Design of rectangular cross-section spring anti-reverse device for a certain type of aviation

-

摘要:

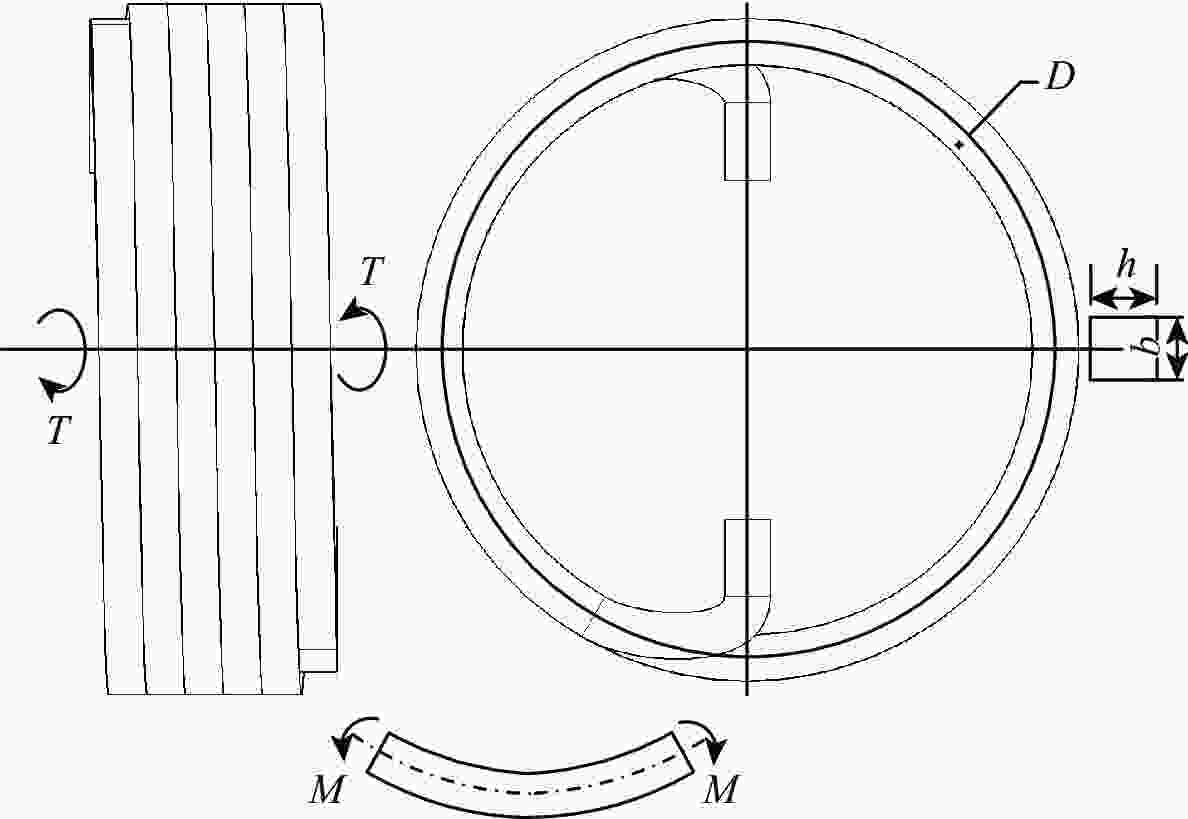

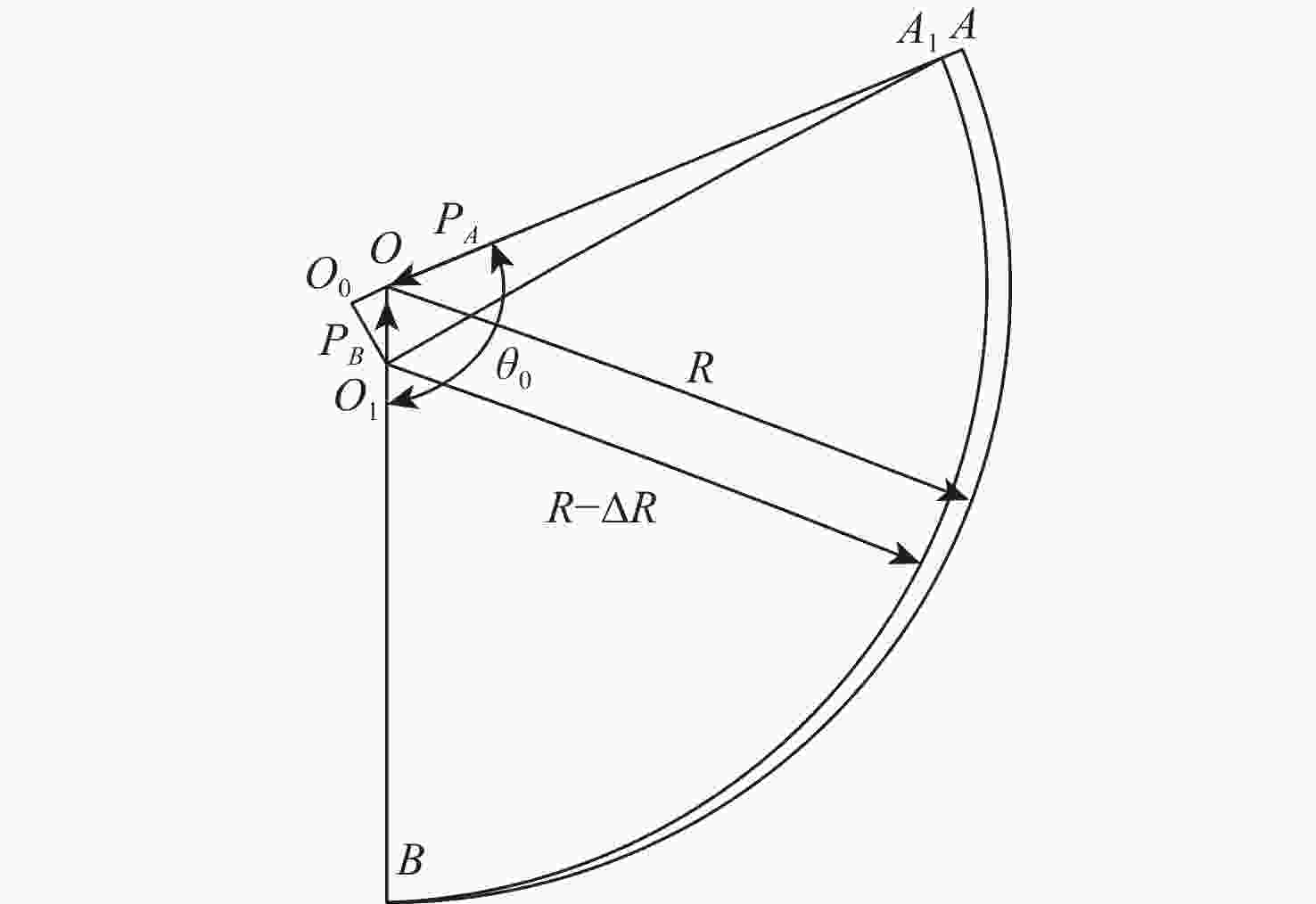

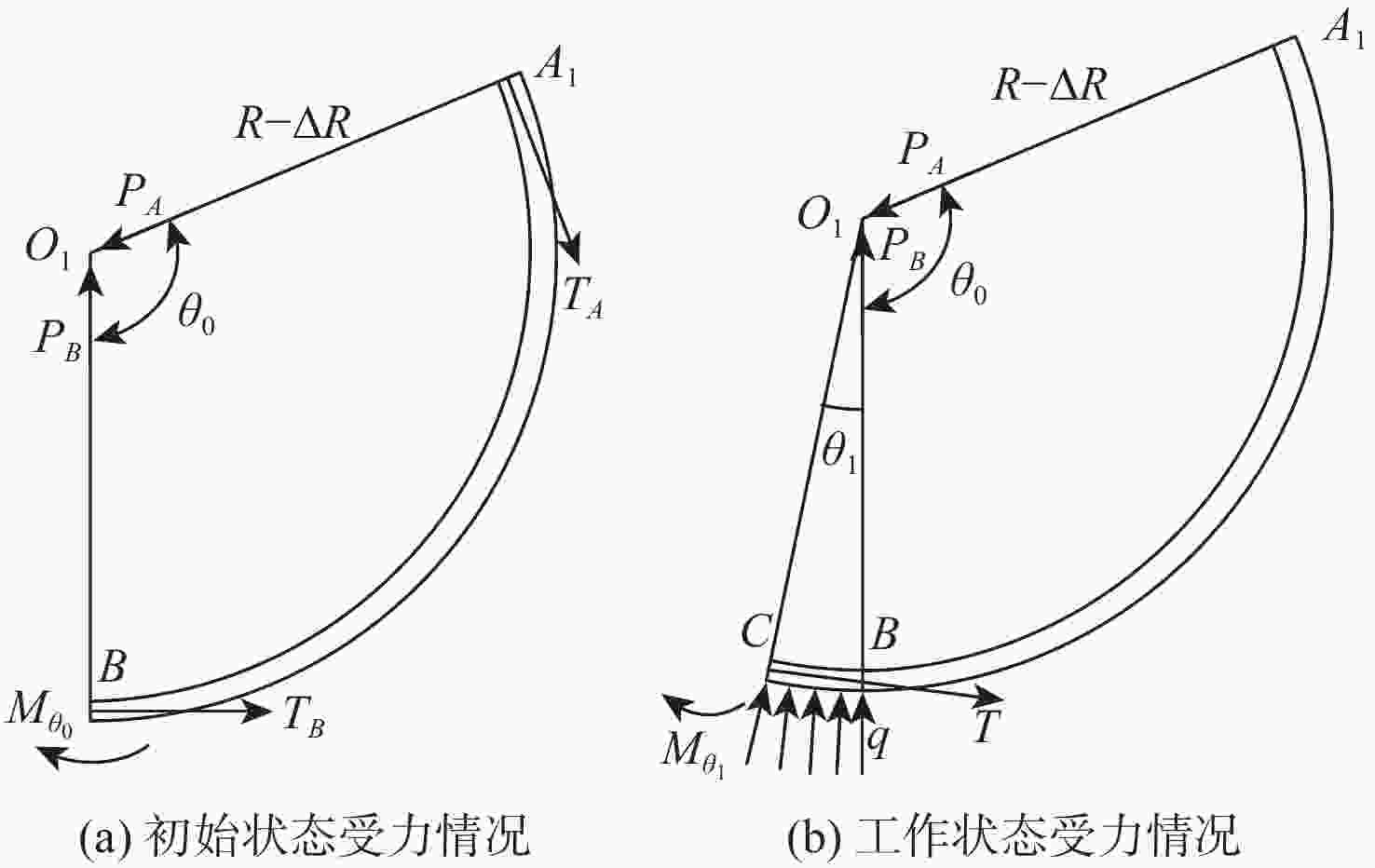

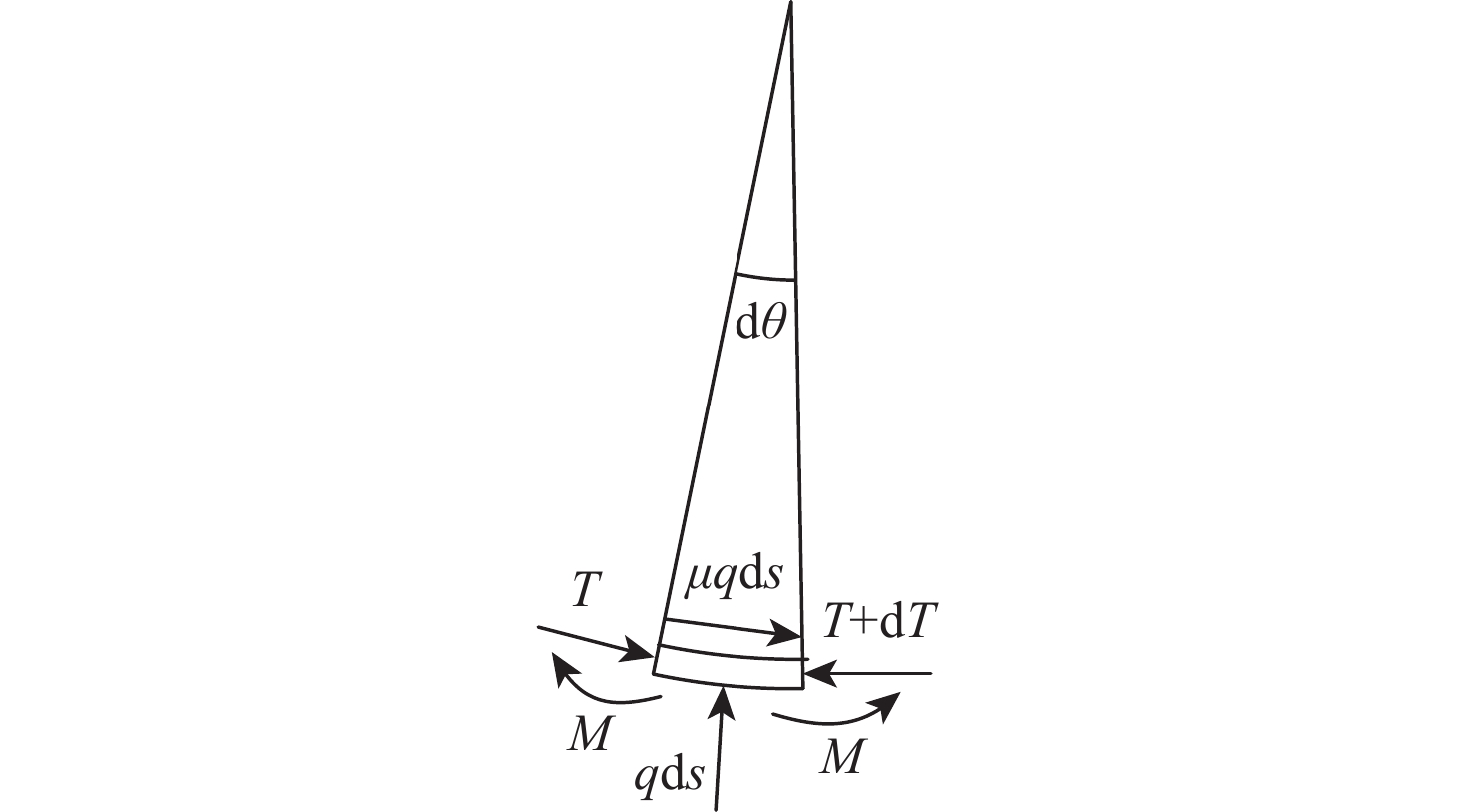

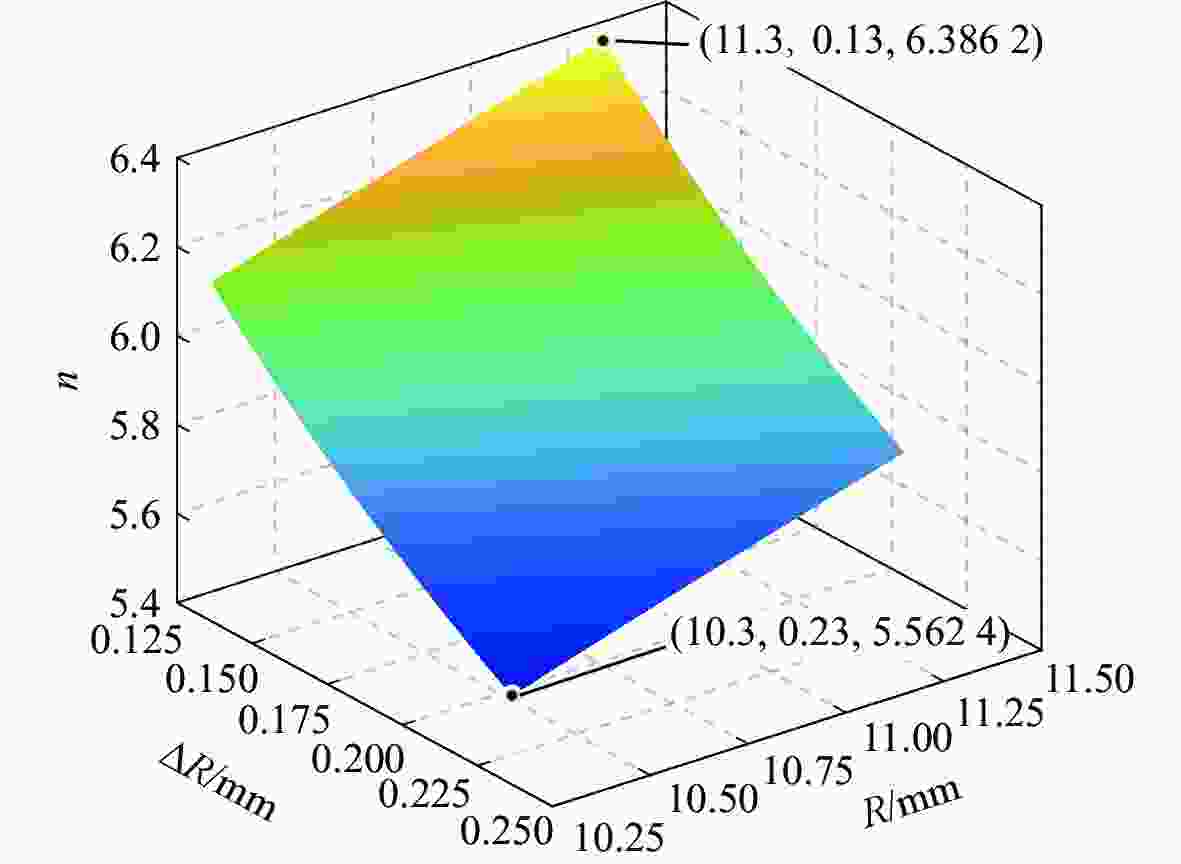

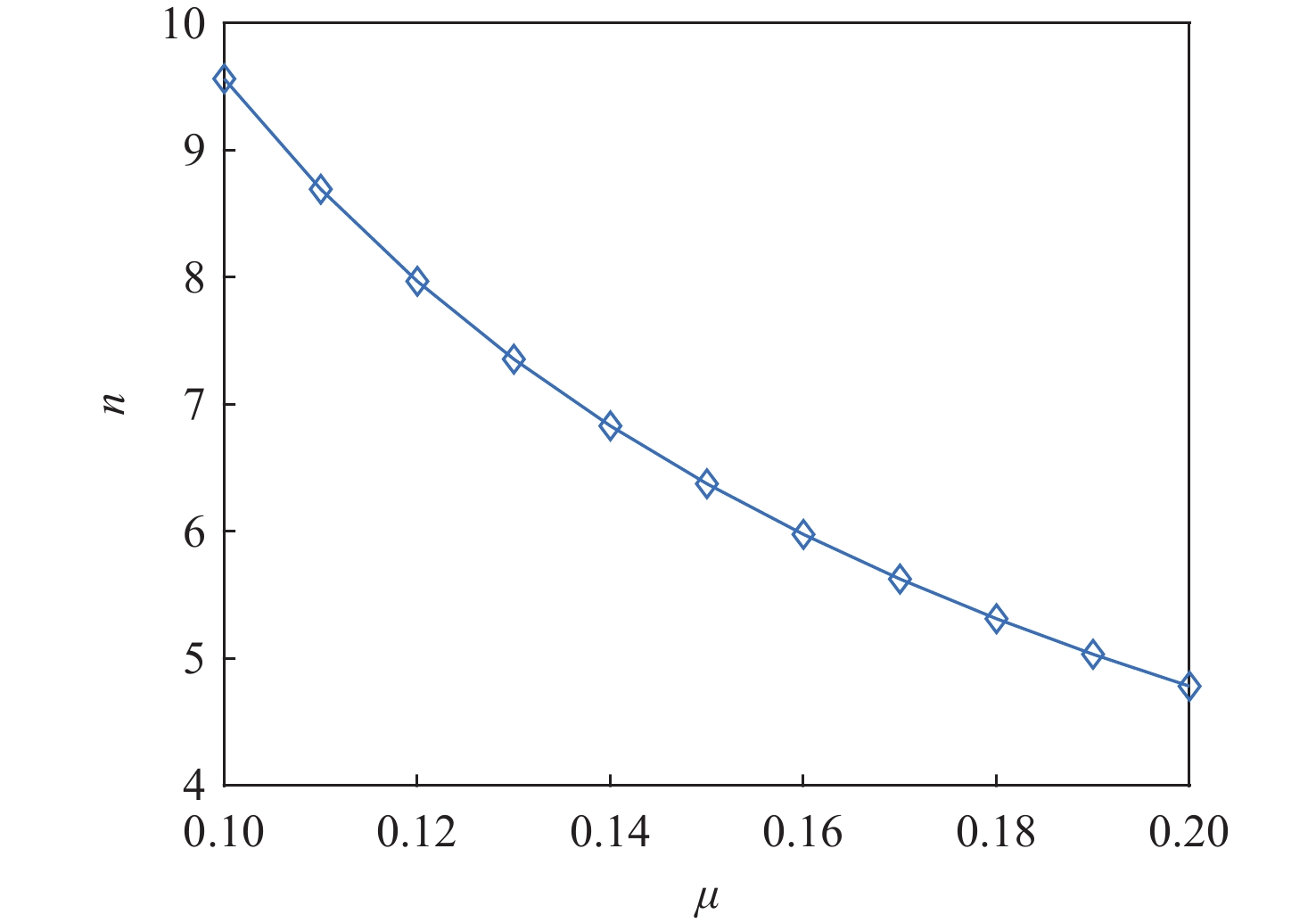

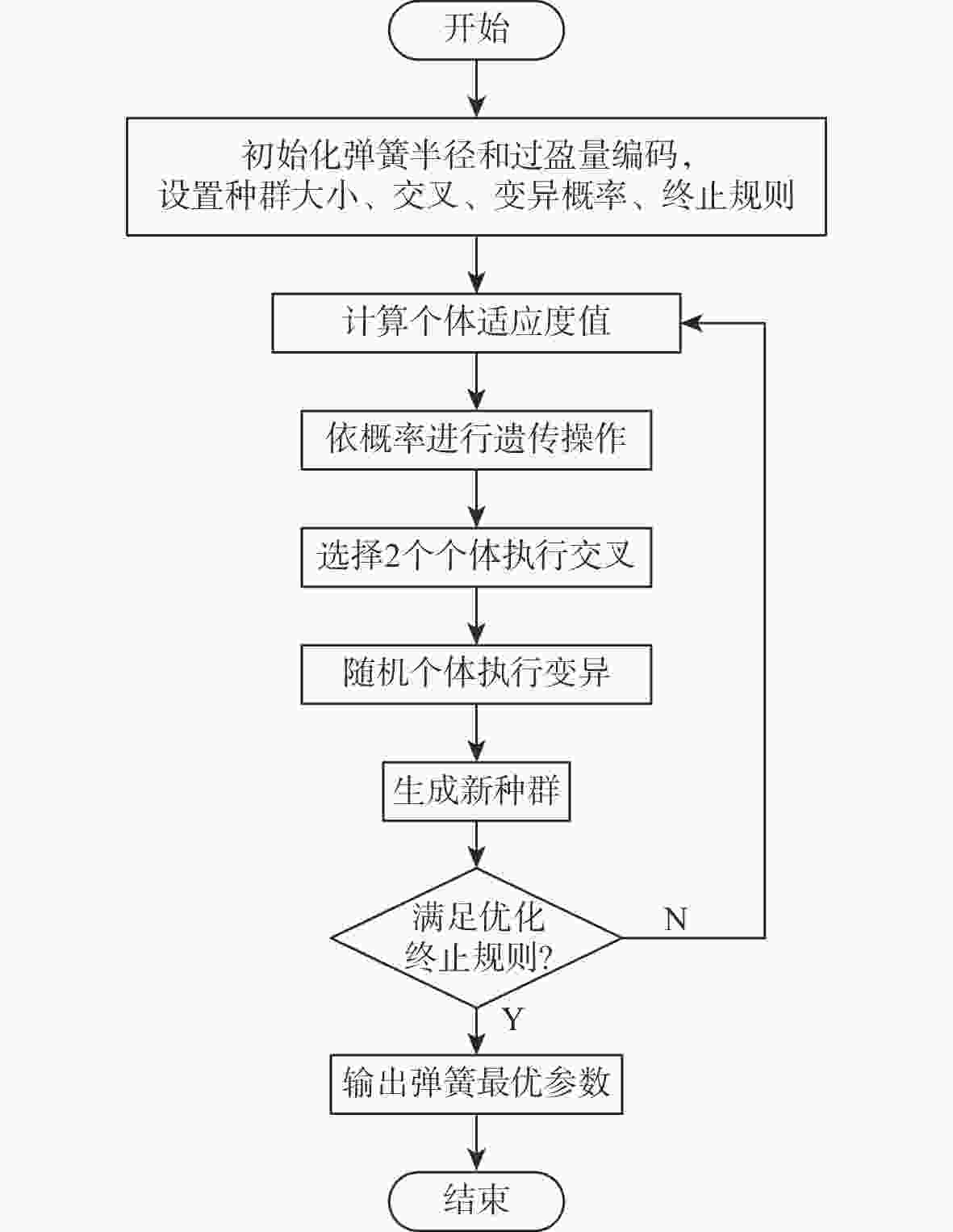

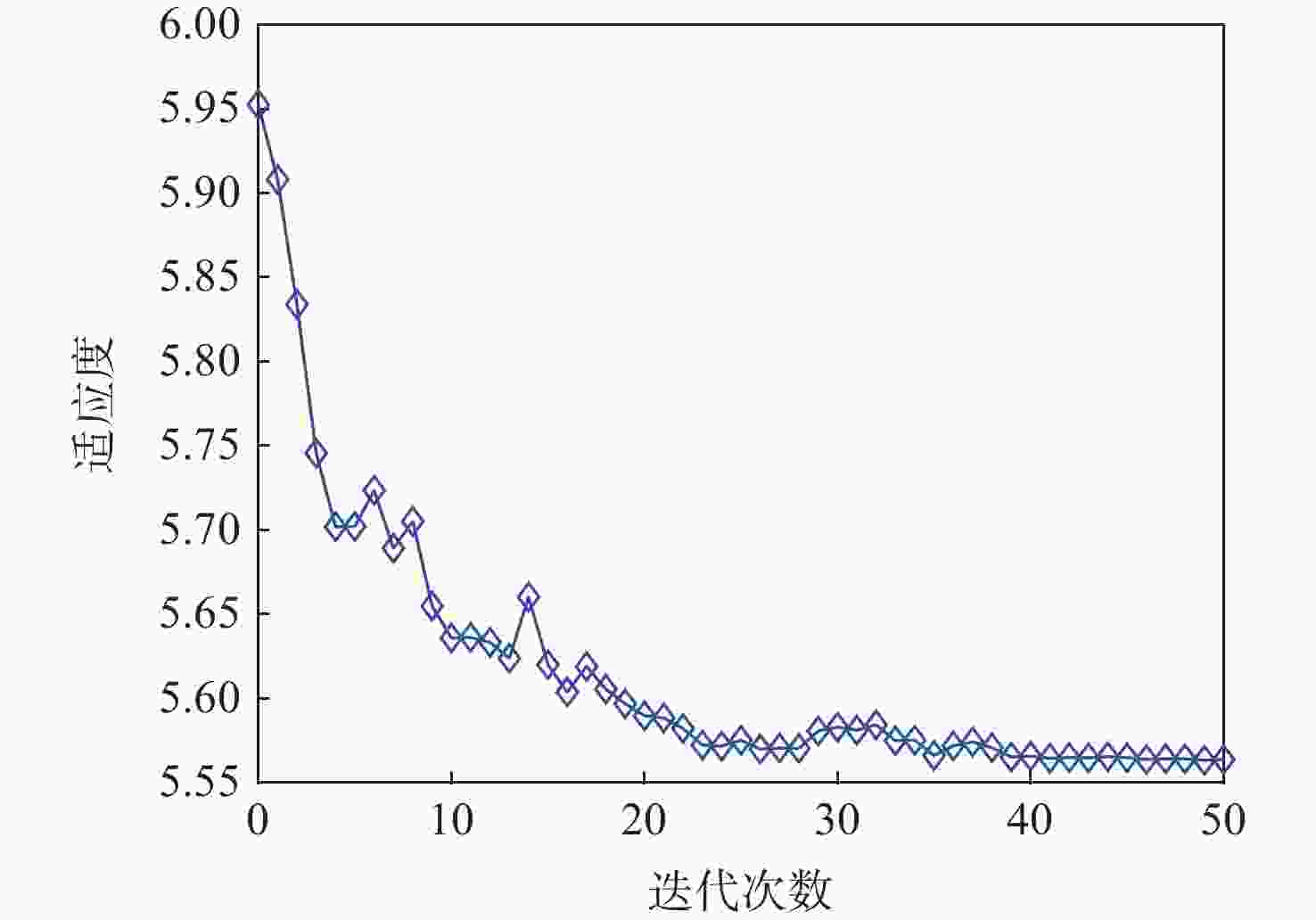

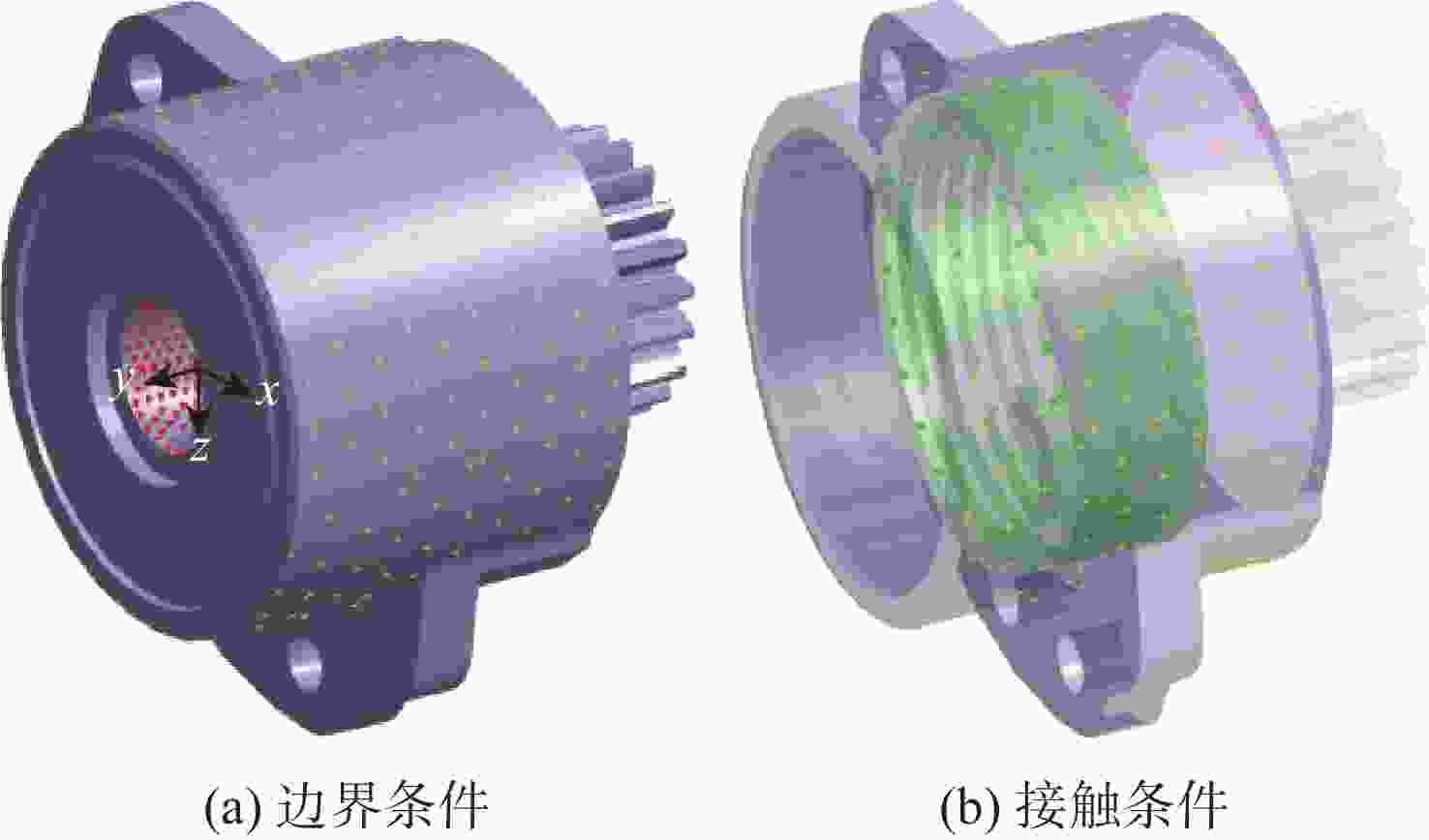

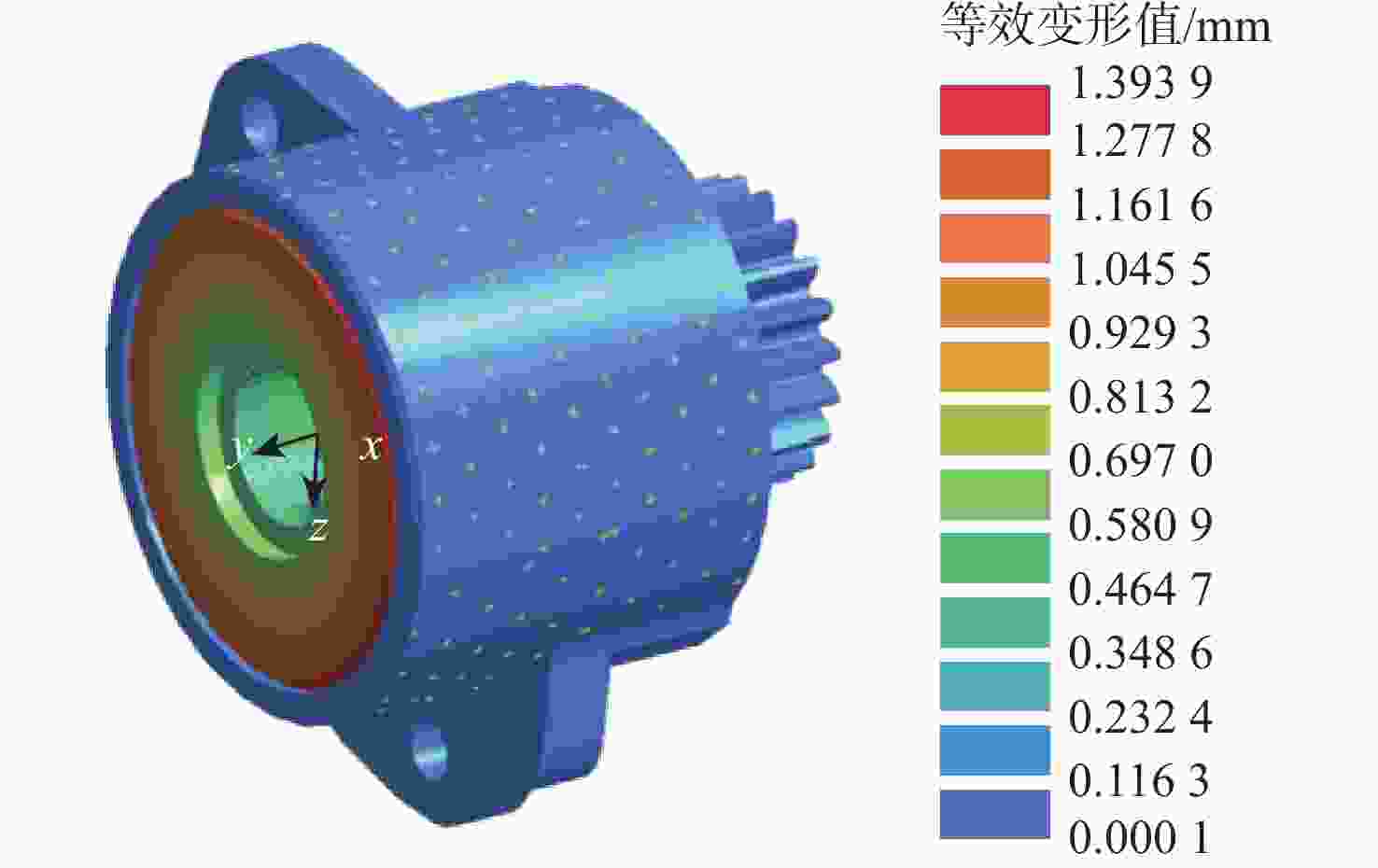

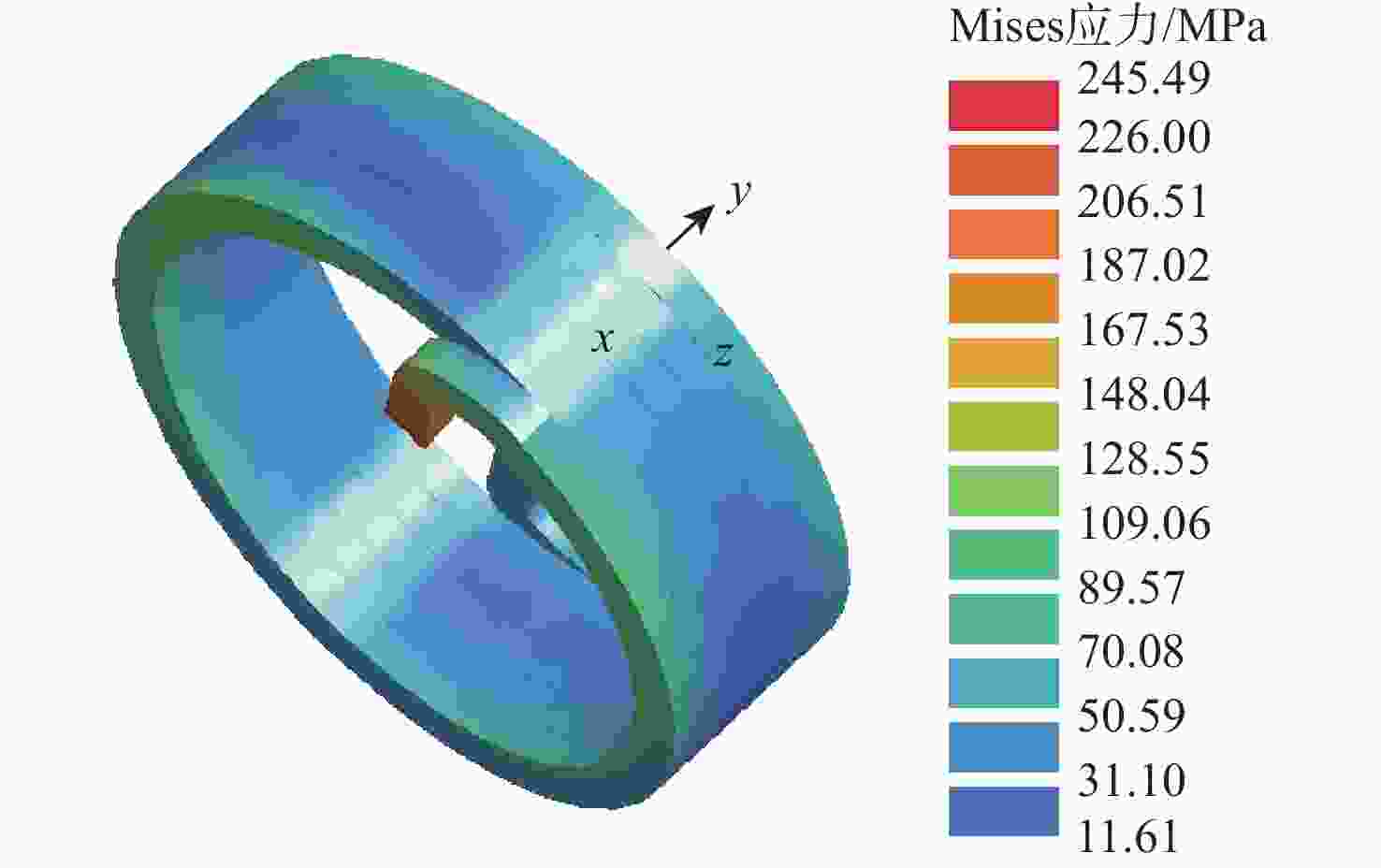

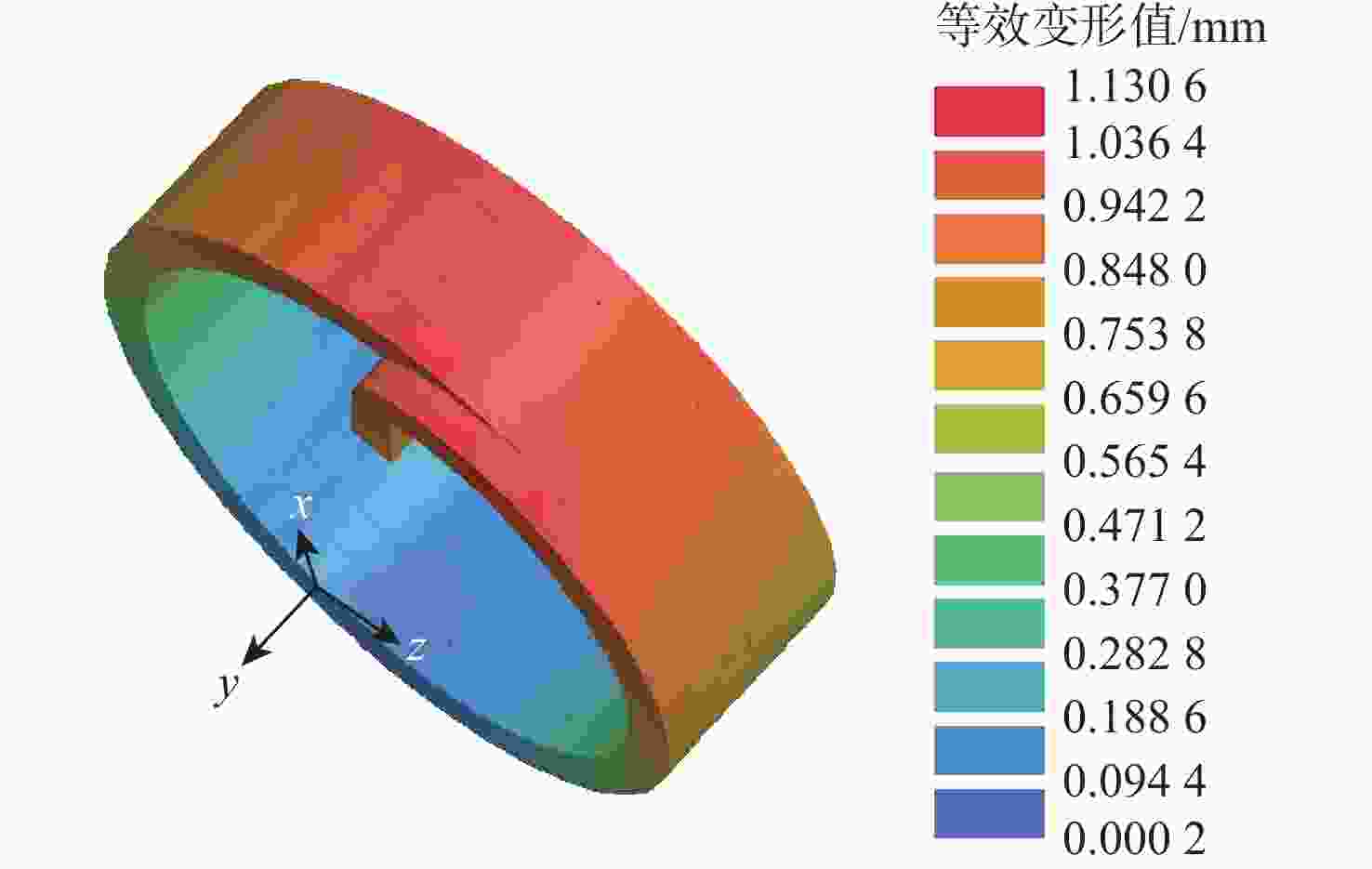

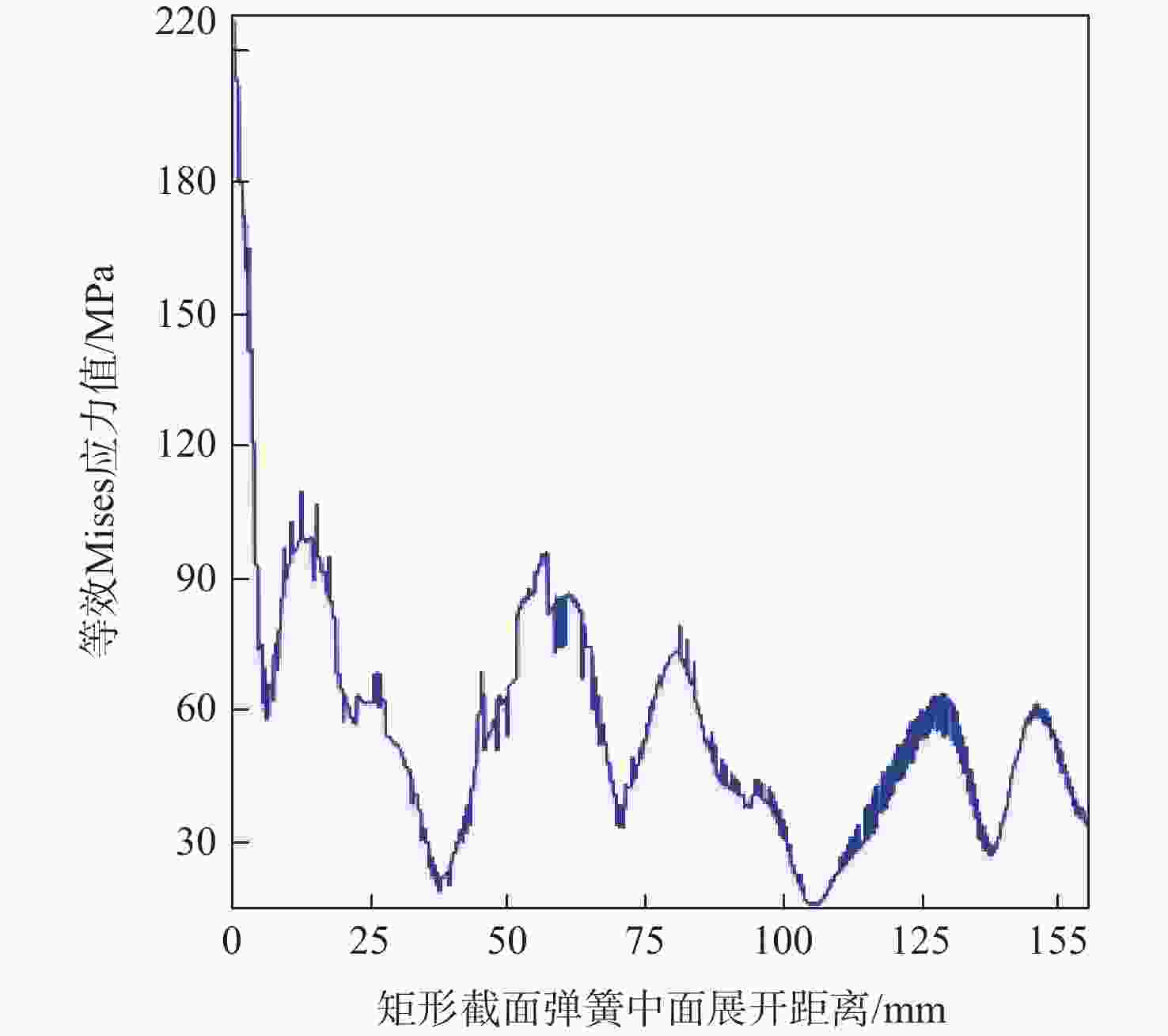

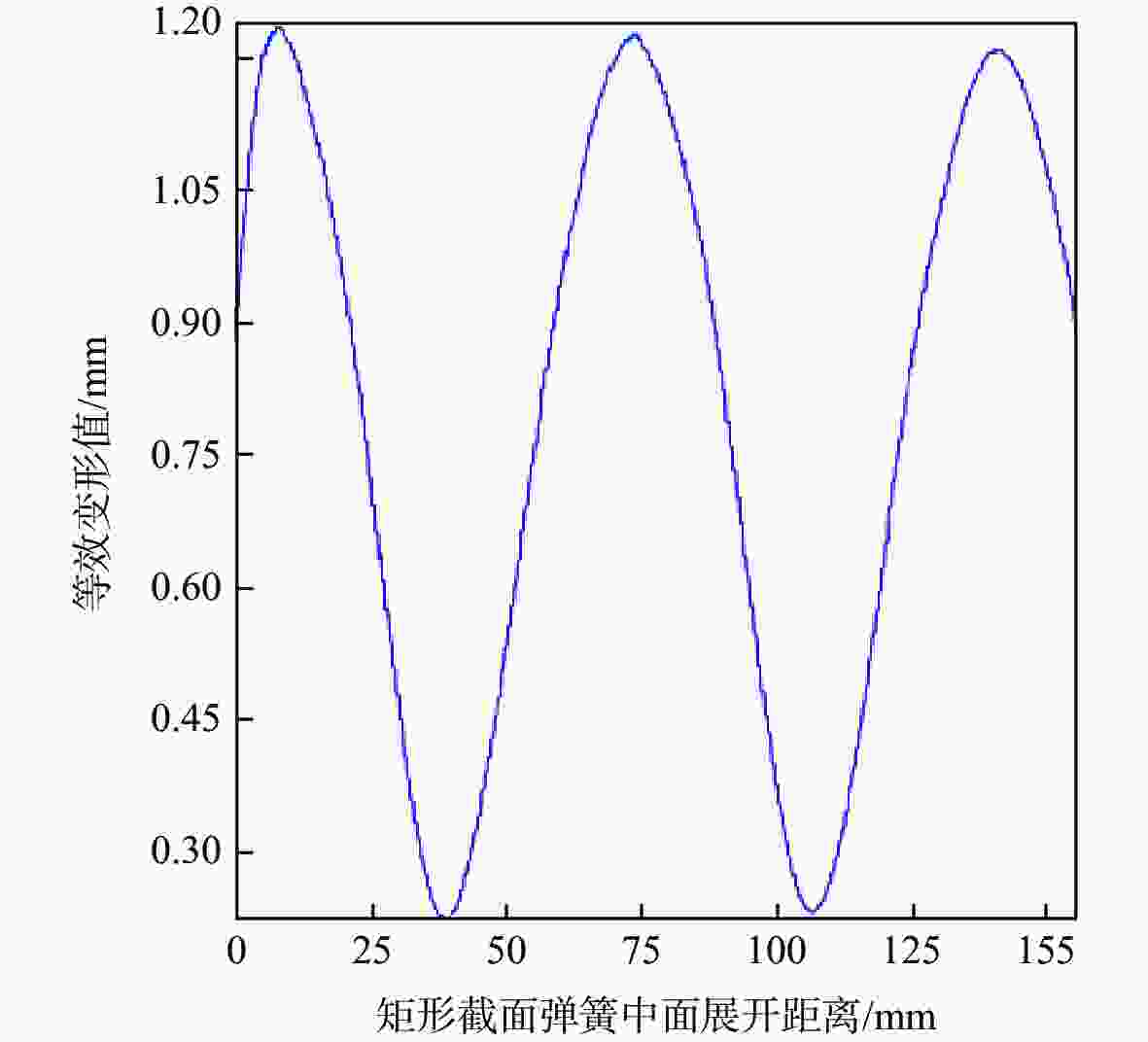

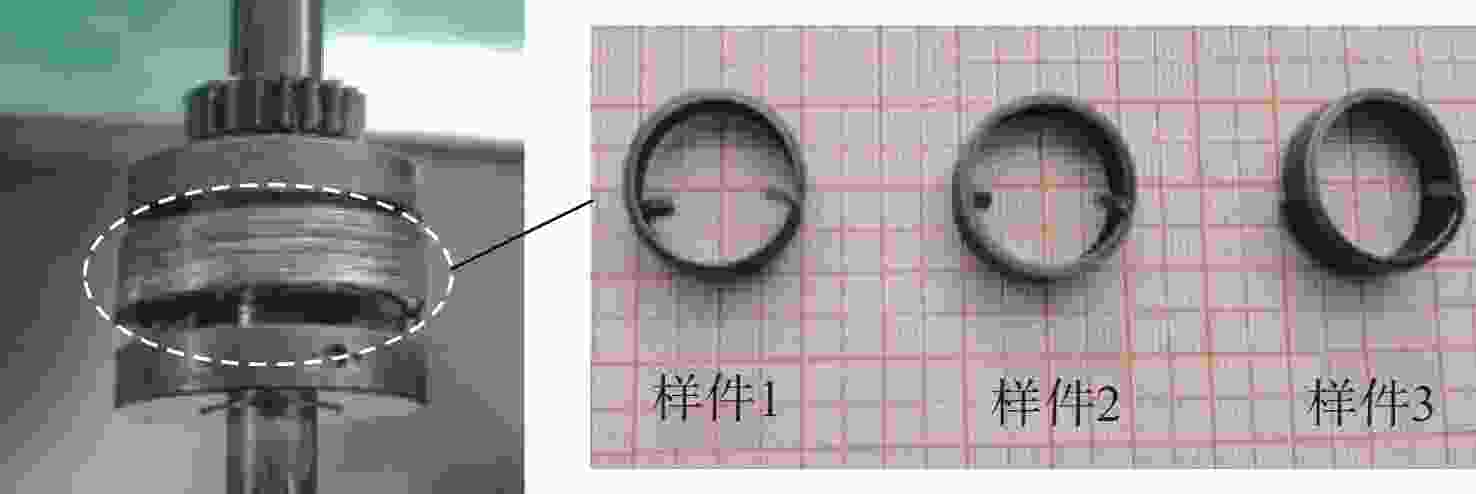

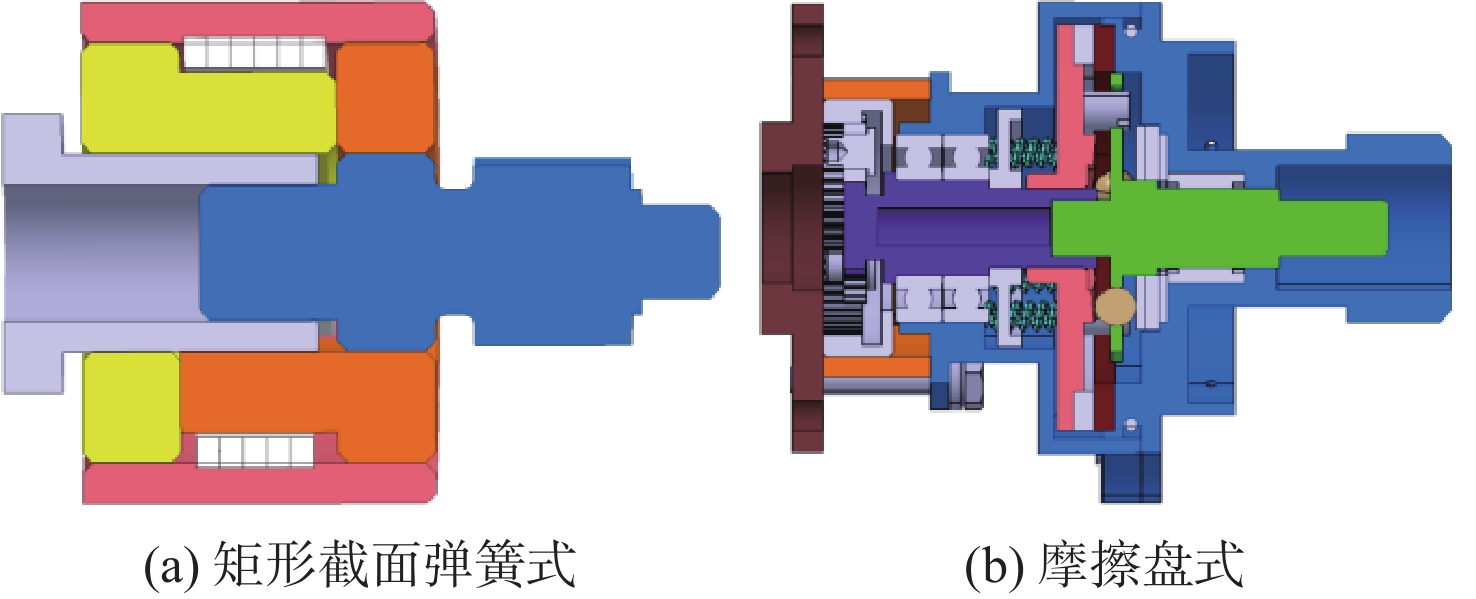

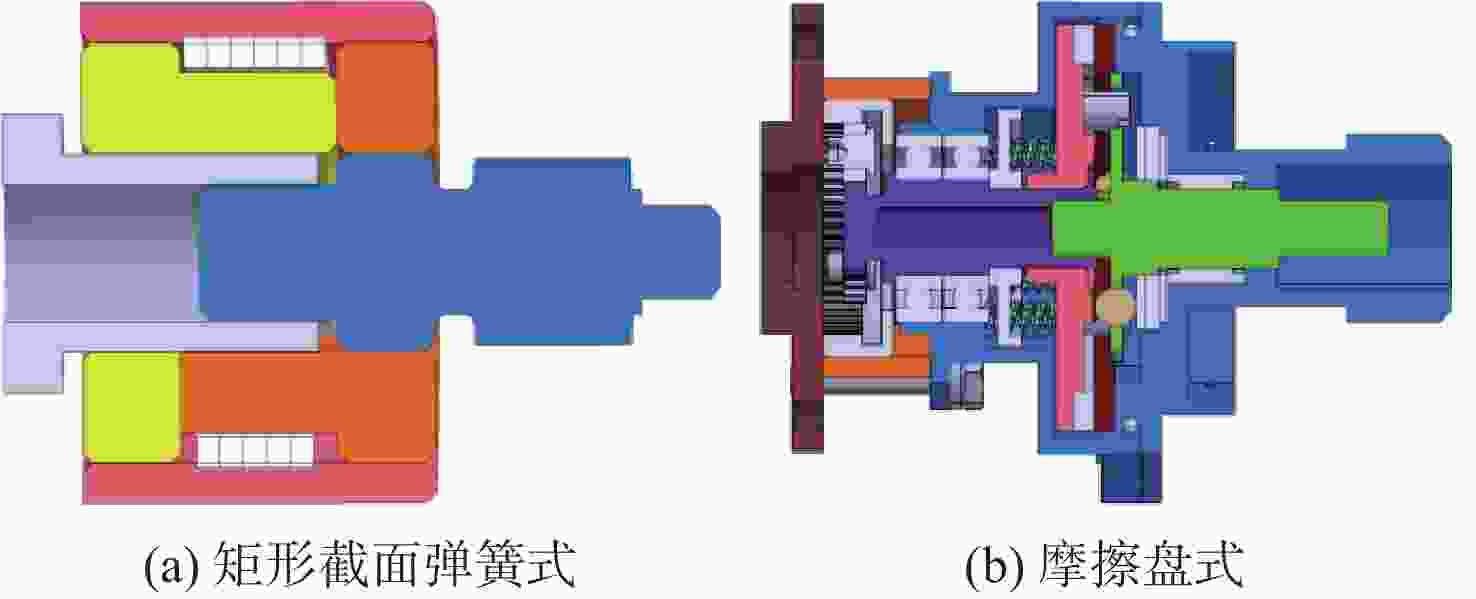

传统的防逆转装置存在体积与质量大的缺点,不适用于对质量指标极度敏感的航空类产品。为此,提出一种小巧轻便的新型矩形截面弹簧逆止器设计方法,通过对逆止器中矩形截面弹簧进行力学分析,明确矩形截面弹簧的受力与变形关系,分析矩形截面弹簧尺寸、配合套筒过盈量与逆止性能的变化特性。推导矩形截面弹簧逆止器逆止有效条件,并引入遗传算法进行求解;根据求得的结构参数,运用CATIA软件建立矩形截面弹簧逆止器结构模型,并导入HyperWorks软件进行校核分析。结合样件试制及测试,结果表明:所提方法与传统摩擦盘式方法相比同负载条件下质量可降低约61%,仿真与实验对照验证所提方法的有效性。

-

关键词:

- 矩形截面弹簧 /

- 逆止器 /

- 遗传算法 /

- 有限元分析 /

- HyperWorks

Abstract:Due to its bulk and weight, the conventional anti-reverse mechanism is not appropriate for use in aircraft items that are very responsive to weight indicators. In this paper, a design method for the small and lightweight rectangular cross-section spring anti-reverse device is proposed. Through the mechanical analysis of the rectangular cross-section spring in the anti-reverse device, the relationship between the force and deformation of the rectangular cross-section spring is deduced. The anti-reverse performance with the size of the rectangular cross-section spring and the interference with the matching sleeve is studied. Genetic algorithms are used to determine and resolve the effective working conditions of the spring anti-reverse device with a rectangular cross-section. The structural model of the rectangular cross-section spring anti-reverse rotation device is established by CATIA software, which is imported into HyperWorks software for verification analysis. By the manufacture and measurement results of the designed prototype, it is shown that the weight of the rectangular section spring anti-reverse device designed based on this study can be reduced by 60% compared with the traditional friction disc type under the same load condition. The correctness and reliability of the design method are verified by comparing the simulation results with the experimental data.

-

表 1 矩形截面弹簧材料属性

Table 1. Material properties of rectangular section spring

材料 弹性模量/GPa 泊松比 力矩/(N·m) 50CrVA 208 0.3 6 表 2 不同矩形截面弹簧实验样件参数、计算和实验值

Table 2. Parameters, calculations and test values of test samples of springs with different rectangular cross-sections

样件 样件弹簧

外径/mm弹簧外径与

衬套内径实际

过盈量/mm计算力矩/

(N·m)实验测试

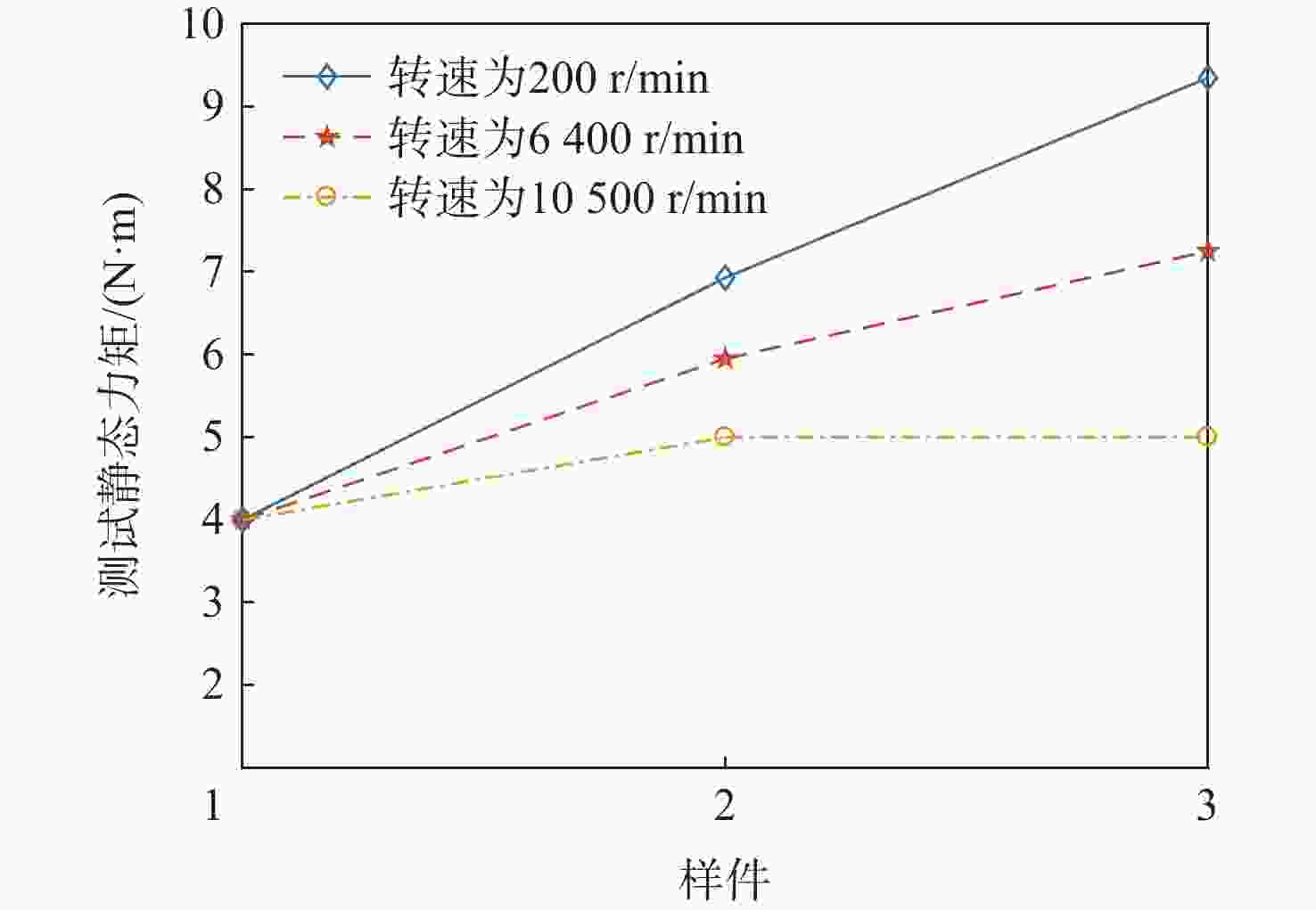

力矩/(N·m)理论样件 21.58 0.2 9 <12.98 1组样件1 21.45 0.11 2.9 <3.15 1组样件2 21.45 0.23 6.1 <6.93 1组样件3 21.45 0.35 9.2 <9.91 2组样件1 21.12 0.11 2.1 <2.52 2组样件2 21.12 0.23 4.3 <4.98 2组样件3 21.12 0.35 6.5 <7.25 3组样件1 21.36 0.02 0.8 <0.91 3组样件2 21.36 0.2 5.3 <5.95 3组样件3 21.36 0.4 8.8 <9.35 表 3 不同转速下矩形截面弹簧工作状态

Table 3. Working state of rectangular section spring at different rotational speeds

样件 转速/

(r·min−1)实验测试

静态力矩/

(N·m)工作状态 样件1 200 <4 工作状态较好,偶尔出现无法逆止现象,声音平稳,拆解后弹簧状态

良好6400 <4 10500 <4 无法逆止,拆解弹簧后,观察弹簧外表面良好 样件2 200 6.93 工作状态良好,声音平稳,拆解后弹簧状态良好 6400 5.95 10500 <5 工作过程中声音刺耳,拆解弹簧后,观察外表面出现磨损 样件3 200 9.35 能够实现逆止功能,出现间断噪声 6400 7.25 10500 <5 工作过程中声音刺耳,拆解弹簧后,观察外表面磨损严重,边缘出现

毛刺 -

[1] KISH J G. Helicopter freewheel unit design guide[M]. Stantford: Applied Technology Laboratory, 1977 : 47-48. [2] KEARNEY H L, ISABELLE C J, KISH J G, et al. Coil spring for overrunning spring clutches: US, 749449-A [P]. 1998-05-12. [3] KISH J G. Overrunning spring clutch assembly: US, 934499-A [P]. 1990-06-19. [4] 常斌, 鲍和云, 朱如鹏. 基于Matlab的超越弹簧离合器弹簧的优化设计[J]. 机械制造与自动化, 2012, 41(3): 107-109. doi: 10.3969/j.issn.1671-5276.2012.03.036CHANG B, BAO H Y, ZHU R P. Optimal design of spring for spring overrunning clutch based on Matlab[J]. Machine Building & Automation, 2012, 41(3): 107-109(in Chinese). doi: 10.3969/j.issn.1671-5276.2012.03.036 [5] 廖厚德. 国内外重要用途弹簧钢丝产品现状[J]. 金属制品, 1995, 21(1): 5-8.LIAO H D. Present situation of important spring steel wire products at home and abroad[J]. Metal Products, 1995, 21(1): 5-8(in Chinese). [6] 张英会, 刘辉航, 王德成, 等. 弹簧手册[M]. 北京: 机械工业出版社, 1997: 259-271.ZHANG Y H, LIU H H, WANG D C, et al. Spring guide[M]. Beijing: Machinery Industry Press, 1997: 259-271(in Chinese) . [7] 舒荣福, 王秀凤. 矩形钢丝圆柱螺旋弹簧的简化设计法[J]. 机械科学与技术, 1997, 16(2) : 245-248.SHU R F, WANG X F. Regression analysis on design method for cylindric helical springs with rectangular wire[J]. Mechanical Science And Technology, 1997, 16(2): 245-248 (in Chinese). [8] 王玉梅, 陈火红, 王军, 等. 基于Marc的螺旋钢弹簧卷制过程的仿真分析[J]. 计算机辅助工程, 2013, 22(S1): 427-430. doi: 10.3969/j.issn.1006-0871.2013.z1.102WANG Y M, CHEN H H, WANG J, et al. Simulation analysis of spiral steel spring coiling process based on Marc[J]. Computer Aided Engineering, 2013, 22(S1): 427-430 (in Chinese). doi: 10.3969/j.issn.1006-0871.2013.z1.102 [9] 严宏志, 谭武中, 韩奉林, 等. 变截面弹簧设计及其刚度特性分析[J]. 机械科学与技术, 2014, 33(2): 298-302.YAN H Z, TAN W Z, HAN F L, et al. Design and stiffness characteristic analysis of a variable cross-section spring[J]. Mechanical Science and Technology for Aerospace Engineering, 2014, 33(2): 298-302 (in Chinese). [10] 于洋, 张怡. 钻井封隔器用矩形截面弹簧的设计与校核[J]. 制造业自动化, 2015, 37(14): 107-109.YU Y, ZHANG Y. Design and check of the spring with rectangular section used in drilling packer[J]. Manufacturing Automation, 2015, 37(14): 107-109 (in Chinese). [11] 王文骞. 弹簧数控卷绕成形及回弹数值分析[D]. 洛阳: 河南科技大学, 2015: 13-24.WANG W Q. Numerical analysis of spring CNC coiling forming and springback[D]. Luoyang: Henan University of Science and Technology, 2015: 13-24(in Chinese). [12] GOBBI M, MASTINU G. On the optimal design of composite material tubular helical[J]. Meccanica, 2002, 36(5): 525-553. [13] PAREDES M, SARTOR M, MASCLET C. An optimization process for extension spring design[J]. Computer Methods in Applied Mechanics and Engineering, 2001, 191(8-10): 783-797. doi: 10.1016/S0045-7825(01)00289-4 [14] PAREDES M, SARTOR M, DAIDIE A. Advanced assistance tool for optimal compression spring design[J]. Engineering with Computers, 2005, 21(2): 140-150. doi: 10.1007/s00366-005-0318-6 [15] TSUBOUCHI T, TAKAHASHI K, KUBOKI T. Development of coiled springs with high rectangular ratio in cross-section[J]. Procedia Engineering, 2014, 81: 574-579. doi: 10.1016/j.proeng.2014.10.042 -

下载:

下载: