Research progress in mechanically fastened polymer-matrix composite joints with protruding-head bolts

-

摘要:

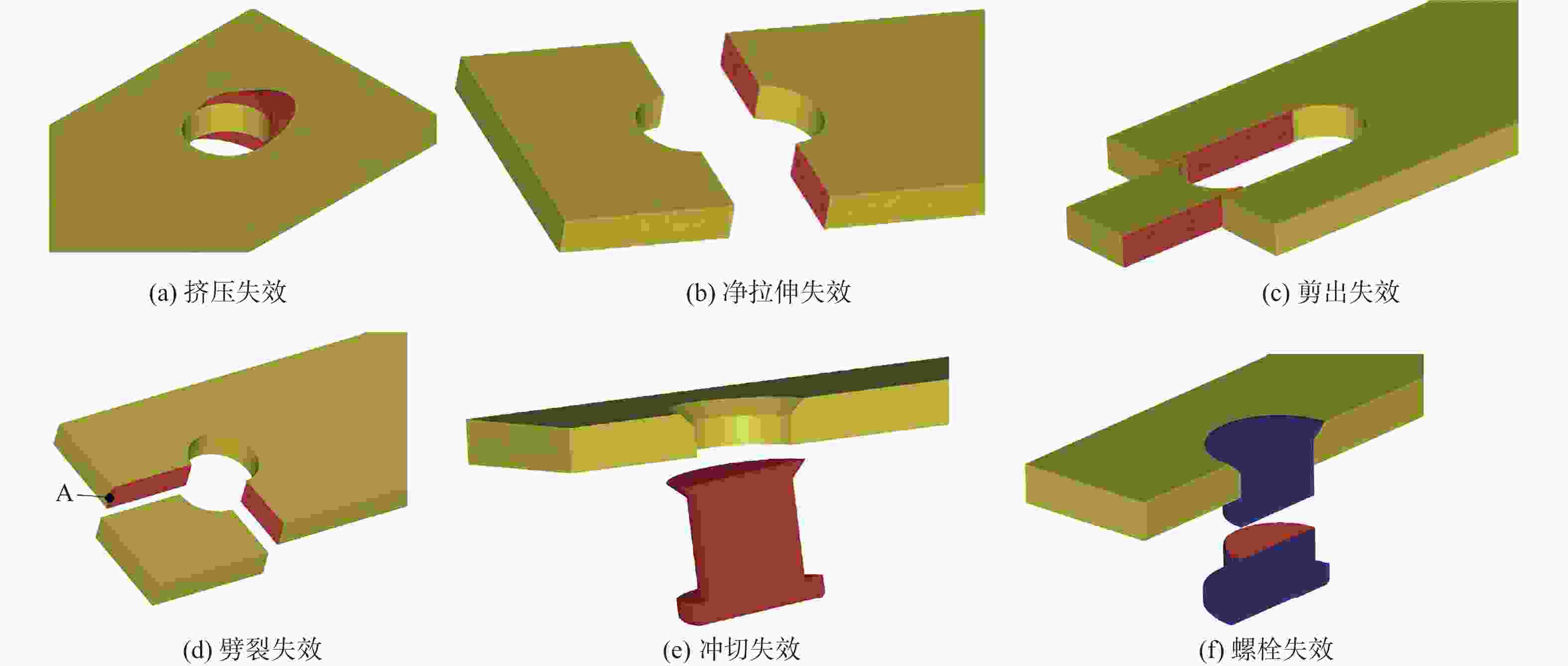

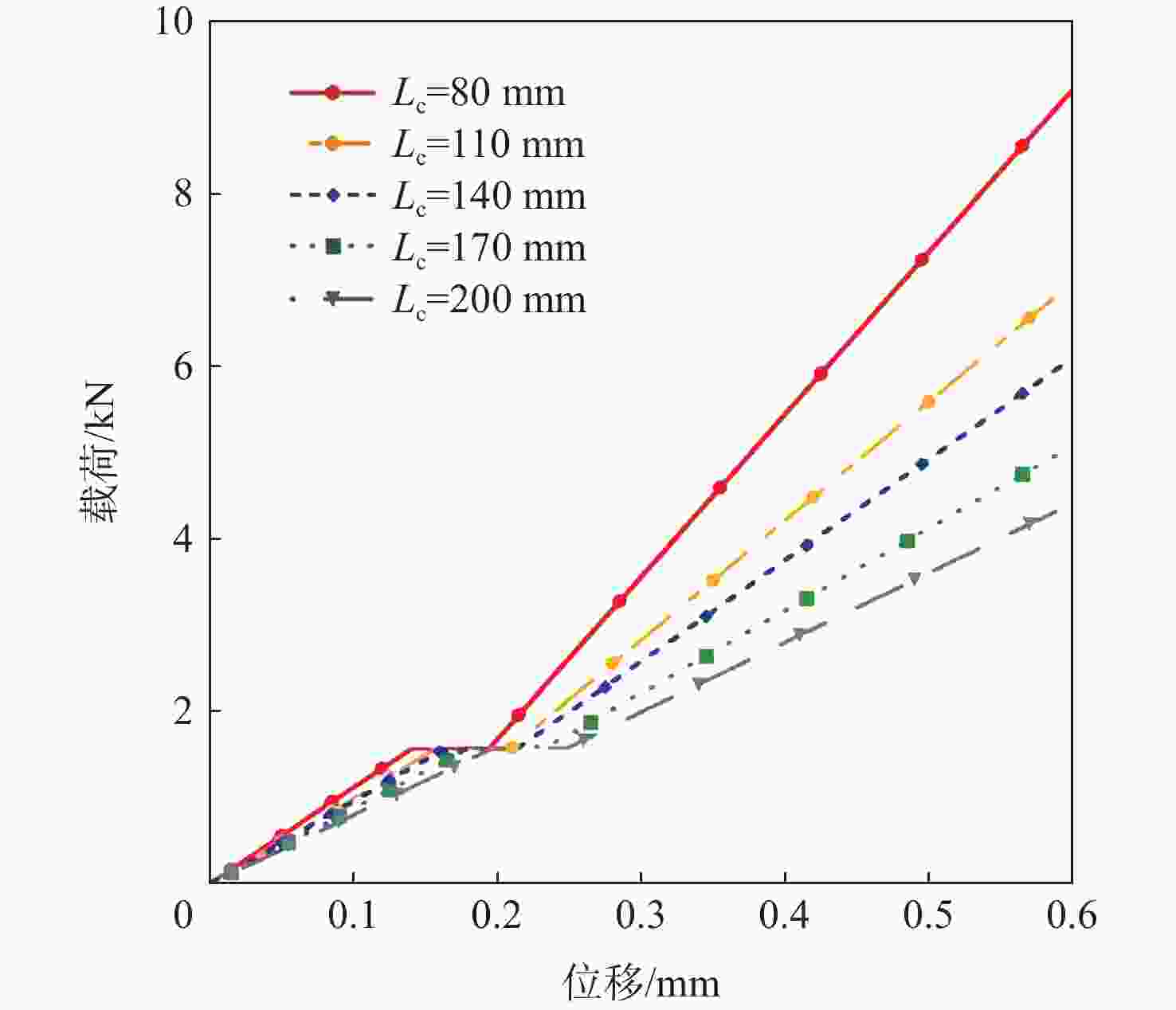

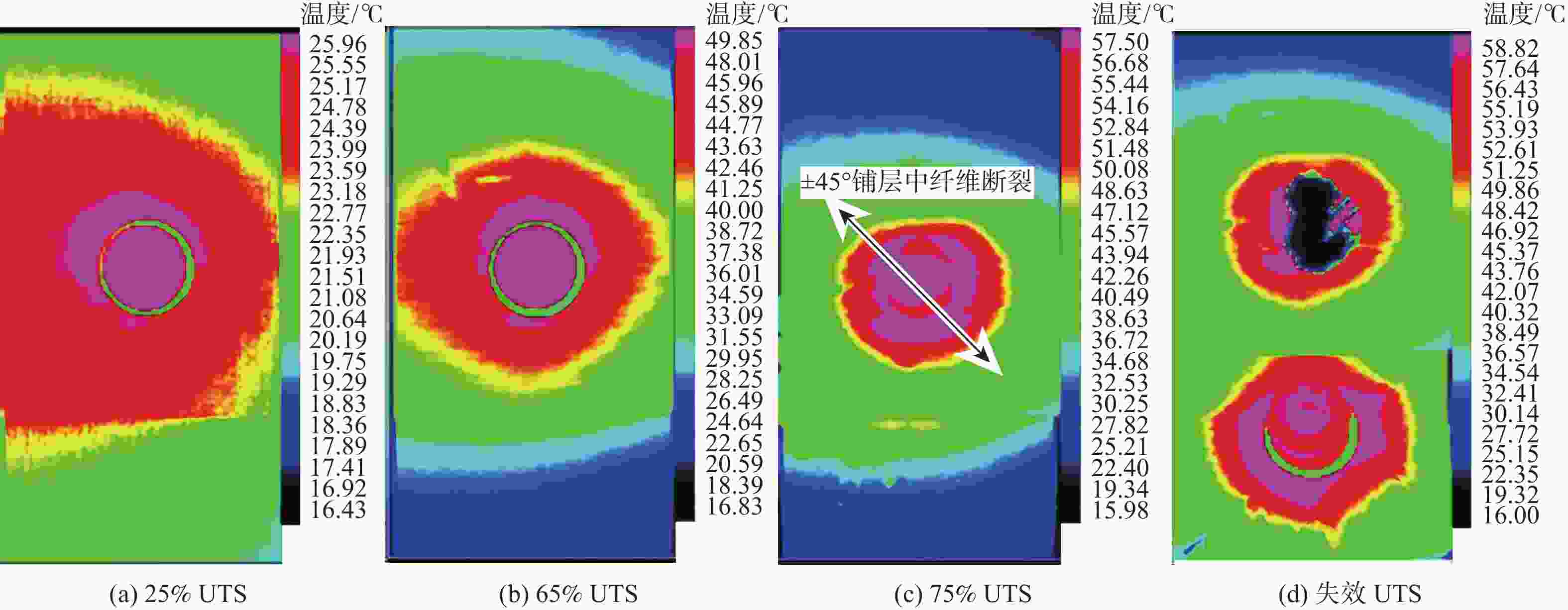

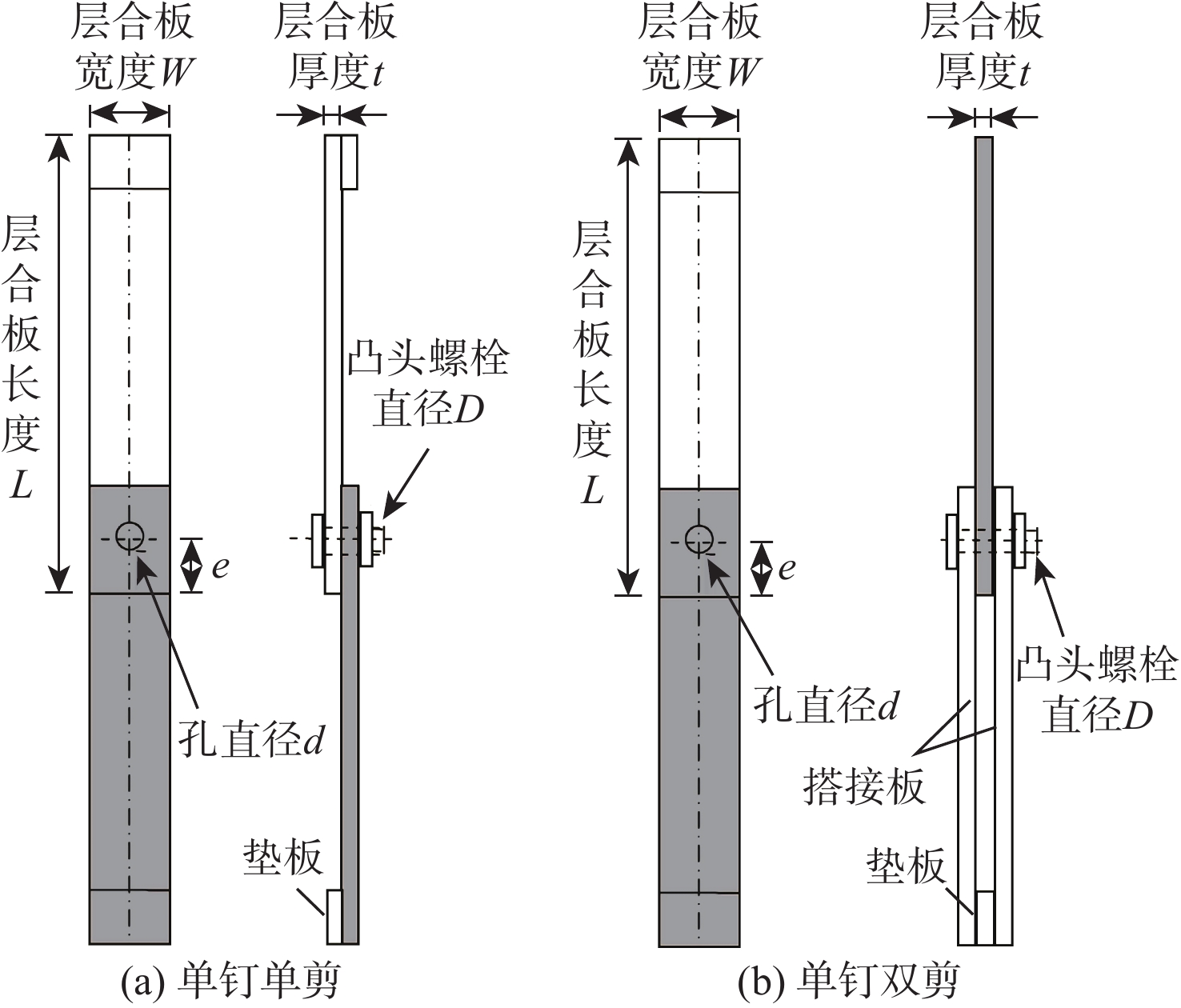

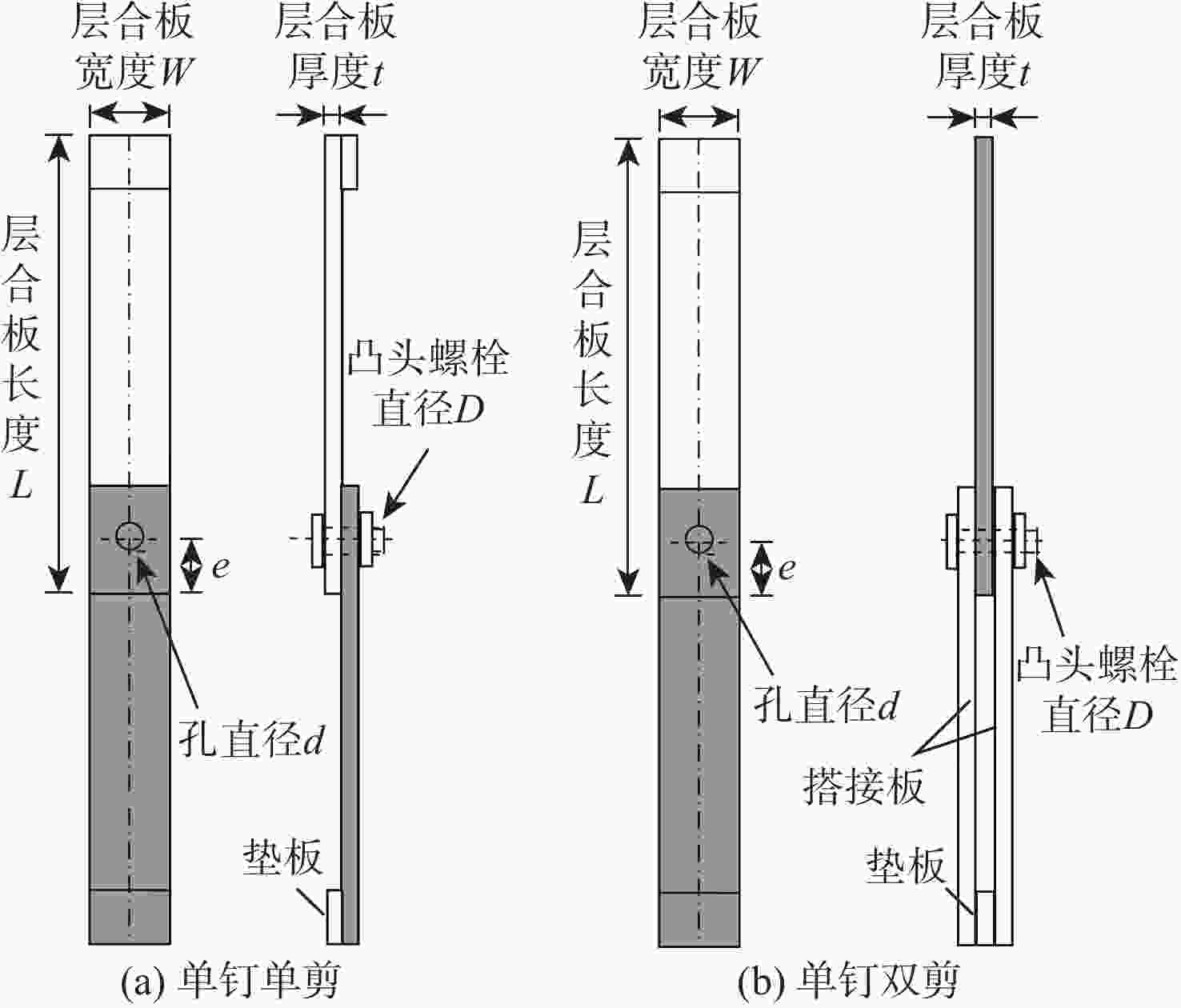

机械连接是聚合物基复合材料最典型的连接方式,因其在连接工艺性和可靠性方面的优势,使其在航空航天制造领域得到了广泛应用。对凸头螺栓连接聚合物基复合材料接头的研究进展进行综述。回顾了复合材料接头的机械连接形式,讨论了在拉伸加载下的失效过程,详细论述了复合材料接头的损伤模式;重点讨论了复合材料接头力学性能影响因素的研究进展,包括复合材料性能(纤维类型、增强体结构形式、纤维与金属混杂层板、铺层角度及比例、固化工艺、初始材料缺陷)、紧固件性能(紧固件刚度、钉头型式、螺栓直径、螺纹密封、间隙配合、干涉配合、紧固件缺失)、连接板性能、侧向约束(拧紧力矩、预紧面积、补偿垫片、接触面摩擦因素)、几何效应(复合材料板尺寸、板厚与孔直径比、层合板宽度与孔直径比、孔端距与孔直径比、螺孔形状、螺孔质量、螺孔位置误差)、载荷(静载荷、动态载荷、疲劳载荷、蠕变、松弛、温湿载荷)等;对聚合物基复合材料凸头螺栓连接的未来研究方向进行了展望。

Abstract:The present article attempts a more comprehensive review of recent literature in the broader area of mechanically fastened polymer-matrix composite joints with protruding-head bolts. The article begins with a review of the mechanical configurations of composite joints. A study of the mechanical configurations of composite joints opens the topic. This is followed by a discussion of the failure progression of composite joints in tensile loading. The remaining sections are devoted to the influence of composite properties (fiber type, reinforcement structure, fiber and metal mixed laminates, ply angle and proportion, curing process, initial material defects), fastener performance (fastener stiffness, bolt head type, bolt diameter, thread seal, gap fit, interference fit, fastener missing), connection plate performance, lateral constraints (tightening moment,bearing area, compensation gasket, contact surface friction factors), geometric effects (composite plate size, plate thickness to hole diameter ratio, specimen width to hole diameter ratio, hole end distance to hole diameter ratio, hole shape, hole quality, hole position error) as well as loads (static load, dynamic load, fatigue load, creep, relaxation, warm and wet load) on joint strength and failure. Finally, comments are offered regarding the most important remaining problems in this area, along with recommendations for future work.

-

Key words:

- polymer-matrix composites /

- mechanical properties /

- protruding-head bolts /

- joining /

- failure analysis

-

-

[1] 方海, 徐超, 孙慧明, 等. 复合材料拉挤方管型材螺栓节点承载力试验[J]. 复合材料学报, 2014, 31(3): 809-817.FANG H, XU C, SUN H M, et al. Experiment on bearing capacity of bolted joints for pultruded composite square profile[J]. Acta Materiae Compositae Sinica, 2014, 31(3): 809-817(in Chinese). [2] KELLY G, HALLSTRÖM S. Bearing strength of carbon fibre/epoxy laminates: Effects of bolt-hole clearance[J]. Composites Part B: Engineering, 2004, 35(4): 331-343. doi: 10.1016/j.compositesb.2003.11.001 [3] SAJID Z, KARUPPANAN S, SALLIH N, et al. Role of washer size in mitigating adverse effects of bolt-hole clearance in a single-lap, single-bolt basalt composite joint[J]. Composite Structures, 2021, 266: 113802. [4] RICCIO A. Effects of geometrical and material features on damage onset and propagation, in single-lap bolted composite joints under tensile load. Part I: Experimental studies[J]. Journal of Composite Materials, 2005, 39(23): 2071-2090. doi: 10.1177/0021998305052026 [5] 尹玉, 李小强, 李东升, 等. 复合材料层合板机械连接研究进展[J]. 航空制造技术, 2016, 59(11): 72-77.YIN Y, LI X Q, LI D S, et al. Research development on mechanical connection of composite laminate[J]. Aeronautical Manufacturing Technology, 2016, 59(11): 72-77(in Chinese). [6] 孙涛, 周金宇. 碳纤维复合材料螺栓连接性能综述[J]. 现代制造工程, 2018, 456(9): 160-166.SUN T, ZHOU J Y. Summary for the connection performance of carbon fiber composite bolt[J]. Modern Manufacturing Engineering, 2018, 456(9): 160-166(in Chinese). [7] SAJID Z, KARUPPANAN S, KEE K E, et al. Carbon/basalt hybrid composite bolted joint for improved bearing performance and cost efficiency[J]. Composite Structures, 2021, 275: 114427. [8] 谢鸣九. 复合材料连接技术[M]. 上海: 上海交通大学出版社, 2016.XIE M J. Joints for composites materials[M]. Shanghai: Shanghai Jiaotong University Press, 2016(in Chinese). [9] OLMEDO A, SANTIUSTE C, BARBERO E. An analytical model for the secondary bending prediction in single-lap composite bolted-joints[J]. Composite Structures, 2014, 111: 354-361. doi: 10.1016/j.compstruct.2014.01.015 [10] GAO Y, ZHANG D, LI F, et al. Bearing strength and failure behaviour of composite pre-tightened multi-tooth joint[J]. Composite Structures, 2021, 272: 114208. doi: 10.1016/j.compstruct.2021.114208 [11] CROXFORD A M, DAVIDSON P, WAAS A M. Influence of hole eccentricity on failure progression in a double shear bolted joint (DSBJ)[J]. Composites Science and Technology, 2018, 168: 179-187. [12] IRVING P E, SOUTIS C. Polymer composites in the aerospace industry[M]. Cambridge: Woodhead Publishing, 2015: 295-334. [13] PRABHAKARAN R, DEVARA S. Load and resistance factor design (LRFD) approach for bolted joints in pultruded composites[J]. Composites Part B:Engineering, 1996, 27(3-4): 351-360. doi: 10.1016/1359-8368(95)00021-6 [14] MCCARTHY M A, LAWLOR V P, STANLEY W F, et a1. Bolt hole clearance effects and strength criteria in single bolt single lap, composite joints[J]. Composites Science and Technology, 2002, 62(10-11): 1415-1431. doi: 10.1016/S0266-3538(02)00088-X [15] LIU W S, YU F, HE Z P, et a1. A progressive damage model introducing temperature field for bolted composite joint with preload[J]. Modelling and Simulation in Materials Science and Engineering, 2019, 27(6): 065011. doi: 10.1088/1361-651X/ab230f [16] OH J H, KIM Y G, LEE D G. Optimum bolted joints for hybrid composite materials[J]. Composite Structures, 1997, 38(1-4): 329-341. doi: 10.1016/S0263-8223(98)80014-7 [17] MOUNIEN R, FAGIANO C, PAULMIER P, et al. Experimental characterization of the bearing behavior of 3D woven composites[J]. Composites Part B:Engineering, 2017, 116: 369-376. doi: 10.1016/j.compositesb.2016.10.077 [18] SALEH M N, WANG Y, YUDHANTO A, et al. Investigating the potential of using off-axis 3D woven composites in composite joints’ applications[J]. Applied Composite Materials, 2016, 24(2): 377-396. [19] WARREN K C, LOPEZ-ANIDO R A, GOERING J. Behavior of three-dimensional woven carbon composites in single-bolt bearing[J]. Composite Structures, 2015, 127: 175-184. doi: 10.1016/j.compstruct.2015.03.022 [20] XU P, ZHOU Z, LIU T, et al. Propagation of damage in bolt jointed and hybrid jointed glare structures subjected to the quasi-static loading[J]. Composite Structures, 2019, 218: 79-94. doi: 10.1016/j.compstruct.2019.03.047 [21] KOLESNIKOV B, HERBECK L, FINK A. CFRP/titanium hybrid material for improving composite bolted joints[J]. Composite Structures, 2008, 83(4): 368-380. doi: 10.1016/j.compstruct.2007.05.010 [22] 刘长喜, 周振功, 王晓宏, 等. 结合改进单胞模型的单钉双剪层合板螺栓连接结构挤压性能的多尺度表征分析[J]. 复合材料学报, 2016, 33(3): 650-656.LIU C X, ZHOU Z G, WANG X H, et al. Multi-scale characterization analysis combined with improved cells model for bearing performance of double-shear single bolted joint laminate structures[J]. Acta Materiae Compositae Sinica, 2016, 33(3): 650-656(in Chinese). [23] LIM T S, KIM B C. Fatigue characteristics of the bolted joints for unidirectional composite laminates[J]. Composite Structures, 2006, 72(1): 58-68. doi: 10.1016/j.compstruct.2004.10.013 [24] 章继峰, 谢永刚, 曹子振. 铺层角度及螺栓-孔间隙对复合材料连接的影响[C]//第17届全国复合材料学术会议, 2012, 36: 290-305.ZHANG J F, XIE Y G, CAO Z Z. Effects of stacking sequence and clearance on the performance of joints in composite laminates[C]//17th National Conference on Composite Materials, 2012, 36: 290-305(in Chinese). [25] 王丹勇, 温卫东, 崔海涛. 复合材料单钉接头三维逐渐损伤破坏分析[J]. 复合材料学报, 2005, 22(3): 168-174.WANG D Y, WEN W D, CUI H T. Three-dimensional progressive damage analysis of single fastener joints in composite laminates[J]. Acta Materiae Compositae Sinica, 2005, 22(3): 168-174(in Chinese). [26] 何柏灵, 葛东云, 莫与明, 等. T800 碳纤维增强复合材料双剪单钉连接的拉伸试验及强度估算铺层顺序[J]. 复合材料学报, 2016, 33(7): 1540-1552.HE B L, GE D Y, MO Y M, et al. Tensile tests and strength estimation for double-lap single-bolt joints in T800 carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2016, 33(7): 1540-1552(in Chinese). [27] 孟毛毛, 王文智. 铺层比例对层合板连接结构损伤特性影响分析[J]. 航空工程进展, 2016, 7(3): 332-337.MENG M M, WANG W Z. Analysis of the lay proportion influence on the damage properties of connecting structure[J]. Advances in Aeronautical Science and Engineering, 2016, 7(3): 332-337(in Chinese). [28] 何旺. 复合材料层合板机械连接损伤机理分析及性能优化[D]. 大连: 大连理工大学, 2014.HE W. Damage mechanism analysis and performance optimization for mechanical joints in composite laminates[D]. Dalian: Dalian University of Technology, 2014(in Chinese). [29] 李跃宇. 含分层损伤复合材料连接件的挤压强度试验研究[J]. 机械工程材料, 2000, 24(4): 4-7.LI Y Y. Experimental study on bearing strength of composite joints with delamination[J]. Materials for Mechanical Engineering, 2000, 24(4): 4-7(in Chinese). [30] 宋恩鹏, 刘文, 谢鸣九, 等. 刚度比对复合材料多钉连接钉载分配影响研究[J]. 飞机设计, 2005(4): 29-32.SONG E P, LIU W, XIE M J, et al. Investigation of the influence of jointed member stiffness on fastener load distribution for composite multiple-bolted joint[J]. Aircraft Design, 2005(4): 29-32(in Chinese). [31] CACCESE V, BERUBE K A, FERNANDEZ M, et al. Influence of stress relaxation on clamp-up force in hybrid composite-to-metal bolted joints[J]. Composite Structures, 2009, 89(2): 285-293. doi: 10.1016/j.compstruct.2008.07.031 [32] 王富生, 岳珠峰, 张红运. 基于三维模型的复合材料层合板单钉螺栓连接件力学性能分析[J]. 航空制造技术, 2010(4): 814-818.WANG F S, YUE Z F, ZHANG H Y. Analysis on mechanical property of single-bolted composites laminate based on three-dimensional model[J]. Aeronautical Manufacturing Technology, 2010(4): 814-818(in Chinese). [33] SUN H T, CHANG F K, QING X. The response of composite joints with bolt-clamping loads. Part II: Model verification[J]. Journal of Composite Materials, 2002, 36(1): 69-92. doi: 10.1177/0021998302036001302 [34] 贾云超, 关志东, 宋晓君. 复合材料-金属机械连接性能研究[J]. 玻璃钢/复合材料, 2015(4): 66-71.JIA Y C, GUAN Z D, SONG X J. Study on performance of composite-metal mechanical joints[J]. Fiber Reinforced Plastics/Composites, 2015(4): 66-71(in Chinese). [35] IREMAN T. Three-dimensional stress analysis of bolted single-lap composite joints[J]. Composite Structures, 1998, 43(3): 195-216. doi: 10.1016/S0263-8223(98)00103-2 [36] RICCIO A. Effects of geometrical and material features on damage onset and propagation in single-lap bolted composite joints under tensile load. Part II: Numerical studies[J]. Journal of Composite Materials, 2005, 39(23): 2091-2112. doi: 10.1177/0021998305052027 [37] QIN T L, ZHAO L B, ZHANG J Y. Fastener effects on mechanical behaviors of double-lap composite joints[J]. Composite Structures, 2013, 100: 413-423. doi: 10.1016/j.compstruct.2013.01.008 [38] THOPPUL S D, GIBSON R F, IBRAHIM R A. Phenomenological modeling and numerical simulation of relaxation in bolted composite joints[J]. Journal of Composite Materials, 2008, 42(17): 1709-1729. doi: 10.1177/0021998308092544 [39] 姜云鹏, 岳珠峰. 复合材料层合板螺栓连接失效的数值模拟[J]. 复合材料学报, 2005, 22(4): 177-182. doi: 10.3321/j.issn:1000-3851.2005.04.030JIANG Y P, YUE Z F. Numerical failure simulation of bolt-loaded composite laminate[J]. Acta Materiae Compositae Sinica, 2005, 22(4): 177-182(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.04.030 [40] LAWLOR V P, MCCARTHY M A, STANLEY W F. Experimental study on effects of clearance on single bolt, single shear, composite bolted joints[J]. Plastics, Rubber and Composites, 2002, 31(9): 405-411. doi: 10.1179/146580102225006521 [41] CHEN C, HU D, LIU Q, et al. Evaluation on the interval values of tolerance fit for the composite bolted joint[J]. Composite Structures, 2018, 206: 628-636. doi: 10.1016/j.compstruct.2018.08.062 [42] 魏景超, 贾普荣, 矫桂琼. 干涉对复合材料层合板连接系统的极限挤压强度影响[J]. 材料开发与应用, 2011, 26(3): 66-77. doi: 10.3969/j.issn.1003-1545.2011.03.018WEI J C, JIA P R, JIAO G Q. An experimental study on ultimate bearing strength of composite bolt joint with interference-fit[J]. Development and Application of Materials, 2011, 26(3): 66-77(in Chinese). doi: 10.3969/j.issn.1003-1545.2011.03.018 [43] 武涛. 复合材料多钉干涉连接应力分布及损伤萌生研究[D]. 西安: 西北工业大学, 2017.WU T. Stress distribution and damage initiation analysis of composite multi-pin joints with interference fit[D]. Xi’an: Northwestern Polytechnical University, 2017(in Chinese). [44] ZHUANG F, CHEN P. Effects of missing fasteners on the mechanical behavior of double-lap, multi-row composite bolted joints[J]. Journal of Composite Materials, 2018, 52(28): 3919-3933. doi: 10.1177/0021998318771464 [45] OLMEDO A, SANTIUSTE C. On the prediction of bolted single-lap composite joints[J]. Composite Structures, 2012, 94(6): 2110-2117. doi: 10.1016/j.compstruct.2012.01.016 [46] MURAT P. The effect of preload on failure response of glass-epoxy laminated composite bolted-joints with clearance[J]. Journal of Reinforced Plastics and Composites, 2007, 26(12): 1239-1251. doi: 10.1177/0731684407079769 [47] 王佳宁, 赵美英, 周银华. 预紧力对层合板螺栓连接强度的影响研究[J]. 航空工程进展, 2012, 3(2): 189-194.WANG J N, ZHAO M Y, ZHOU Y H. Research on influence of pre-tightening force to laminate bolt joint strength[J]. Advances in Aeronautical Science and Engineering, 2012, 3(2): 189-194(in Chinese). [48] 黄志超, 卢能芝, 吕世亮, 等. 复合材料与铝板螺栓连接强度试验研究[J]. 锻压技术, 2014, 39(12): 115-119. doi: 10.13330/j.issn.1000-3940.2014.12.025HUANG Z C, LU N Z, LV S L, et al. Experimental study on bolts connection strength between composite and aluminum sheets[J]. Forging & Stamping Technology, 2014, 39(12): 115-119(in Chinese). doi: 10.13330/j.issn.1000-3940.2014.12.025 [49] 王景泽. 复合材料机械连接湿热效应及预紧力衰减规律研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.WANG J Z. The research of hygrothermal effects and clamp force degradation for the composite bolted joints[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [50] TONG L. Bearing failure of composite bolted joints with non-uniform bolt-to-washer clearance[J]. Composites Part A:Applied Science and Manufacturing, 2000, 31(6): 609-615. doi: 10.1016/S1359-835X(99)00090-1 [51] DHOE J X, COMER A J, STANLEY W F, et al. Study of the effect of liquid shim on single-lap joint using 3D digital image correlation[J]. Composite Structures, 2013, 96: 216-225. doi: 10.1016/j.compstruct.2012.08.058 [52] LIU L, ZHANG J, CHEN K, et al. Experimental and numerical analysis of the mechanical behavior of composite-to-titanium bolted joints with liquid shim[J]. Aerospace Science and Technology, 2016, 100(49): 167-172. [53] ESENDEMIR Ü. An experimental study of mechanically fastened composite joints with clearance[J]. International Journal of Damage Mechanics, 2011, 20(3): 464-480. doi: 10.1177/1056789510397068 [54] ZHOU S, WANG Z, ZHOU J, et al. Experimental and numerical investigation on bolted composite joint made by vacuum assisted resin injection[J]. Composites Part B:Engineering, 2013, 45(1): 1620-1628. doi: 10.1016/j.compositesb.2012.08.025 [55] KRETSIS G, MATTHEWS F L. The strength of bolted joints in glass fibre/epoxy laminates[J]. Composites, 1985, 16(2): 92-102. doi: 10.1016/0010-4361(85)90615-9 [56] SEN F, PAKDIL M, SAYMAN O, et al. Experimental failure analysis of glass-epoxy laminated composite bolted-joints with clearance under preload[J]. International Journal of Damage Mechanics, 2011, 20(2): 163-178. doi: 10.1177/1056789509344039 [57] 周松. 复合材料螺栓连接渐进损伤的实验及数值分析[D]. 哈尔滨: 哈尔滨工程大学, 2013.ZHOU S. Experimental and numericial investigation on progressive failure response of composite bolted joint[D]. Harbin: Harbin Engineering University, 2013(in Chinese). [58] 刘博凯. 复合材料连接结构失效强度及影响因素研究[D]. 哈尔滨: 哈尔滨工程大学, 2017.LIU B K. Study on the failure strength and influencing factors of composite connecting structure[D]. Harbin: Harbin Engineering University, 2017(in Chinese). [59] 王富生, 刘洋, 岳珠峰. 复合材料层合板连接件力学性能影响因素分析[J]. 材料科学与工程学报, 2010, 28(1): 58-61. doi: 10.14136/j.cnki.issn1673-2812.2010.01.008WANG F S, LIU Y, YUE Z F. Analysis of the influence factors on the mechanical properties of single-bolted composite laminates[J]. Journal of Materials Science and Engineering, 2010, 28(1): 58-61(in Chinese). doi: 10.14136/j.cnki.issn1673-2812.2010.01.008 [60] SALEEM M, ZITOUNE R, SAWI I E, et al. Role of the surface quality on the mechanical behavior of CFRP bolted composite joints[J]. International Journal of Fatigue, 2015, 80: 246-256. [61] LECOMTE J, BOIS C, WARGNIER H, et al. An analytical model for the prediction of load distribution in multi-bolt composite joints including hole-location errors[J]. Composite Structures, 2014, 117: 354-361. [62] 李想. 复合材料多钉连接强度预测方法及其关键技术[D]. 西安: 西北工业大学, 2017.LI X. Strength prediction method of multi-bolt composite joint and its key technologies[D]. Xi’an: Northwestern Polytechnical University, 2017(in Chinese). [63] LUO C, YANG B, XUAN F Z, et al. Experimental investigation of double-lap bolted composite joints with different outer plates subjected to bending loads[J]. Polymers & Polymer Composites, 2018, 26(7): 408-419. [64] ZHOU S, SUN Y, GE J, et al. Multiaxial fatigue life prediction of composite bolted joint under constant amplitude cycle loading[J]. Composites Part B: Engineering, 2015, 74: 131-137. doi: 10.1016/j.compositesb.2015.01.013 [65] KAPIDŽIĆ Z, ANSELL H, SCHÖN J, et al. Quasi-static bearing failure of CFRP composite in biaxially loaded bolted joints[J]. Composite Structures, 2015, 125: 60-71. doi: 10.1016/j.compstruct.2015.01.038 [66] WEI J, JIAO G, JIA P, et al. The effect of interference fit size on the fatigue life of bolted joints in composite laminates[J]. Composites, 2013, 53: 62-68. doi: 10.1016/j.compositesb.2013.04.048 [67] SCHON J. Spectrum fatigue loading of composite bolted joints-small cycle elimination[J]. International Journal of Fatigue, 2006, 28(1): 73-78. doi: 10.1016/j.ijfatigue.2005.01.016 [68] AHMAD H, JOHNSON W S, COUNTS W A. Evaluation of bolt bearing behavior of highly loaded composite joints at elevated temperature[J]. Journal of Composite Materials, 2003, 37(6): 559-571. doi: 10.1177/0021998303037006679 [69] NAZARI F, SAFARABADI M. Experimental and numerical investigation of loading speed effect on the bearing strength of glass/epoxy composite joints[J]. Composite Structures, 2018, 195: 211-218. doi: 10.1016/j.compstruct.2018.04.064 [70] 潘文革, 矫桂琼, 杨杰. 二维机织复合材料湿热环境下挤压和断纹剪切强度研究[J]. 机械强度, 2007, 29(5): 848-851. doi: 10.16579/j.issn.1001.9669.2007.05.034PAN W G, JIAO G Q, YANG J. Experimental studies of bearing strength and punch-type strength of woven-fiber iaminate composites in hygrothermal environment[J]. Journal of Mechanical Strength, 2007, 29(5): 848-851(in Chinese). doi: 10.16579/j.issn.1001.9669.2007.05.034 [71] 程小全, 杨琨, 范舟. 国产炭纤维复合材料层合板高温单钉连接性能试验[J]. 高分子材料科学与工程, 2011, 27(7): 118-121.CHENG X Q, YANG K, FAN Z. Experiment on tensile properties of domestic carbon fiber reinforced composite laminates with single bolt joint under high temperature[J]. Polymer Materials Science & Engineering, 2011, 27(7): 118-121(in Chinese). [72] SOYKOK I F, SAYMAN O, OZEN M. Low temperature and tightening torque effects on the failure response of bolted glass fiber/epoxy composite joints[J]. Journal of Composite Materials, 2013, 47(26): 3257-3268. doi: 10.1177/0021998312463828 -

下载:

下载: