An elliptical damage detection method using full matrix capture for stiffened plate

-

摘要:

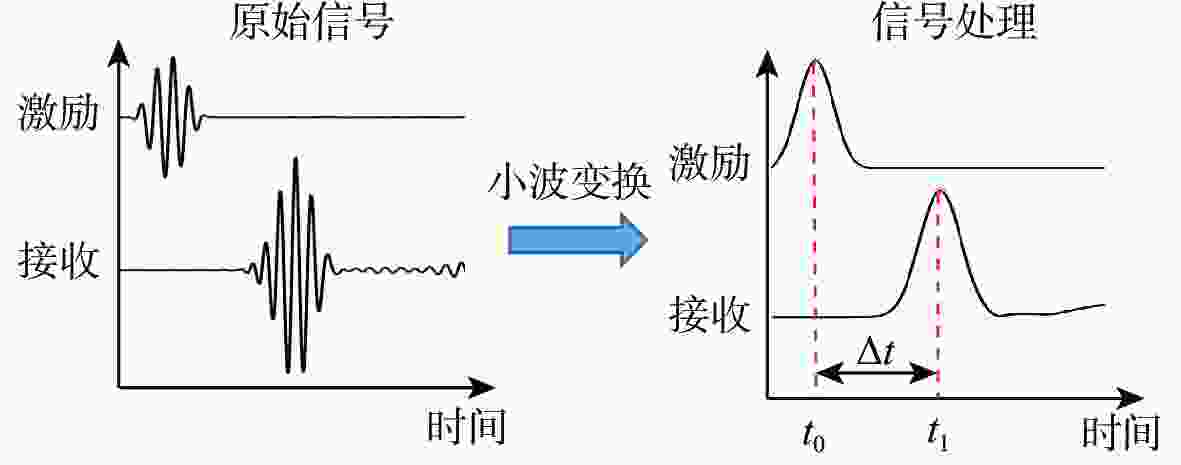

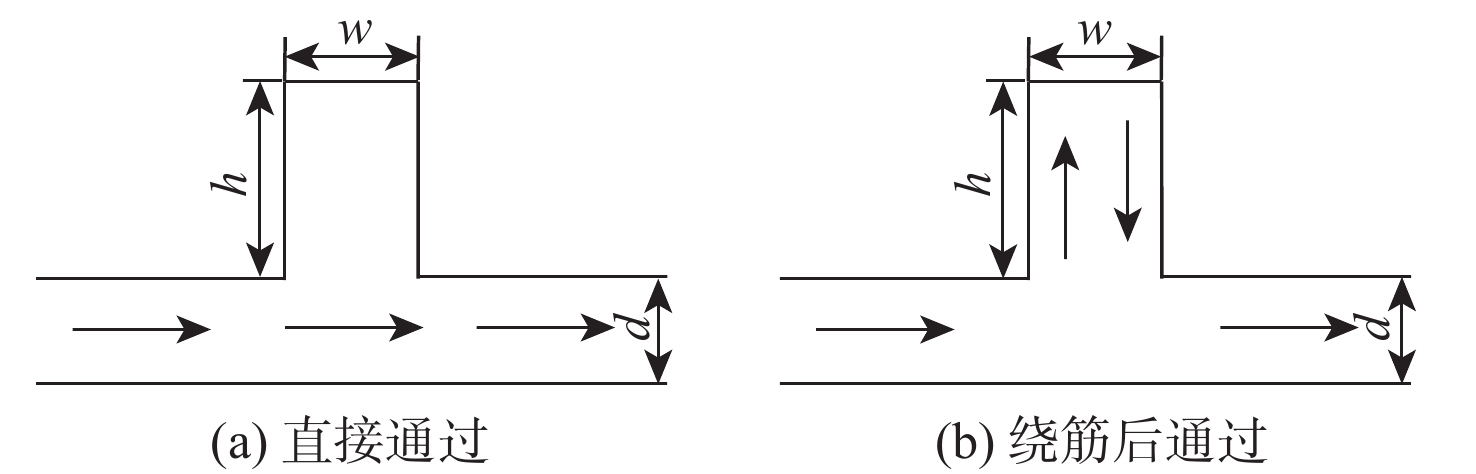

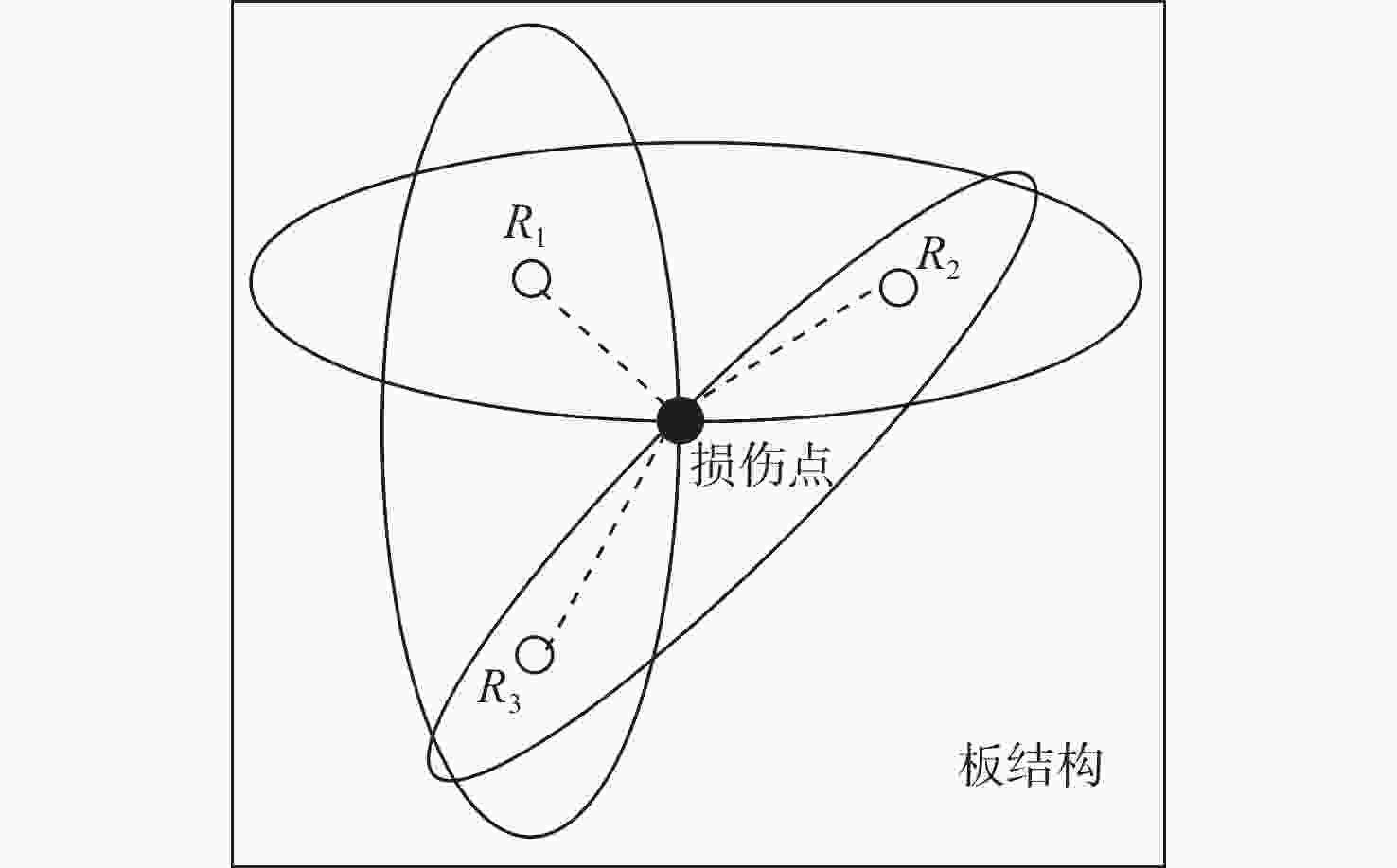

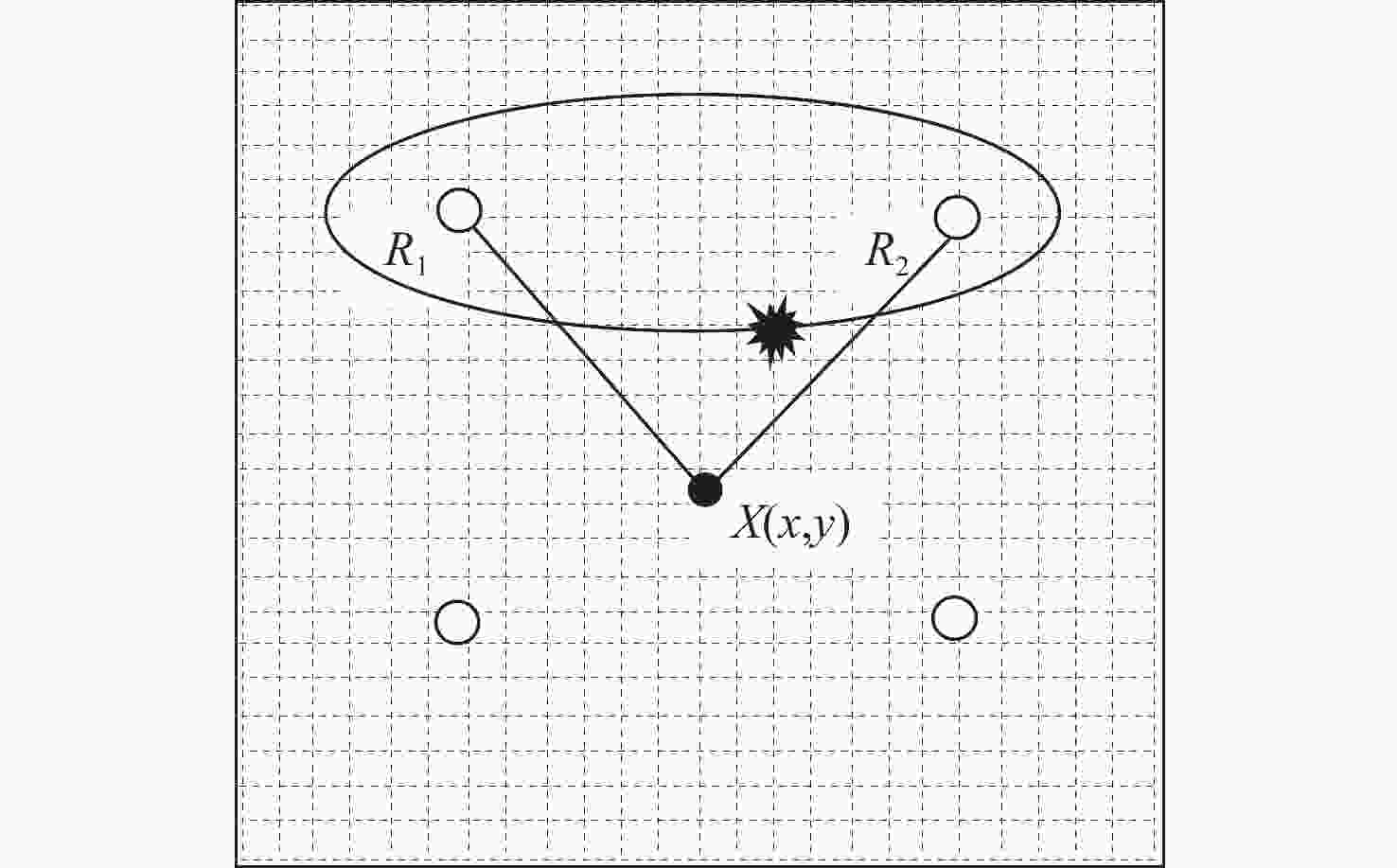

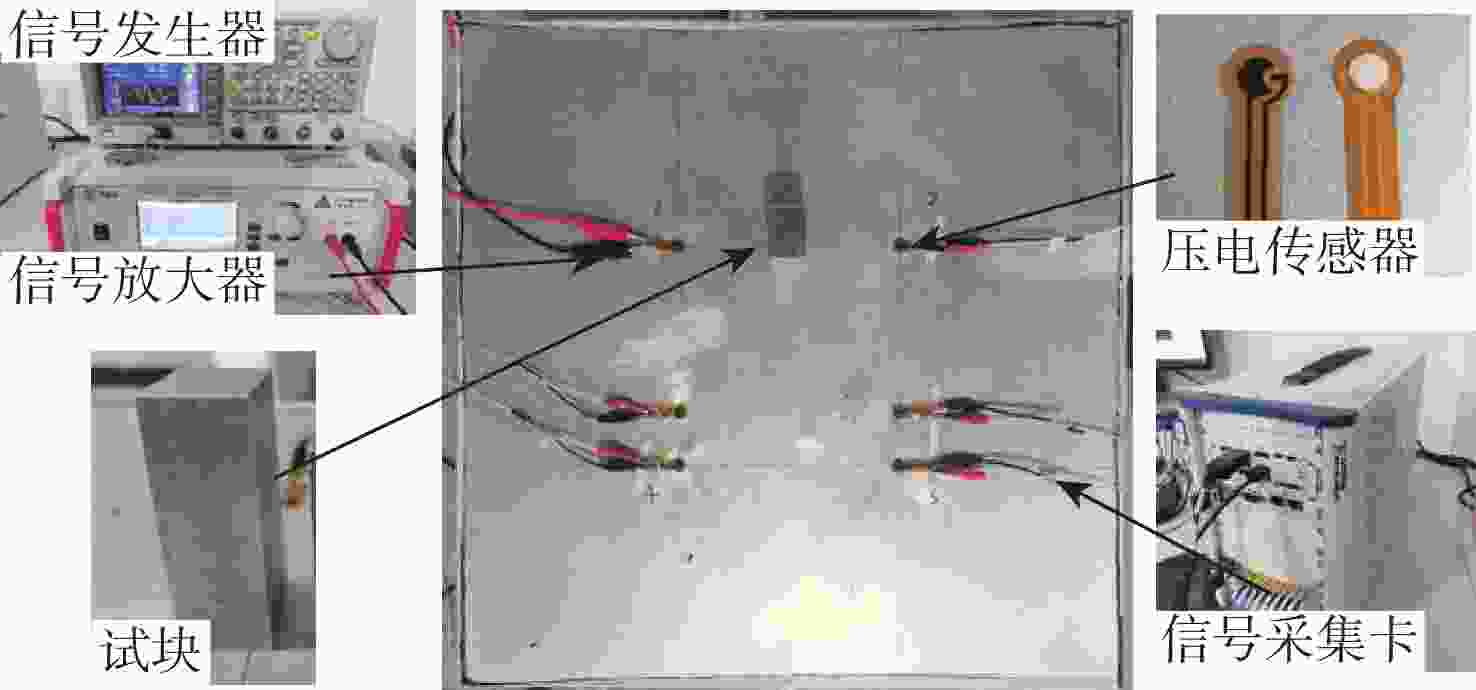

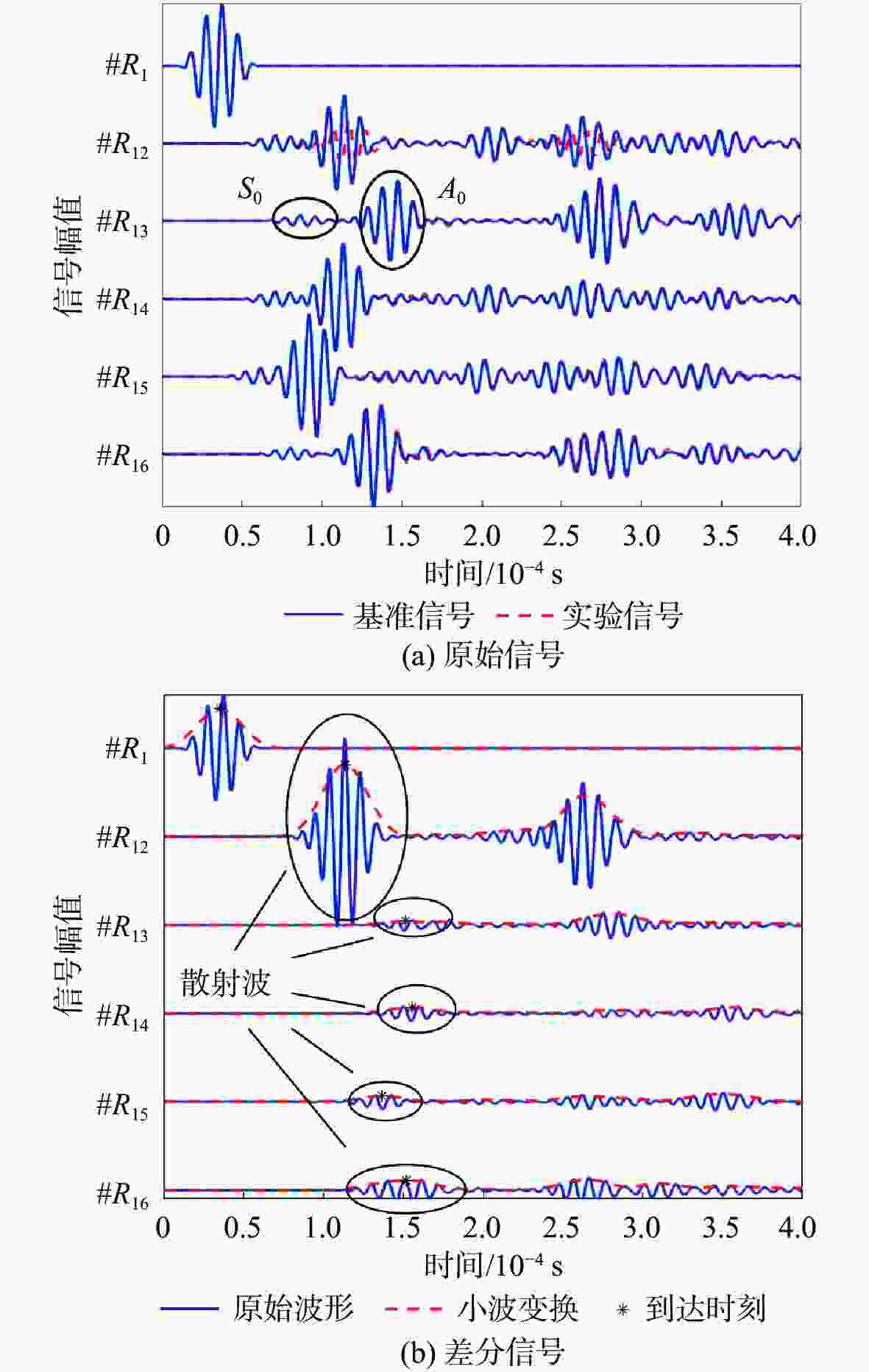

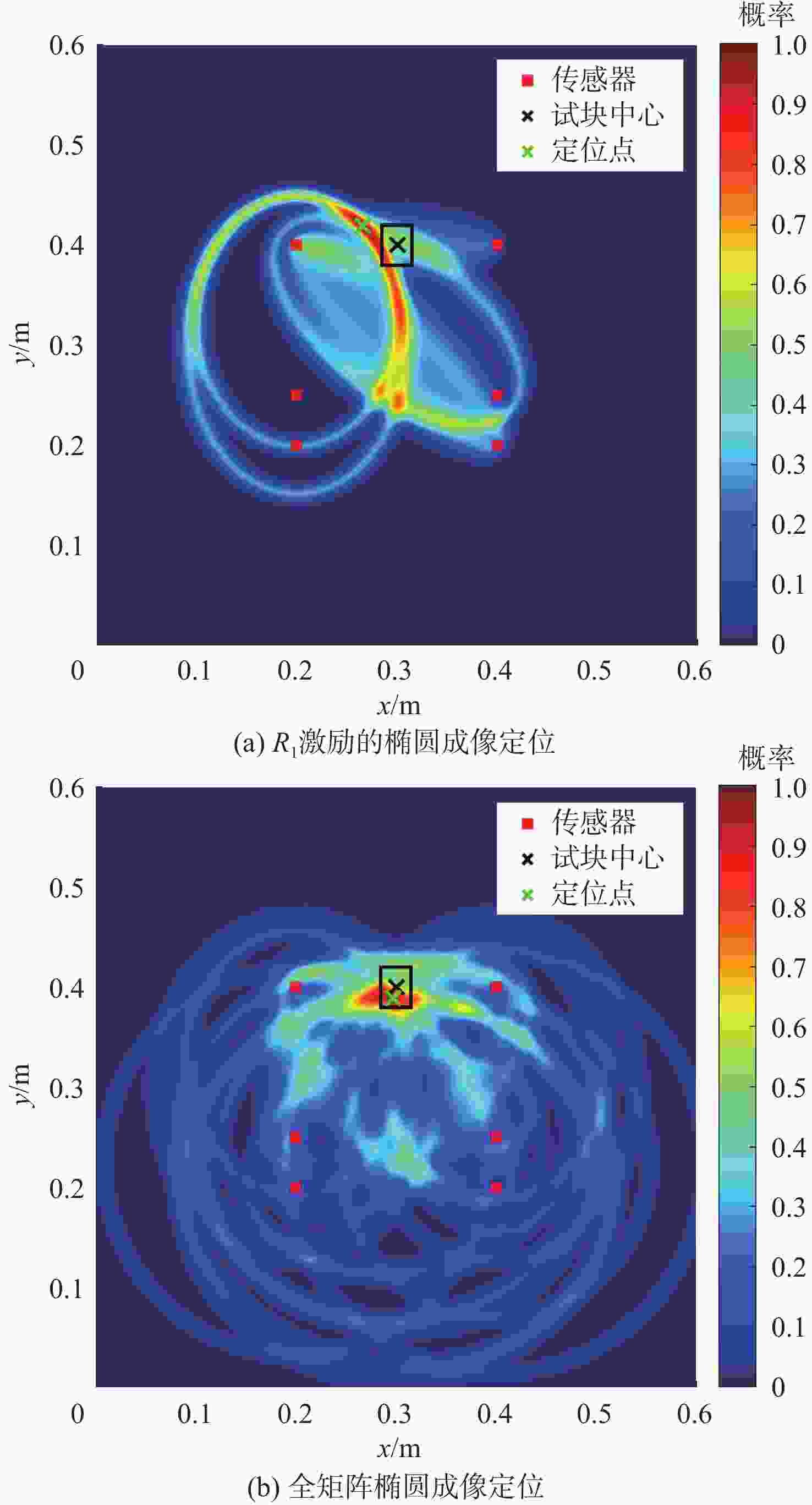

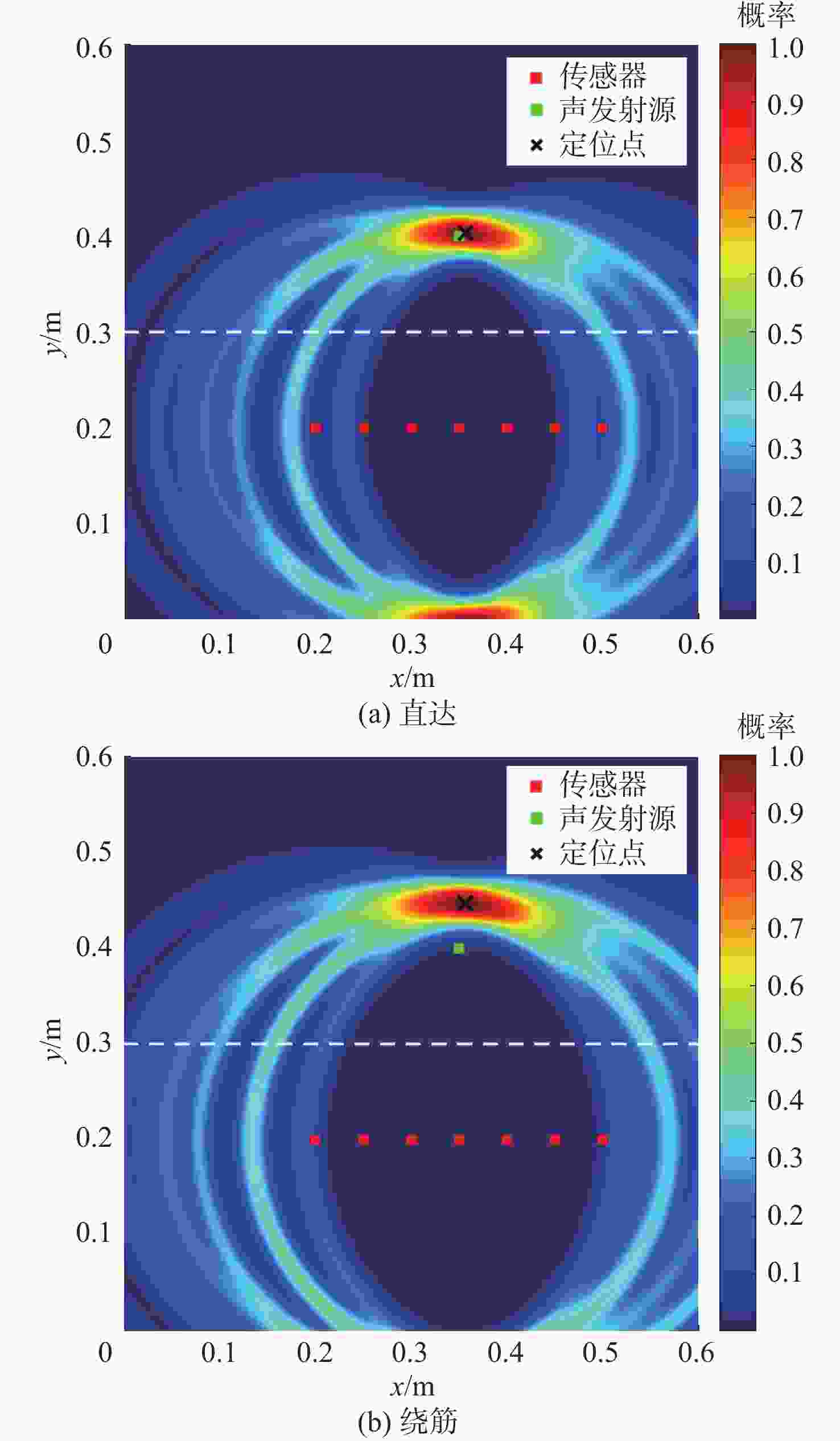

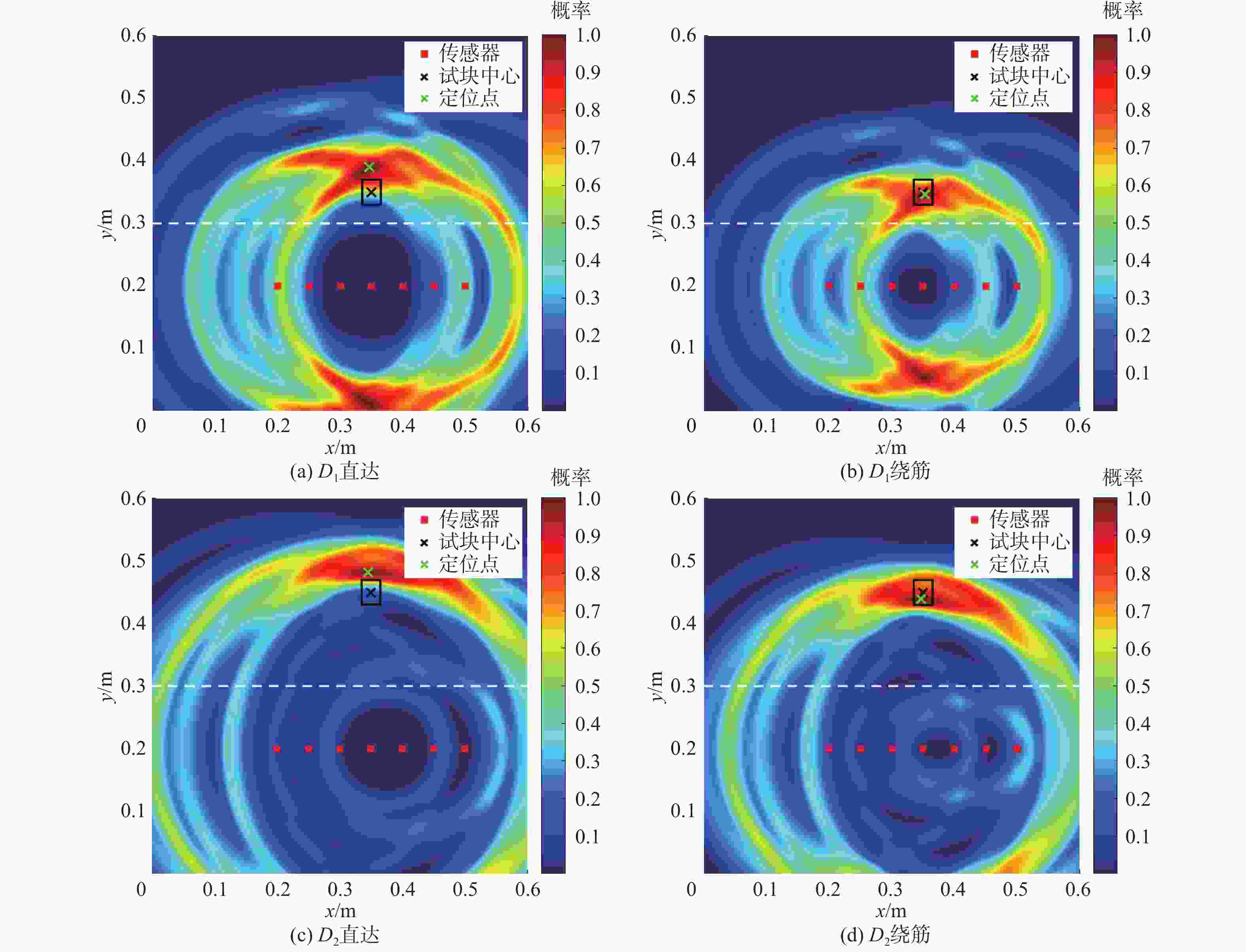

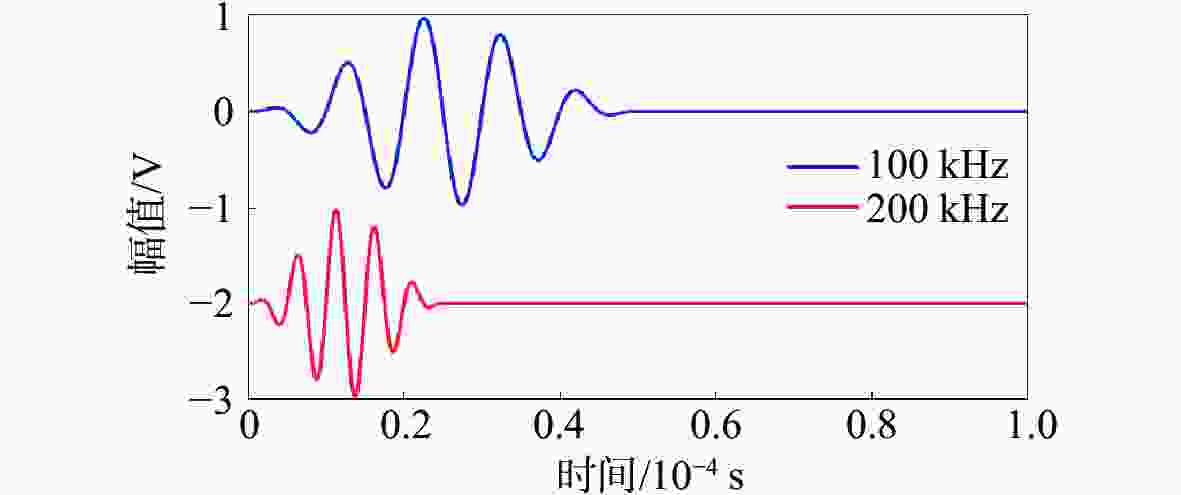

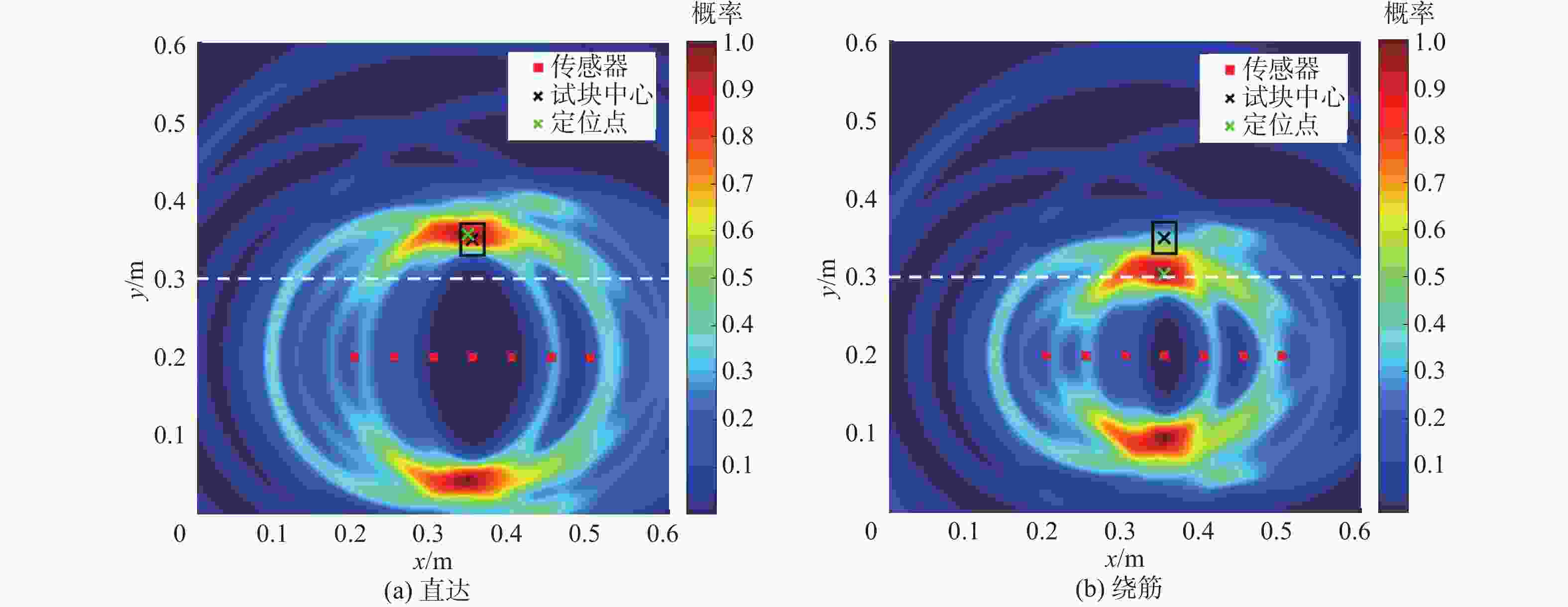

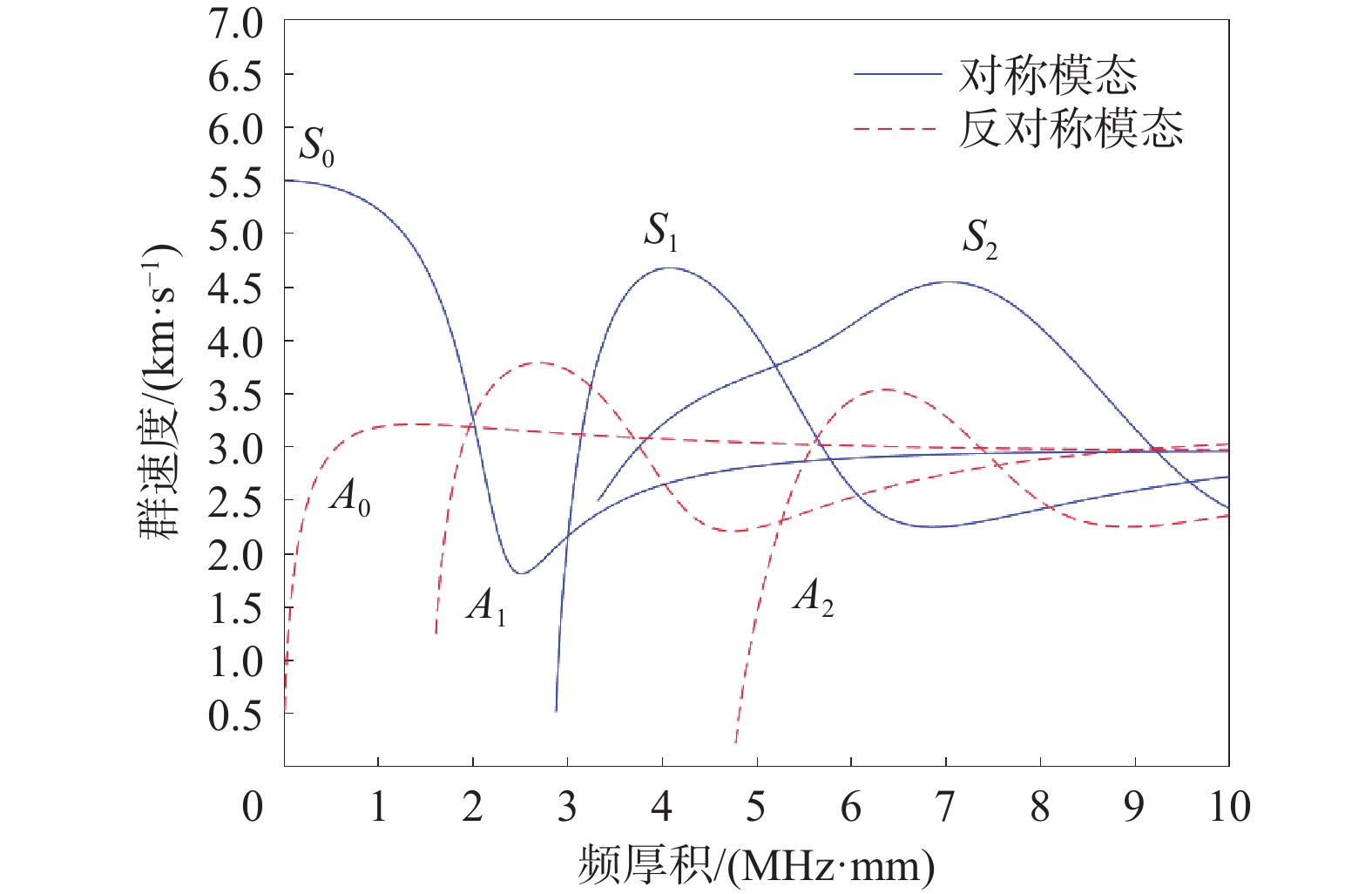

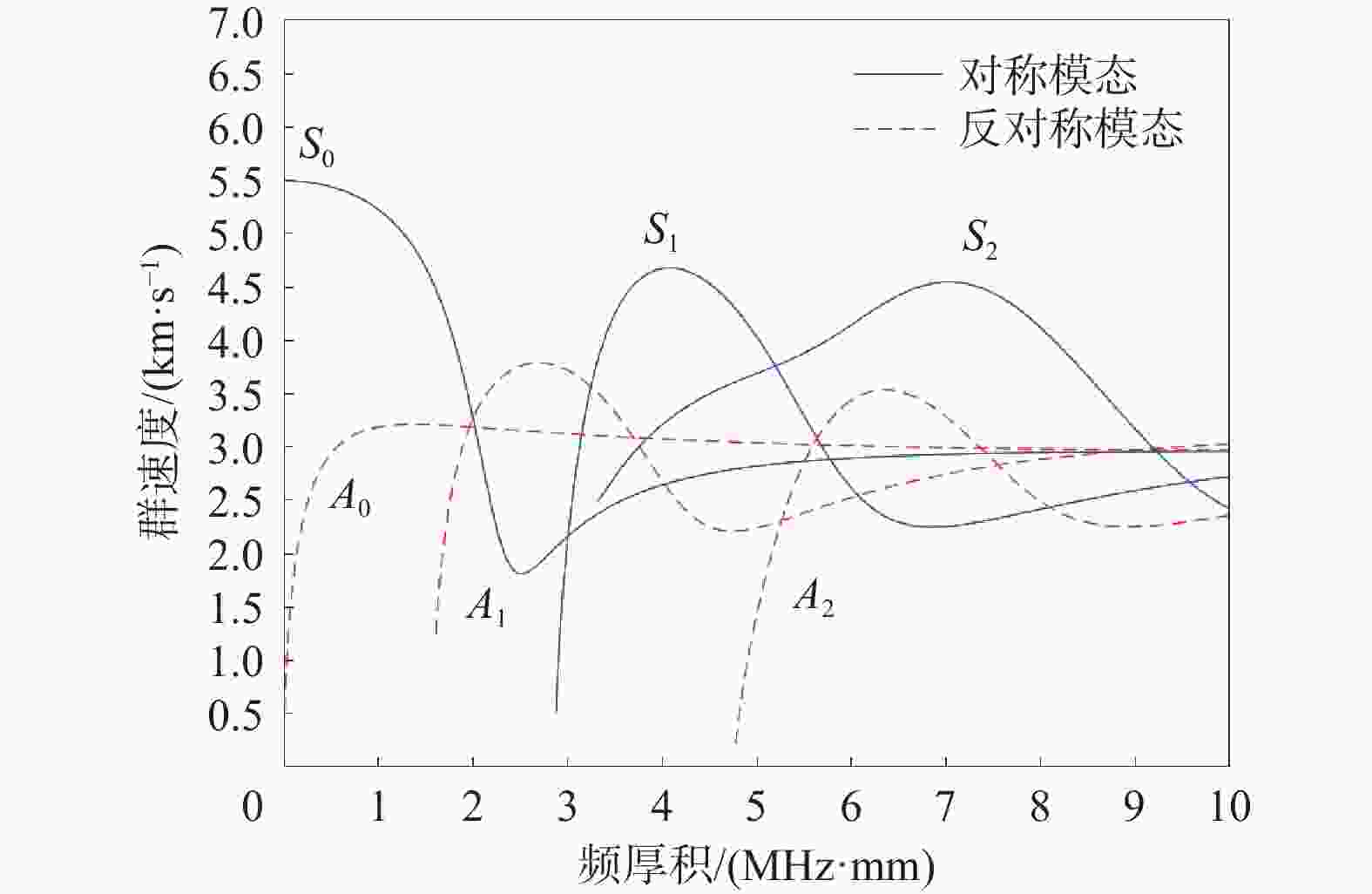

对航天器结构进行损伤检测对于保障航天器的可靠运行十分重要。Lamb波声学定位是一种常用的损伤检测方法,但在航天器常用的加筋板结构中,加强筋会对板中Lamb波的传播产生反射、透射、延迟叠加等效应,导致常用检测方法的效果大打折扣。为此,提出一种基于全矩阵采样和模型补偿的超声Lamb波的全矩阵椭圆成像定位方法。将全矩阵采样方法引入椭圆成像定位中,通过聚焦的方式,减小加强筋对信号的衰减和干扰所产生的误差。针对Lamb波在加强筋结构中绕筋和直达两种传播特征,提出了一种绕筋补偿策略,消除加强筋的延迟叠加影响。实验表明,全矩阵椭圆成像法能够实现损伤信号的聚焦,提高损伤定位的精度,引入绕筋补偿策略后,实现加筋板的准确损伤定位。

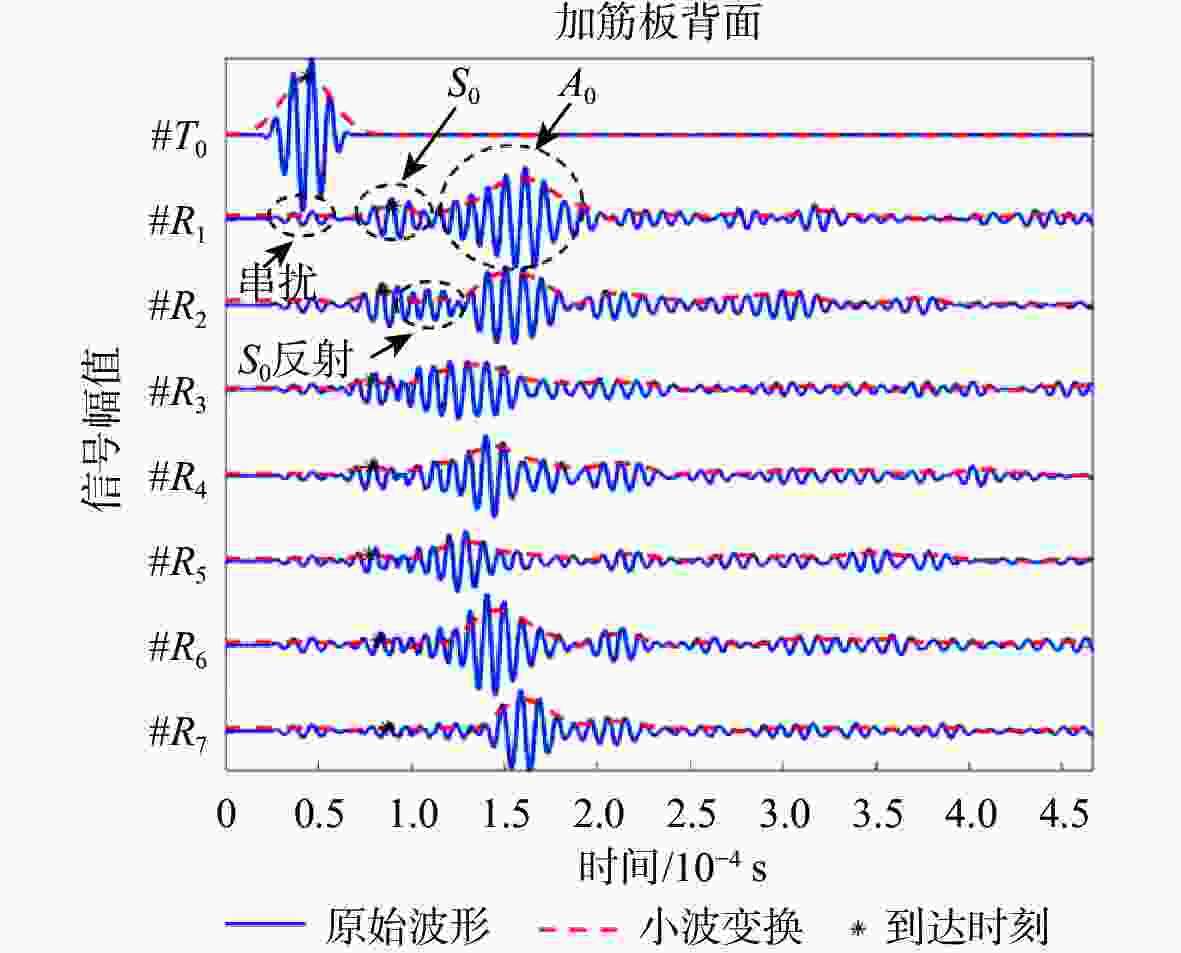

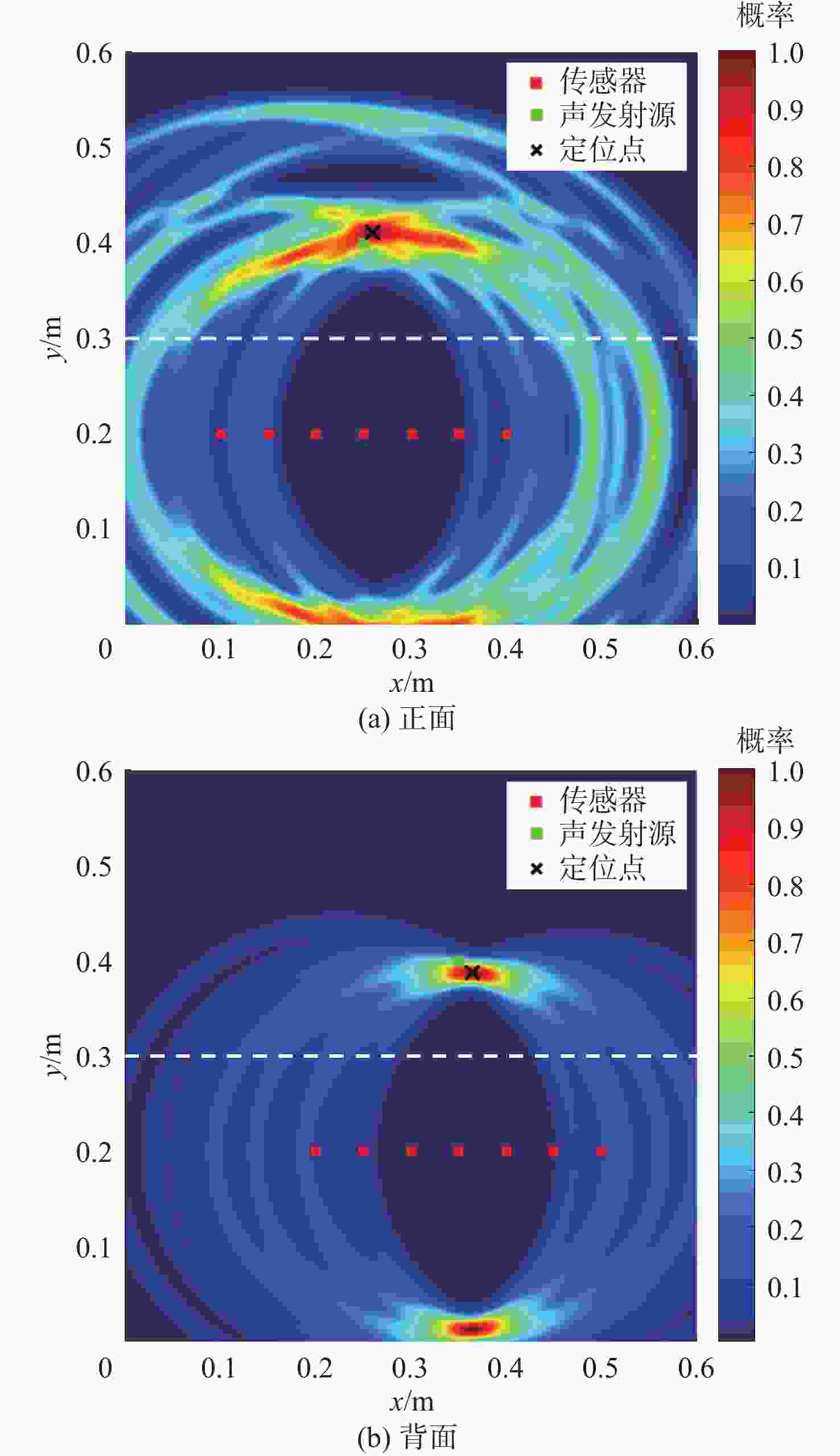

Abstract:Damage detection on spacecraft structures is crucial for ensuring the reliability of the spacecraft. Acoustic localization based on Lamb waves is a common method for damage detection. However, the existence of stiffeners, which are commonly used in spacecraft structures, will produce reflection, transmission, and superposition on the propagation of the Lamb waves in the plate, making it bad or even impossible to detect the damage in the stiffened structure using the general method. I This study presents an approach to precisely localize damage in stiffened plates using whole matrix elliptical image localization, which is based on complete matrix capture and model correction. The full matrix capture method is introduced into elliptic imaging localization for focusing, thereby mitigating errors arising from signal attenuation and interference attributed to stiffeners. Considering the wave propagation around and directly, an arrival time compensation strategy is proposed for eliminating the delayed superposition effects of stiffeners on Lamb waves. The full-matrix elliptical imaging method is effective in improving damage signal focussing, as demonstrated by experiments on both flat and stiffened plates. The arrival time compensation model could be used to obtain precise damage localization.

-

Key words:

- Lamb wave /

- elliptical imaging /

- wavelet transform /

- stiffened plate /

- structural health monitoring

-

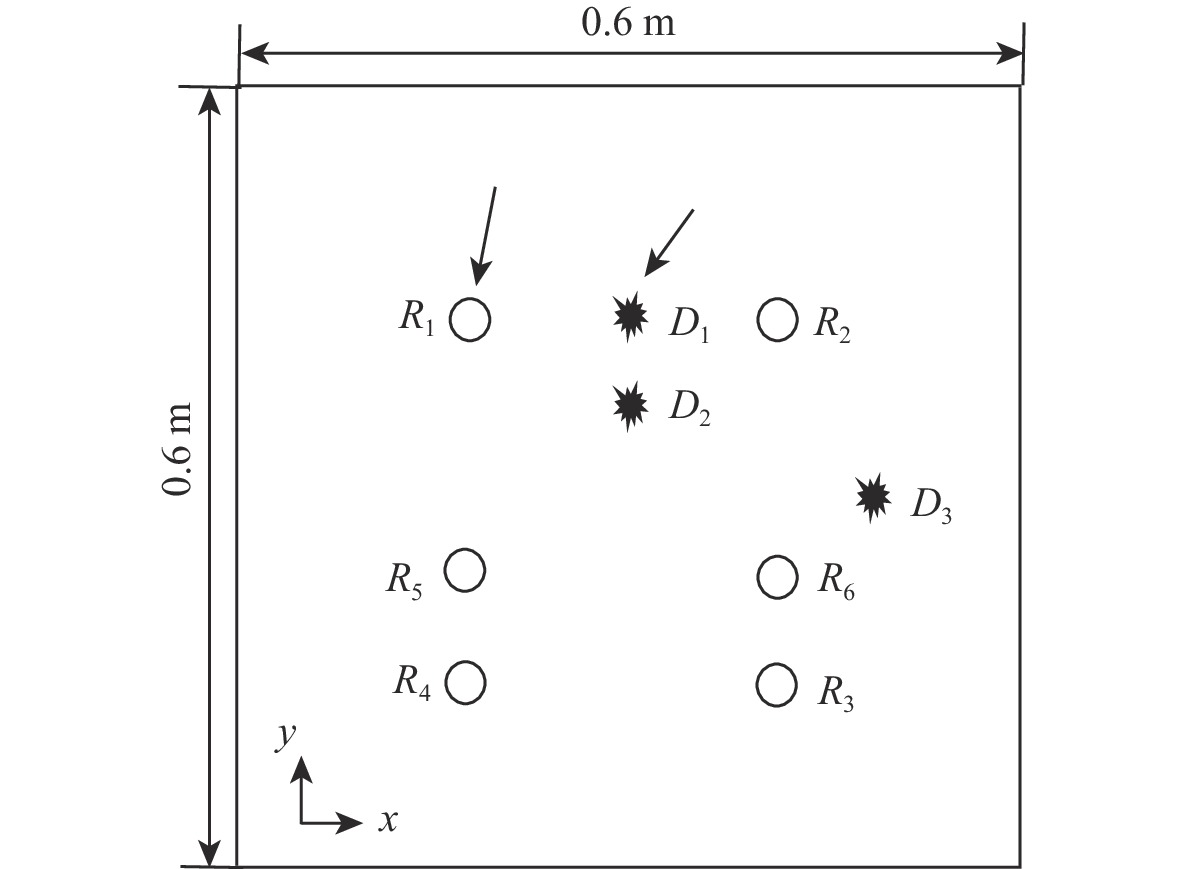

表 1 各个传感器和损伤的位置坐标

Table 1. Position coordinates of all sensors and damages

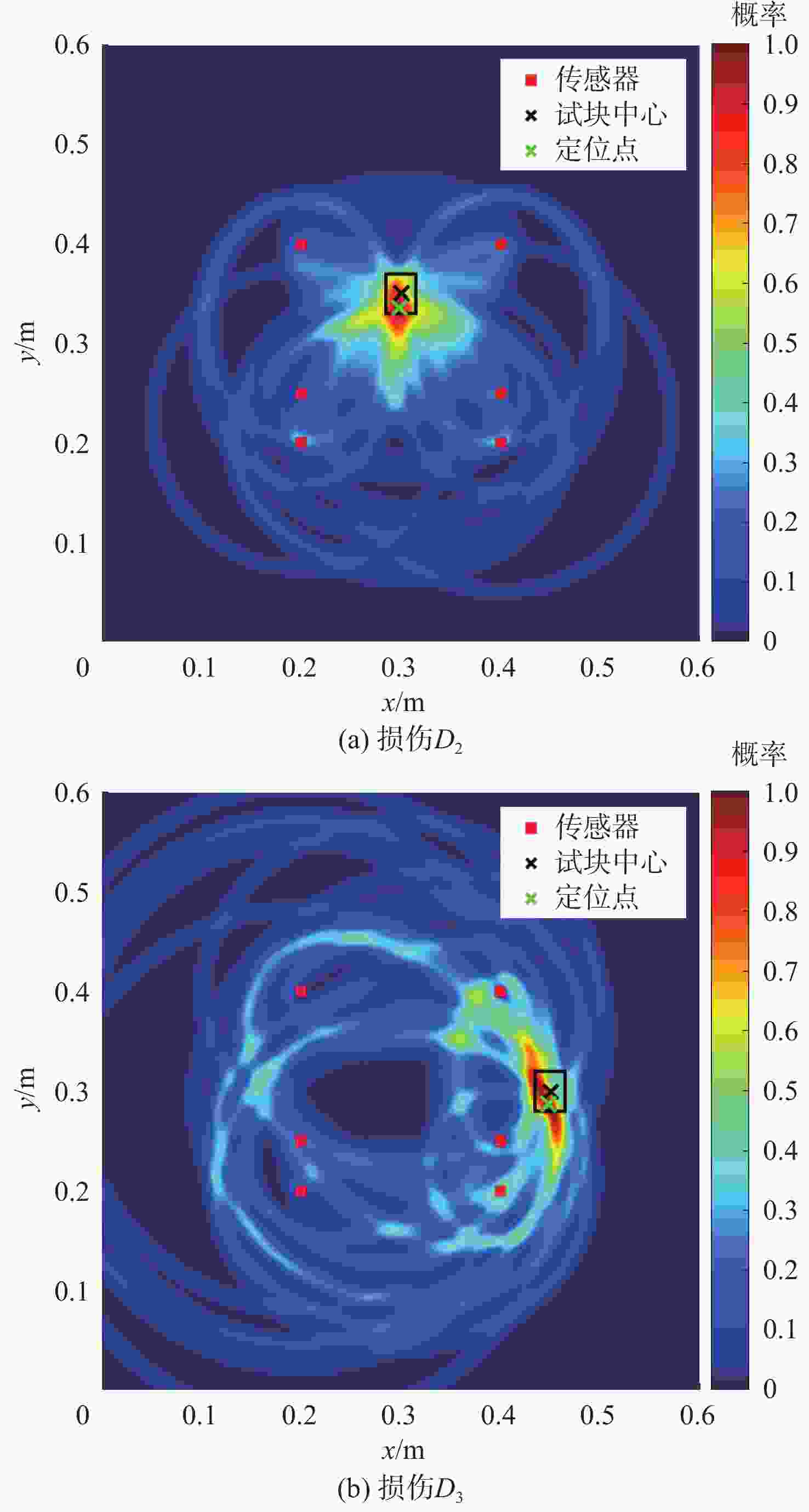

项目 编号 位置坐标(x,y)/m 传感器 R1 (0.2,0.4) R2 (0.4,0.4) R3 (0.4,0.2) R4 (0.2,0.2) R5 (0.200,0.25) R6 (0.40,0.25) 损伤 D1 (0.3,0.4) D2 (0.30,0.35) D3 (0.45,0.30) 表 2 各个压电传感器位置坐标

Table 2. Position coordinates of all piezoelectric sensors

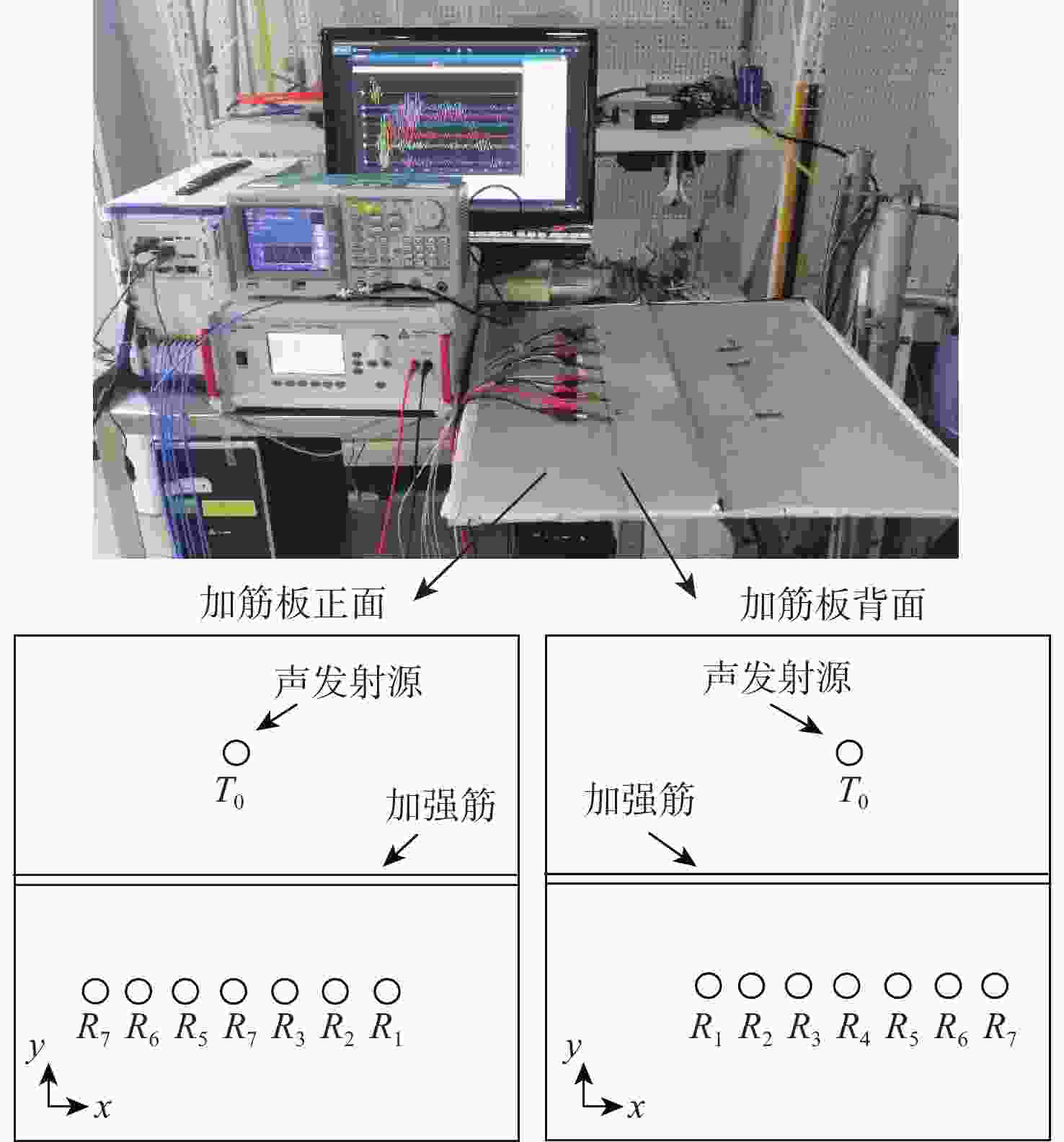

编号 正面坐标(x,y)/m 背面坐标(x,y)/m R1 (0.4,0.2) (0.2,0.2) R2 (0.35,0.20) (0.25,0.20) R3 (0.3,0.2) (0.3,0.2) R4 (0.25,0.20) (0.35,0.20) R5 (0.2,0.2) (0.4,0.2) R6 (0.15,0.20) (0.45,0.20) R7 (0.1,0.2) (0.5,0.2) T0 (0.2,0.4) (0.35,0.40) -

[1] REUSSER R S, HOLLAND S D, CHIMENTI D E, et al. Reflection and transmission of guided ultrasonic plate waves by vertical stiffeners[J]. The Journal of the Acoustical Society of America, 2014, 136(1): 170-182. doi: 10.1121/1.4883386 [2] TANG E L, LIANG Z Q, WANG L, et al. Experimental investigation on location of debris impact source based on acoustic emission[J]. Advances in Space Research, 2019, 64(11): 2390-2404. doi: 10.1016/j.asr.2019.09.015 [3] 谭翔飞, 何宇廷, 侯波, 等. 腐蚀环境下铜薄膜传感器金属结构裂纹监测[J]. 北京航空航天大学学报, 2017, 43(7): 1433-1441.TAN X F, HE Y T, HOU B, et al. Metal structure crack monitoring based on copper film sensor in corrosion environment[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(7): 1433-1441 (in Chinese). [4] 赵发刚, 冯彦军, 范凡, 等. 卫星复合材料结构在轨健康监测方法[J]. 科技导报, 2016, 34(8): 15-17.ZHAO F G, FENG Y J, FAN F, et al. Research on on-orbit health monitoring method about composite structure in satellites[J]. Science & Technology Review, 2016, 34(8): 15-17 (in Chinese). [5] 侯波, 何宇廷, 崔荣洪, 等. 基于涂层传感器的金属结构疲劳裂纹监测[J]. 北京航空航天大学学报, 2013, 39(10): 1298-1302.HOU B, HE Y T, CUI R H, et al. Fatigue crack monitoring of metallic structure based on coating sensor[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(10): 1298-1302 (in Chinese). [6] 卿新林, 王奕首, 赵琳. 结构健康监测技术及其在航空航天领域中的应用[J]. 实验力学, 2012, 27(5): 517-526.QING X L, WANG Y S, ZHAO L. Structural health monitoring technology and its application in aeronautics and astronautics[J]. Journal of Experimental Mechanics, 2012, 27(5): 517-526 (in Chinese). [7] SU Z Q, YE L, LU Y. Guided Lamb waves for identification of damage in composite structures: a review[J]. Journal of Sound and Vibration, 2006, 295(3/4/5): 753-780. doi: 10.1016/j.jsv.2006.01.020 [8] YU T H. Plate waves scattering analysis and active damage detection[J]. Sensors, 2021, 21(16): 5458. doi: 10.3390/s21165458 [9] ZHANG Y, WANG J G, ZENG L. Damage localization in composite plates that exploits edge-reflected Lamb waves[J]. IOP Conference Series:Materials Science and Engineering, 2021, 1043(4): 042001. doi: 10.1088/1757-899X/1043/4/042001 [10] ZENG L, HUANG L P, LIN J. Damage imaging of composite structures using multipath scattering Lamb waves[J]. Composite Structures, 2019, 216: 331-339. doi: 10.1016/j.compstruct.2019.03.008 [11] 杨晓华, 刘学君, 张玎, 等. 基于振动声调制的板类结构裂纹定位成像[J]. 北京航空航天大学学报, 2017, 43(8): 1509-1516.YANG X H, LIU X J, ZHANG D, et al. Localization and imaging of crack damage in plate-like structures based on vibro-acousic modulation[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(8): 1509-1516 (in Chinese). [12] ZHAO X L, GAO H D, ZHANG G F, et al. Active health monitoring of an aircraft wing with embedded piezoelectric sensor/actuator network: I. Defect detection, localization and growth monitoring[J]. Smart Materials and Structures, 2007, 16(4): 1208-1217. doi: 10.1088/0964-1726/16/4/032 [13] ING R K, FINK M. Time-reversed Lamb waves[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 1998, 45(4): 1032-1043. doi: 10.1109/58.710586 [14] 周正干, 滕利臣, 李洋. 复杂结构焊缝缺陷双线阵全聚焦超声成像方法[J]. 北京航空航天大学学报, 2021, 47(12): 2407-2413.ZHOU Z G, TENG L C, LI Y. Dual-linear-array TFM ultrasonic imaging method for weld defects of complex structure[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(12): 2407-2413 (in Chinese). [15] SHEN Q, YUE S Y, LU W, et al. Ultrasonic guided wave damage detection method for stiffened plates based on deep learning[J]. Journal of Physics:Conference Series, 2021, 1894(1): 012069. doi: 10.1088/1742-6596/1894/1/012069 [16] 徐颖娣, 袁慎芳, 彭鸽. 二维结构损伤的主动Lamb波定位技术研究[J]. 航空学报, 2004, 25(5): 476-479. doi: 10.3321/j.issn:1000-6893.2004.05.011XU Y D, YUAN S F, PENG G. Study on two-dimensional damage location in structure based on active lamb wave detection technique[J]. Acta Aeronautica et Astronautica Sinica, 2004, 25(5): 476-479 (in Chinese). doi: 10.3321/j.issn:1000-6893.2004.05.011 [17] 尹本进, 李友荣, 鲁光涛. 基于Lamb波混合成像算法的薄板结构损伤定位[J]. 武汉科技大学学报, 2017, 40(2): 132-137. doi: 10.3969/j.issn.1674-3644.2017.02.010YIN B J, LI Y R, LU G T. Damage location for thin plate structures using hybrid imaging algorithm based on Lamb waves[J]. Journal of Wuhan University of Science and Technology, 2017, 40(2): 132-137 (in Chinese). doi: 10.3969/j.issn.1674-3644.2017.02.010 [18] ZIMA B, RUCKA M. Guided waves for monitoring of plate structures with linear cracks of variable length[J]. Archives of Civil & Mechanical Engineering, 2016, 16(3): 387-396. [19] 刘增华, 徐营赞, 何存富, 等. 板状结构中基于Lamb波单模态的缺陷成像试验研究[J]. 工程力学, 2014, 31(4): 232-238.LIU Z H, XU Y Z, HE C F, et al. Experimental study on defect imaging based on single lamb wave mode in plate-like structures[J]. Engineering Mechanics, 2014, 31(4): 232-238 (in Chinese). [20] HOLMES C, DRINKWATER B W, WILCOX P D. Post-processing of the full matrix of ultrasonic transmit–receive array data for non-destructive evaluation[J]. NDT & E International, 2005, 38(8): 701-711. [21] FAN C G, YANG L, ZHAO Y. Preprocessing of the full matrix capture data for time-reversal-based super-resolution imaging[J]. Insight: Non-Destructive Testing and Condition Monitoring, 2017, 59(11): 586-590. doi: 10.1784/insi.2017.59.11.586 [22] 约瑟夫·罗斯. 固体中的超声导波[M]. 高会栋, 崔寒茵, 王继锋, 译. 北京: 科学出版社, 2019: 53-55.ROSE J L. Ultrasonic guided waves in solid media[M]. GAO H D, CUI H Y, WANG J F, translated. Beijing: Science Press, 2019: 53-55(in Chinese). [23] 孙增寿, 范科举, 张波. 基于第二代小波变换的结构损伤检测研究进展[J]. 郑州大学学报(工学版), 2010, 31(1): 1-5.SUN Z S, FAN K J, ZHANG B. New development of research on the second wavelet transform based structural damage detection[J]. Journal of Zhengzhou University (Engineering Science), 2010, 31(1): 1-5 (in Chinese). [24] YU Z X, XU C, SUN J Y, et al. Guided wave propagation analysis in stiffened panel using time-domain spectral finite element method[J]. Chinese Journal of Aeronautics, 2022, 35(10): 208-221. doi: 10.1016/j.cja.2021.11.014 [25] FAN C G, YANG L, CHEN Y, et al. Ultrasonic time-reversal-based imaging for rapid non-destructive evaluation[J]. Insight, 2018, 60(11): 613-618. doi: 10.1784/insi.2018.60.11.613 [26] 魏勤, 骆英, 王自平, 等. Lamb波驱动器的最佳激励波形选择[J]. 压电与声光, 2011, 33(6): 863-866. doi: 10.3969/j.issn.1004-2474.2011.06.005WEI Q, LUO Y, WANG Z P, et al. Optimal excitation waveform selection for lamb wave actuator[J]. Piezoelectrics & Acoustooptics, 2011, 33(6): 863-866 (in Chinese). doi: 10.3969/j.issn.1004-2474.2011.06.005 [27] 邹明霞, 关立强, 李义丰. 基于时间反转加权分布的复合材料Lamb波损伤成像[J]. 声学技术, 2021, 40(5): 630-638.ZOU M X, GUAN L Q, LI Y F. Lamb wave damage imaging of composite plate based on time reversal and weighted distribution[J]. Technical Acoustics, 2021, 40(5): 630-638 (in Chinese). [28] 王莉, 刘国强, 肖迎春. 基于代理模型的复合材料加筋壁板分层损伤定量监测方法[J]. 复合材料学报, 2020, 37(2): 302-308.WANG L, LIU G Q, XIAO Y C. Quantitative monitoring method for delamination damage of stiffened composite panel based on surrogate model[J]. Acta Materiae Compositae Sinica, 2020, 37(2): 302-308 (in Chinese). -

下载:

下载: