-

摘要:

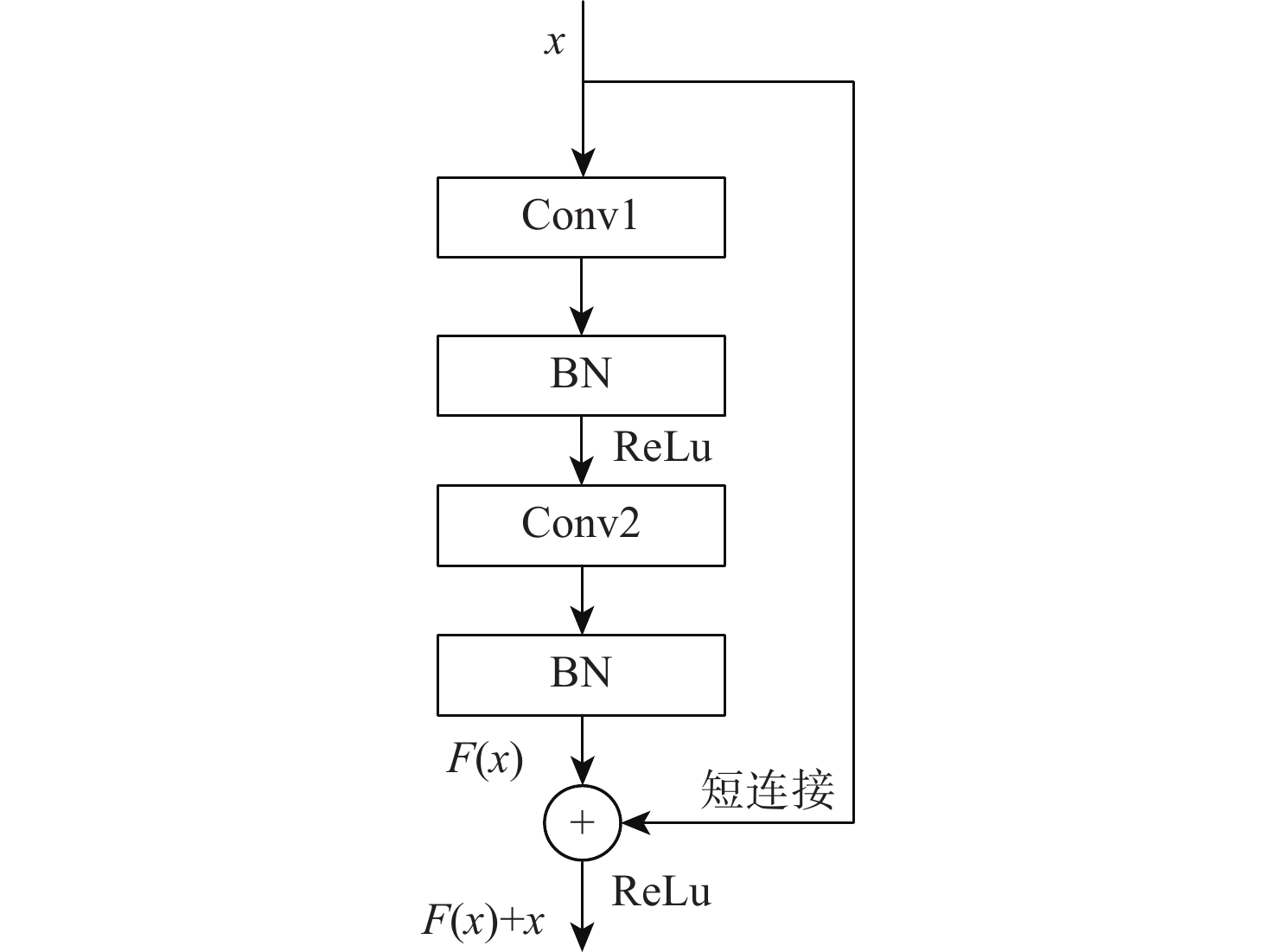

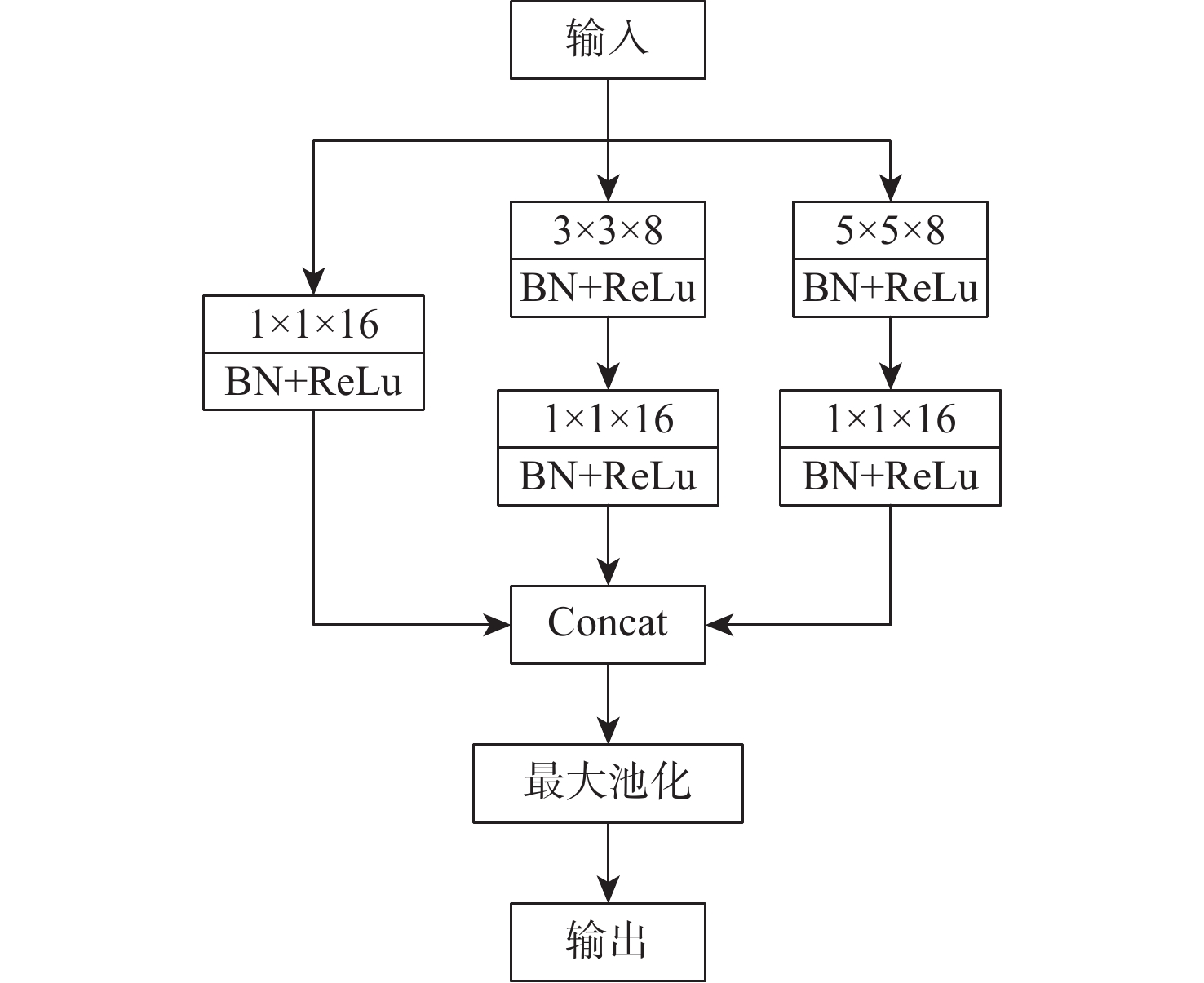

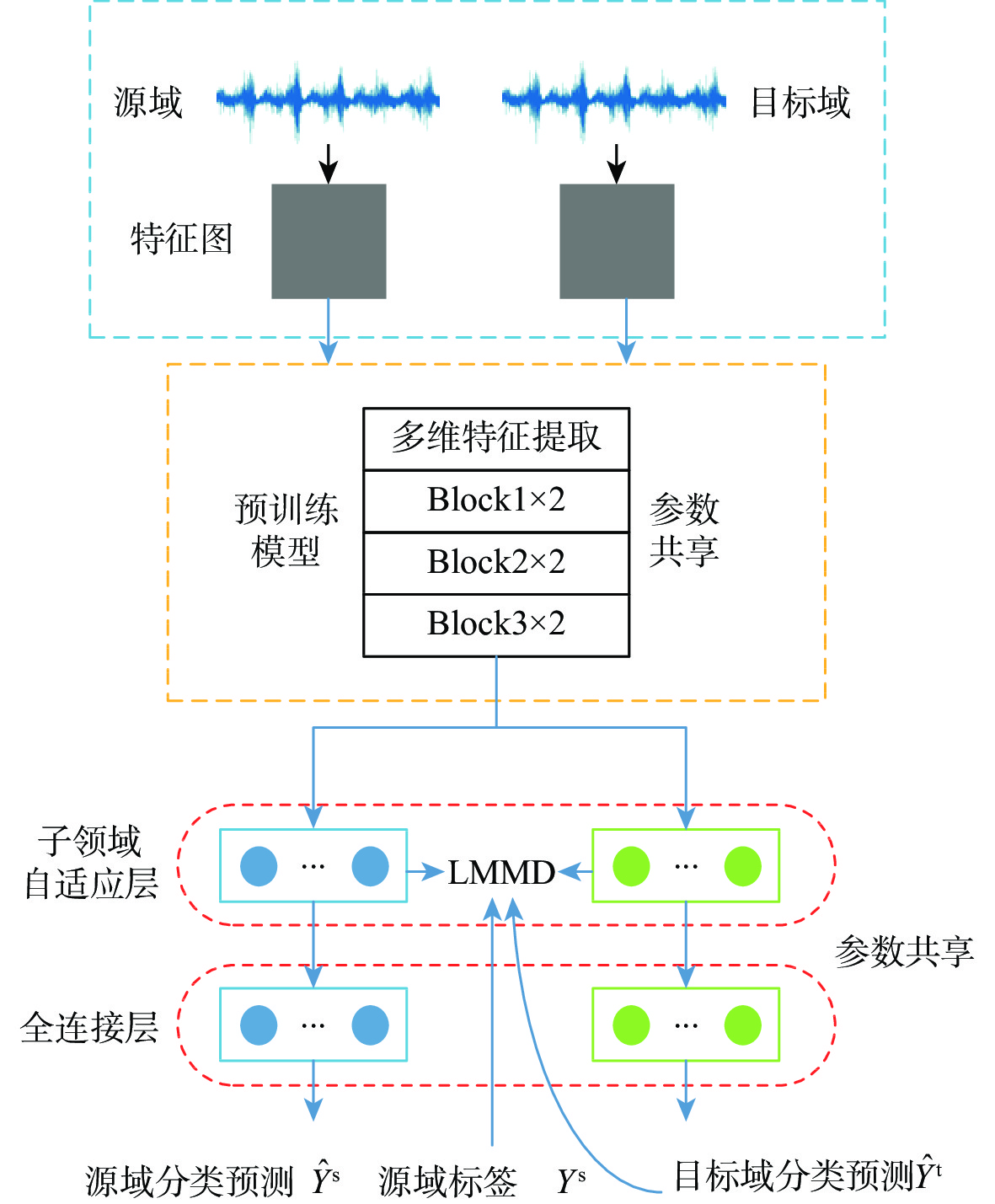

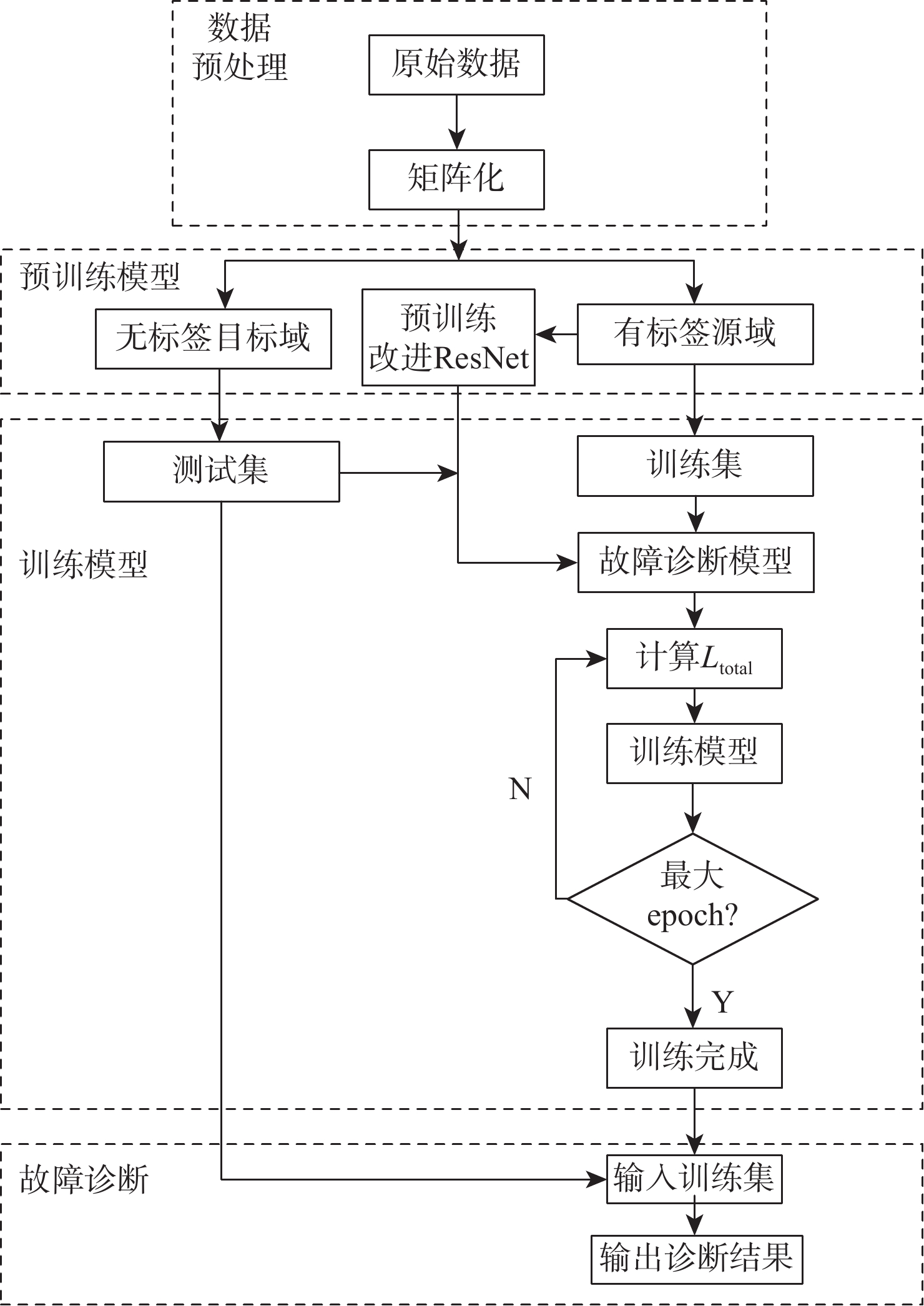

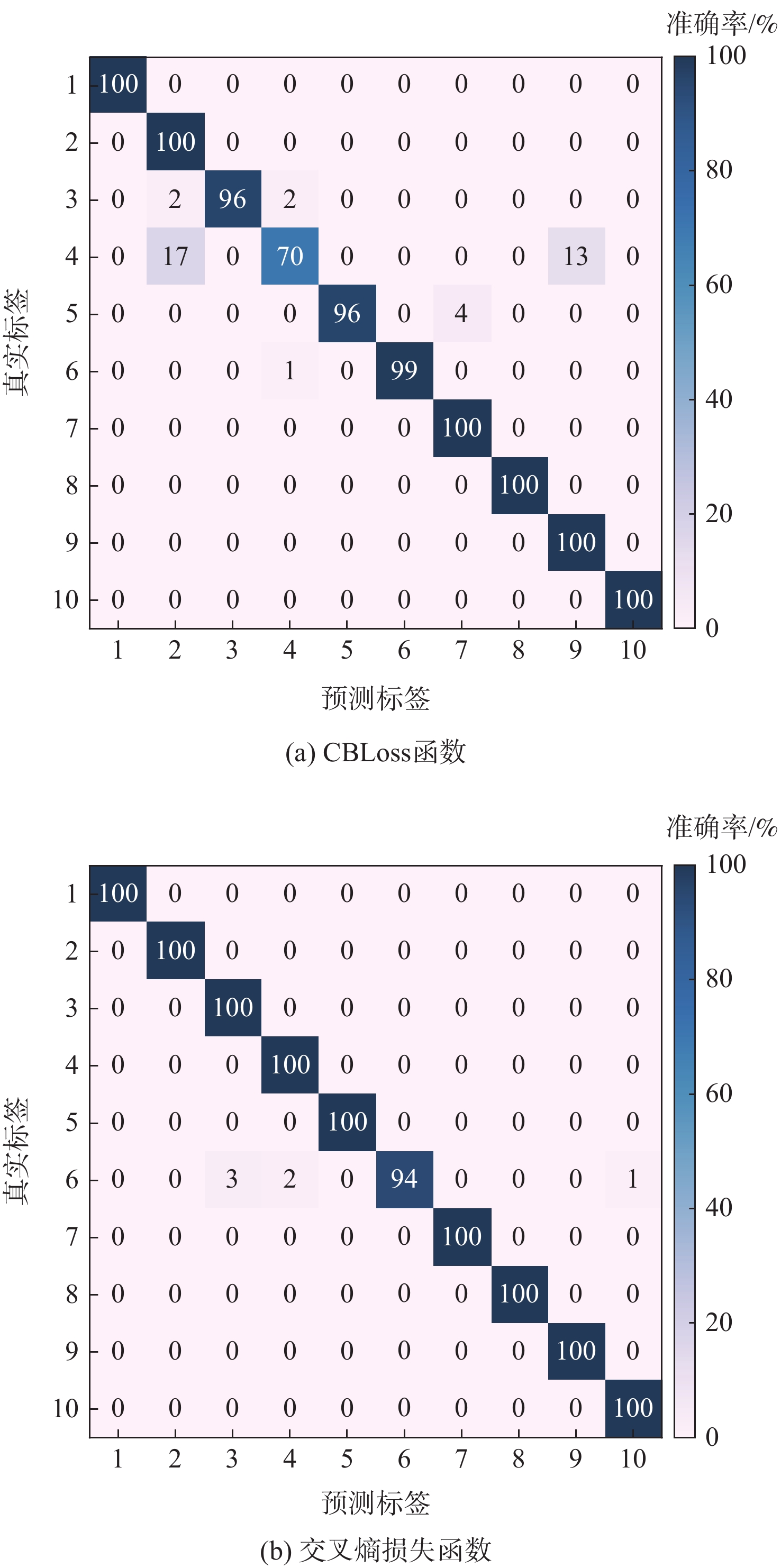

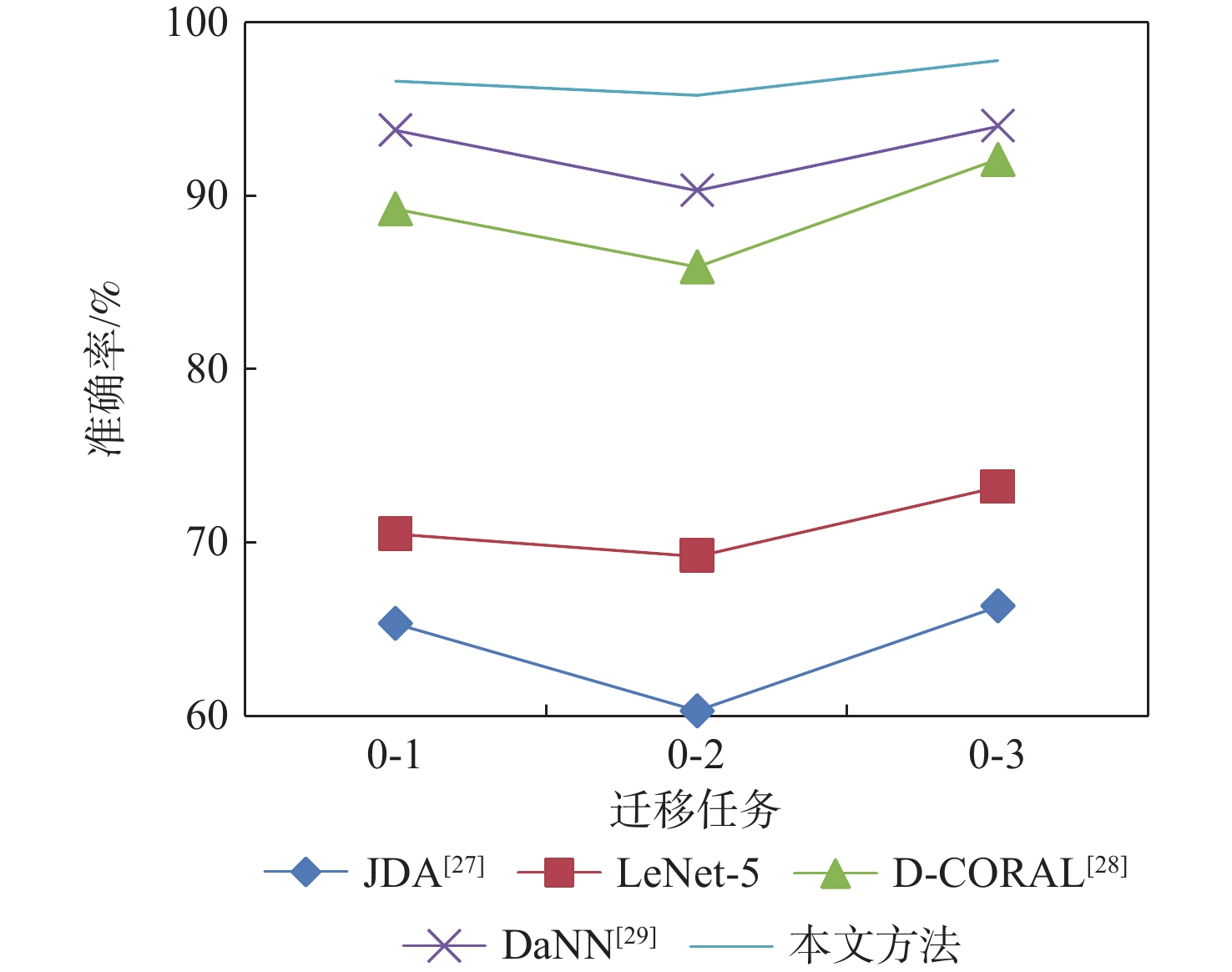

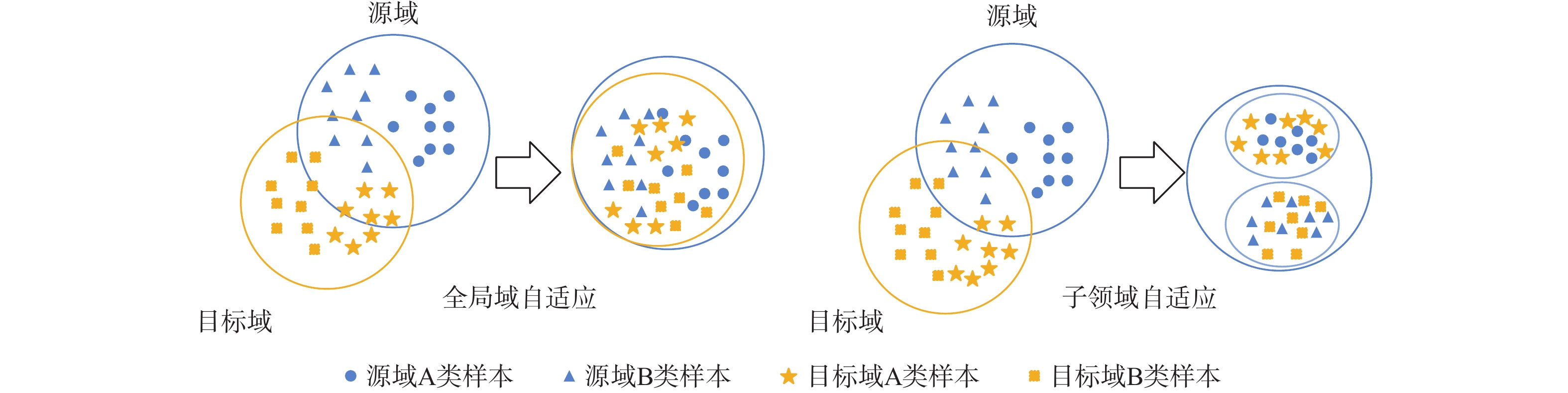

针对轴承故障诊断中存在训练样本和测试样本分布不同及各类故障数据不平衡导致故障识别率低的问题,设计了一种基于改进残差网络(ResNet)的领域自适应故障诊断方法。在诊断网络第1层使用多维度卷积结构进行特征提取,得到不同维度的故障特征信息;在领域自适应层采用局部最大平均差异(LMMD)对齐源域和目标域的分布,获取更多细粒度信息;使用类平衡损失函数(CBLoss)解决不平衡数据的训练问题,以Adam优化网络实现故障诊断。实验结果表明,所提方法可在故障样本类别不平衡下有较高的诊断结果。在2个轴承数据集和采集的风力发电机数据上进行实验验证,结果表明,所提方法具有一定的优越性,在数据样本不平衡情况下,诊断性能优于深度神经网络和领域自适应网络等深度迁移学习方法,可作为一种有效的跨工况故障分析方法。

Abstract:This research develops a domain adaptive fault diagnosis method based on an enhanced residual network (ResNet) to address the issues that the distribution of training samples and test samples differs in bearing fault diagnosis and the imbalance of different fault data results in a low fault recognition rate.First, the multi-dimensional convolution structure is used for feature extraction in the first layer of the diagnosis network to obtain fault feature information of different dimensions.Then, the local maximum mean difference (LMMD) is used in the domain adaptation layer to align the distribution of the source and target domains, to obtain more fine-grained information. Finally, the class-balanced loss (CBLoss) function is used to solve the training problem of unbalanced data, and the Adam optimization network is used to achieve fault diagnosis. The experimental findings demonstrate that, even in cases when fault sample categories are unbalanced, the enhanced approach suggested in this work can produce better diagnosis outcomes. Experiments are carried out on two bearing datasets and collected wind turbine data. The results show that the improved method has certain advantages, and its diagnostic performance is better than other deep transfer learning methods in the case of imbalanced data samples. It can be used as an effective cross-condition failure analysis method.

-

Key words:

- fault diagnosis /

- residual network /

- data imbalance /

- local maximum mean difference /

- class-balanced loss /

- bearings

-

表 1 残差块参数

Table 1. Residual block parameters

残差块 残差块参数 Conv1 Conv2 Block1×2 Conv(3,3,1,16) Conv(3,3,1,32) Block2×2 Conv(3,3,1,32) Conv(3,3,1,64) Block3×2 Conv(3,3,1,64) Conv(3,3,1,128) 表 2 数据集设置

Table 2. Dataset settings

故障类型 尺寸/cm 训练集数量 测试集数量 正常 200 150 滚子故障 2.54 150 100 5.08 150 100 7.62 150 100 内圈故障 2.54 150 100 5.08 150 100 7.62 100 50 外圈故障 2.54 100 50 5.08 100 50 7.62 100 50 表 3 不同方法诊断精度

Table 3. Diagnostic accuracy of different methods

方法 准确率/% 平均准确率 A→B A→C A→D B→A B→C B→D C→A C→B C→D D→A D→B D→C JDA[27] 71.3 68.5 70.2 66.8 69.9 73.6 70.4 72.6 71.2 69.1 68.5 73.6 70.5 LeNet-5 82.1 83.9 79.7 81.5 80.3 84.4 80.3 82.1 81.9 77.6 81.4 83.2 81.5 D-CORAL[28] 98.4 96.8 88.9 96.5 97.3 95.6 91.3 97.2 98.7 87.6 93.6 95.7 94.8 DaNN[29] 97.0 97.5 94.4 96.5 98.2 98.6 95.2 97.6 98.1 89.1 96.2 97.2 96.3 本文方法 99.4 98.8 99.1 99.3 98.5 99.8 98.2 99.1 99.5 98.4 99.7 99.3 99.1 表 4 不同工况详细信息

Table 4. Details of different working conditions

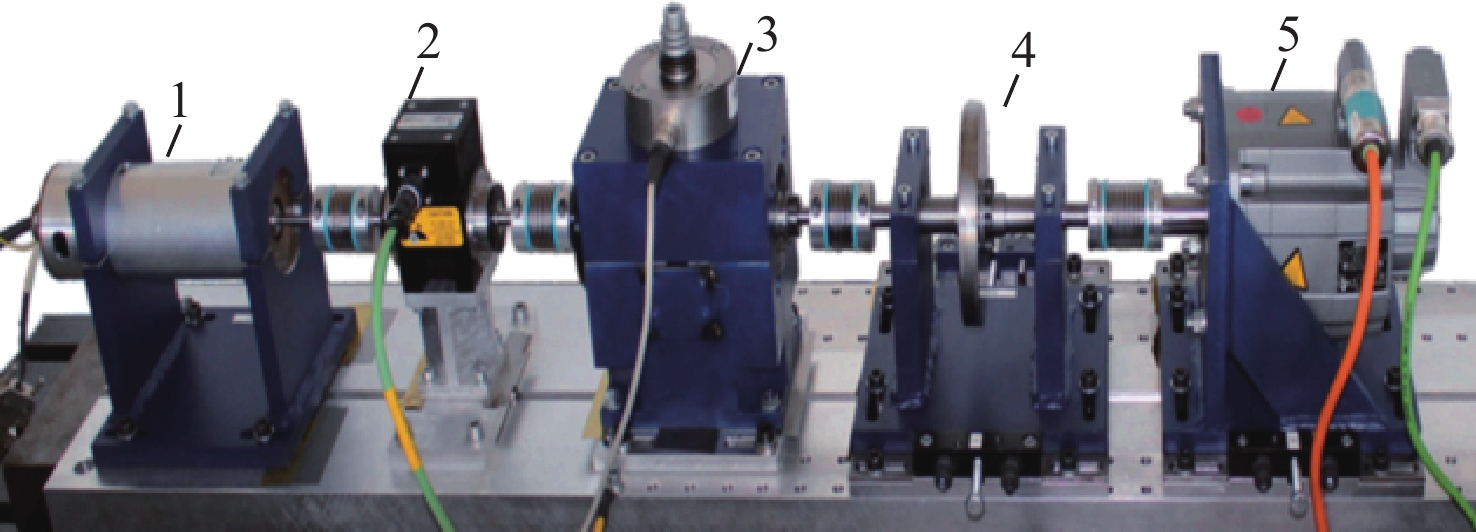

编号 转速/(r·min−1) 扭矩/(N·m) 径向负载/N 0 1500 0.7 1000 1 900 0.7 1000 2 1500 0.1 1000 3 1500 0.7 400 表 5 目标域数据代码

Table 5. Target domain data codes

迁移任务 正常 内圈故障(OR) 外圈故障(IR) 0-1 K002 KI04 KA04 0-2 K003 KI14 KA15 0-3 K004 KI16 KA22 表 6 轴承数据集划分

Table 6. Bearing dataset partitioning

故障类型 训练集数量 测试集数量 正常 500 300 内圈损伤 200 100 外圈损伤 100 50 表 7 目标域数据集划分

Table 7. Target domain dataset partitioning

迁移任务 故障类型 a-b 故障Ⅰ 故障Ⅱ 故障Ⅲ a-c 故障Ⅰ 故障Ⅱ 故障Ⅲ 表 8 风机数据集划分

Table 8. Wind turbine dataset partitioning

故障类型 训练集数量 测试集数量 故障Ⅰ 200 100 故障Ⅱ 100 50 故障Ⅲ 50 25 -

[1] JIAO J Y, ZHAO M, LIN J, et al. Hierarchical discriminating sparse coding for weak fault feature extraction of rolling bearings[J]. Reliability Engineering & System Safety, 2019, 184: 41-54. [2] LIM D H, KIM K S. Development of deep learning-based detection technology for vortex-induced vibration of a ship’s propeller[J]. Journal of Sound and Vibration, 2022, 520: 116629. doi: 10.1016/j.jsv.2021.116629 [3] YU L, QU J L, GAO F, et al. A novel hierarchical algorithm for bearing fault diagnosis based on stacked LSTM[J]. Shock and Vibration, 2019, 2019: 2756284. [4] JIN T T, YAN C L, CHEN C H, et al. New domain adaptation method in shallow and deep layers of the CNN for bearing fault diagnosis under different working conditions[J]. The International Journal of Advanced Manufacturing Technology, 2023, 124(11): 3701-3712. [5] LI H. Deeplearning for natural language processing: Advantages and challenges[J]. National Science Review, 2018, 5(1): 24-26. [6] KHAN S, YAIRI T. A review on the application of deep learning in system health management[J]. Mechanical Systems and Signal Processing, 2018, 107: 241-265. doi: 10.1016/j.ymssp.2017.11.024 [7] WANG J Y, MO Z L, ZHANG H, et al. A deep learning method for bearing fault diagnosis based on time-frequency image[J]. IEEE Access, 2019, 7: 42373-42383. [8] HASSAN S M, MAJI A K, JASIŃSKI M, et al. Identification of plant-leaf diseases using CNN and transfer-learning approach[J]. Electronics, 2021, 10(12): 1388. [9] PATEL V M, GOPALAN R, LI R N, et al. Visual domain adaptation: Asurvey of recent advances[J]. IEEE Signal Processing Magazine, 2015, 32(3): 53-69. doi: 10.1109/MSP.2014.2347059 [10] KERMANY D S, GOLDBAUM M, CAI W J, et al. Identifying medical diagnoses and treatable diseases by image-based deep learning[J]. Cell, 2018, 172(5): 1122-1131. doi: 10.1016/j.cell.2018.02.010 [11] 张西宁, 余迪, 刘书语. 基于迁移学习的小样本轴承故障诊断方法研究[J]. 西安交通大学学报, 2021, 55(10): 30-37. doi: 10.7652/xjtuxb202110004ZHANG X N, YU D, LIU S Y. Faultdiagnosis method for small sample bearing based on transfer learning[J]. Journal of Xi’an Jiaotong University, 2021, 55(10): 30-37(in Chinese). doi: 10.7652/xjtuxb202110004 [12] LI F D, CHEN J L, PAN J, et al. Cross-domain learning in rotating machinery fault diagnosis under various operating conditions based on parameter transfer[J]. Measurement Science and Technology, 2020, 31(8): 085104. [13] ZHU J, CHEN N, SHEN C Q. A new deep transfer learning method for bearing fault diagnosis under different working conditions[J]. IEEE Sensors Journal, 2020, 20(15): 8394-8402. [14] WEN L, GAO L, LI X Y. A new deep transfer learning based on sparse auto-encoder for fault diagnosis[J]. IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2019, 49(1): 136-144. doi: 10.1109/TSMC.2017.2754287 [15] GUO L, LEI Y G, XING S B, et al. Deep convolutional transfer learning network: A new method for intelligent fault diagnosis of machines with unlabeled data[J]. IEEE Transactions on Industrial Electronics, 2019, 66(9): 7316-7325. doi: 10.1109/TIE.2018.2877090 [16] CHE C C, WANG H W, NI X M, et al. Domain adaptive deep belief network for rolling bearing fault diagnosis[J]. Computers & Industrial Engineering, 2020, 143: 106427. [17] SHAO J J, HUANG Z W, ZHU J M. Transfer learning method based on adversarial domain adaption for bearing fault diagnosis[J]. IEEE Access, 2020, 8: 119421-119430. doi: 10.1109/ACCESS.2020.3005243 [18] 康守强, 刘旺辉, 王玉静, 等. 基于深度在线迁移的变负载下轴承故障诊断方法[J]. 控制与决策, 2022, 37(6): 1521-1530.KANG S Q, LIU W H, WANG Y J, et al. Bearing fault diagnosis method under variable load based on deep online migration[J]. Control and Decision, 2022, 37(6): 1521-1530(in Chinese). [19] ZHAO C, LIU G K, SHEN W M, et al. A multi-representation-based domain adaptation network for fault diagnosis[J]. Measurement, 2021, 182: 109650. doi: 10.1016/j.measurement.2021.109650 [20] WANG X, SHEN C Q, XIA M, et al. Multi-scale deep intra-class transfer learning for bearing fault diagnosis[J]. Reliability Engineering & System Safety, 2020, 202: 107050. [21] FU S F, CAI F H, WANG W. Fault diagnosis of photovoltaic array based on SE-ResNet[J]. Journal of Physics: Conference Series, 2020, 1682(1): 012004. doi: 10.1088/1742-6596/1682/1/012004 [22] GROVER C, TURK N. A novel fault diagnostic system for rolling element bearings using deep transfer learning on bispectrum contour maps[J]. Engineering Science and Technology, an International Journal, 2022, 31: 101049. doi: 10.1016/j.jestch.2021.08.006 [23] ZOU Y S, LIU Y Z, DENG J L, et al. A novel transfer learning method for bearing fault diagnosis under different working conditions[J]. Measurement, 2021, 171: 108767. doi: 10.1016/j.measurement.2020.108767 [24] LESSMEIER C, KIMOTHO J K, ZIMMER D, et al. Conditionmonitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: A benchmark data set for data-driven classification[C]//Proceedings of the European Conference of the Prognostics and Health Management Society. ST Roch: PHM Society, 2016: 1-17. [25] ZHU Y C, ZHUANG F Z, WANG J D, et al. Deep subdomain adaptation network for image classification[J]. IEEE Transactions on Neural Networks and Learning Systems, 2021, 32(4): 1713-1722. doi: 10.1109/TNNLS.2020.2988928 [26] CUI Y, JIA M L, LIN T Y, et al. Class-balanced loss based on effective number of samples[C]//Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition. Piscataway: IEEE Press, 2019: 9260-9269. [27] WANG Y X, YAN J, YANG Z, et al. A domain adaptive deep transfer learning method for gas-insulated switchgear partial discharge diagnosis[J]. IEEE Transactions on Power Delivery, 2022, 37(4): 2514-2523. doi: 10.1109/TPWRD.2021.3111862 [28] LI R R, LI S M, XU K, et al. Deep domain adaptation with adversarial idea and coral alignment for transfer fault diagnosis of rolling bearing[J]. Measurement Science and Technology, 2021, 32(9): 094009. doi: 10.1088/1361-6501/abe163 [29] GHIFARY M, KLEIJN W B, ZHANG M J. Domain adaptive neural networks for object recognition[C]//Proceedings of the Pacific Rim International Conference on Artificial Intelligence. Berlin: Springer, 2014: 898-904. [30] LI X D, HU Y, ZHENG J H, et al. Central moment discrepancy based domain adaptation for intelligent bearing fault diagnosis[J]. Neurocomputing, 2021, 429: 12-24. doi: 10.1016/j.neucom.2020.11.063 -

下载:

下载: