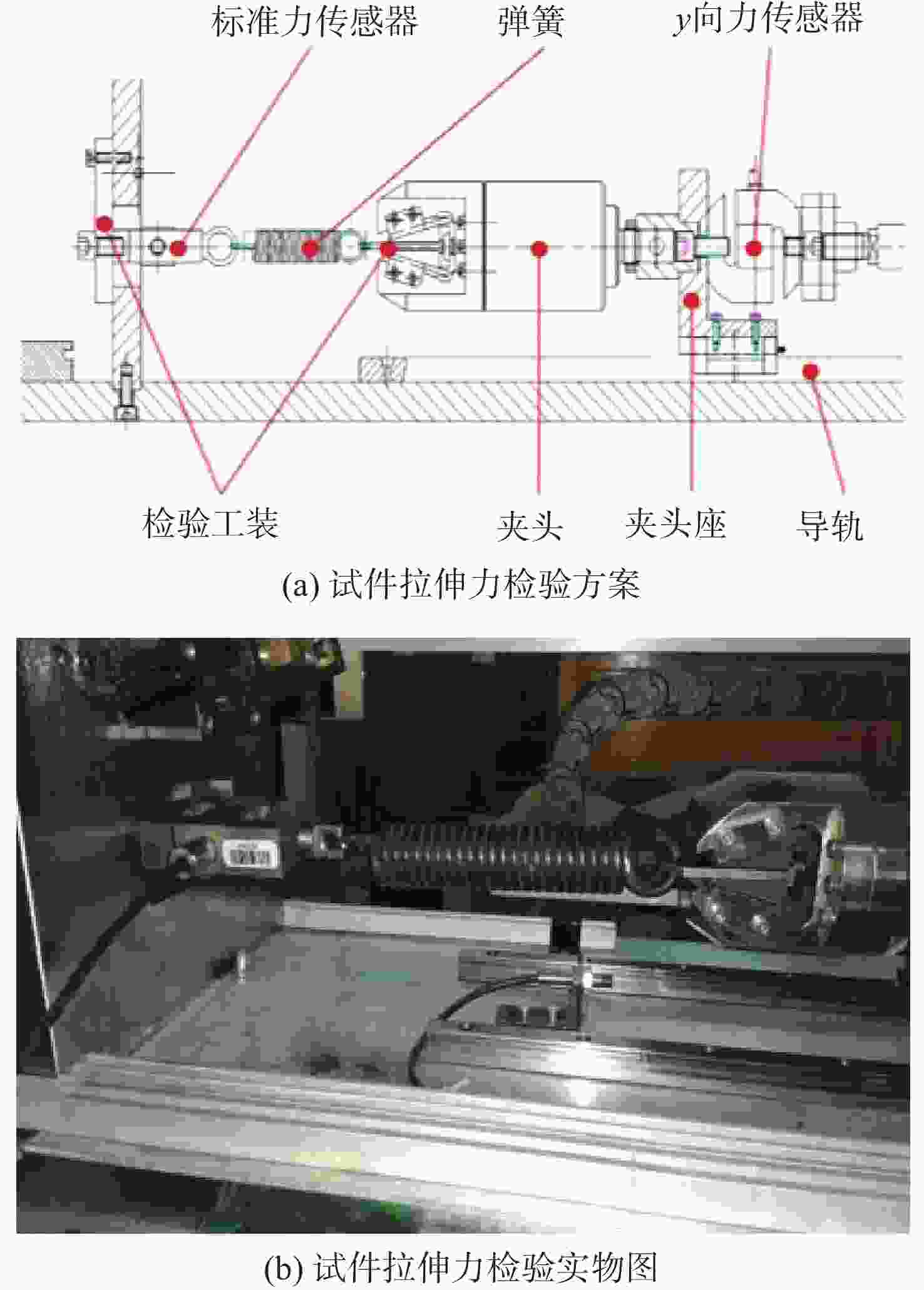

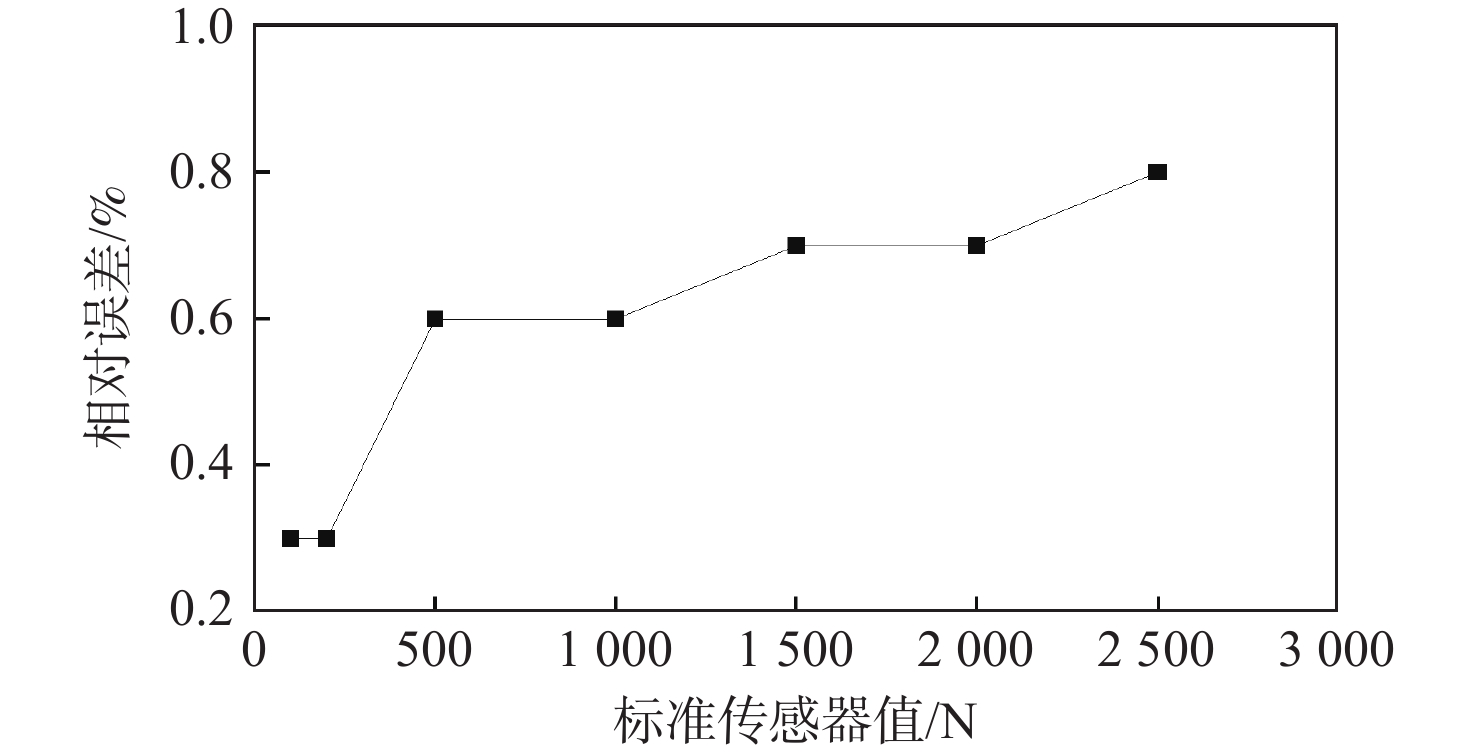

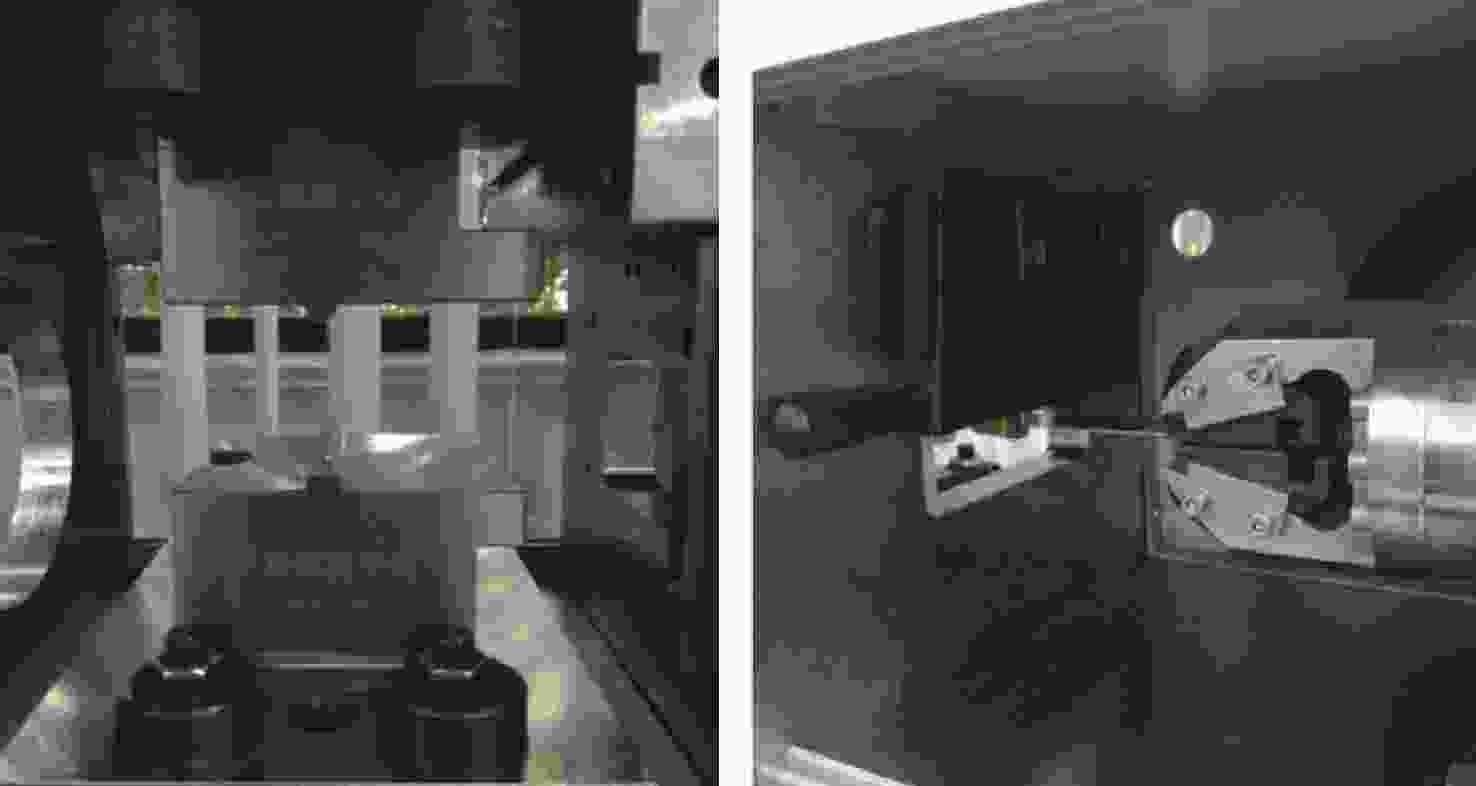

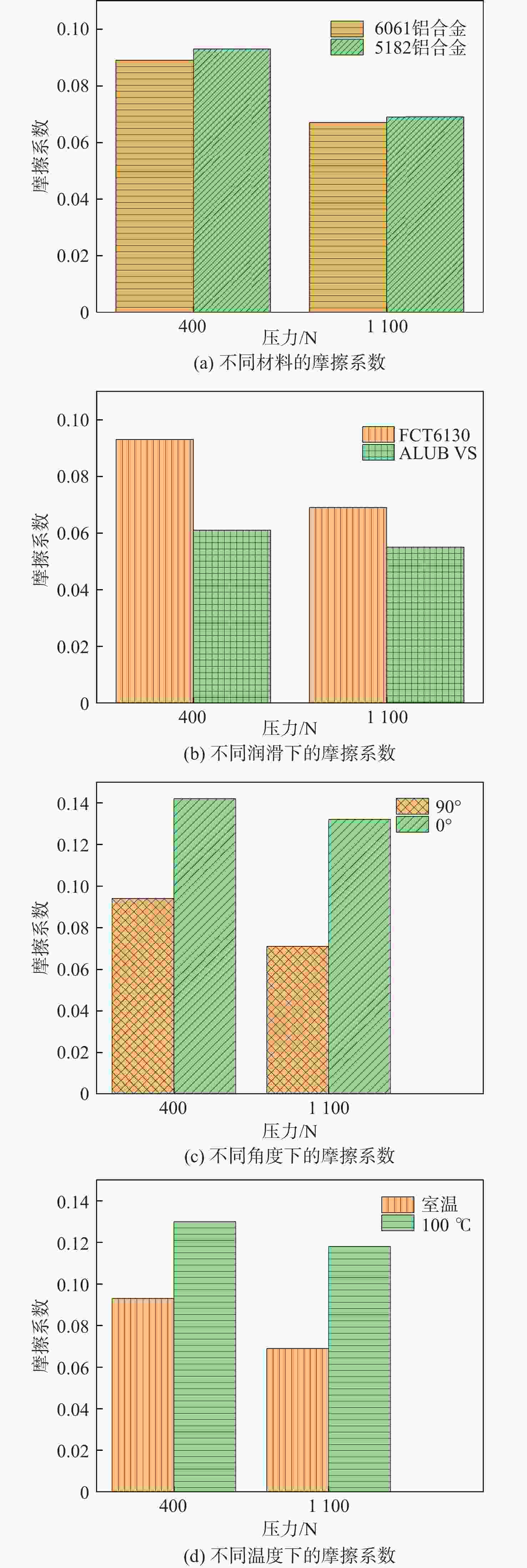

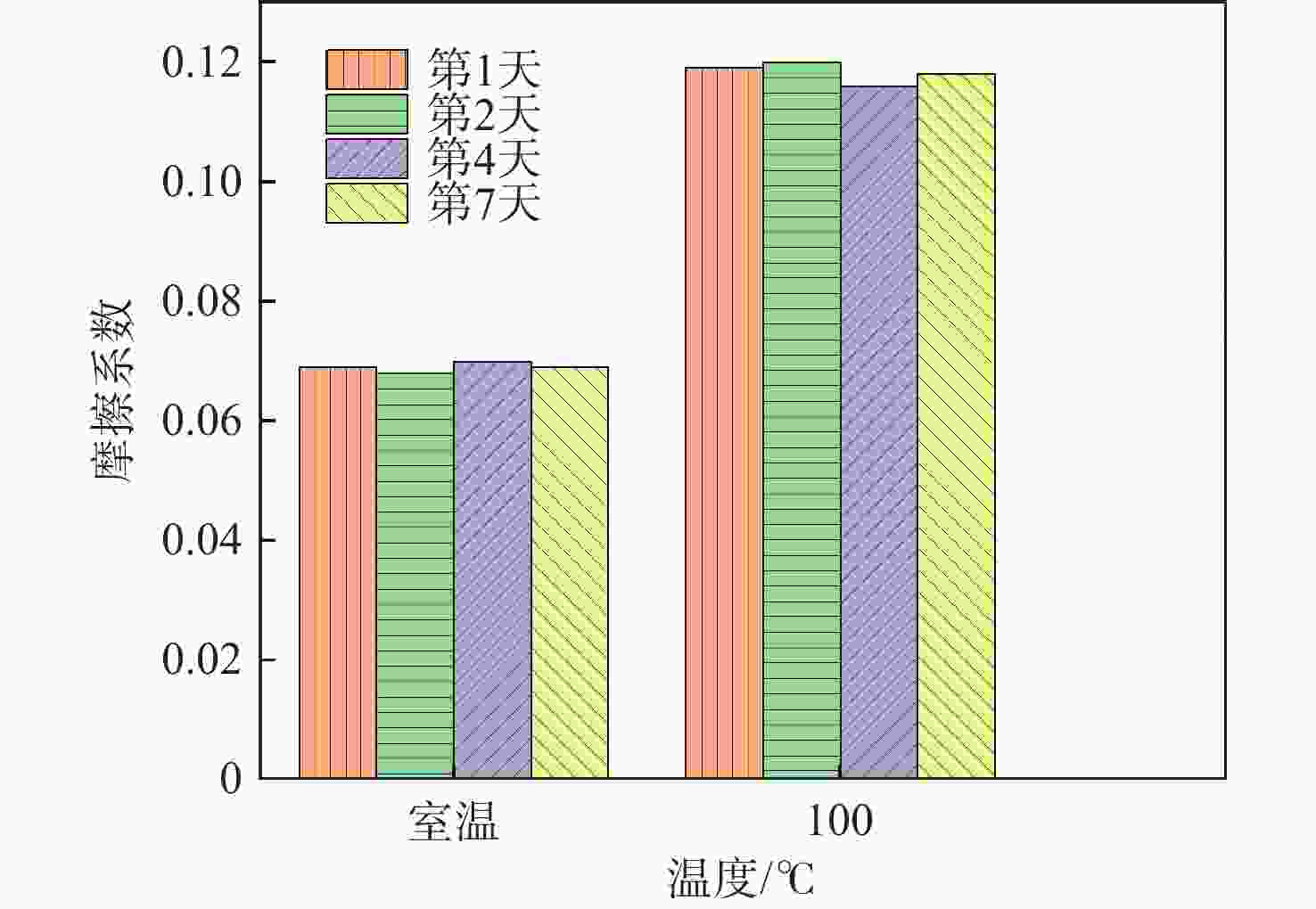

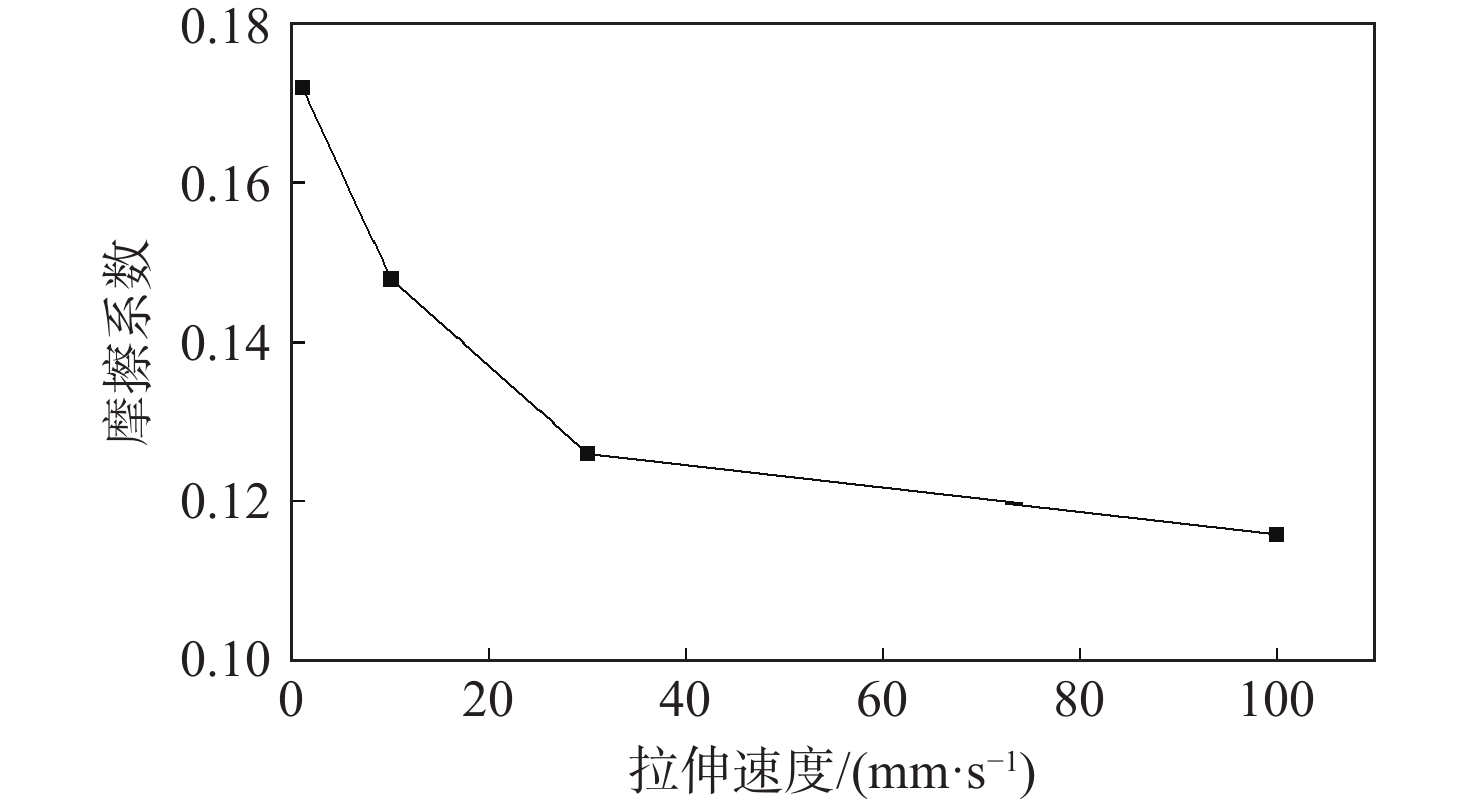

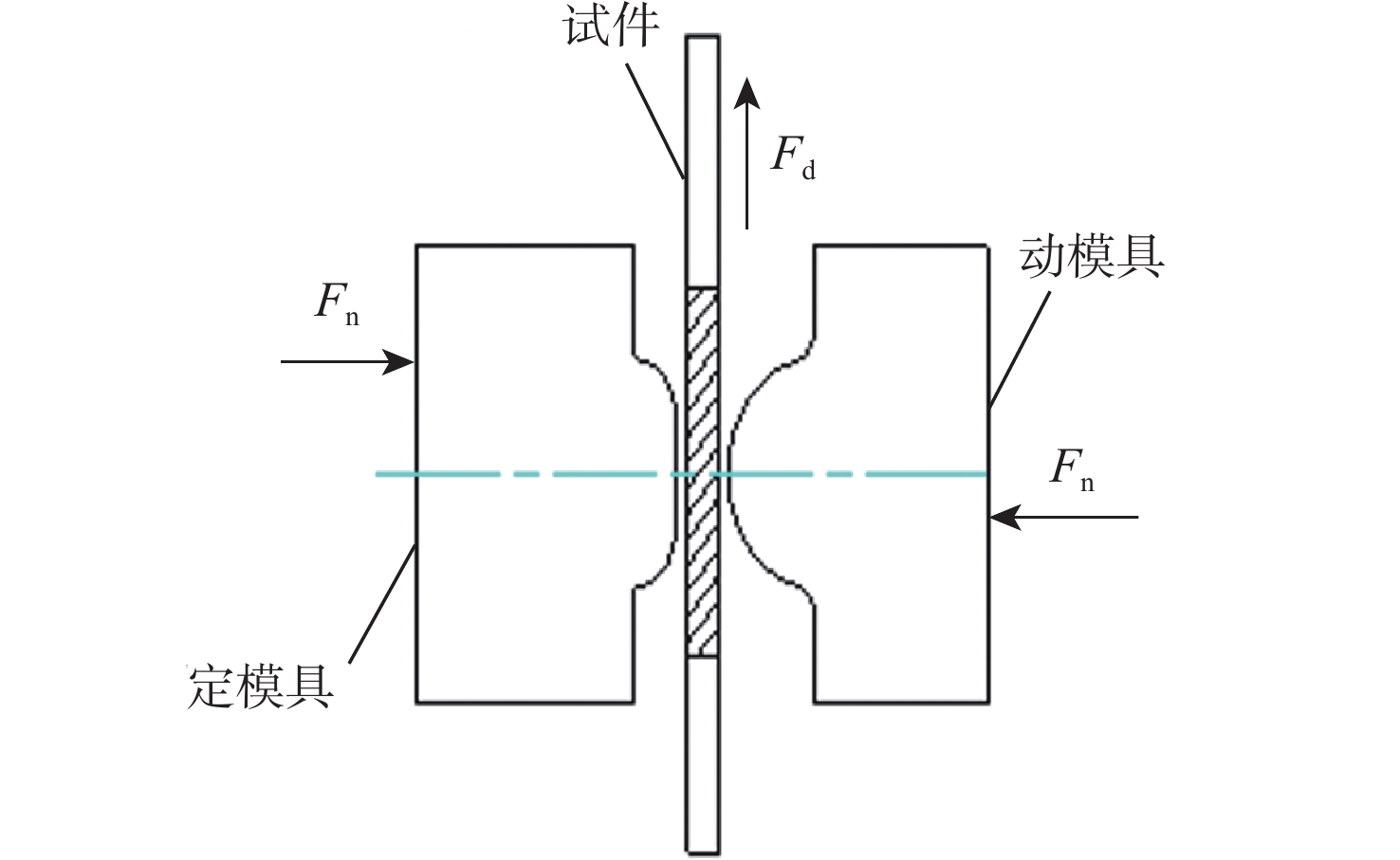

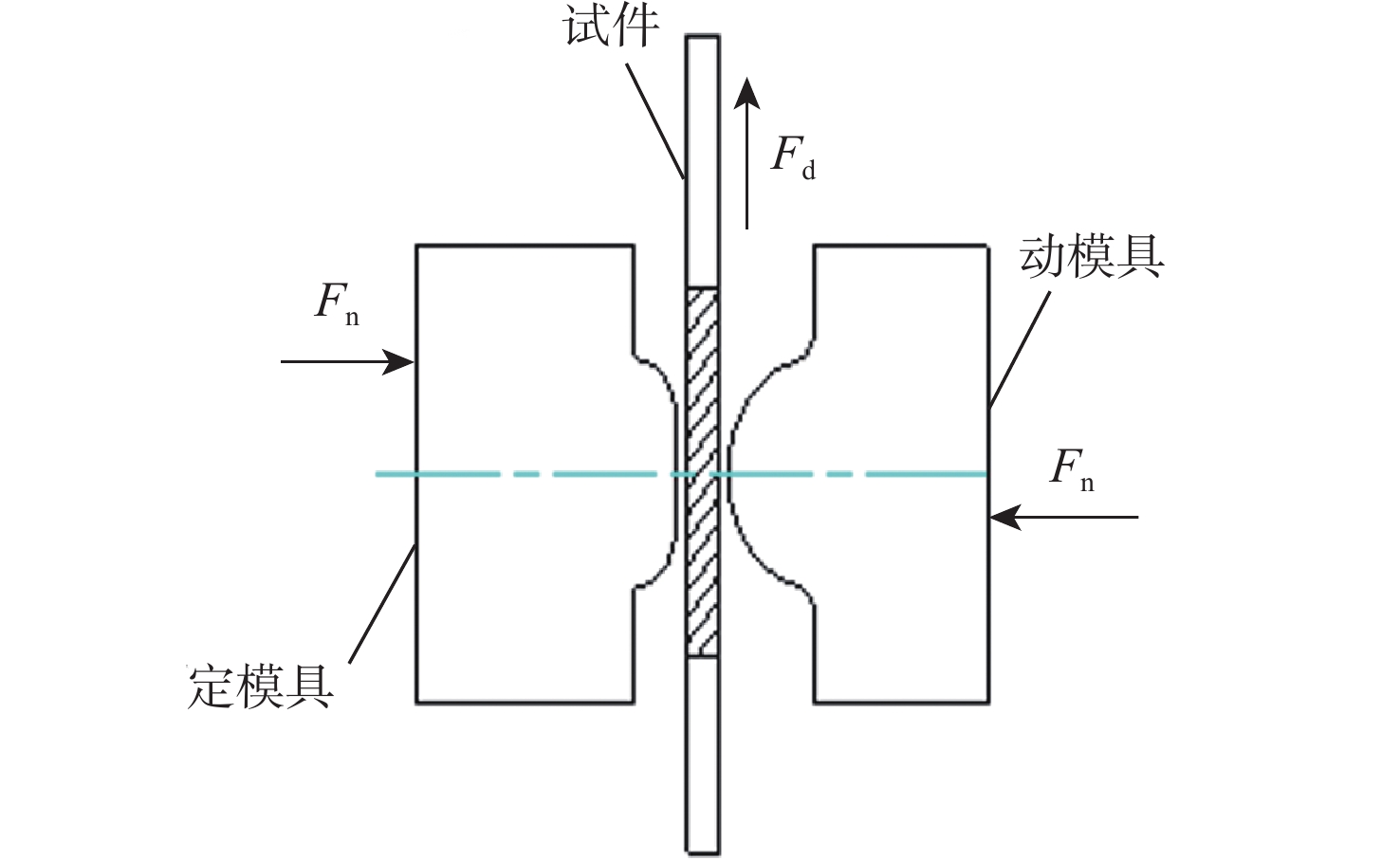

针对铝合金板冲压成形对摩擦测试的需求,确定考虑加热条件下铝合金板材冲压摩擦伺服压力摩擦测试平台的总体设计方案,开发适用于铝合金板材成形的小载荷高精度多功能摩擦试验机系统。该系统由运动组件、加热系统及控制系统组成。运动组件实现上模具和夹头的运动支撑;加热系统实现模具与试件单独加热;在伺服控制模式下,结合外部力传感器和光栅尺,实现试件压力和模具间隙高精度高稳定性控制。实际应用检验该试验机对不同因素的区分度和重复性,并设计正交试验,探索不同因素对铝合金板材摩擦的影响。结果表明:试验机性能稳定,重复性好;影响摩擦系数因素的重要次序为:模具温度、压力、速度、润滑剂;温度越低,压力越大,速度越快,摩擦系数越小;同一种类型的润滑剂对摩擦系数的影响较小。随着压力的增大,摩擦系数减少的趋势越来越小,逐渐趋于平稳。

Abstract:The overall design concept of the servo pressure and friction test platform for aluminum alloy sheets under heating circumstances was designed with the aim of meeting the need for friction testing of aluminum alloy sheet stamping. A small-load high-precision multi-functional friction testing machine system suitable for aluminum alloy sheet forming was developed. The system consists of a mechanical system, a heating system and a control system. The mechanical system realizes the movement support of the upper tool and chuck. The heating system realizes the separate heating of tools and specimens. In the servo control mode, combined with the external force sensor and the grating ruler, the force and displacement control double closed loop system is realized, which realizes the high precision and stability control of the specimen pressure and the tool gap. Finally, the orthogonal experiment was designed to explore the influence of different factors on the friction of aluminum alloy blank. The results show that the friction tester has stable performance and good repeatability. The important order of factors affecting friction coefficient is tool temperature, pressure, speed, and lubricant. The lower the temperature, the greater the pressure, the faster the speed, and the smaller the friction coefficient. The same type of lubricant has less influence on the coefficient of friction. The tendency of the coefficient of friction decreasing decreases with increasing pressure and eventually becomes more steady.

-

Key words:

- friction tester /

- aluminum alloy sheet stamping /

- servo control /

- friction test /

- tribological behaviour

-

表 1 铝合金板材摩擦试验机参数指标

Table 1. Parameters index of aluminum alloy sheet friction tester

压力控制

范围/N载荷控制

精度/%拉力提供

范围/N试验速度范围/

(mm·s−1)有效拉伸

范围/mm温度控制

范围/℃温度控制

精度/℃板料厚度

范围/mm模具对中

精度/mm模具间隙

控制/mm≤2500 ≤±1 ≤2800 ≤100 ≤150 室温~300 ≤±1 0.7-1.5 ≤±0.1 ≤±0.02 表 2 试验分组明细

Table 2. Test group details

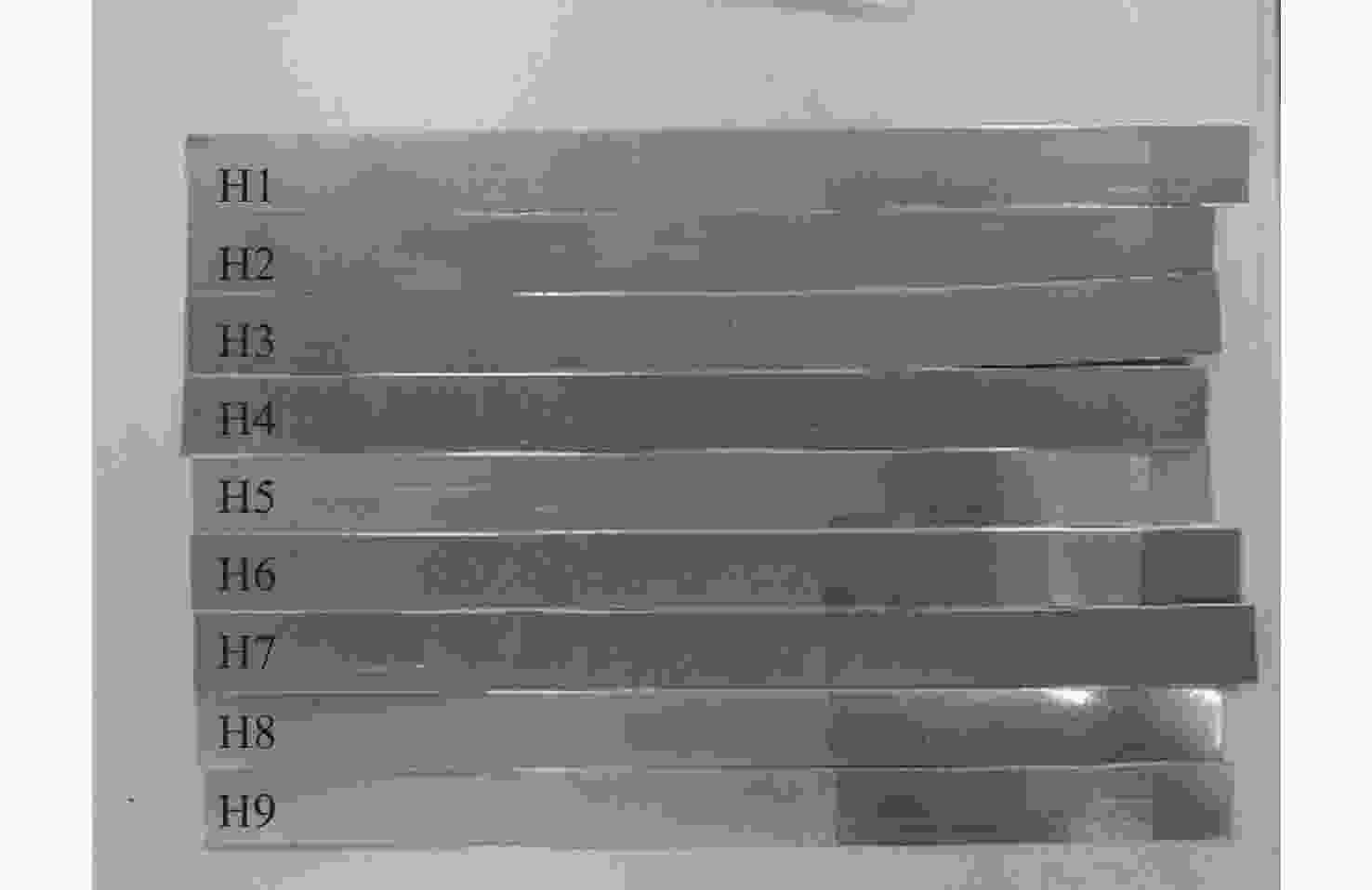

编号 长度/mm 宽度/mm 厚度/mm 表面状态 a 350 25 0.8 出厂防锈漆 b 350 25 1.2 c 350 35 0.8 d 350 35 1.2 表 3 区分度试验设置

Table 3. Distinction test setup

材料 润滑剂 压力/N 取样角度/(°) 温度/℃ 5182铝合金 FCT6130 400 0 室温 6016铝合金 ALUB VS 1100 90 100 表 4 不同工况下的摩擦系数

Table 4. Friction coefficients under different operating conditions

序号 润滑剂 模具温度/℃ 压力/N 拉伸速度/(mm·s−1) 摩擦系数 H1 F 室温 600 5 0.099 H2 F 100 1200 20 0.080 H3 F 150 1800 35 0.077 H4 A 室温 1200 35 0.032 H5 A 100 1800 5 0.080 H6 A 150 600 20 0.115 H7 Q 室温 1800 20 0.058 H8 Q 100 600 35 0.098 H9 Q 150 1200 5 0.117 表 5 正交试验分析结果

Table 5. Analysis results of orthogonal experiments

j Kj1 Kj2 Kj3 Rj 1 0.0853 0.0757 0.0910 0.0153 2 0.063 0.086 0.103 0.040 3 0.104 0.0763 0.0717 0.0323 4 0.0987 0.0843 0.0690 0.0297 注:Kji表示表4中j列i组摩擦系数之和的平均值,Rj为极差,即j列中每个因数的最大Kji与最小Kji之差。(j=1,2,3,4,分别应对表4中的第2~第5列,i=1,2,3, 分别对应表4中第j列中的3个分组,数值相同为1组)。 表 6 压力对摩擦影响试验设置

Table 6. Experimental settings for effect of pressure on friction

试验材料 取样

方向/(°)润滑剂 拉伸速度/

(mm·s−1)温度 压力/N 5182

铝合金90 FCT6130 10 室温 400,1100,

1800,2500表 7 拉伸速度对摩擦影响试验设置

Table 7. Experimental settings for the effect of speed on friction

试验材料 取样方向/(°) 润滑剂 拉伸速度/

(mm·s−1)温度 压力/N 5182铝合金 0 FCT6130 1,10,30,100 室温 1000 -

[1] 王凯, 何勇灵, 孟广威. 客车铝合金车架设计与典型工况分析[J]. 北京航空航天大学学报, 2018, 44(8): 1780-1786.WANG K, HE Y L, MENG G W. Design and analysis of an aluminum alloy bus frame under typical conditions[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(8): 1780-1786(in Chinese). [2] 尹尚豹. 5754铝合金板热成形性能研究及应用[D]. 武汉: 华中科技大学, 2016: 1-3.YIN S B. Investigation and application of thermal formability of 5754 aluminum alloy sheet[D]. Wuhan: Huazhong University of Science and Technology, 2016: 1-3(in Chinese). [3] 居龙. 5000系铝合金汽车板成形性能研究[D]. 北京: 北京科技大学, 2015: 40-42.JU L. Investigations for formability of 5000 series aluminum alloy sheets for automotive application[D]. Beijing: University of Science and Technology Beijing, 2015: 40-42(in Chinese). [4] BONG H J, LEEM D, KIM J H, et al. Practical determination of friction coefficient of Al 3003 for forming of backward extruded part using simple tip test and inverse finite element analysis[J]. Metals and Materials International, 2016, 22(3): 356-363. doi: 10.1007/s12540-015-5158-3 [5] DOHDA K, BOHER C, REZAI-ARIA F, et al. Tribology in metal forming at elevated temperatures[J]. Friction, 2015, 3(1): 1-27. doi: 10.1007/s40544-015-0077-3 [6] 罗红宇, 李东升, 吕晓东, 等. 拉延筋/摩擦试验机测控系统设计与实践[J]. 塑性工程学报, 2004, 11(5): 33-36.LUO H Y, LI D S, LU X D, et al. Practice & design on measure and control system of drawbead/friction simulator[J]. Journal of Plasticity Engineering, 2004, 11(5): 33-36 (in Chinese). [7] 王亮, 李东升, 罗红宇. 板材成形拉延摩擦试验机系统设计与实践[J]. 塑性工程学报, 2009, 16(6): 107-112. doi: 10.3969/j.issn.1007-2012.2009.06.022WANG L, LI D S, LUO H Y. Design and application of drawing-friction testing system used in sheet metal forming[J]. Journal of Plasticity Engineering, 2009, 16(6): 107-112 (in Chinese). doi: 10.3969/j.issn.1007-2012.2009.06.022 [8] 张建忠, 汪久根, 马家驹, 等. 微载荷含油轴承摩擦性能研究 Ⅱ. 摩擦试验分析[J]. 摩擦学学报, 2006, 26(5): 472-477.ZHANG J Z, WANG J G, MA J J, et al. Tribological characteristics of porous bearings under microload Ⅱ. Experimental study of friction[J]. Tribology, 2006, 26(5): 472-477 (in Chinese). [9] MARZOUKI M, KOWANDY C, RICHARD C. Experimental simulation of tool/product interface during hot drawing[J]. Wear, 2007, 262(3-4): 235-241. doi: 10.1016/j.wear.2006.05.017 [10] CAO J, ZHOU R, WANG Q, et al. Strip-on-cylinder test apparatus for die wear characterization[J]. CIRP Annals, 2009, 58(1): 251-254. [11] YANAGIDA A, KURIHARA T, AZUSHIMA A. Development of tribo-simulator for hot stamping[J]. Journal of Materials Processing Technology, 2010, 210(3): 456-460. [12] TIAN X W, ZHANG Y S, WANG Z, et al. Design of a tribo-simulator for the high strength steel friction and wear investigation in hot stamping[J]. Advanced Materials Research, 2011, 421: 147-150. doi: 10.4028/www.scientific.net/AMR.421.147 [13] 张逸青. 重载荷往复式摩擦磨损试验机[J]. 轴承, 2016, 435(2): 53-56.ZHANG Y Q. Heavy load reciprocating friction and wear tester[J]. Bearing, 2016, 435(2): 53-56(in Chinese). [14] Interlaken Technology Company. Draw bead simulator[EB/OL]. (2022-03-28 ) [2022-06-01].https://interlaken.com/docs/DBS.pdf. [15] 雷玉兰, 韩光超, 盛超杰, 等. 10 kN超声辅助塑性成形压力机设计与试验[J]. 北京航空航天大学学报, 2019, 45(8): 1622-1629.LEI Y L, HAN G C, SHENG C J, et al. Design of 10 kN ultrasonic-assisted plastic forming press machine and experiment[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(8): 1622-1629 (in Chinese). [16] 张春波, 周军, 梁武, 等. 位置控制模式及力控制模式交互作用的轴向摩擦焊接装置以及摩擦焊接工艺: CN109623134A[P]. 2019-04-16.ZHANG C B, ZHOU J, LIANG W, et al. Position control mode and force control mode interaction axial friction welding device and friction welding technology: CN109623134A[P]. 2019-04-16 (in Chinese). [17] SHI Z, WANG L, MOHAMED M, et al. A new design of friction test rig and determination of friction coefficient when warm forming an aluminium alloy[J]. Procedia Engineering, 2017, 207: 2274-2279. doi: 10.1016/j.proeng.2017.10.994 [18] BAY N, OLSSON D D, ANDREASEN J L. Lubricant test methods for sheet metal forming[J]. Tribology International, 2008, 41(9): 844-853. [19] LI M, KLAMECKI B E, WEINMANN K J. SN-Gage and instrurnented pin: To measure shear and normal tool forces in sheet metal foming[J]. Transactions of Namrusme, 1992, 20: 103-109. [20] SHI M F, MEULEMAN D J. An evaluation of interface friction in different forming models for coated steel sheets[C]//Proceedings of the SAE Technical Paper Series. Warrendale: SAE International, 1992: 135-142. [21] SANCHEZ L R. Characterisation of a measurement system for reproducible friction testing on sheet metal under plane strain[J]. Tribology International, 1999, 20: 575-586. [22] TRZEPIECIŃSKI T, LEMU H G. Frictional conditions of AA5251 aluminium alloy sheets using drawbead simulator tests and numerical methods[J]. Strojniški Vestnik – Journal of Mechanical Engineering, 2014, 60(1): 51-60. doi: 10.5545/sv-jme.2013.1310 -

下载:

下载: