Experiment on dynamic response alleviation of a wing with variable-camber flexible trailing edge

-

摘要:

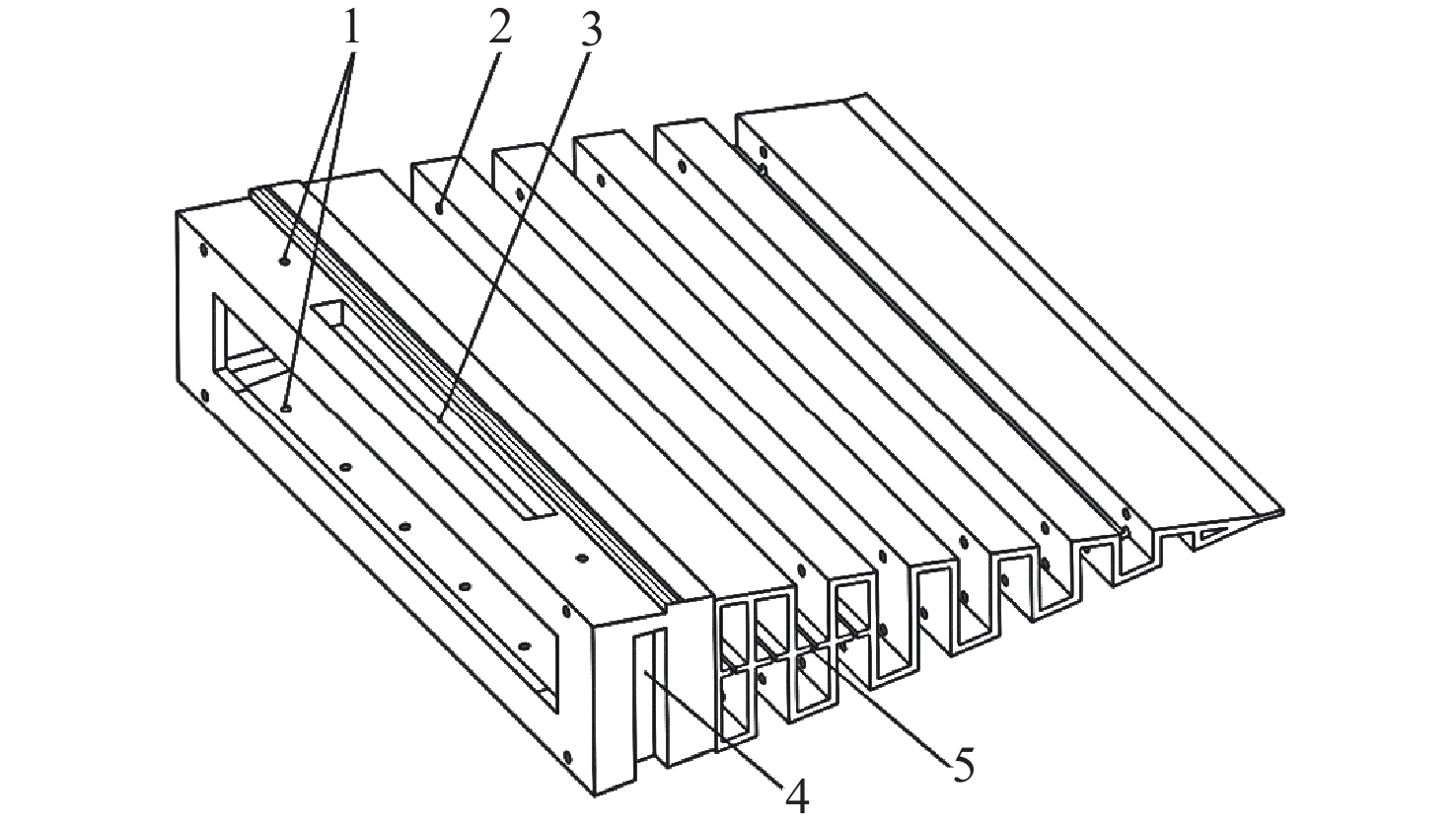

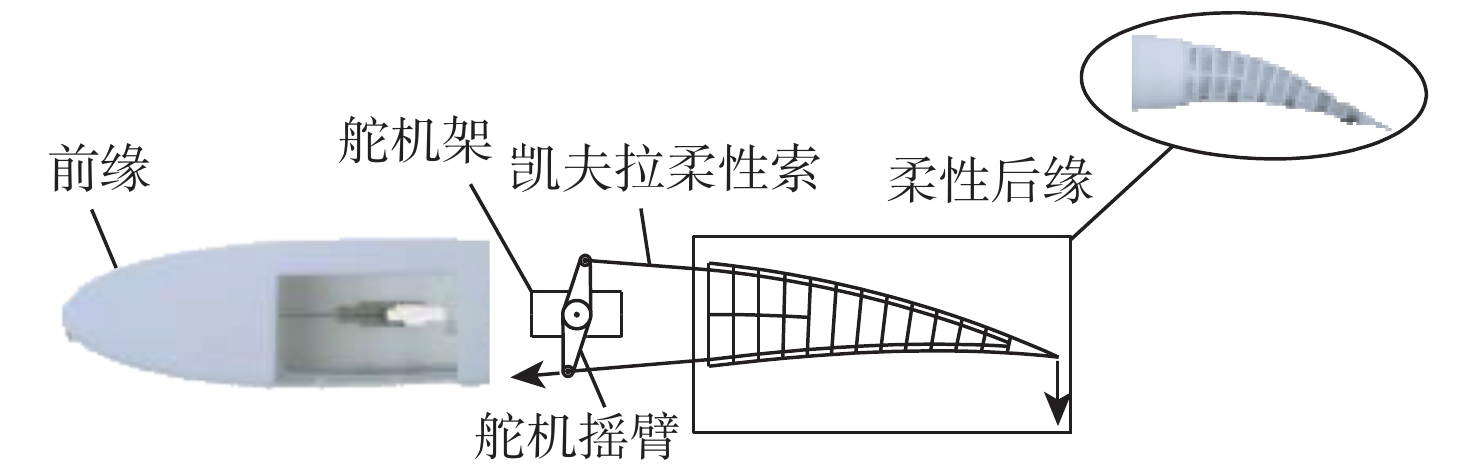

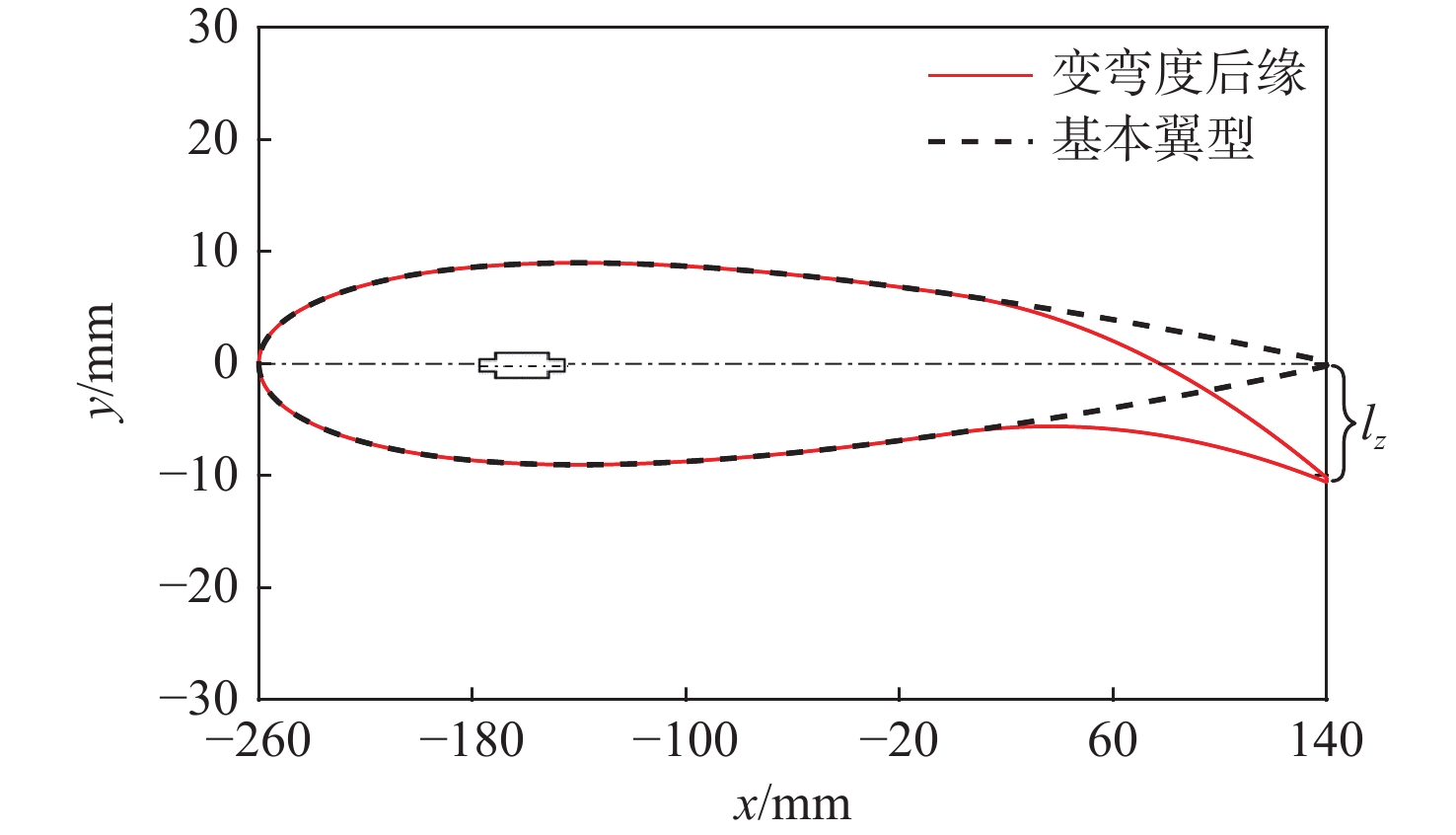

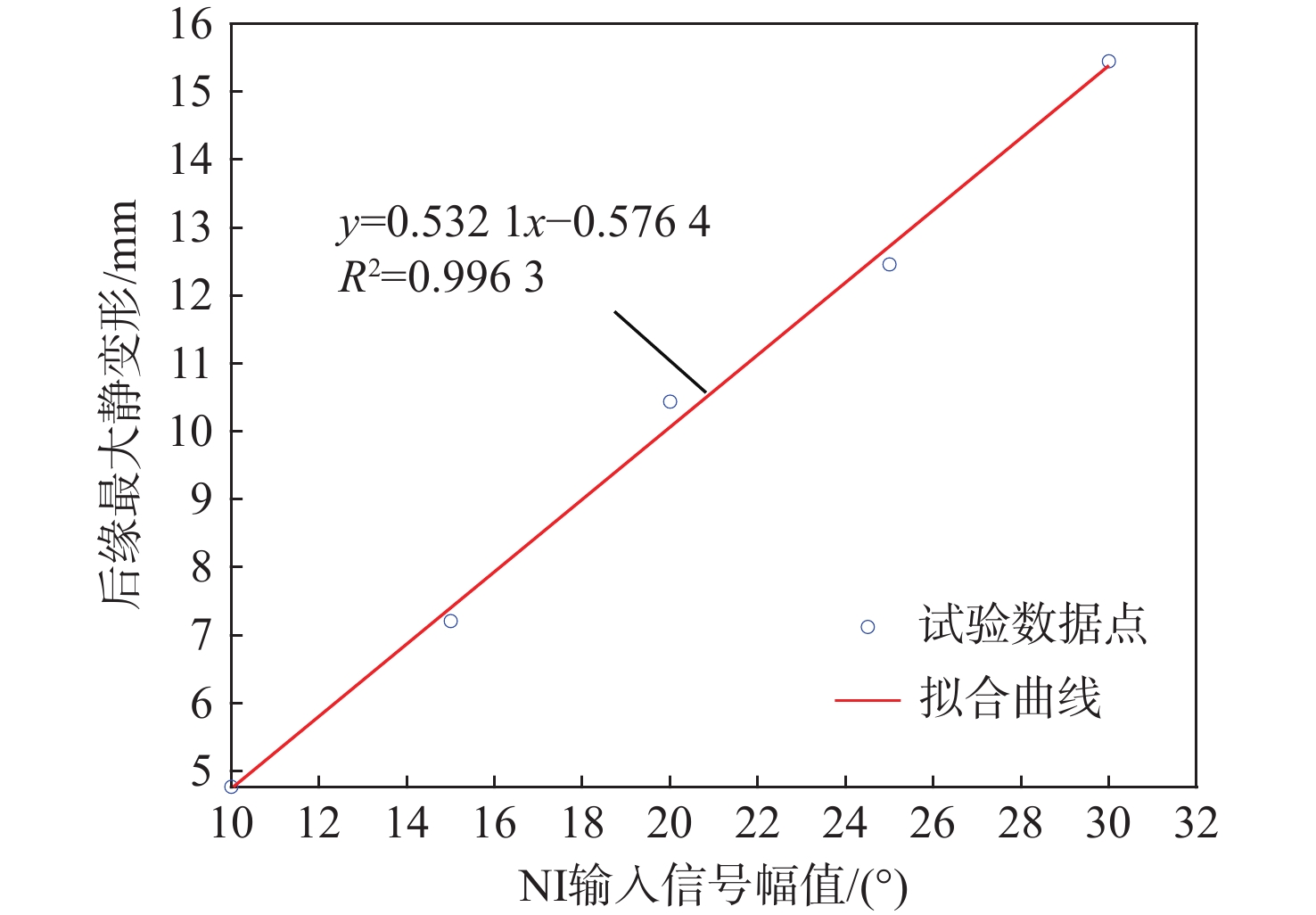

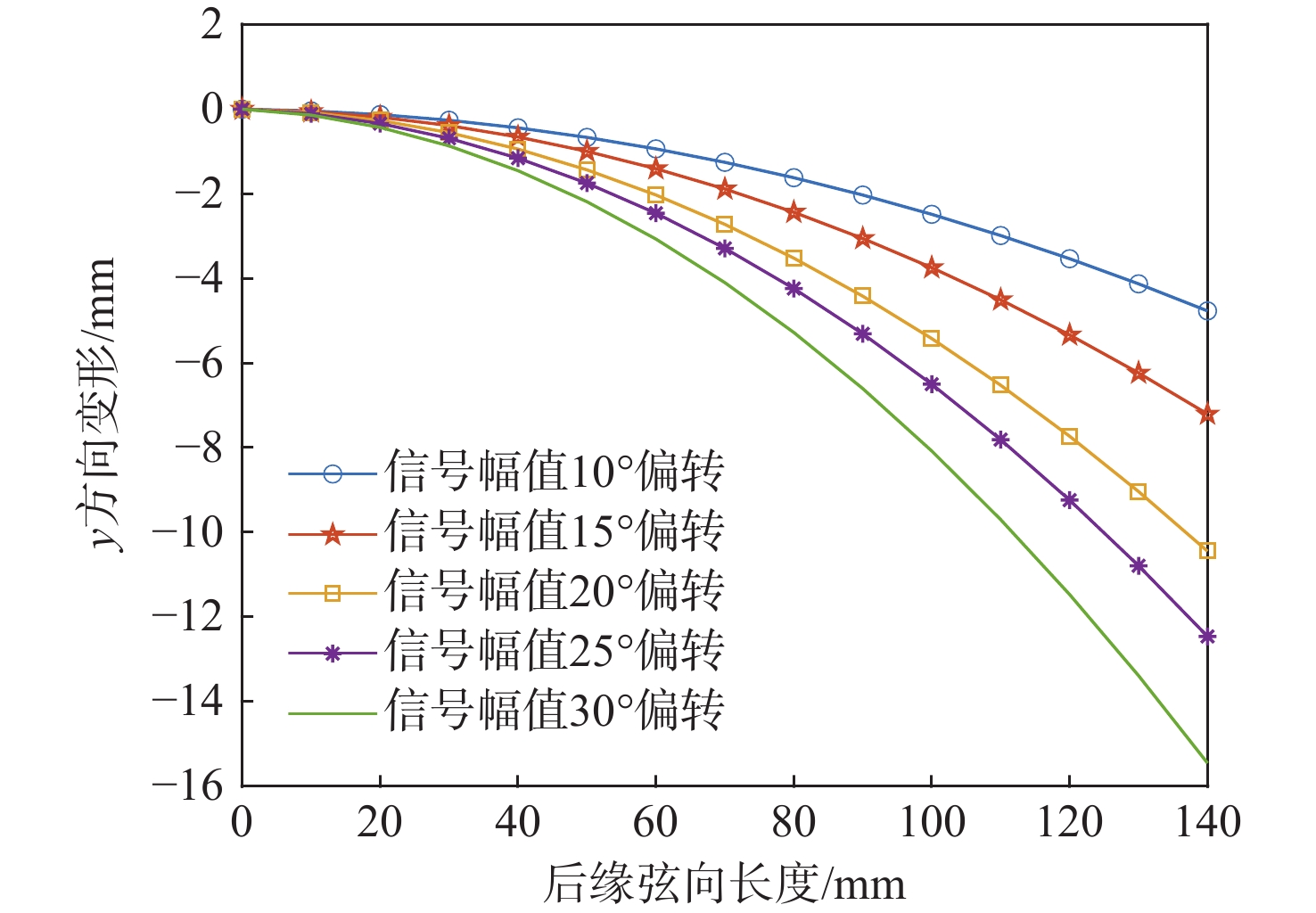

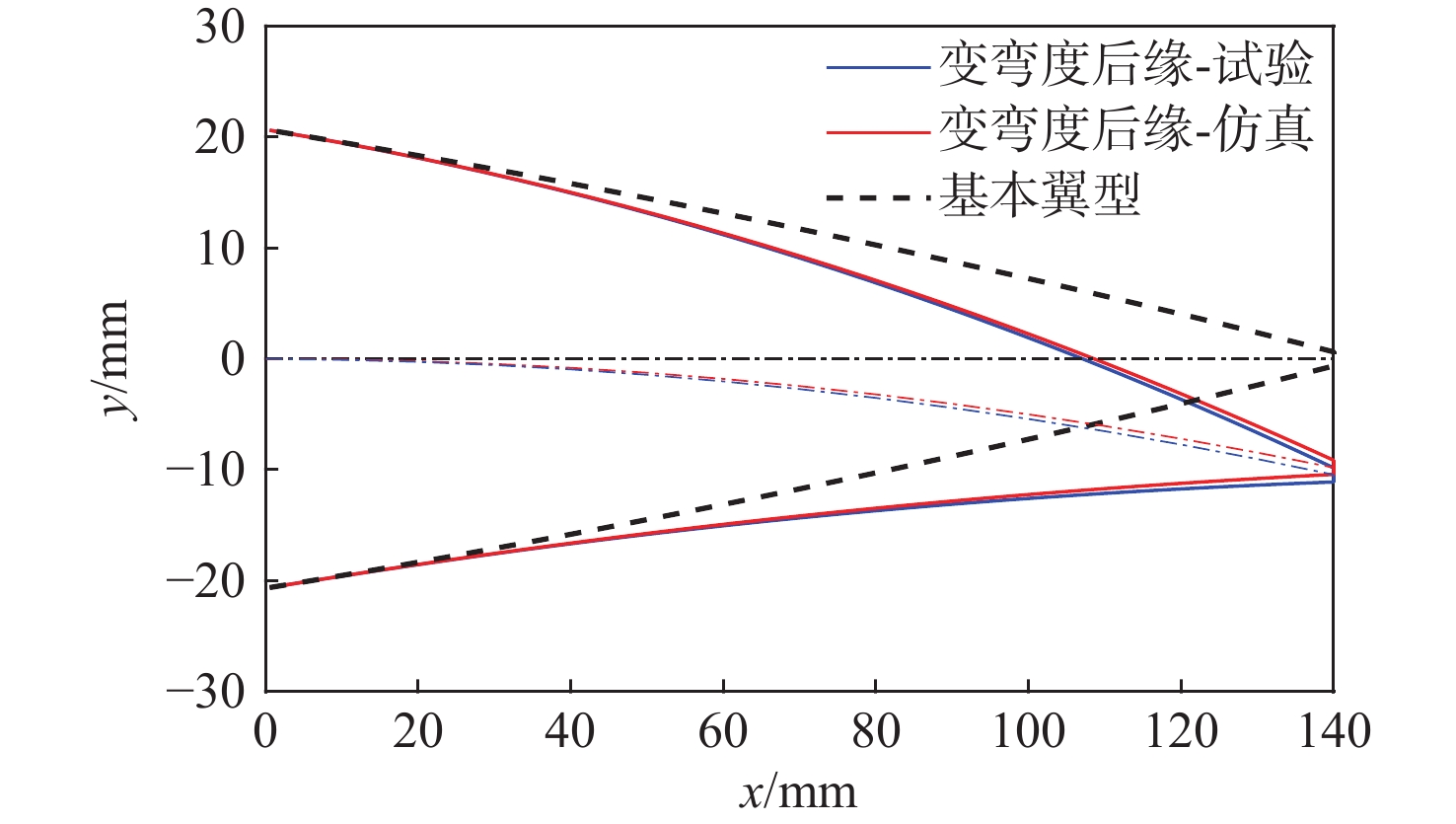

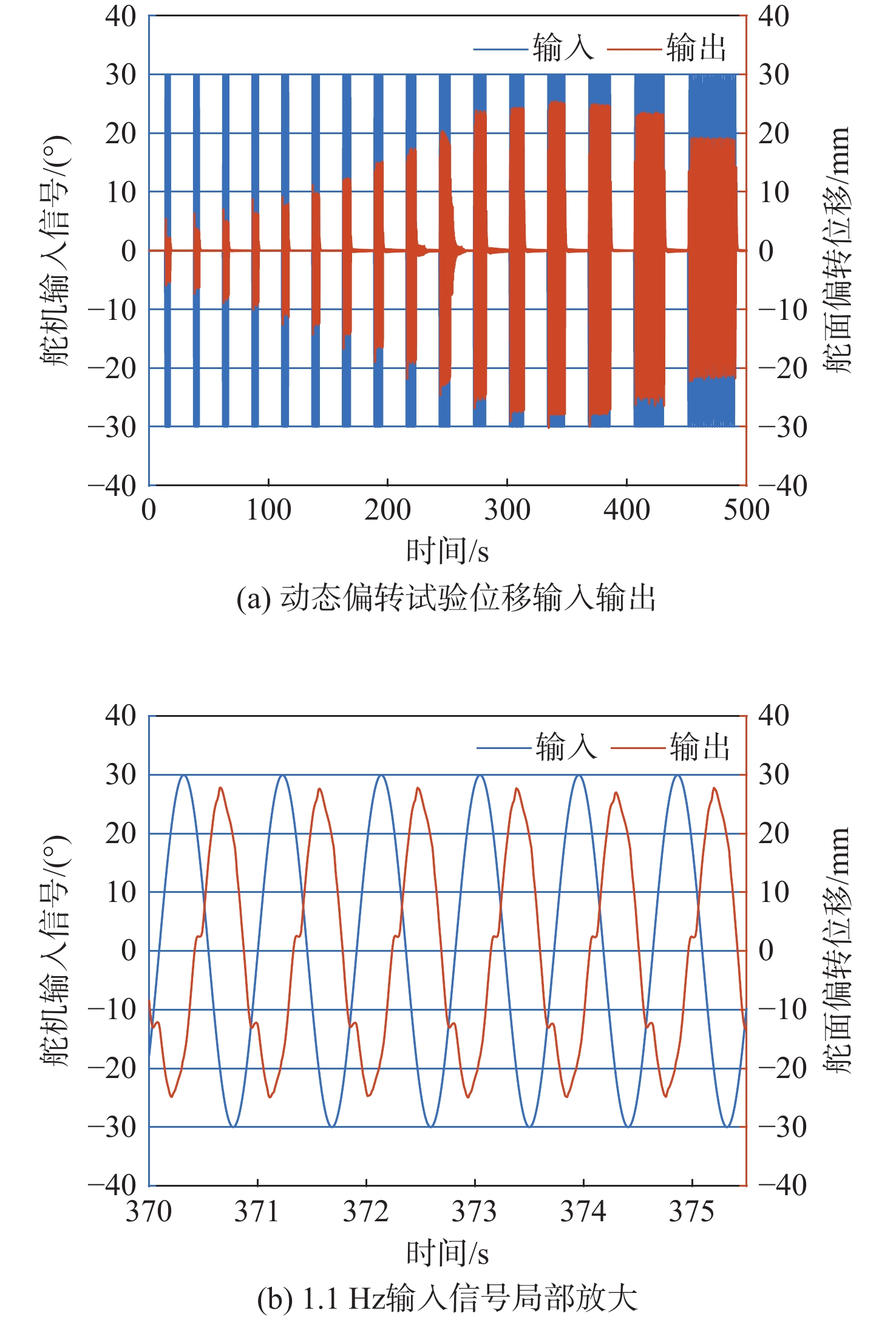

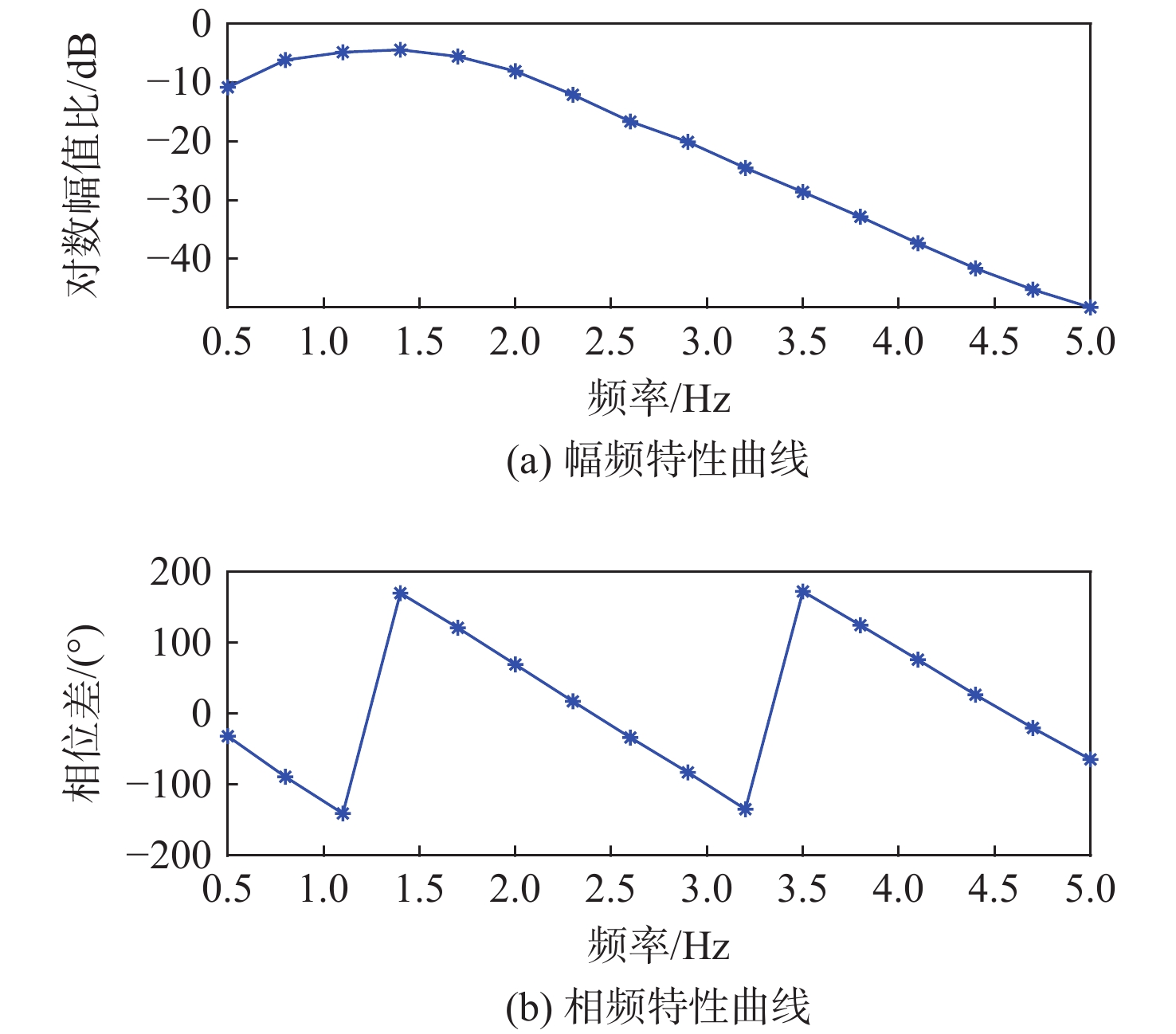

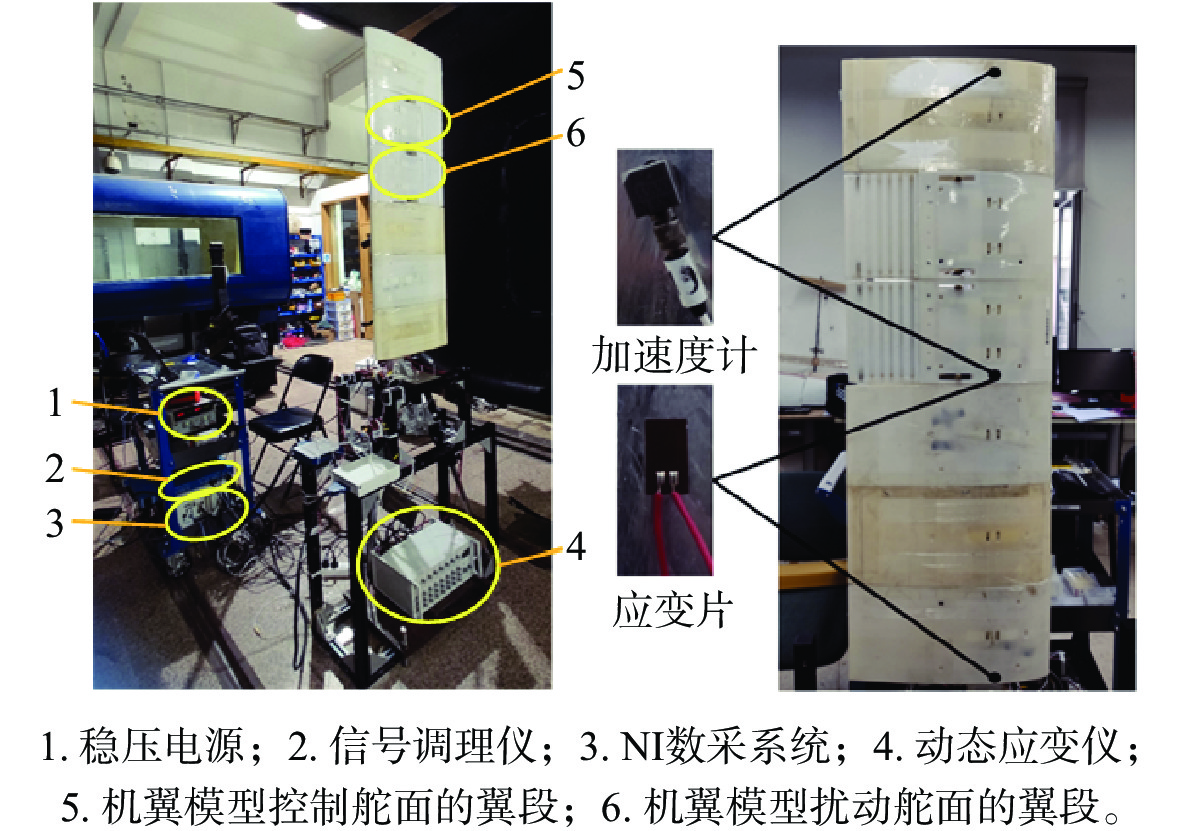

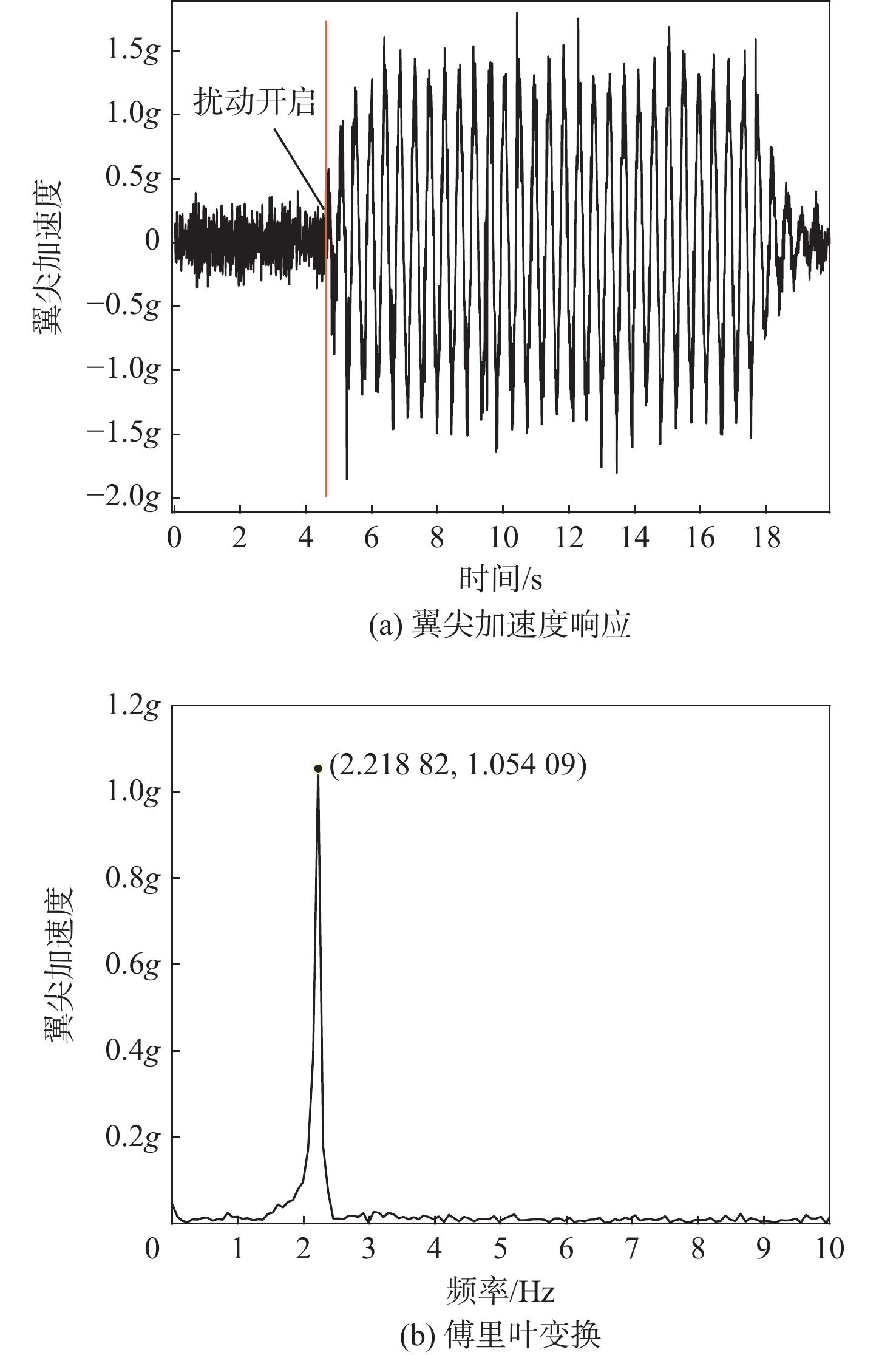

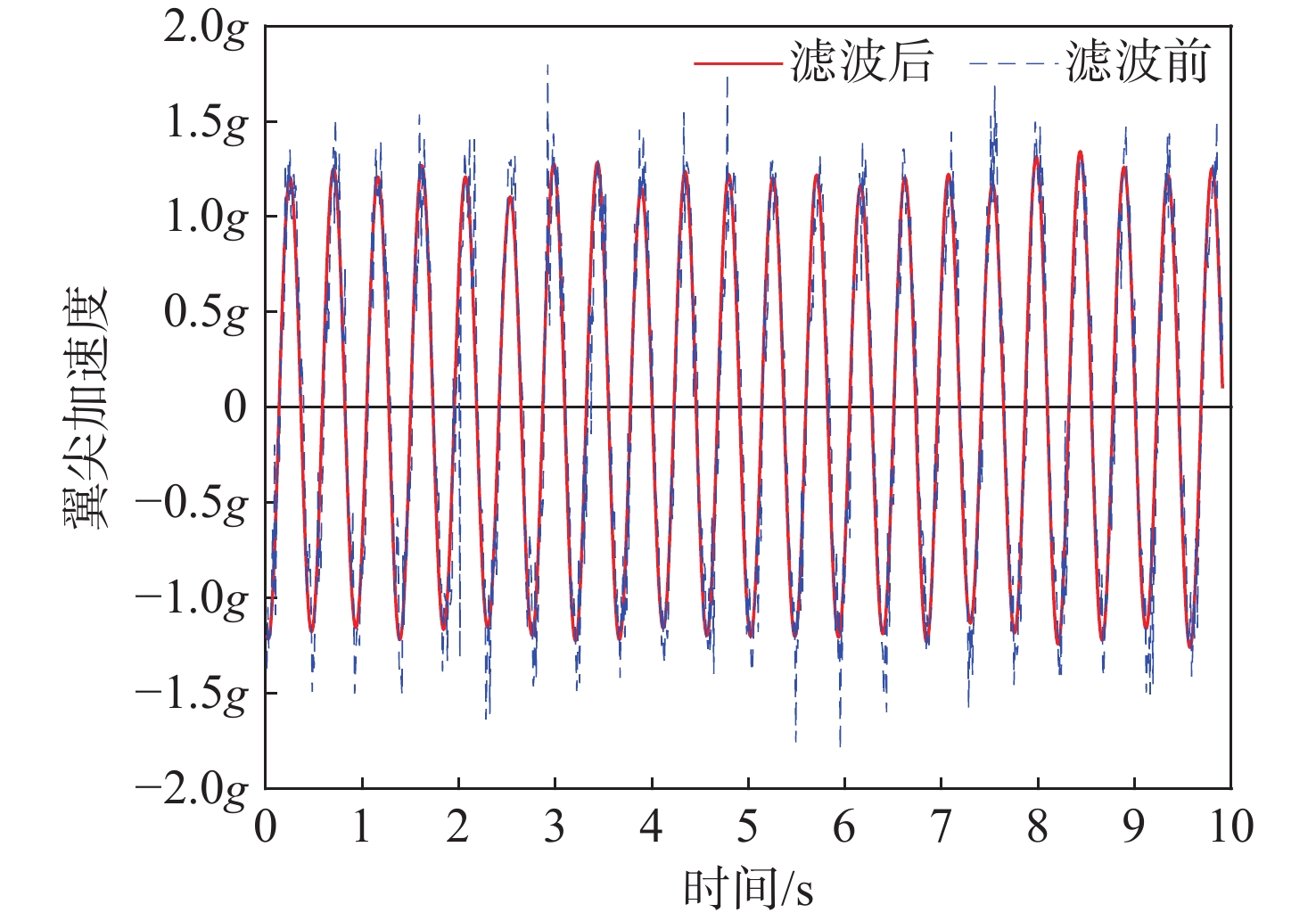

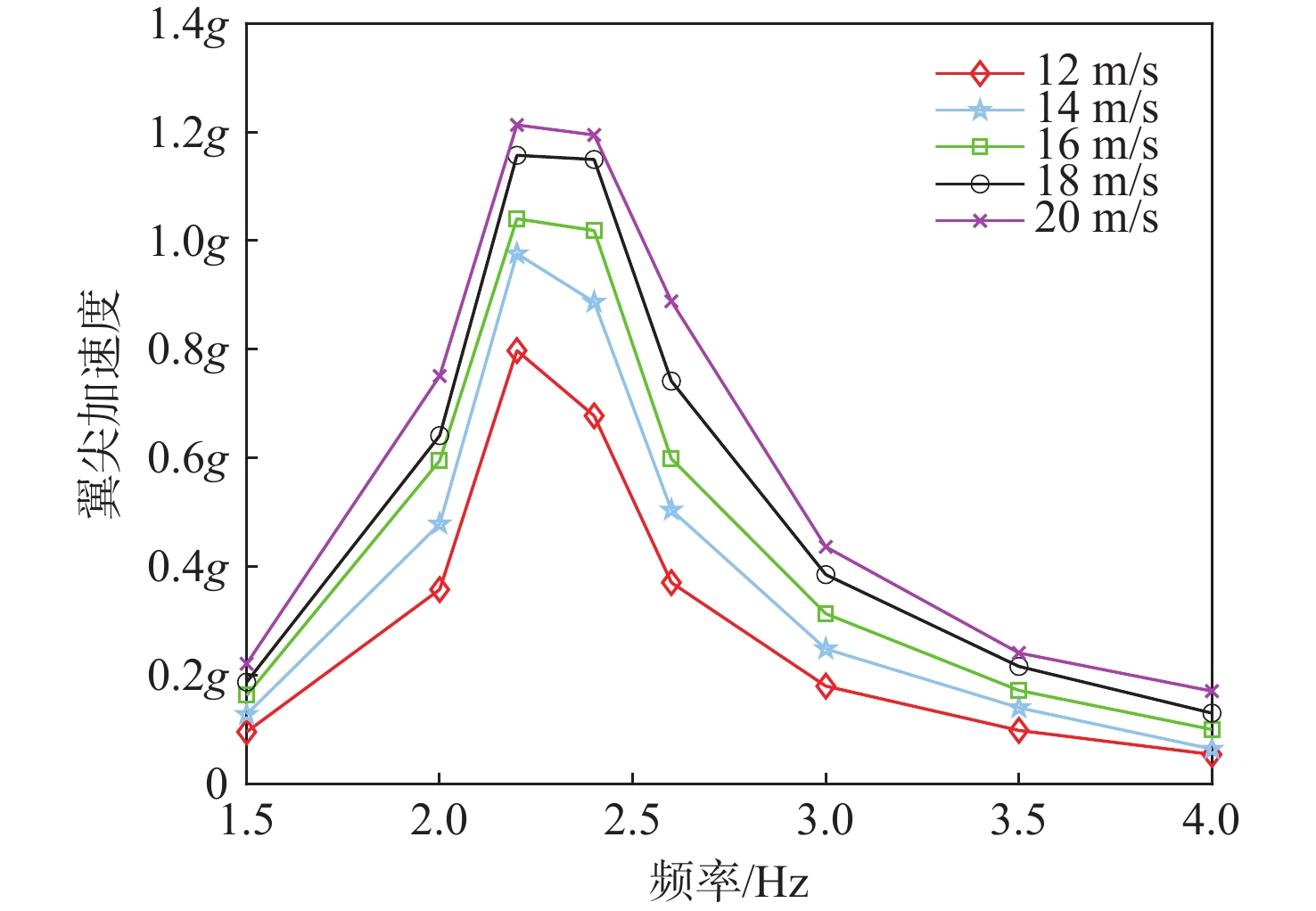

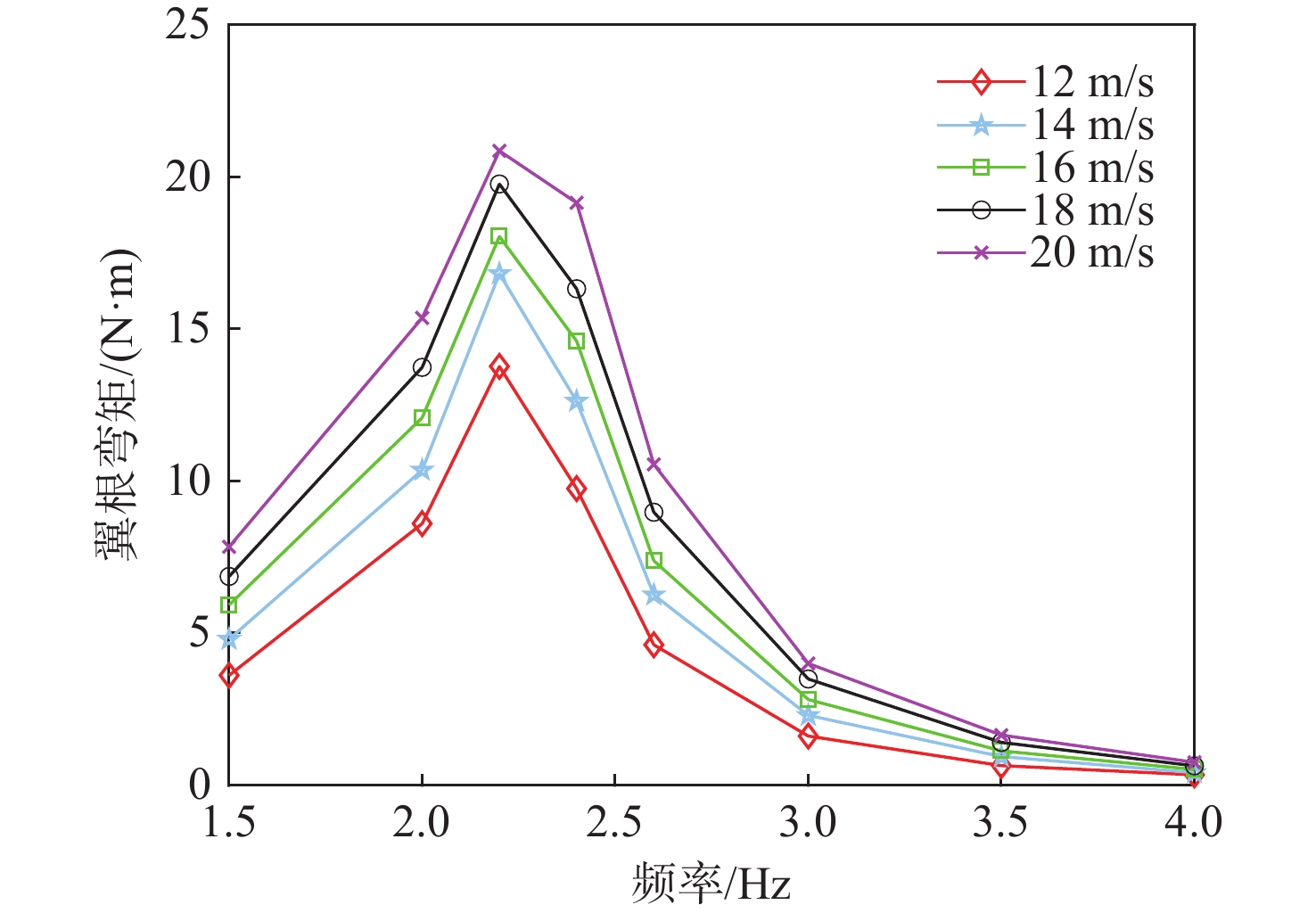

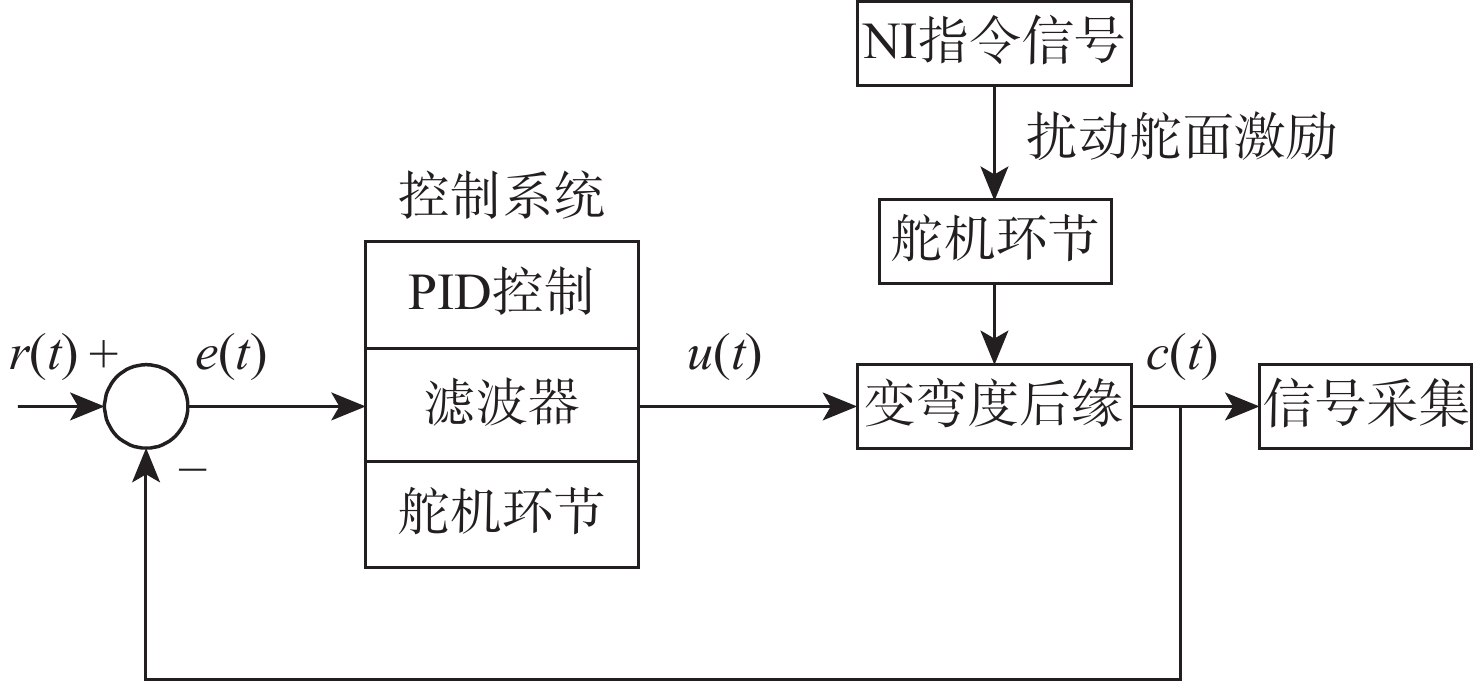

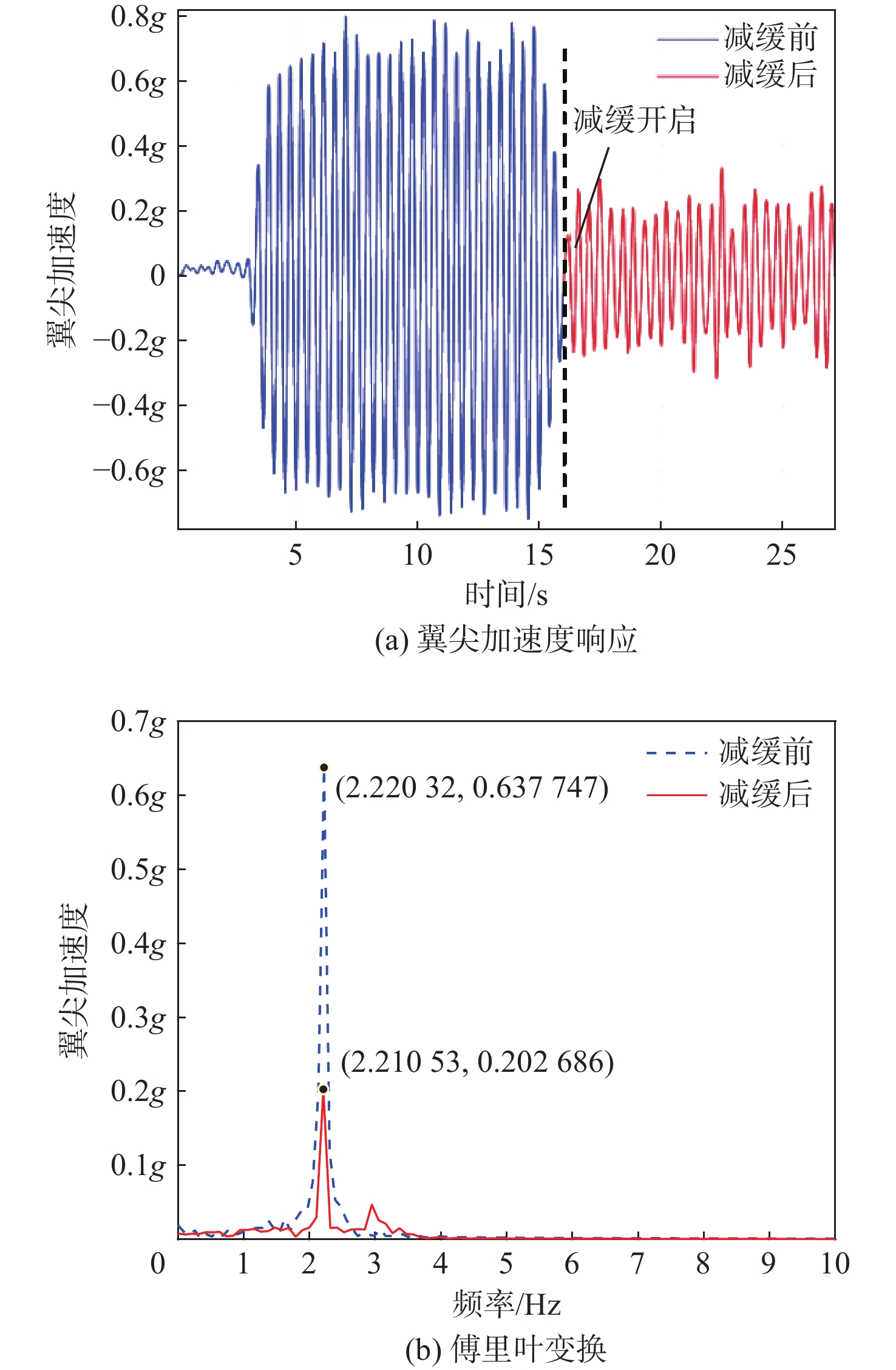

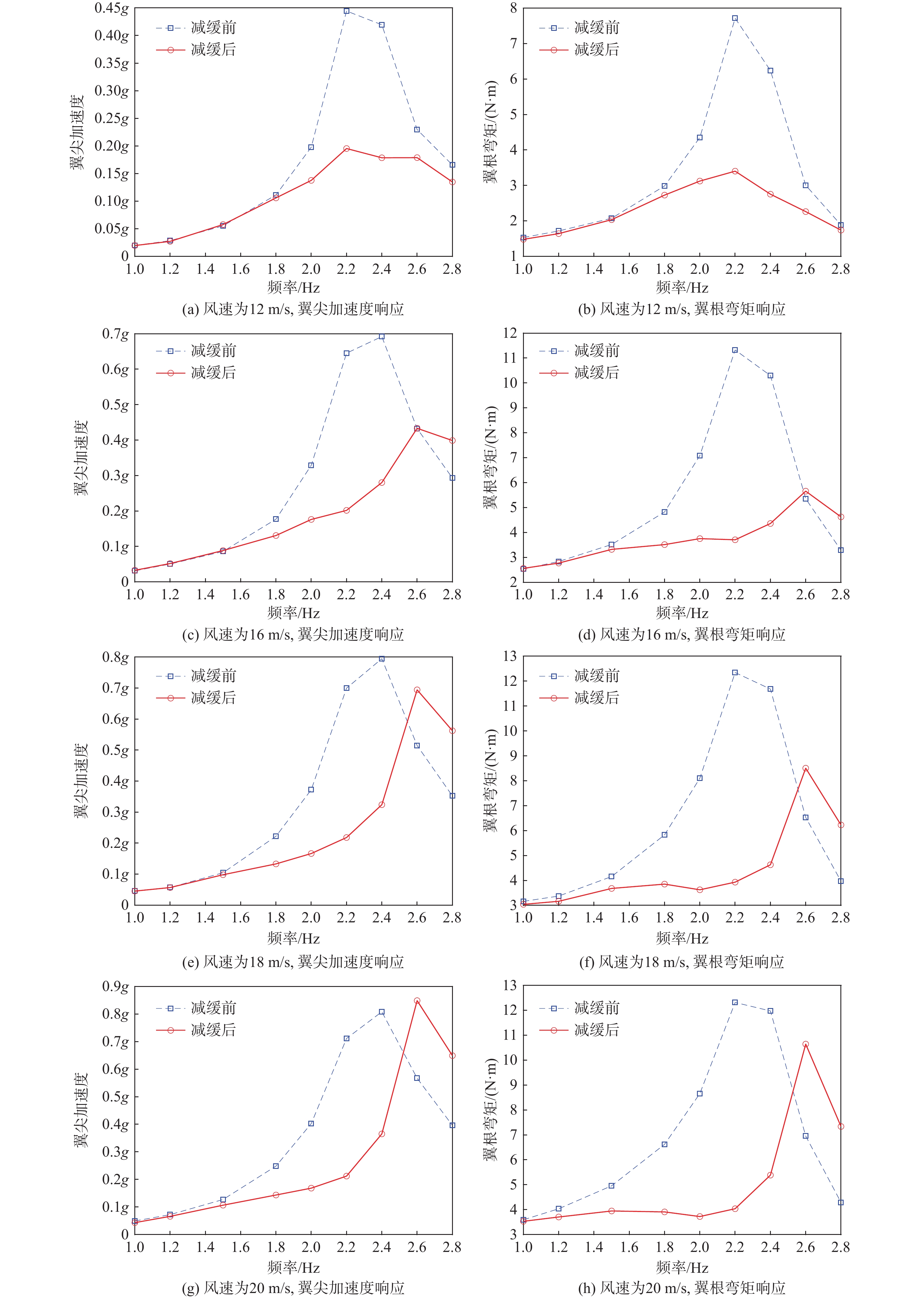

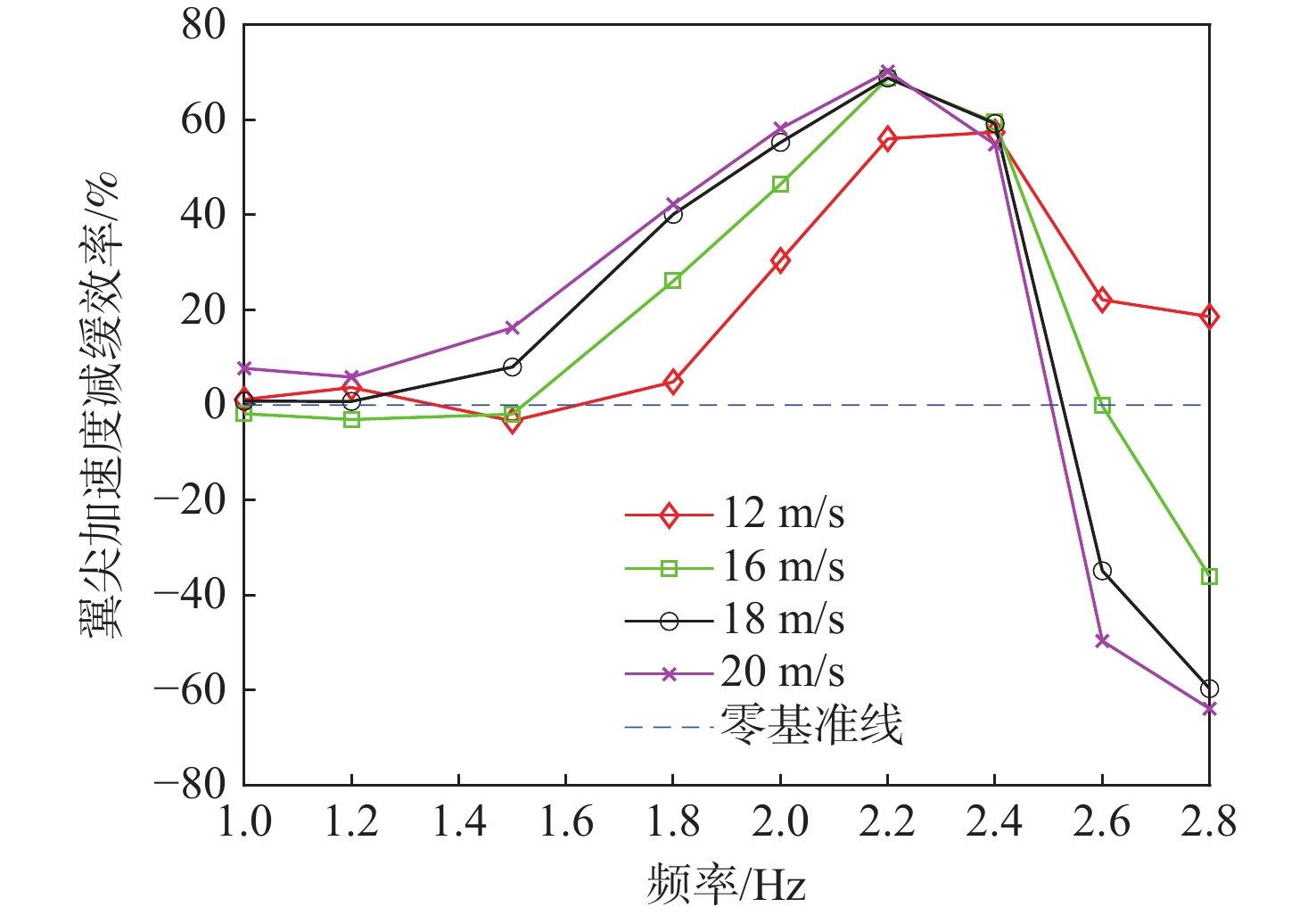

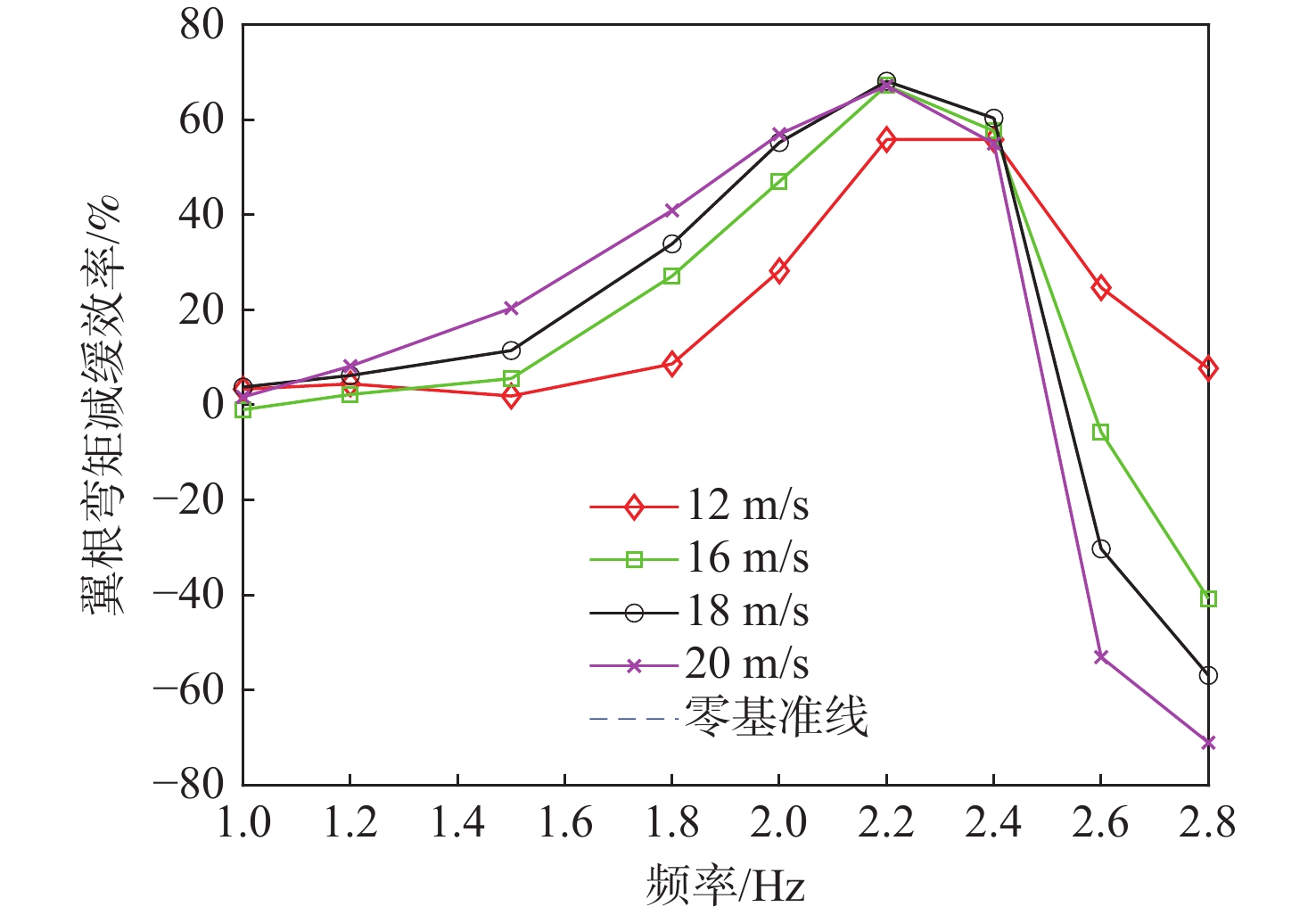

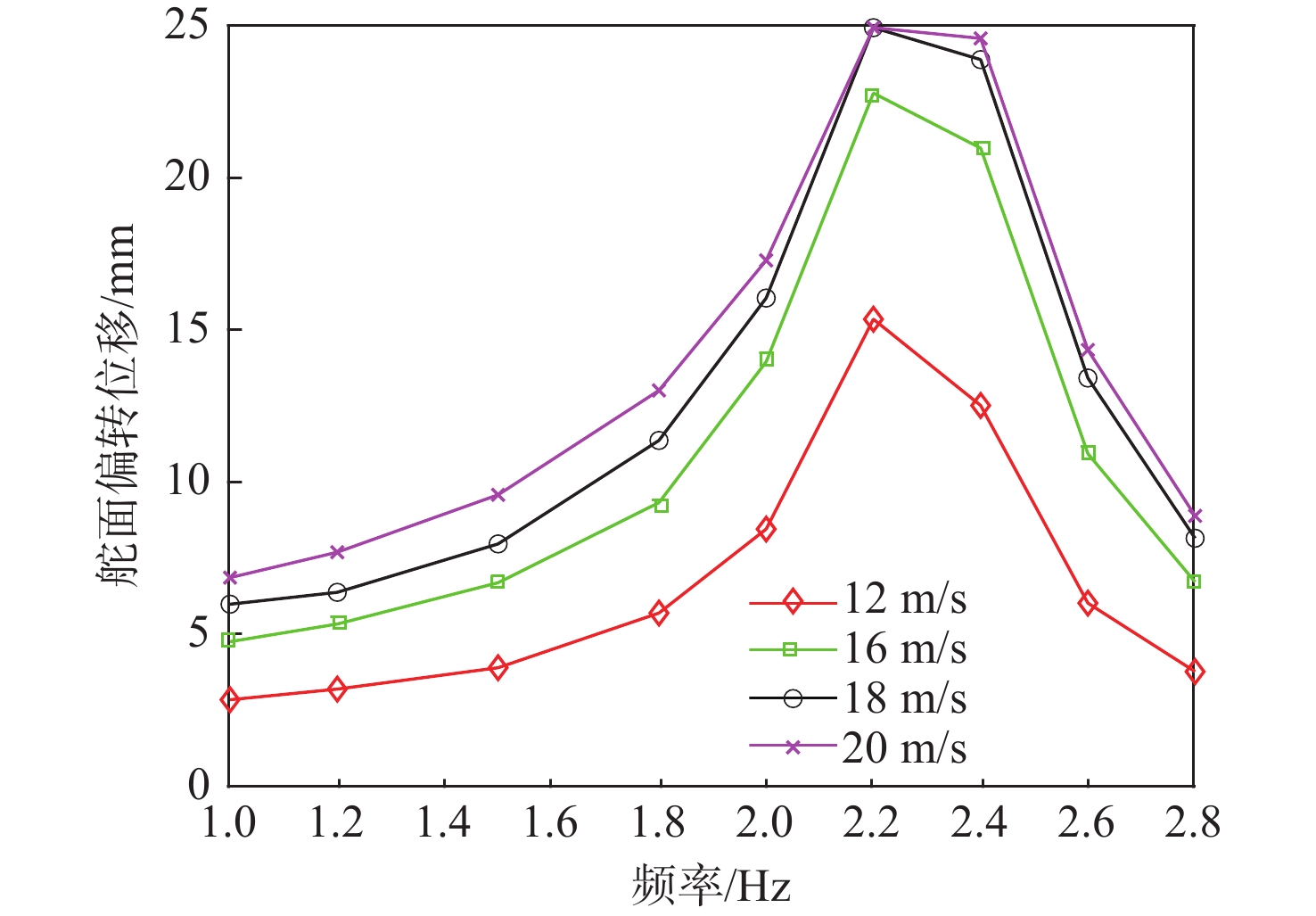

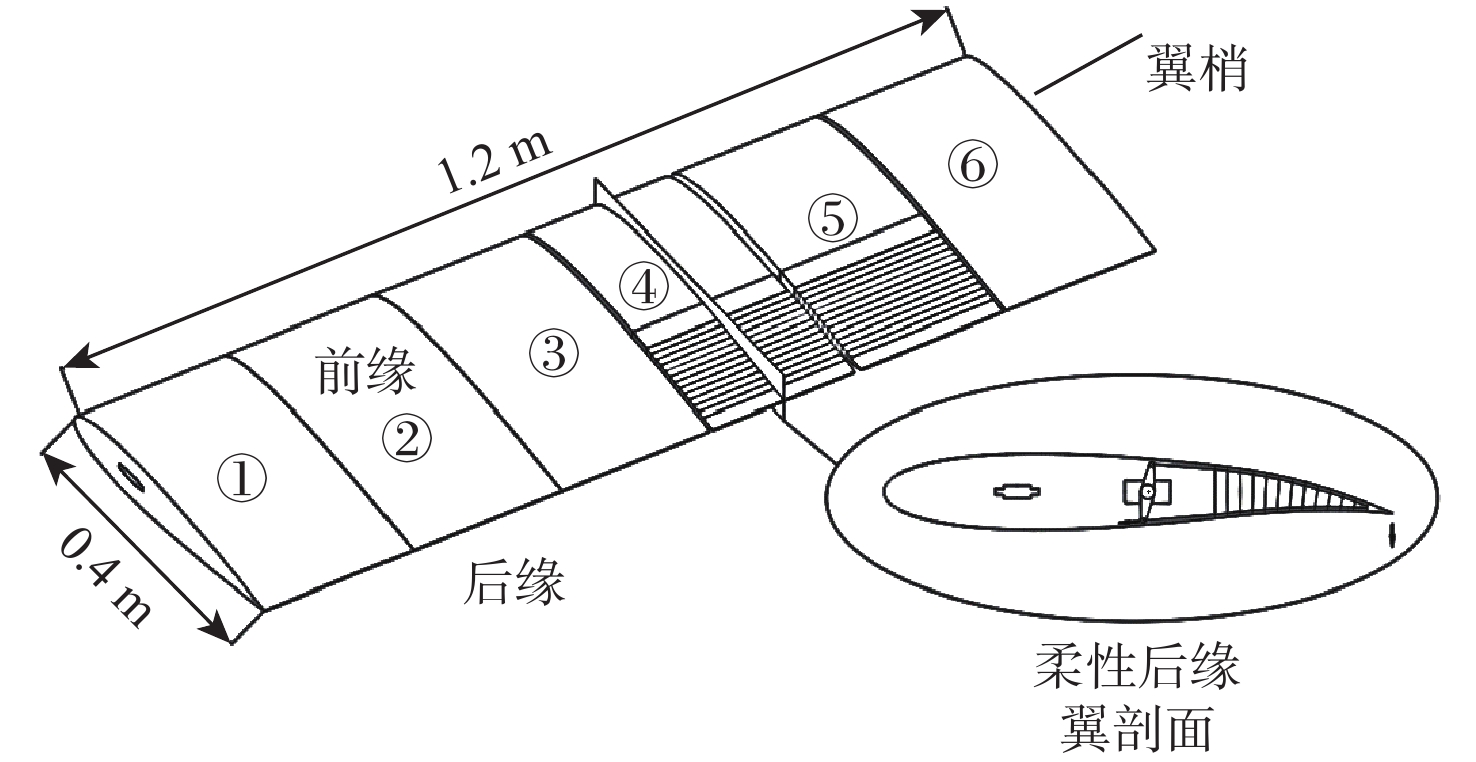

变体飞行器能显著提升飞行器的气动性能,而变弯度柔性后缘是实现变体飞行器的重要方式之一。为探究柔性后缘动态偏转下机翼动响应特性及减缓效率 ,设计了一个变弯度柔性后缘机翼模型并开展了风洞试验。该机翼模型由承弯翼梁和6个3D打印的翼段组成。其中,2个翼段后缘分别设计2个变弯度柔性后缘舵面,这2个舵面分别用于动响应激励和动响应减缓控制。变弯度柔性后缘舵面由数字舵机、柔性索、波纹板结构和聚二甲基硅氧烷(PDMS)柔性蒙皮组成。对变弯度柔性后缘进行地面静态偏转试验和地面动态偏转试验测试,以研究后缘弯度变形规律及舵机动态时滞特性。在此基础上,在低速风洞试验中研究变弯度柔性后缘机翼动响应规律和基于变弯度柔性和闭环反馈控制的动响应减缓效率。风洞试验结果表明:机翼的翼尖加速度响应及翼根弯矩在频率为1.5~4 Hz时先增大后减小,并在接近机翼一弯频率时达到峰值。采用PID控制律和变弯度后缘进行闭环反馈控制后,在风速20 m/s、扰动频率2.2 Hz时翼尖加速度最大减缓效率达到70.18%,翼根弯矩的最大减缓效率为68.14%。此外,还提出了动响应减缓效率为正值的理论公式并分析了动响应减缓效率的影响机制和因素。

Abstract:Morphing aircraft can significantly enhance the aerodynamic performance of the aircraft, and variable camber flexible trailing edge is one of the important ways to achieve this. To investigate the dynamic response characteristics and alleviation efficiency of the wing under the dynamic deflection of flexible trailing edge, a variable camber flexible trailing edge wing model was designed and a wind tunnel tests was conducted. The wing model consisted of a bending wing beam and six 3D-printed wing panels. Two variable-camber flexible trailing edge rudder surfaces were installed at the trailing edge of two wing panels. These two rudder surfaces were used for dynamic response excitation and dynamic response alleviation control, respectively. The variable-camber flexible trailing edge rudder surface was composed of a digital actuator, flexible cables, a corrugated plate structure, and a flexible polydimethylsiloxane (PDMS) skin. Ground static and dynamic deflection tests were carried out for the variable-camber flexible trailing edge, so as to investigate the camber deformation law of the trailing edge and the dynamic time-delayed characteristics of the actuator. On this basis, a low-speed wind tunnel test was carried out to investigate the dynamic response law of the wing with variable-camber flexible trailing edge and the dynamic response alleviation efficiency based on variable-camber flexible trailing edge and closed-loop feedback control. The wind tunnel test results show that the wing tip acceleration response and the wing root bending moment increase first and then decrease in the frequency range of 1.5–4 Hz, and it reaches the peak value when approaching the first bending frequency of the wing. After closed-loop feedback control by proportional-integral-derivative (PID) control law and variable-camber flexible trailing edge, the maximum alleviation efficiency of the wing tip acceleration and wing root bending moment is 70.18% and 68.14%, respectively, at a wind speed of 20 m/s and disturbance frequency of 2.2 Hz. A theoretical formula with positive dynamic response alleviation efficiency was proposed, and the influencing mechanism and factors of dynamic response alleviation efficiency were analyzed.

-

Key words:

- flexible trailing edge /

- variable camber /

- dynamic response /

- alleviation efficiency /

- wind tunnel test

-

表 1 地面试验测量的前3阶模态频率

Table 1. First three modal frequencies measured by ground tests

模态名称 频率/Hz 面外一弯 2.3 面外二弯 14.9 一扭 24.5 表 2 2.6 Hz动响应减缓效率分析

Table 2. Dynamic response alleviation efficiency at 2.6 Hz

风速/(m·s−1) β0/(°) β1/(°) cos(φ0−φ1) F1/2F0 12 −151 −33 0.469 0.465 16 −198 −33 0.967 1.186 18 −113 −33 −0.171 1.457 20 −94 −33 −0.481 1.705 表 3 2.8 Hz动响应减缓效率分析

Table 3. Dynamic response alleviation efficiency at 2.8 Hz

风速/(m·s−1) β0/(°) β1/(°) cos(φ0−φ1) F1/2F0 12 −205 −67 0.758 0.426 16 −277 −67 0.853 1.109 18 −288 −67 0.747 1.299 20 −318 −67 0.301 1.414 -

[1] MCGOWAN A M R, VICROY D D, BUSAN R C, et al. Perspectives on Highly adaptive or morphing aircraft[C]//NATO RTO AVT-168 Symposium. Lisbon: NTRS, 2009: RTO-MP-AVT-168. [2] MAJID T, JO B W. Comparative aerodynamic performance analysis of camber morphing and conventional airfoils[J]. Applied Sciences, 2021, 11(22): 10663. doi: 10.3390/app112210663 [3] 祝连庆, 孙广开, 李红, 等. 智能柔性变形机翼技术的应用与发展[J]. 机械工程学报, 2018, 54(14): 28-42.ZHU L Q, SUN G K, LI H, et al. Intelligent and flexible morphing wing technology: A review[J]. Journal of Mechanical Engineering, 2018, 54(14): 28-42 (in Chinese). [4] SOFLA A Y N, MEGUID S A, TAN K T, et al. Shape morphing of aircraft wing: Status and challenges[J]. Materials & Design, 2010, 31(3): 1284-1292. [5] THILL C, ETCHES J, BOND I, et al. Morphing skins[J]. The Aeronautical Journal, 2008, 112(1129): 117-139. doi: 10.1017/S0001924000002062 [6] BARBARINO S, BILGEN O, AJAJ R M, et al. A review of morphing aircraft[J]. Journal of Intelligent Material Systems and Structures, 2011, 22(9): 823-877. doi: 10.1177/1045389X11414084 [7] 冷劲松, 孙健, 刘彦菊. 智能材料和结构在变体飞行器上的应用现状与前景展望[J]. 航空学报, 2014, 35(1): 29-45.LENG J S, SUN J, LIU Y J. Application status and future prospect of smart materials and structures in morphing aircraft[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(1): 29-45 (in Chinese). [8] ISMAIL N I, ZULKIFLI A H, ABDULLAH M Z, et al. Optimization of aerodynamic efficiency for twist morphing MAV wing[J]. Chinese Journal of Aeronautics, 2014, 27(3): 475-487. doi: 10.1016/j.cja.2014.04.017 [9] HUANG R, QIU Z P. Transient aeroelastic responses and flutter analysis of a variable-span wing during the morphing process[J]. Chinese Journal of Aeronautics, 2013, 26(6): 1430-1438. doi: 10.1016/j.cja.2013.07.047 [10] KOREANSCHI A, SUGAR GABOR O, ACOTTO J, et al. Optimization and design of an aircraft’s morphing wing-tip demonstrator for drag reduction at low speed, Part I—Aerodynamic optimization using genetic, bee colony and gradient descent algorithms[J]. Chinese Journal of Aeronautics, 2017, 30(1): 149-163. doi: 10.1016/j.cja.2016.12.013 [11] KOREANSCHI A, GABOR O S, ACOTTO J, et al. Optimization and design of an aircraft’s morphing wing-tip demonstrator for drag reduction at low speeds, Part II - Experimental validation using Infra-Red transition measurement from Wind Tunnel tests[J]. Chinese Journal of Aeronautics, 2017, 30(1): 164-174. doi: 10.1016/j.cja.2016.12.018 [12] LI D C, LIU Q C, WU Y N, et al. Design and analysis of a morphing drag rudder on the aerodynamics, structural deformation, and the required actuating moment[J]. Journal of Intelligent Material Systems and Structures, 2018, 29(6): 1038-1049. doi: 10.1177/1045389X17730910 [13] AJAJ R M, PARANCHEERIVILAKKATHIL M S, AMOOZGAR M, et al. Recent developments in the aeroelasticity of morphing aircraft[J]. Progress in Aerospace Sciences, 2021, 120: 100682. doi: 10.1016/j.paerosci.2020.100682 [14] MOLINARI G, QUACK M, ARRIETA A F, et al. Design, realization and structural testing of a compliant adaptable wing[J]. Smart Material Structures, 2015, 24(10): 105027. doi: 10.1088/0964-1726/24/10/105027 [15] TAKAHASHI H, YOKOZEKI T, HIRANO Y. Development of variable camber wing with morphing leading and trailing sections using corrugated structures[J]. Journal of Intelligent Material Systems and Structures, 2016, 27(20): 2827-2836. doi: 10.1177/1045389X16642298 [16] WOODS B K S, FINCHAM J H S, FRISWELL M I. Aerodynamic modelling of the fish bone active camber morphing concept[C]//Proceedings of the RAeS Applied Aerodynamics Conference. Bristol: The Aeromatical Journal, 2014: 2224. [17] ZHAO S W, LI D C, ZHOU J, et al. Numerical and experimental study of a flexible trailing edge driving by pneumatic muscle actuators[J]. Actuators, 2021, 10(7): 142. doi: 10.3390/act10070142 [18] 雷朝辉, 宋晨, 张桢锴, 等. 后缘柔性可变形翼肋模块设计分析与试验[J]. 工程与试验, 2020, 60(4): 16-22.LEI C H, SONG C, ZHANG Z K, et al. Design, analysis and test of morphing trailing edge flexible rib[J]. Engineering & Test, 2020, 60(4): 16-22 (in Chinese). [19] PECORA R, AMOROSO F, SICIM M S. Design of a morphing test-article for large-scale, high-speed wind tunnel tests of an adaptive wing flap[C]//Active and Passive Smart Structures and Integrated Systems XV. San Diego: SPIE, 2021, 11588: 7-15. [20] RIVERO A E, FOURNIER S, MANOLESOS M, et al. Wind tunnel comparison of flapped and FishBAC camber variation for lift control[C]// Proceedings of the AIAA Scitech 2020 Forum. Reston: AIAA, 2020: 1300. [21] VARTIO E, SHAW E, VETTER T. Gust load alleviation flight control system design for a SensorCraft vehicle[C]// Proceedings of the 26th AIAA Applied Aerodynamics Conference. Reston: AIAA, 2008: 7192. [22] WONG A, BIL C, MARINO M. Design and aerodynamic performance of a FishBAC morphing wing[C]// Proceedings of the AIAA SCITECH 2022 Forum. Reston: AIAA, 2022: 1298. [23] LU C. Development of variable camber continuous trailing edge flap for performance adaptive aeroelastic wing[C]// Multidisciplinary Design Analysis and Optimization of Aerospace Composites. Piscataway: IEEE Press, 2020: 67-122. [24] NGUYEN N T, CRAMER N B, HASHEMI K E, et al. Progress on gust load alleviation wind tunnel experiment and aeroservoelastic model validation for a flexible wing with variable camber continuous trailing edge flap system[C]// Proceedings of the AIAA Scitech 2020 Forum. Reston: AIAA, 2020: 0214. -

下载:

下载: