A system group maintenance scheduling method based on iteratively dynamic information

-

摘要:

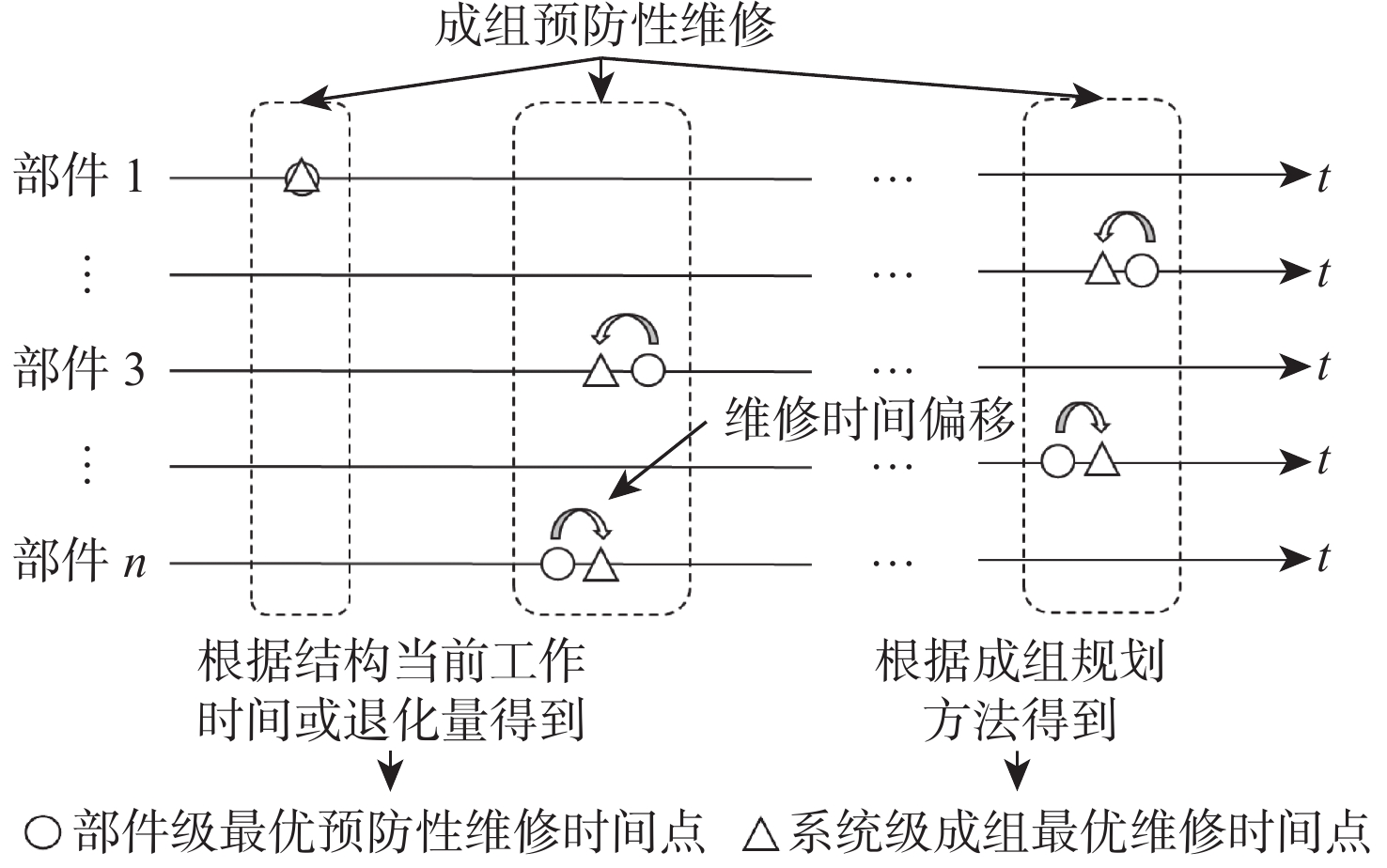

可用度是衡量设备系统服役效能的重要指标,目前大部分面向系统可用度优化的群组维修方法均为静态框架,无法充分利用健康状态信息实时高效调整维修计划。基于此,提出了一种考虑动态信息迭代机制的智能群组维修规划方法。该方法充分兼容突发型和退化型等典型系统故障分布特点,设计耦合预防性计划维修和机会维修的两级群组维修方案,并根据每次成组时的各部件实时状态-年龄信息,迭代更新下一次成组时间和需维修部件序列。针对飞机群组部件的算例验证表明,所提方法相比于传统的静态群组维修,在减少停机次数、提升稳态可用度方面具有显著优势。

Abstract:Availability is an important index to measure the service efficiency of equipment system. At present, most of the group maintenance frameworks for system availability optimization are static, which cannot make full use of health status information to effectively adjust real-time maintenance plans. To address these problems, this paper proposes an intelligent group maintenance planning approach based on a dynamic information iterative mechanism. By creating a two-level group maintenance scheme that couples pre-planned maintenance with opportunistic maintenance, the suggested approach is entirely compatible with common fault distribution features like sudden failure type and degradation type. Based on the real-time age and condition information of components in each group, we iteratively update the next grouping time and the sequence of components to be repaired. The numerical experience result demonstrates that the suggested strategy works better at lowering downtime and enhancing the system’s steady availability than conventional static group maintenance.

-

表 1 各部件的退化/失效参数

Table 1. Degradation/failure parameters of components

部件

编号退化失效

阈值${X_{\text{F}}}$漂移

系数$\nu $扩散

系数$\sigma $形状

参数$\alpha $尺度

参数$\beta $D1 25 0.481 0.407 D2 20 0.473 0.412 D3 15 0.432 0.428 T1 1.021 0.012 T2 1.282 0.025 T3 1.252 0.028 T4 1.083 0.021 T5 1.102 0.010 表 2 各部件的维修所需时间

Table 2. Maintenance durations of components

部件编号 预防性维修工时${t_{{\text{pr}}}}$/h 修复性维修工时${t_{{\text{cr}}}}$/h D1 1 6 D2 1.5 12 D3 2 15 T1 1.5 12 T2 2 15 T3 1 9 T4 1.5 12 T5 2 15 表 3 各部件最佳维修间隔及最大稳态可用度

Table 3. Optimal maintenance interval and maximum stable availability of components

部件编号 期望寿命/h 部件级最佳维修间隔/h 最大稳态可用度 D1 52 52 0.931 D2 42 48 0.951 D3 35 43 0.956 T1 85 26 0.772 T2 51 22 0.786 T3 45 19 0.757 T4 52 19 0.761 T5 110 32 0.796 表 4 T=100 h下的系统级最优维修计划

Table 4. Optimal system-level maintenance plan under T=100 hours

成组维

修次数最优维护组 成组维修

完成时间/h稳态可

用度提升提升

比例/%1 {T1,T2,T3,T4} 19 0.08 4.5 2 {D3,T2,T3,T4,T5} 38 0.12 4.1 3 {D1,D2,T1} 48 0.07 2.7 4 {T2,T3,T4} 57 0.07 2.7 5 {D3,T1,T2,T3,T4,T5} 74 0.10 3.9 6 {D1,D2,T1,T2,T3,T4} 93 0.14 4.9 -

[1] ZHANG Z H, YANG L. State-based opportunistic maintenance with multifunctional maintenance windows[J]. IEEE Transactions on Reliability, 2021, 70(4): 1481-1494. doi: 10.1109/TR.2020.2995277 [2] ZHANG Z H, YANG L. Postponed maintenance scheduling integrating state variation and environmental impact[J]. Reliability Engineering & System Safety, 2020, 202: 107065. [3] WANG J T, PENG R, QIU Q A, et al. An inspection-based replacement planning in consideration of state-driven imperfect inspections[J]. Reliability Engineering & System Safety, 2023, 232: 109064. [4] REN H, CHEN X, CHEN Y. Reliability based aircraft maintenance optimization and applications[M]. London: Academic Press, 2017. [5] 苏亨锔. 测试数据下的航空设备视情维修研究[J]. 设备管理与维修, 2018(21): 54-55.SU H J. Research on condition-based maintenance of aviation equipment based on test data[J]. Plant Maintenance Engineering, 2018(21): 54-55(in Chinese). [6] 郑志霖, 叶晓东. 基于统计分析方法的飞机维修方案优化[J]. 航空维修与工程, 2020(11): 29-33. doi: 10.3969/j.issn.1672-0989.2020.11.011ZHENG Z L, YE X D. Optimization of aircraft maintenance scheme based on statistical analysis method[J]. Aviation Maintenance & Engineering, 2020(11): 29-33(in Chinese). doi: 10.3969/j.issn.1672-0989.2020.11.011 [7] LIU J Q. Maintenance model of aircraft structure based on three-stage degradation process[J]. Computers & Industrial Engineering, 2021, 157: 107335. [8] ZHANG C X, LI Q, LIU Y K. Optimal replacement policy with minimal repair and preventive maintenance of an aircraft structure subjected to corrosion[J]. Soft Computing, 2020, 24(1): 375-384. doi: 10.1007/s00500-019-03919-2 [9] 潘刚, 尚朝轩, 蔡金燕, 等. 基于Semi-Markov模型的多态系统不完全维修决策[J]. 航空学报, 2017, 38(2): 320192.PAN G, SHANG C X, CAI J Y, et al. Imperfect maintenance decision for multi-state system based on Semi-Markov model[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(2): 320192(in Chinese). [10] WANG J J, YANG L, MA X B, et al. Joint optimization of multi-window maintenance and spare part provisioning policies for production systems[J]. Reliability Engineering & System Safety, 2021, 216: 108006. [11] YANG L, CHEN Y, MA X B, et al. A prognosis-centered intelligent maintenance optimization framework under uncertain failure threshold[J]. IEEE Transactions on Reliability, 2024, 73(1): 115-130. doi: 10.1109/TR.2023.3273082 [12] 李大伟, 张志华, 钟强晖, 等. 复杂退化系统的组合维修策略优化[J]. 航空学报, 2015, 36(3): 872-880.LI D W, ZHANG Z H, ZHONG Q H, et al. Optimal combination maintenance strategy of deteriorating complex system[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(3): 872-880(in Chinese). [13] 林琳, 罗斌, 钟诗胜. 基于视情维修的机队维修决策方法[J]. 计算机集成制造系统, 2019, 25(3): 661-672.LIN L, LUO B, ZHONG S S. Maintenance decision-making based on condition-based maintenance for fleet[J]. Computer Integrated Manufacturing Systems, 2019, 25(3): 661-672(in Chinese). [14] YANG L, CHEN Y, QIU Q A, et al. Risk control of mission-critical systems: Abort decision-makings integrating health and age conditions[J]. IEEE Transactions on Industrial Informatics, 2022, 18(10): 6887-6894. doi: 10.1109/TII.2022.3141416 [15] YANG L, WEI F P, QIU Q A. Mission risk control via joint optimization of sampling and abort decisions[J] Risk Analysis, 2024, 44(3): 666-685. [16] DO P, VU C, BARROS A, et al. Maintenance grouping for multi-component systems with availability constraints and limited maintenance teams[J]. Reliability Engineering & System Safety, 2015, 142: 56-67. [17] 王蕴, 王乃超, 马麟, 等. 考虑备件约束的多部件串联系统使用可用度计算方法[J]. 航空学报, 2015, 36(4): 1195-1201.WANG Y, WANG N C, MA L, et al. Operational availability calculation methods of various series systems under the constraint of spare parts[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(4): 1195-1201(in Chinese). [18] 李军亮, 滕克难, 夏菲. 一种复杂可修系统的可用度计算方法[J]. 航空学报, 2017, 38(12): 221169.LI J L, TENG K N, XIA F. An availability calculation method for complex repairable systems[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(12): 221169(in Chinese). [19] DINH D, DO P, IUNG B. Reliability modeling and opportunistic maintenance optimization for a multicomponent system with structural dependence[J]. Reliability Engineering & System Safety, 2024, 241: 109708. [20] 王炳辉. 考虑故障相关性的动车组部件维护策略研究[D]. 兰州: 兰州交通大学, 2021.WANG B H. Research on maintenance strategy of EMU components considering fault correlation[D]. Lanzhou: Lanzhou Jiaotong University, 2021(in Chinese). [21] 王颖. 成组维修在通用飞机维修中的应用研究[D]. 天津: 中国民航大学, 2019.WANG Y. Application research of group maintenance in general aircraft maintenance[D]. Tianjin: Civil Aviation University of China, 2019(in Chinese). [22] 罗斌. 基于结构疲劳寿命预测的机队维修决策方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.LUO B. Research on fleet maintenance decision-making based on structure fatigue life prediction[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [23] JIA H P, PENG R, YANG L, et al. Reliability evaluation of demand-based warm standby systems with capacity storage[J]. Reliability Engineering & System Safety, 2022, 218: 108132. [24] CHEN Y, MA X B, WEI F P, et al. Dynamic scheduling of intelligent group maintenance planning under usage availability constraint[J]. Mathematics, 2022, 10(15): 2730. doi: 10.3390/math10152730 [25] 孔祥芬, 蔡峻青, 张利寒, 等. CFM56-3发动机高压点火导线可靠性分析[J]. 机械设计与制造, 2020(5): 289-292.KONG X F, CAI J Q, ZHANG L H, et al. Reliability analysis of CFM56-3 engine high voltage ignition wire[J]. Machinery Design & Manufacture, 2020(5): 289-292(in Chinese). [26] YANG L, YE Z S, LEE C G, et al. A two-phase preventive maintenance policy considering imperfect repair and postponed replacement[J]. European Journal of Operational Research, 2019, 274(3): 966-977. doi: 10.1016/j.ejor.2018.10.049 [27] WU T Y, WEI F P, YANG L, et al. Maintenance optimization of k-out-of-n load-sharing systems under continuous operation[J] IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2023, 53(10): 6329-6341. [28] 柏文峰, 洪黎, 张超, 等. 机载往复密封二元时变相关退化建模与可靠度评估[J]. 液压与气动, 2022, 46(2): 31-38.BAI W F, HONG L, ZHANG C, et al. Dual time-varying correlation degradation modeling and reliability evaluation of airborne reciprocating seals[J]. Chinese Hydraulics & Pneumatics, 2022, 46(2): 31-38(in Chinese). [29] 董青, 郑建飞, 胡昌华, 等. 考虑随机冲击影响的自适应Wiener过程剩余寿命预测方法[J]. 航空学报, 2022, 43(9): 486-498.DONG Q, ZHENG J F, HU C H, et al. Remaining useful life prediction for adaptive Wiener process method with random shock[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(9): 486-498(in Chinese). [30] YANG L, CHEN Y, MA X B. A state-age-dependent opportunistic intelligent maintenance framework for wind turbines under dynamic wind conditions[J]. IEEE Transactions on Industrial Informatics, 2023, 19(10): 10434-10443. doi: 10.1109/TII.2023.3240727 [31] WANG J T, TANG L Y, MA X B, et al. Prognosis-driven reliability analysis and replacement policy optimization for two-phase continuous degradation[J] Reliability Engineering & System Safety, 2023, 230: 108909. -

下载:

下载: