-

摘要:

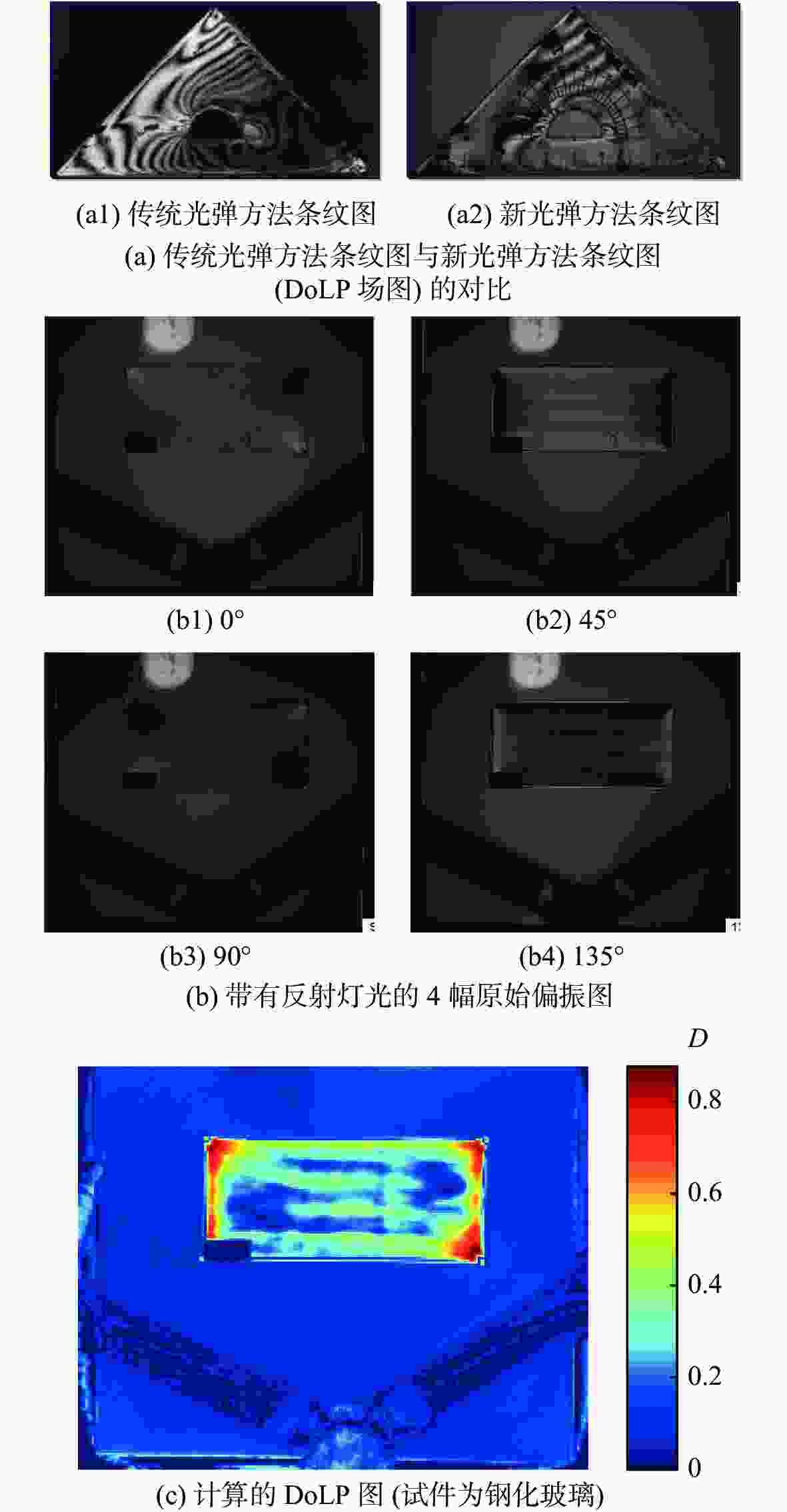

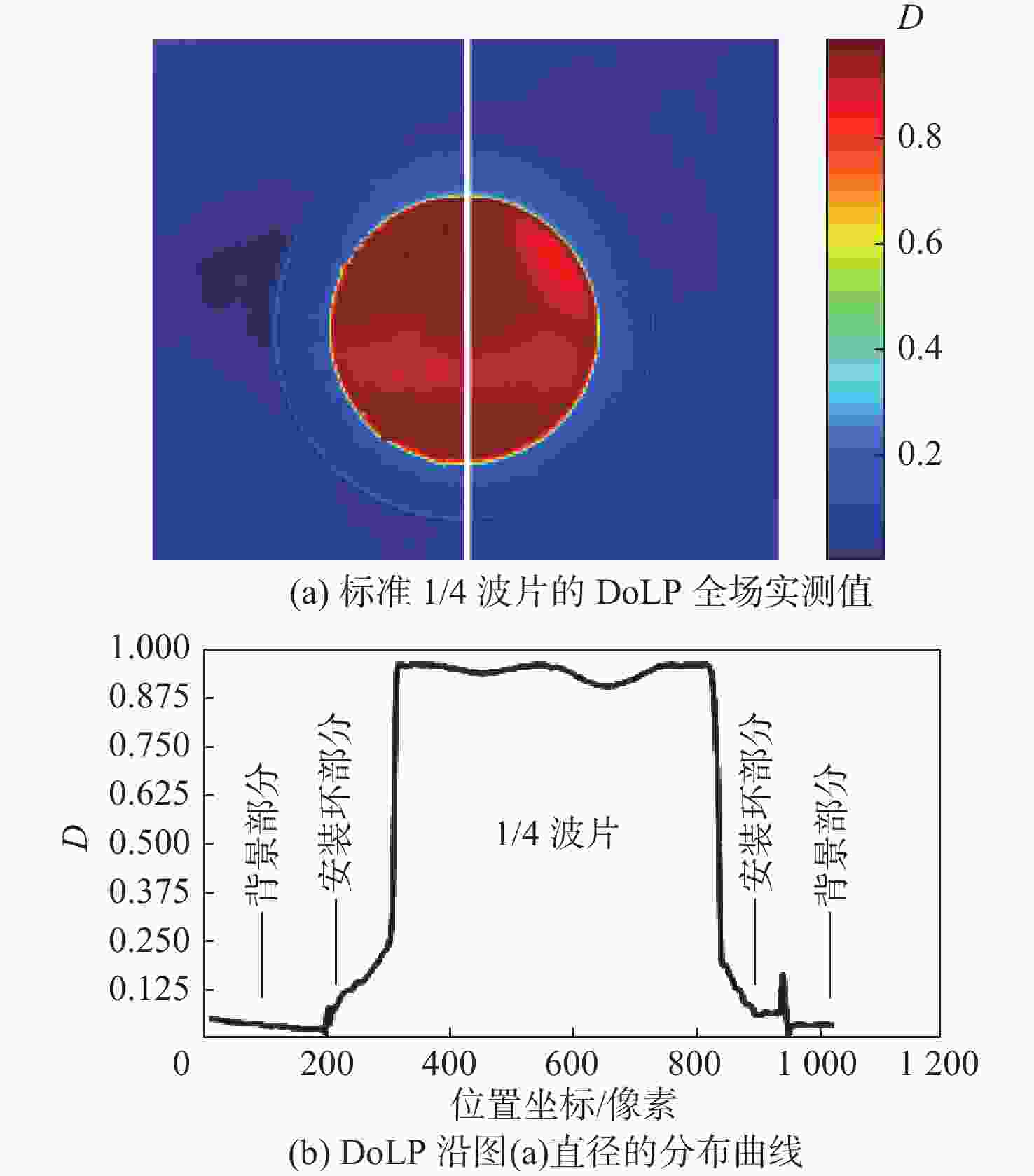

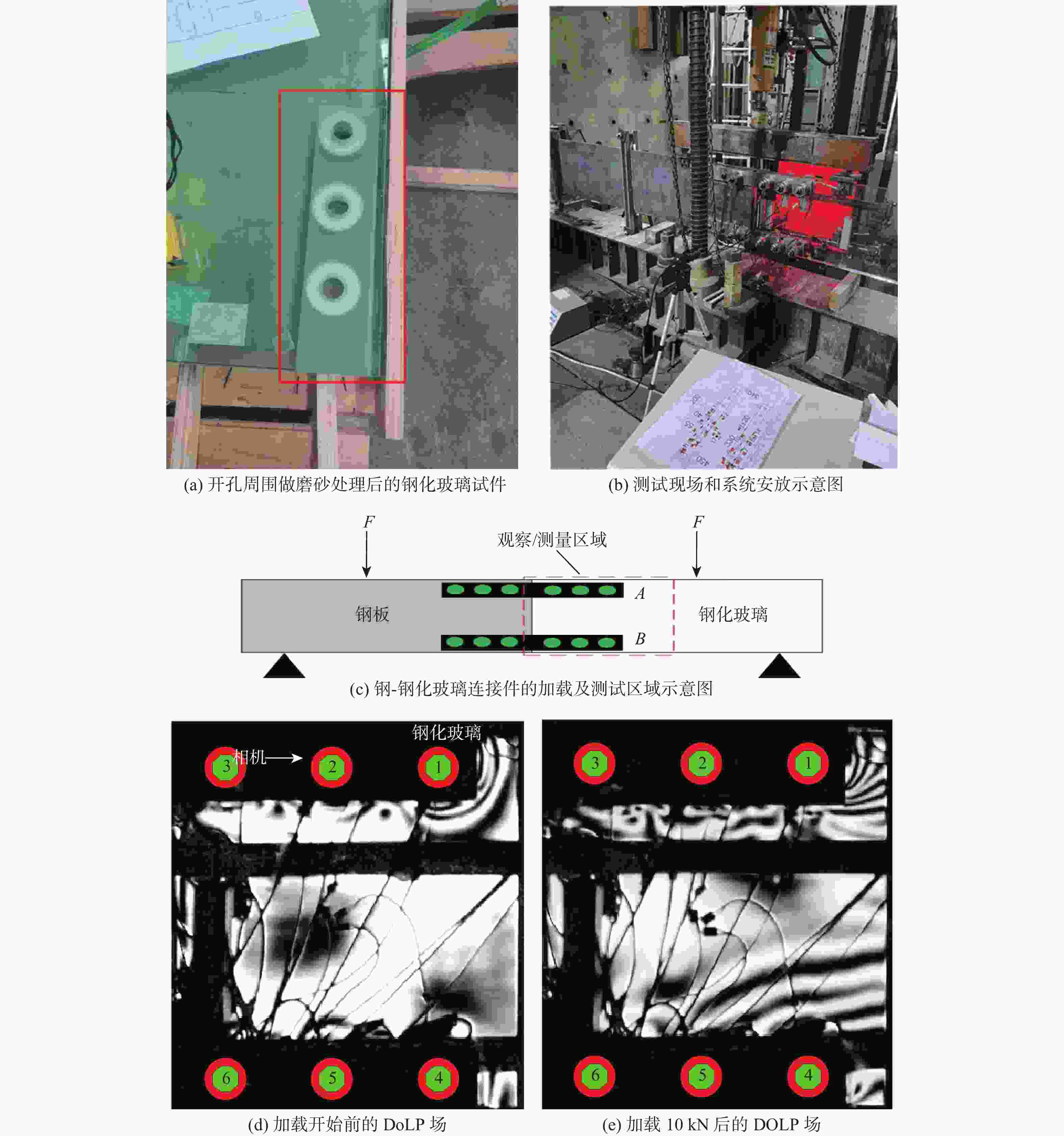

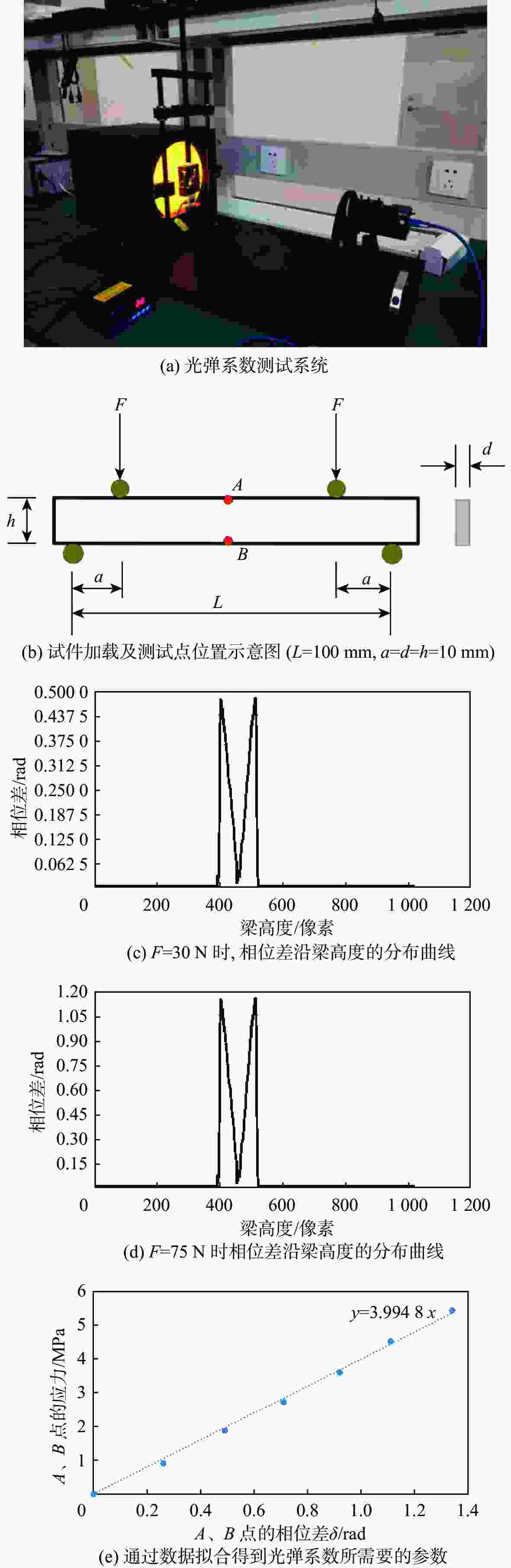

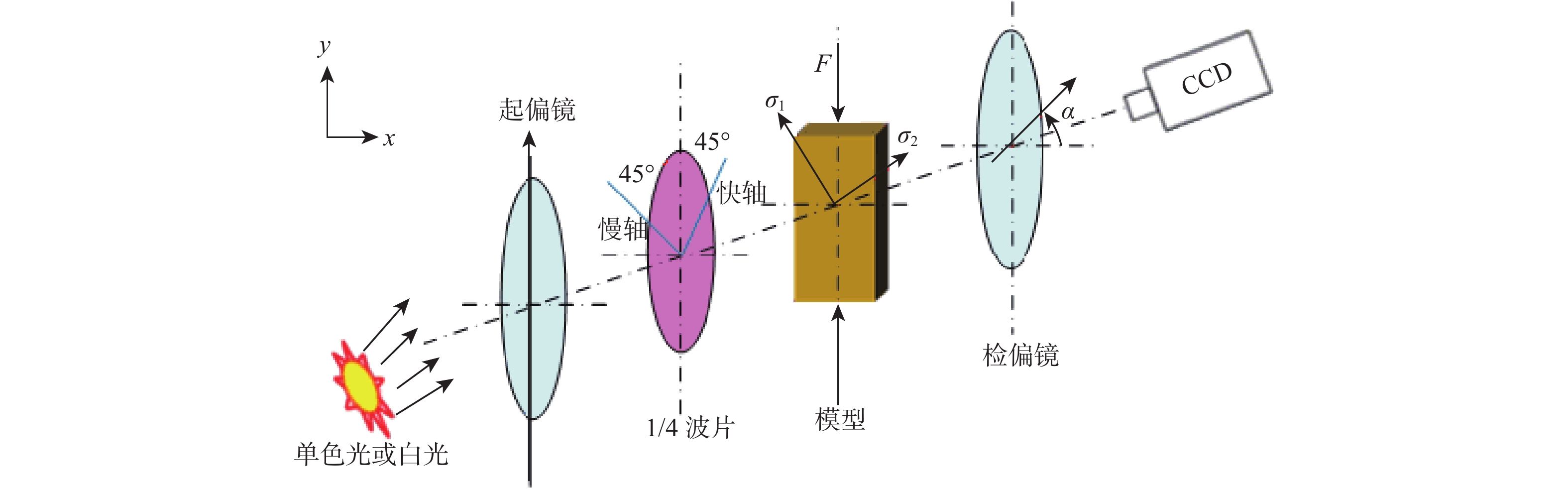

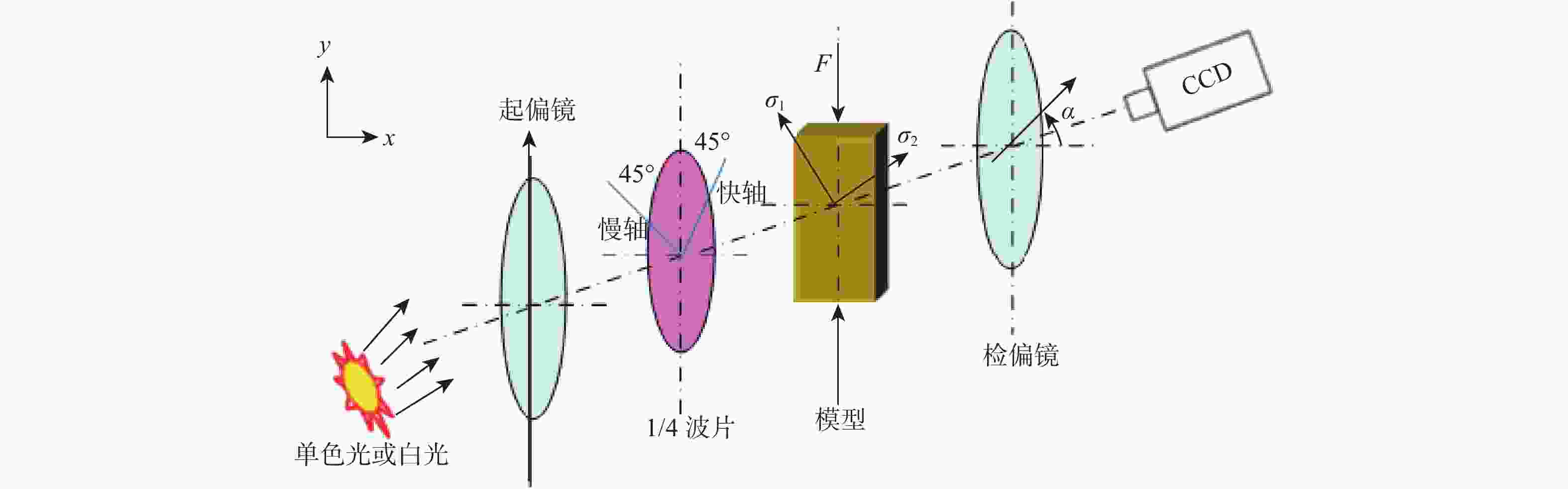

像素偏振相机与传统光弹方法相结合是近20年来发展起来的一种新型应力测试技术,其克服了传统光弹方法抗环境光干扰能力弱、定量测试操作复杂、很难实现实时测量等缺点。基于此,介绍了该方法的工作原理,并通过2个实例展示了该方法在适应复杂环境及高精度测试方面的巨大技术优势。给出了该新型光弹技术的若干前瞻性应用建议,包括玻璃幕墙安装应力的高效率检测及钢化玻璃内部缺陷的在线检测等。

Abstract:A new type of stress testing technology has been developed in the last 20 years by combining pixelated polarization cameras with traditional photoelastic methods. It overcomes the disadvantages of traditional photoelastic methods such as weak ability to resist environmental light interference, complex quantitative measurement operation, and difficulty in realizing real-time measurement. This paper introduced the working principle of this method and showed its great technical advantages in adapting to complex environments and high-precision testing through two examples. Some forward-looking application suggestions of the new photoelastic technology were given, including the efficient detection of the installation stress of the glass curtain wall and the online detection of the internal defects of the tempered glass.

-

Key words:

- photoelasticity /

- glass /

- stress /

- pixelated polarization camera /

- real-time detection

-

-

[1] 雷振坤. 结构分析数字光测力学[M]. 大连: 大连理工大学出版社, 2012.LEI Z K. Digital photomechanics for structural analysis[M]. Dalian: Dalian University of Technology Press, 2012(in Chinese). [2] ASUNDI A, TONG L, BOAY C G. Dynamic phase-shifting photoelasticity[J]. Applied Optics, 2001, 40(22): 3654-3658. doi: 10.1364/AO.40.003654 [3] KRAMER S L B, BEIERMANN B A, WHITE S R, et al. Simultaneous observation of phase-stepped images for photoelasticity using diffraction gratings[J]. Experimental Mechanics, 2013, 53(8): 1343-1355. doi: 10.1007/s11340-013-9747-0 [4] NORDIN G P, MEIER J T, DEGUZMAN P C, et al. Micropolarizer array for infrared imaging polarimetry[J]. Journal of the Optical Society of America A, 1999, 16(5): 1168-1174. doi: 10.1364/JOSAA.16.001168 [5] 马宣. 高性能像素偏振相机的研制与相关应用研究[D]. 合肥: 中国科学技术大学, 2019.MA X. Development of high-performance pixelated-polarization-camera and related application research[D]. Hefei: University of Science and Technology of China, 2019(in Chinese). [6] ZHANG Z G, DONG F L, CHENG T, et al. Nano-fabricated pixelated micropolarizer array for visible imaging polarimetry[J]. The Review of Scientific Instruments, 2014, 85(10): 105002. doi: 10.1063/1.4897270 [7] ARANCHUK V, LAL A K, HESS C F, et al. Pulsed spatial phase-shifting digital shearography based on a micropolarizer camera[J]. Optical Engineering, 2018, 57: 024109. [8] ONUMA T, OTANI Y. A development of two-dimensional birefringence distribution measurement system with a sampling rate of 1.3 MHz[J]. Optics Communications, 2014, 315: 69-73. doi: 10.1016/j.optcom.2013.10.086 [9] KUNNEN B, MACDONALD C, DORONIN A, et al. Application of circularly polarized light for non-invasive diagnosis of cancerous tissues and turbid tissue-like scattering media[J]. Journal of Biophotonics, 2015, 8(4): 317-323. doi: 10.1002/jbio.201400104 [10] ZHANG Z G, DONGF L, QIAN K M, et al. Real-time phase measurement of optical vortices based on pixelated micropolarizer array[J]. Optics Express, 2015, 23(16): 20521-20528. doi: 10.1364/OE.23.020521 [11] SAKAUE K, YONEYAMA S, KIKUTA H, et al. Evaluating crack tip stress field in a thin glass plate under thermal load[J]. Engineering Fracture Mechanics, 2008, 75(5): 1015-1026. doi: 10.1016/j.engfracmech.2007.04.025 [12] YONEYAMA S, KAMIHORIUCHI H. A method for evaluating full-field stress components from a single image in interferometric photoelasticity[J]. Measurement Science and Technology, 2009, 20(7): 075302. doi: 10.1088/0957-0233/20/7/075302 [13] 尚奇. 光学玻璃在大功率连续激光辐照下的应力研究[D]. 南京: 南京理工大学, 2020.SHANG Q. Study on stress of optical glass under high power continuous laser irradiation[D]. Nanjing: Nanjing University of Science and Technology, 2020(in Chinese). [14] GOLDSTEIN D H. Polarizedlight[M]. New York: CRC Press, 2016. [15] 杨洁, 金伟其, 裘溯, 等. 考虑偏振片非理想性的可见光偏振成像修正模型[J]. 光学精密工程, 2020, 28(2): 334-339.YANG J, JIN W Q, QIU S, et al. Correction model for visible light polarization imaging considering non-ideality of polarizers[J]. Optics and Precision Engineering, 2020, 28(2): 334-339(in Chinese). [16] SU F, WANG Z J. Error analysis and correction of a photoelastic method based on a pixelated polarization camera[J]. Optics and Lasers in Engineering, 2023, 161: 107374. doi: 10.1016/j.optlaseng.2022.107374 -

下载:

下载: