Corrosion and fatigue life prediction of aircraft typical lap structures based on life envelope

-

摘要:

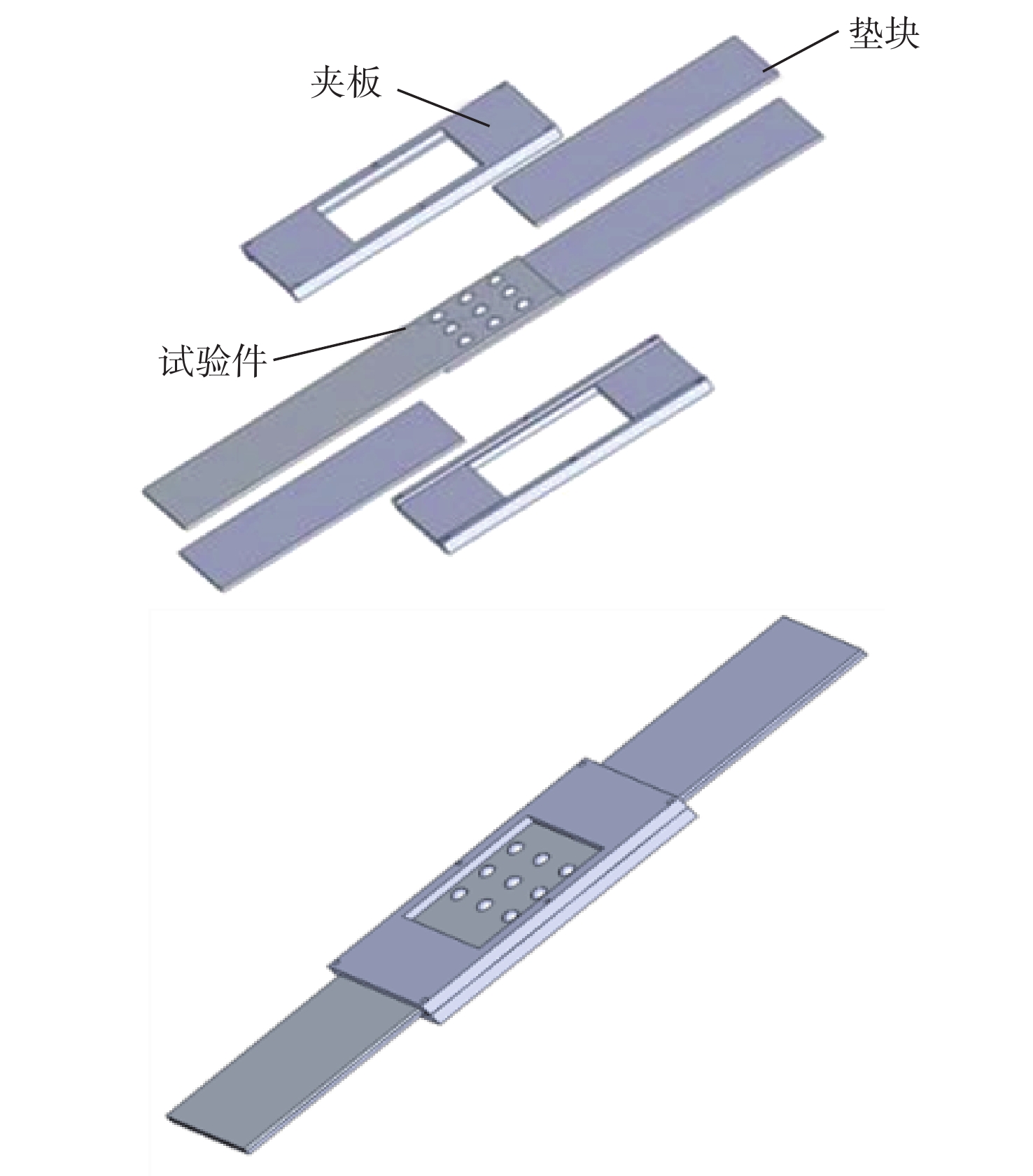

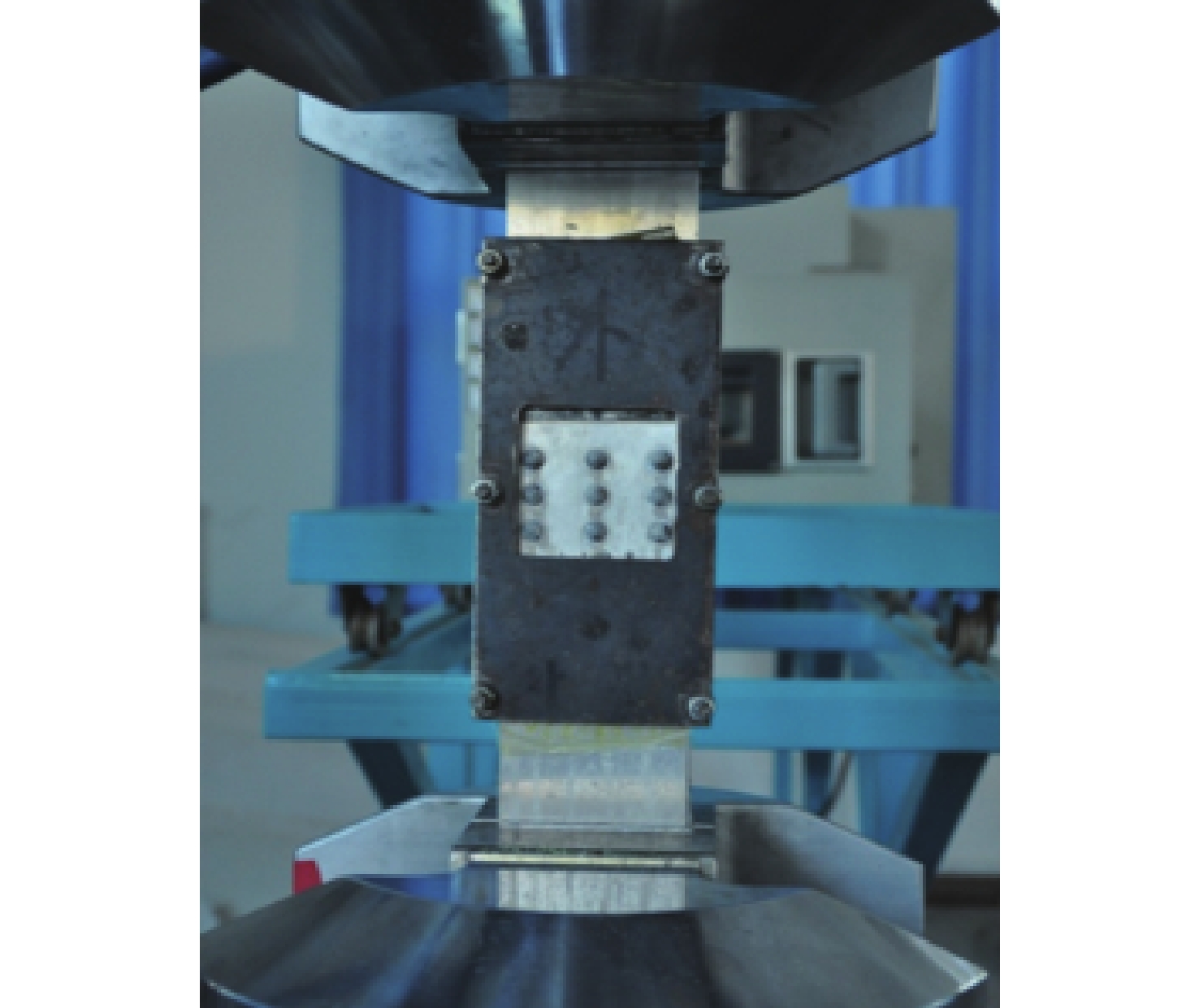

针对飞机在腐蚀环境下服役的寿命预测问题,开展了某型飞机机身壁板搭接结构的腐蚀-疲劳交替试验。基于试验结果和飞机结构寿命包线理论体系,建立了该型飞机机身壁板搭接结构在不同服役地区、不同飞行强度下的寿命包线,并基于寿命包线对其剩余寿命进行了预测。通过开展验证试验,将试验结果与计算结果进行对比,发现预测误差为17.4%。说明结构寿命包线是飞机典型搭接结构寿命预测的有力工具,其预测结果是飞机服役过程中检修周期及寿命管理的一项重要参考依据。

Abstract:The corrosion and fatigue tests of a certain type of aircraft fuselage panel lap structure were conducted alternatively. Based on the test results and the concept of aircraft structure life envelope, the life envelope of the lap joint structure of the fuselage panel in different service areas and under different flight intensities was established. Then, based on this life envelope, the remaining lifetime of the structure was predicted. The prediction error was found to be 17.4% by comparing the experimental results with the calculated results. It is shown that the structural life envelope is a powerful tool for life prediction of aircraft typical lap structures, and its prediction result is an important reference for the maintenance cycle and life management of aircraft in service.

-

表 1 纯疲劳试验结果

Table 1. Fatigue test results

试验件编号 疲劳寿命/周期 对应飞行小时数/efh 0-1 138 324 17 290.5 0-2 176 771 22 096.4 0-3 195 420 24 427.5 0-4 134 194 16 774.3 表 2 腐蚀-疲劳交替试验结果

Table 2. Results of alternating corrosion and fatigue tests

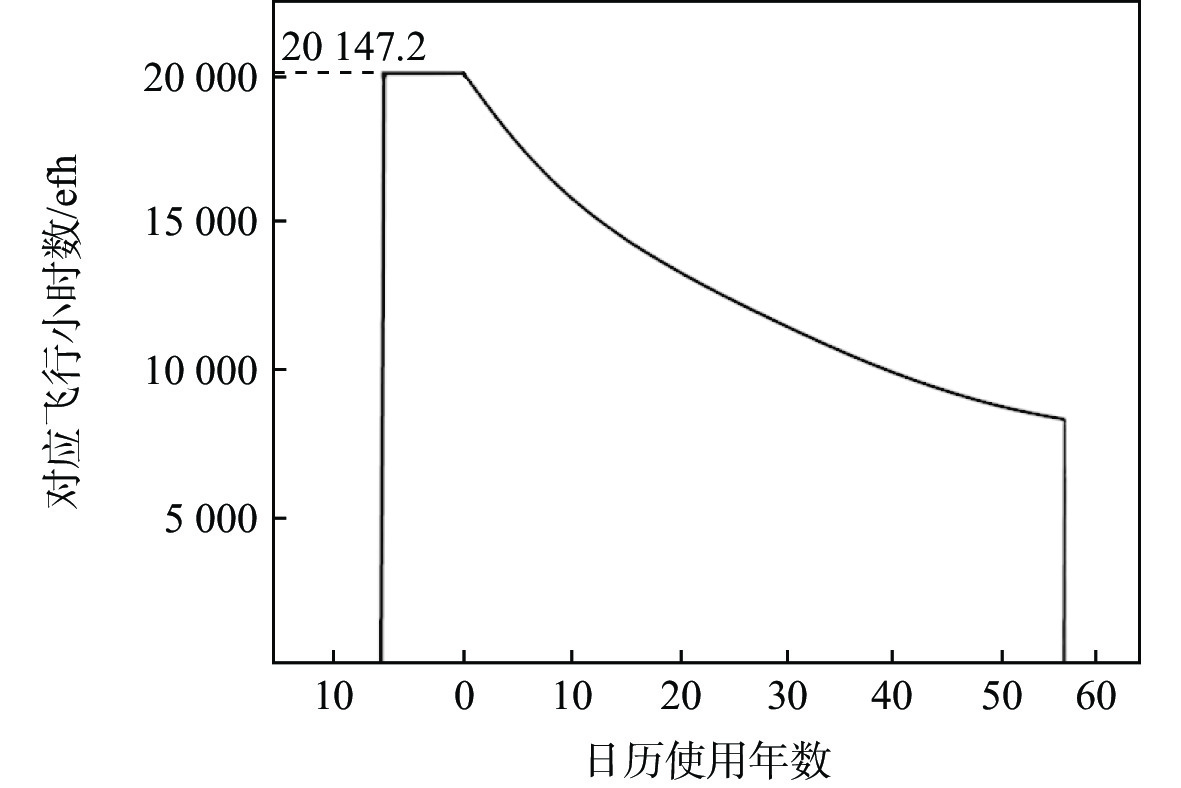

总腐蚀时间/h 试验件编号 疲劳寿命/周期 对应飞行小时数/efh 325 1-1 90 485 11 310.6 1-2 113 470 14 183.8 1-3 128 705 16 088.1 1-4 151 690 18 961.3 975 2-1 110 077 13 759.6 2-2 103 176 12 897.0 2-3 77 767 9 720.9 2-4 73 607 9 200.9 1300 3-1 65 469 8 183.6 3-2 93 485 11 685.6 3-3 94 003 11 750.4 3-4 60 460 7 557.5 1625 4-1 87 463 10 932.9 4-2 75 508 9 438.5 4-3 52 756 6 594.5 4-4 60 634 7 579.3 1950 5-1 68 997 8 622.1 5-2 87 102 10 887.8 5-3 53 866 6 733.3 5-4 48 095 6 011.9 表 3 不同腐蚀年限下的疲劳寿命与腐蚀影响系数

Table 3. Fatigue life and corrosion impact factor for different corrosion years

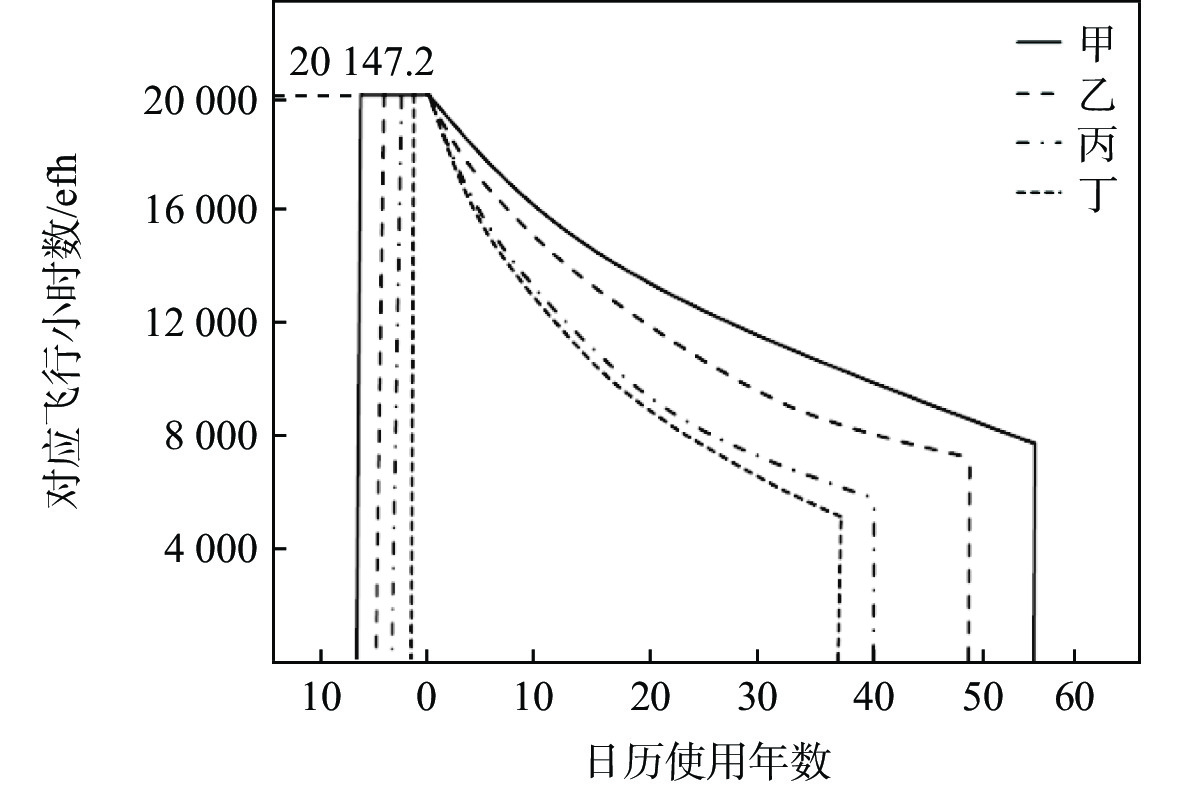

试验腐蚀时间/h 等效腐蚀年限/a 对应飞行小时数/efh C(T) 0 0 20 147.2 1.000 0 325 10.00 15 135.9 0.751 3 975 30.00 11 394.6 0.565 6 1 300 40.00 9 794.3 0.486 1 1 625 50.00 8 636.3 0.428 7 1 950 60.00 8 064.4 0.400 3 表 4 不同地区的结构寿命包线

Table 4. Structural life envelops for different regions

服役

地区防护层

有效期/a对应飞行

小时数/efhC(T)曲线公式 相关系数 甲 6.14 20 147.2 C(T)=1−0.078 4T0.504 0 0.997 乙 4.10 20 147.2 C(T)=1−0.091 3T0.504 0 0.997 丙 3.08 20 147.2 C(T)=1−0.115 4T0.503 8 0.997 丁 2.48 20 147.2 C(T)=1−0.120 2T0.504 3 0.997 表 5 验证试验加载条件与假设服役历程对应关系

Table 5. Correspondence between validation test loading conditions and assumed service history

服役

地区飞行强度/

(efh·a−1)服役

年数/a试验腐蚀

周期/h试验疲劳

循环数/周期甲 272 5.1 0 11 100 乙 240 0.7 0 1 350 乙 240 2.5 110 4 800 丁 187 4 304 6 000 丙 254 3.2 224 6 500 甲 待求 8 260 疲劳加载至断裂 注:在甲地服役的5.1 a和乙地服役的前0.7 a,防护体系未失效,试验中为纯疲劳加载。 表 6 模拟结构转场服役/使用的腐蚀-疲劳交替试验结果

Table 6. Results of alternate corrosion and fatigue tests simulating transfer of structure into service/use

试验件编号 疲劳寿命/周期 对应飞行小时数/efh 6-1 72 325 9 040.6 6-2 103 274 12 909.3 6-3 103 843 12 980.4 6-4 66 791 8 348.9 -

[1] 田建学, 魏俊淦. 搭接技术在飞机上的应用[J]. 电子世界, 2014(5): 68.TIAN J X, WEI J G. Application of lapping technology in aircraft[J]. Electronics World, 2014(5): 68(in Chinese). [2] 杨静, 姜兴长, 王慧梅. 飞机蒙皮典型搭接结构附加弯矩分析[J]. 机械强度, 2019, 41(2): 389-392.YANG J, JIANG X C, WANG H M. Secondary bending analysis of airplane typical single-shear lap joint[J]. Journal of Mechanical Strength, 2019, 41(2): 389-392(in Chinese). [3] 王晨光, 陈跃良, 张勇, 等. 飞机用7B04铝合金缝隙腐蚀试验及仿真研究[J]. 装备环境工程, 2017, 14(3): 39-46.WANG C G, CHEN Y L, ZHANG Y, et al. Crevice corrosion experiment and simulation study of 7B04 aluminum alloy for aircraft[J]. Equipment Environmental Engineering, 2017, 14(3): 39-46(in Chinese). [4] 李玉海, 王成波, 陈亮, 等. 先进战斗机寿命设计与延寿技术发展综述[J]. 航空学报, 2021, 42(8): 525791.LI Y H, WANG C B, CHEN L, et al. Overview of advanced fighter life design and life extension technology development[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(8): 525791(in Chinese). [5] 何宇廷. 飞机结构寿命控制原理与技术 [M]. 北京: 国防工业出版社, 2017: 251-260.HE Y T. Principle and technology of aircraft structure life control [M]. Beijing: National Defense Industry Press, 2017: 251-260 (in Chinese). [6] 高长宝. 飞机结构使用寿命评定技术研究[J]. 中国设备工程, 2021(3): 200-201.GAO C B. Research on service life assessment technology of aircraft structures[J]. China Plant Engineering, 2021(3): 200-201(in Chinese). [7] 陈群志, 康献海, 刘建光, 等. 军用飞机腐蚀防护与日历寿命研究[J]. 中国表面工程, 2010, 23(4): 1-6.CHEN Q Z, KANG X H, LIU J G, et al. Discussion about military aircraft anti-corrosion and calendar life research[J]. China Surface Engineering, 2010, 23(4): 1-6(in Chinese). [8] 杨晓华, 刘学君, 张泰峰. 基于年飞行强度的飞机日历寿命研究[J]. 南京航空航天大学学报, 2017, 49(1): 56-59.YANG X H, LIU X J, ZHANG T F. Research on aircraft calendar life based on annual flight intensity[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2017, 49(1): 56-59(in Chinese). [9] 陈跃良, 王晨光, 张勇, 等. 钛-钢螺栓搭接件涂层腐蚀失效分析及影响[J]. 航空学报, 2016, 37(11): 3528-3534.CHEN Y L, WANG C G, ZHANG Y, et al. Coating corrosion failure analysis and influence of titanium-steel bolted lap joints[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(11): 3528-3534(in Chinese). [10] 王晨光, 陈跃良, 张勇, 等. 表面涂层破损对7B04铝合金点蚀的影响及仿真研究[J]. 航空材料学报, 2016, 36(6): 48-53.WANG C G, CHEN Y L, ZHANG Y, et al. Influence and simulation study of surface coating damage on pitting corrosion of 7B04 aluminum alloy[J]. Journal of Aeronautical Materials, 2016, 36(6): 48-53(in Chinese). [11] KRUZIC J J. Predicting fatigue failures[J]. Science, 2009, 325(5937): 156-158. doi: 10.1126/science.1173432 [12] 何宇廷. 飞机结构寿命包线的建立[J]. 空军工程大学学报(自然科学版), 2005, 6(6): 4-6.HE Y T. Establishment of aircraft structural life envelope[J]. Journal of Air Force Engineering University (Natural Science Edition), 2005, 6(6): 4-6(in Chinese). [13] 何宇廷, 范超华. 飞机结构寿命包线的确定方法[J]. 空军工程大学学报(自然科学版), 2006, 7(6): 1-3.HE Y T, FAN C H. Determination method of aircraft structure life envelope[J]. Journal of Air Force Engineering University (Natural Science Edition), 2006, 7(6): 1-3(in Chinese). [14] 张海威, 何宇廷, 范超华, 等. 腐蚀/疲劳交替作用下飞机金属材料疲劳寿命计算方法[J]. 航空学报, 2013, 34(5): 1114-1121.ZHANG H W, HE Y T, FAN C H, et al. Fatigue life prediction method for aircraft metal material under alternative corrosion/fatigue process[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(5): 1114-1121(in Chinese). [15] 张腾, 何宇廷, 张海威, 等. 基于寿命包线的飞机金属结构寿命预测方法[J]. 南京航空航天大学学报, 2014, 46(3): 413-418.ZHANG T, HE Y T, ZHANG H W, et al. Life prediction method of aircraft metal structure based on life envelope[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2014, 46(3): 413-418(in Chinese). [16] HE Y, LI C, ZHANG T, et al. Service fatigue life and service calendar life limits of aircraft structure: aircraft structural life envelope[J]. The Aeronautical Journal, 2016, 120(1233): 1746-1762. doi: 10.1017/aer.2016.93 [17] 李玉海, 刘文珽, 杨旭, 等. 军用飞机结构日历寿命体系评定应用范例[M]. 北京: 航空工业出版社, 2005: 185-200.LI Y H, LIU W T, YANG X, et al. Application example of calendar life system evaluation of military aircraft structure[M]. Beijing: Aviation Industry Press, 2005: 185-200(in Chinese). [18] 李曙林. 飞机与发动机强度[M]. 北京: 国防工业出版社, 2007: 159-163.LI S L. Aircraft and engine strength[M]. Beijing: National Defense Industry Press, 2007: 159-163(in Chinese). -

下载:

下载: