Research progress on key materials of phosphoric acid doped high-temperature proton exchange membrane fuel cells

-

摘要:

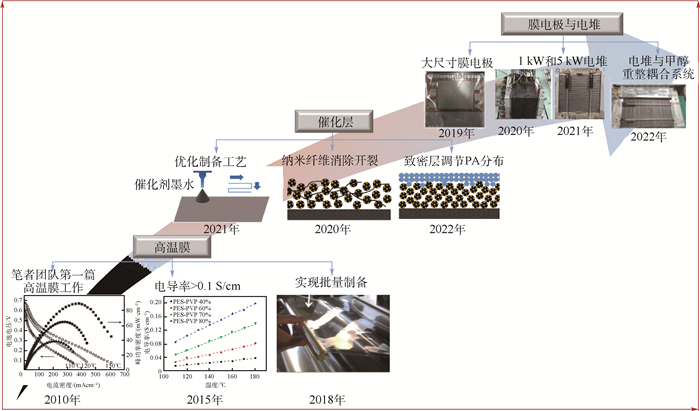

高温质子交换膜燃料电池(HT-PEMFC)由于较高的工作温度(130~220℃),具有较快的电极反应动力学、较强的抗燃料/空气中杂质毒化能力、广泛的燃料来源(甲醇重整气、工业副产氢等)及简单的水/热管理系统等优点。因此,HT-PEMFC将成为聚合物膜燃料电池的重要前沿发展方向之一。重点介绍了北京航空航天大学团队近十年来在HT-PEMFC关键材料-高温膜、催化层和膜电极等方面的研究进展,针对磷酸(PA)掺杂型高温膜的质子传导率和机械性能之间的最佳平衡点、催化层中PA分布和迁移对电池性能的影响机制,以及大尺寸膜电极一致性对电堆性能影响与衰减机制等科学问题,从聚电解质膜材料的分子设计、有序催化层结构调控和大尺寸膜电极电堆优化等工作进行了梳理,对HT-PEMFC技术所面临的技术挑战问题与未来发展趋势做出了评述和展望。

Abstract:High-temperature proton exchange membrane fuel cells (HT-PEMFC) has fast electrode reaction kinetics, strong resistance to fuel/air impurity poisoning, a wide range of fuel sources (pure hydrogen, methanol-reforming gas, formic acid, etc.), and simple water/thermal management systems due to their high operating temperature (130℃-200℃). They have become one of the important development directions of polymer membrane fuel cells. This paper mainly introduces the research progress of Beihang University in HT-PEMFC key materials-high-temperature membrane, catalytic layer, and membrane electrode assemblies in recent ten years. Aiming at the best balance between proton conductivity and mechanical properties of phosphoric acid (PA) doped high-temperature membrane, the influence mechanism of PA distribution and migration in the catalytic layer on cell performance, and the influence and attenuation mechanism of large-size membrane electrode consistency on stack performance. The molecular design of polyelectrolyte membrane materials, the regulation of ordered catalytic layer structure, and the optimization of large-size membrane electrode stack were reviewed, and the technical challenges faced by HT-PEMFC technology as well as the future development trend are reviewed and prospected.

-

-

[1] HAIDER R, WEN Y C, MA Z F, et al. High temperature proton exchange membrane fuel cells: Progress in advanced materials and key technologies[J]. Chemical Society Reviews, 2021, 50(2): 1138-1187. doi: 10.1039/D0CS00296H [2] CANO Z P, BANHAM D, YE S Y, et al. Batteries and fuel cells for emerging electric vehicle markets[J]. Nature Energy, 2018, 3(4): 279-289. doi: 10.1038/s41560-018-0108-1 [3] ZHANG H W, SHEN P K. Advances in the high performance polymer electrolyte membranes for fuel cells[J]. Chemical Society Reviews, 2012, 41(6): 2382-2394. doi: 10.1039/c2cs15269j [4] RIBEIRINHA P, SCHULLER G, BOAVENTURA M, et al. Synergetic integration of a methanol steam reforming cell with a high temperature polymer electrolyte fuel cell[J]. International Journal of Hydrogen Energy, 2017, 42(19): 13902-13912. doi: 10.1016/j.ijhydene.2017.01.172 [5] CHENG Y, ZHANG J, LU S F, et al. Significantly enhanced performance of direct methanol fuel cells at elevated temperatures[J]. Journal of Power Sources, 2020, 450: 227620. doi: 10.1016/j.jpowsour.2019.227620 [6] YAN W R, XIANG Y, ZHANG J, et al. Substantially enhanced power output and durability of direct formic acid fuel cells at elevated temperatures[J]. Advanced Sustainable Systems, 2020, 4(7): 2000065. doi: 10.1002/adsu.202000065 [7] CHENG Y, ZHANG J, LU S F, et al. High CO tolerance of new SiO2 doped phosphoric acid/polybenzimidazole polymer electrolyte membrane fuel cells at high temperatures of 200-250 degrees C[J]. International Journal of Hydrogen Energy, 2018, 43(49): 22487-22499. doi: 10.1016/j.ijhydene.2018.10.036 [8] ZHANG J, LU S F, ZHU H J, et al. Amino-functionalized mesoporous silica based polyethersulfone-polyvinylpyrrolidone composite membranes for elevated temperature proton exchange membrane fuel cells[J]. RSC Advances, 2016, 6(89): 86575-86585. doi: 10.1039/C6RA15093D [9] ZHANG J J, ZHANG J, WANG H N, et al. Advancement in distribution and control strategy of phosphoric acid in membrane electrode assembly of high-temperature polymer electrolyte membrane fuel cells[J]. Acta Physico-Chimica Sinica, 2021, 37(9): 2010071. [10] BARRON O, SU H N, LINKOV V, et al. Enhanced performance and stability of high temperature proton exchange membrane fuel cell by incorporating zirconium hydrogen phosphate in catalyst layer[J]. Journal of Power Sources, 2015, 278: 718-724. doi: 10.1016/j.jpowsour.2014.12.139 [11] LEE H S, ROY A, LANE O, et al. Synthesis and characterization of poly(arylene ether sulfone)-b-polybenzimidazole copolymers for high temperature low humidity proton exchange membrane fuel cells[J]. Polymer, 2008, 49(25): 5387-5396. doi: 10.1016/j.polymer.2008.09.019 [12] AILI D, ZHANG J, JAKOBSEN M T D, et al. Exceptional durability enhancement of PA/PBI based polymer electrolyte membrane fuel cells for high temperature operation at 200℃[J]. Journal of Materials Chemistry A, 2016, 4(11): 4019-4024. doi: 10.1039/C6TA01562J [13] LI X B, WANG P, LIU Z C, et al. Arylether-type polybenzimidazoles bearing benzimidazolyl pendants for high-temperature proton exchange membrane fuel cells[J]. Journal of Power Sources, 2018, 393: 99-107. doi: 10.1016/j.jpowsour.2018.05.011 [14] CHEN J C, CHEN P Y, LEE S W, et al. Synthesis of soluble polybenzimidazoles for high-temperature proton exchange membrane fuel cell (PEMFC) applications[J]. Reactive and Functional Polymers, 2016, 108: 122-129. doi: 10.1016/j.reactfunctpolym.2016.05.006 [15] ZHANG J J, WANG H N, LI W, et al. Effect of catalyst layer microstructures on performance and stability for high temperature polymer electrolyte membrane fuel cells[J]. Journal of Power Sources, 2021, 505: 230059. doi: 10.1016/j.jpowsour.2021.230059 [16] KASERER S, CALDWELL K M, RAMAKER D E, et al. Analyzing the influence of H3PO4 as catalyst poison in high temperature PEM fuel cells using in-operando X-ray absorption spectroscopy[J]. The Journal of Physical Chemistry C, 2013, 117(12): 6210-6217. doi: 10.1021/jp311924q [17] PIMPERL N, BEVILACQUA N, SCHMID M A, et al. Nitrogen-functionalized carbon-supported Pt catalysts implemented in high-temperature polymer electrolyte membrane fuel cell[J]. Journal of Power Sources, 2021, 507: 229971. doi: 10.1016/j.jpowsour.2021.229971 [18] LEE K S, SPENDELOW J S, CHOE Y K, et al. An operationally flexible fuel cell based on quaternary ammonium-biphosphate ion pairs[J]. Nature Energy, 2016, 1: 16120. doi: 10.1038/nenergy.2016.120 [19] TANG H Y, GENG K, WU L, et al. Fuel cells with an operational range of -20℃ to 200℃ enabled by phosphoric acid-doped intrinsically ultramicroporous membranes[J]. Nature Energy, 2022, 7: 153-162. doi: 10.1038/s41560-021-00956-w [20] ATANASOV V, LEE A S, PARK E J, et al. Synergistically integrated phosphonated poly(pentafluorostyrene) for fuel cells[J]. Nature Materials, 2021, 20: 370-377. doi: 10.1038/s41563-020-00841-z [21] LIM K H, LEE A S, ATANASOV V, et al. Protonated phosphonic acid electrodes for high power heavy-duty vehicle fuel cells[J]. Nature Energy, 2022, 7: 248-259. doi: 10.1038/s41560-021-00971-x [22] ZHANG J, AILI D, LU S F, et al. Advancement toward polymer electrolyte membrane fuel cells at elevated temperatures[J]. Research, 2020, 2020: 9089405. [23] LI Q F, JENSEN J O, SAVINELL R F, et al. High temperature proton exchange membranes based on polybenzimidazoles for fuel cells[J]. Progress in Polymer Science, 2009, 34(5): 449-477. doi: 10.1016/j.progpolymsci.2008.12.003 [24] LI W, WANG H N, ZHANG J, et al. Advancements of polyvinylpyrrolidone-based polymer electrolyte membranes for electrochemical energy conversion and storage devices[J]. ChemSusChem, 2022, 15(10): e202200071. [25] LU S F, XU X, ZHANG J, et al. Progress of phosphoric acid doped high temperature proton exchange membrane for fuel cells[J]. Scientia Sinica Chimica, 2017, 47(5): 565-572. doi: 10.1360/N032016-00219 [26] XU X, WANG H N, LU S F, et al. A novel phosphoric acid doped poly(ethersulphone)-poly(vinyl pyrrolidone) blend membrane for high-temperature proton exchange membrane fuel cells[J]. Journal of Power Sources, 2015, 286: 458-463. doi: 10.1016/j.jpowsour.2015.04.028 [27] GUO Z B, XU X, XIANG Y, et al. New anhydrous proton exchange membranes for high-temperature fuel cells based on PVDF-PVP blended polymers[J]. Journal of Materials Chemistry A, 2015, 3(1): 148-155. doi: 10.1039/C4TA04952G [28] REN X R, LI H H, LIU K, et al. Preparation and investigation of reinforced PVP blend membranes for high temperature polymer electrolyte membranes[J]. Fibers and Polymers, 2019, 19(12): 2449-2457. [29] LI M Q, SCOTT K. Polymer electrolyte membrane for high temperature fuel cells to fit vehicle applications[J]. Electrochimica Acta, 2010, 55(6): 2123-2128. doi: 10.1016/j.electacta.2009.11.044 [30] LU S F, XIU R J, XU X, et al. Polytetrafluoroethylene (PTFE) reinforced poly(ethersulphone)-poly(vinyl pyrrolidone) composite membrane for high temperature proton exchange membrane fuel cells[J]. Journal of Membrane Science, 2014, 464: 1-7. doi: 10.1016/j.memsci.2014.03.053 [31] MONG A L, YANG S, KIM D. Pore-filling polymer electrolyte membrane based on poly (arylene ether ketone) for enhanced dimensional stability and reduced methanol permeability[J]. Journal of Membrane Science, 2017, 543: 133-142. doi: 10.1016/j.memsci.2017.07.060 [32] GUO Z B, XIU R J, LU S F, et al. Submicro-pore containing poly(ether sulfones)/polyvinylpyrrolidone membranes for high-temperature fuel cell applications[J]. Journal of Materials Chemistry A, 2015, 3(16): 8847-8854. doi: 10.1039/C5TA00415B [33] GUO Z M, CHEN J N, BYUM J J, et al. Insights into the performance and degradation of polybenzimidazole/muscovite composite membranes in high-temperature proton exchange membrane fuel cells[J]. Journal of Membrance Science, 2022, 641: 119868. doi: 10.1016/j.memsci.2021.119868 [34] KUMAR S R, WANG J J, WU Y S, et al. Synergistic role of graphene oxide-magnetite nanofillers contribution on ionic conductivity and permeability for polybenzimidazole membrane electrolytes[J]. Journal of Power Sources, 2020, 445: 227293. doi: 10.1016/j.jpowsour.2019.227293 [35] BAI H J, WANG H N, ZHANG J, et al. Simultaneously enhancing ionic conduction and mechanical strength of poly (ether sulfones)-poly(vinyl pyrrolidone) membrane by introducing graphitic carbon nitride nanosheets for high temperature proton exchange membrane fuel cell application[J]. Journal of Membrane Science, 2018, 558: 26-33. doi: 10.1016/j.memsci.2018.04.039 [36] BAI H J, ZHANG J, WANG H N, et al. Highly conductive quaternary ammonium-containing cross-linked poly(vinyl pyrrolidone) for high-temperature PEM fuel cells with high-performance[J]. Journal of Membrance Science, 2022, 645: 120194-120203. doi: 10.1016/j.memsci.2021.120194 [37] KOURASI M, WILLS R G A, SHAH A A, et al. Heteropolyacids for fuel cell applications[J]. Electrochimica Acta, 2014, 127(5): 454-466. [38] STAILI P, MINUTOLI M, HOCEVAR S. Membranes based on phosphotungstic acid and polybenzimidazole for fuel cell application[J]. Journal of Power Sources, 2000, 90(2): 231-235. doi: 10.1016/S0378-7753(00)00401-8 [39] LU S F, XU X, ZHANG J, et al. A self-anchored phosphotungstic acid hybrid proton exchange membrane achieved via one-step synthesis[J]. Advanced Energy Materials, 2014, 4(17): 1400842. doi: 10.1002/aenm.201400842 [40] XU X, WANG H N, LU S F, et al. A phosphotungstic acid self-anchored hybrid proton exchange membrane for direct methanol fuel cells[J]. RSC Advances, 2016, 6(49): 43049-43055. doi: 10.1039/C6RA07318B [41] YUAN Z Z, DAI Q, QIAO L, et al. Highly stable aromatic poly (ether sulfone) composite ion exchange membrane for vanadium flow battery[J]. Journal of Membrane Science, 2017, 541: 465-473. doi: 10.1016/j.memsci.2017.07.036 [42] ZHANG J, LIU J, LU S F, et al. Ion-exchange-induced selective etching for the synthesis of amino-functionalized hollow mesoporous silica for elevated-high-temperature fuel cells[J]. ACS Applied Materials & Interfaces, 2017, 9(37): 31922-31930. [43] LU S F, WANG D L, JIANG S P P, et al. HPW/MCM-41 phosphotungstic acid/mesoporous silica composites as novel proton-exchange membranes for elevated-temperature fuel cells[J]. Advanced Materials, 2010, 22(9): 971-976. doi: 10.1002/adma.200903091 [44] ZHANG J, CHEN S A, BAI H J, et al. Effects of phosphotungstic acid on performance of phosphoric acid doped polyethersulfone-polyvinylpyrrolidone membranes for high temperature fuel cells[J]. International Journal of Hydrogen Energy, 2021, 46(19): 11104-11114. doi: 10.1016/j.ijhydene.2020.07.082 [45] ZHANG J J, ZHANG J, BAI H J, et al. A new high temperature polymer electrolyte membrane based on trifunctional group grafted polysulfone for fuel cell application[J]. Journal of Membrane Science, 2019, 572: 496-503. doi: 10.1016/j.memsci.2018.11.035 [46] BAI H J, WANG H N, ZHANG J, et al. High temperature polymer electrolyte membrane achieved by grafting poly(1-vinylimidazole) on polysulfone for fuel cells application[J]. Journal of Membrane Science, 2019, 592: 117395. doi: 10.1016/j.memsci.2019.117395 [47] BAI H J, PENG H G, XIANG Y, et al. Poly(arylene piperidine)s with phosphoric acid doping as high temperature polymer electrolyte membrane for durable, high-performance fuel cells[J]. Journal of Power Sources, 2019, 443: 227219. doi: 10.1016/j.jpowsour.2019.227219 [48] DANG J C, ZHAO L P, ZHANG J, et al. Imidazole microcapsules toward enhanced phosphoric acid loading of polymer electrolyte membrane for anhydrous proton conduction[J]. Journal of Membrane Science, 2018, 545: 88-98. doi: 10.1016/j.memsci.2017.09.062 [49] TANG H Y, GENG K, HAO J K, et al. Properties and stability of quaternary ammonium-biphosphate ion-pair poly(sulfone)s high temperature proton exchange membranes for H2/O2 fuel cells[J]. Journal of Power Sources, 2020, 475: 228521. doi: 10.1016/j.jpowsour.2020.228521 [50] JIANG Z Y, ZHENG X H, WU H, et al. Proton conducting membranes prepared by incorporation of organophosphorus acids into alcohol barrier polymers for direct methanol fuel cells[J]. Journal of Power Sources, 2008, 185(1): 85-94. doi: 10.1016/j.jpowsour.2008.06.086 [51] SCHUSTER M, RAGER T, NODA A, et al. About the choice of the protogenic group in PEM separator materials for intermediate temperature, low humidity operation: A critical comparison of sulfonic acid, phosphonic acid and imidazole functionalized model compounds[J]. Fuel Cells, 2005, 5(3): 355-365. doi: 10.1002/fuce.200400059 [52] RAGER T, SCHUSTER M, STEININGER H, et al. Poly(1, 3-phenylene-5-phosphonic acid), a fully aromatic polyelectrolyte with high ion exchange capacity[J]. Advanced Materials, 2007, 19(20): 3317-3321. doi: 10.1002/adma.200602788 [53] NAGAO M, TAKEUCHI A, HEO P, et al. A proton-conducting In3+-doped SnP2O7 electrolyte for intermediate-temperature fuel cells[J]. Electrochemical and Solid-State Letters, 2006, 9(3): 105-109. doi: 10.1149/1.2159298 [54] WU X, VERMA A, SCOTT K. A Sb-doped SnP2O7 solid proton conductor for intermediate temperature fuel cells[J]. Fuel Cells, 2008, 8(6): 453-458. doi: 10.1002/fuce.200800032 [55] FORAN G Y, GOWARD G R. Site-specific proton dynamics in indium-doped tin pyrophosphate[J]. The Journal of Physical Chemistry C, 2020, 124(52): 28407-28416. doi: 10.1021/acs.jpcc.0c09290 [56] KANNAN A, LI Q F, CLEEMANN L N, et al. Acid distribution and durability of HT-PEM fuel cells with different electrode supports[J]. Fuel Cells, 2018, 18(2): 103-112. doi: 10.1002/fuce.201700181 [57] BECKER H, REIMER U, AILI D, et al. Determination of anion transference number and phosphoric acid diffusion coefficient in high temperature polymer electrolyte membranes[J]. Journal of the Electrochemical Society, 2018, 165(10): 863-869. doi: 10.1149/2.1201810jes [58] BECKER H, CLEEMANN L N, AILI D, et al. Probing phosphoric acid redistribution and anion migration in polybenzimidazole membranes[J]. Electrochemistry Communications, 2017, 82: 21-24. doi: 10.1016/j.elecom.2017.07.005 [59] MARTIN S, LI Q, STEENBERG T, et al. Binderless electrodes for high-temperature polymer electrolyte membrane fuel cells[J]. Journal of Power Sources, 2014, 272: 559-566. doi: 10.1016/j.jpowsour.2014.08.112 [60] LEE E, KIM D H, PAK C. Effects of cathode catalyst layer fabrication parameters on the performance of high-temperature polymer electrolyte membrane fuel cells[J]. Applied Surface Science, 2020, 510: 145461. doi: 10.1016/j.apsusc.2020.145461 [61] MARTIN S, GARCIA YBRRA P L, CASTILLO J L. Ten-fold reduction from the state-of-the-art platinum loading of electrodes prepared by electrospraying for high temperature proton exchange membrane fuel cells[J]. Electrochemistry Communications, 2018, 93: 57-61. doi: 10.1016/j.elecom.2018.06.007 [62] MACK F, KLAGES M, SCHOLTA J, et al. Morphology studies on high-temperature polymer electrolyte membrane fuel cell electrodes[J]. Journal of Power Sources, 2014, 255: 431-438. doi: 10.1016/j.jpowsour.2014.01.032 [63] HALTER J, BEVILACQUA N, ZEIS R, et al. The impact of the catalyst layer structure on phosphoric acid migration in HT-PEMFC-An operando X-ray tomographic microscopy study[J]. Journal of Electroanalytical Chemistry, 2020, 859: 113832. doi: 10.1016/j.jelechem.2020.113832 [64] HALTER J, GLOOR T, AMOROSO B, et al. Wetting properties of porous high temperature polymer electrolyte fuel cells materials with phosphoric acid[J]. Physical Chemistry Chemical Physics, 2019, 21(24): 13126-13134. doi: 10.1039/C9CP02149C [65] JIN H, NAYEEM M O G, LEE S, et al. Highly durable nanofiber-reinforced elastic conductors for skin-tight electronic textiles[J]. ACS Nano, 2019, 13(7): 7905-7912. doi: 10.1021/acsnano.9b02297 [66] XIA L, LI X, WU Y, et al. Electrodes derived from carbon fiber-reinforced cellulose nanofiber/multiwalled carbon nanotube hybrid aerogels for high-energy flexible asymmetric supercapacitors[J]. Chemical Engineering Journal, 2020, 379: 122325. doi: 10.1016/j.cej.2019.122325 [67] ZHANG J J, BAI H J, YAN W R, et al. Enhancing cell performance and durability of high temperature polymer electrolyte membrane fuel cells by inhibiting the formation of cracks in catalyst layers[J]. Journal of the Electrochemical Society, 2020, 167(11): 114501. doi: 10.1149/1945-7111/ab9fe0 -

下载:

下载: