Analysis of effect of construction process on electrical properties of composite skins

-

摘要:

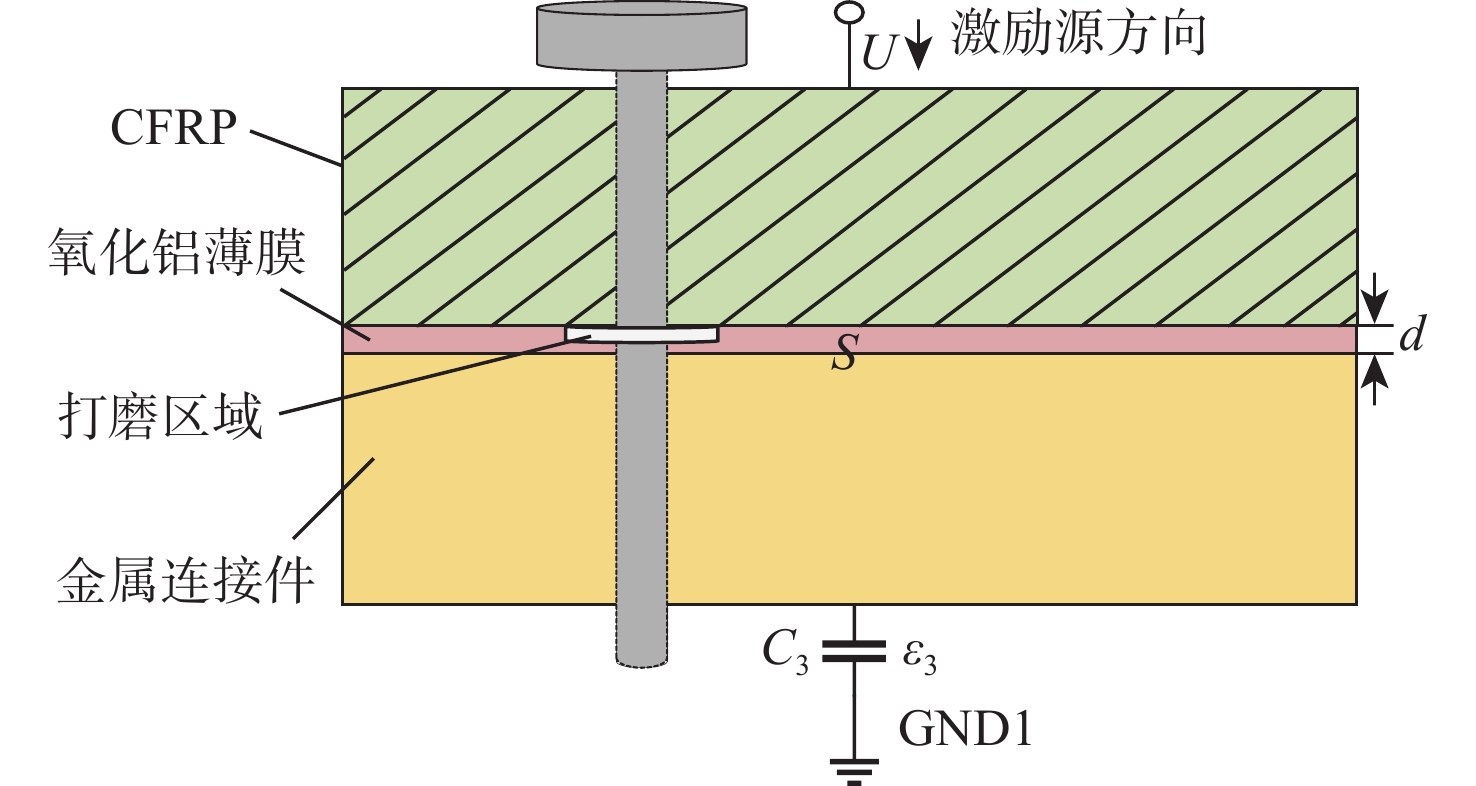

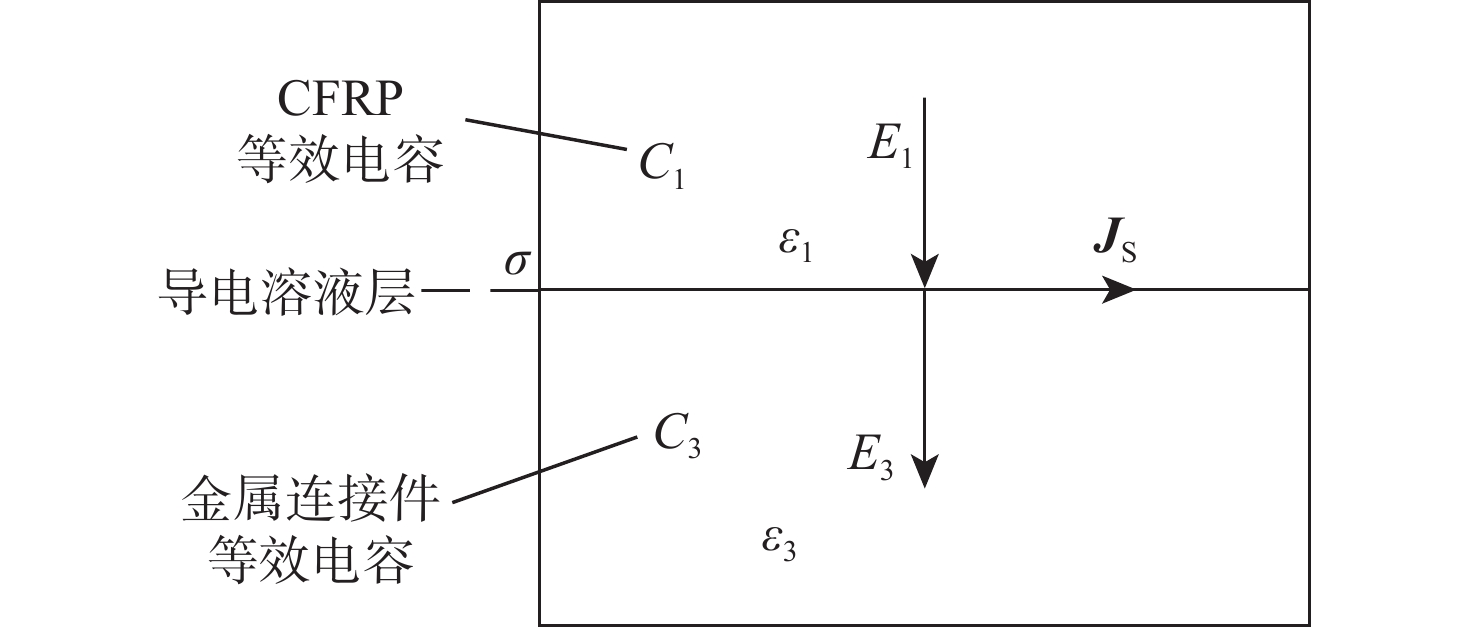

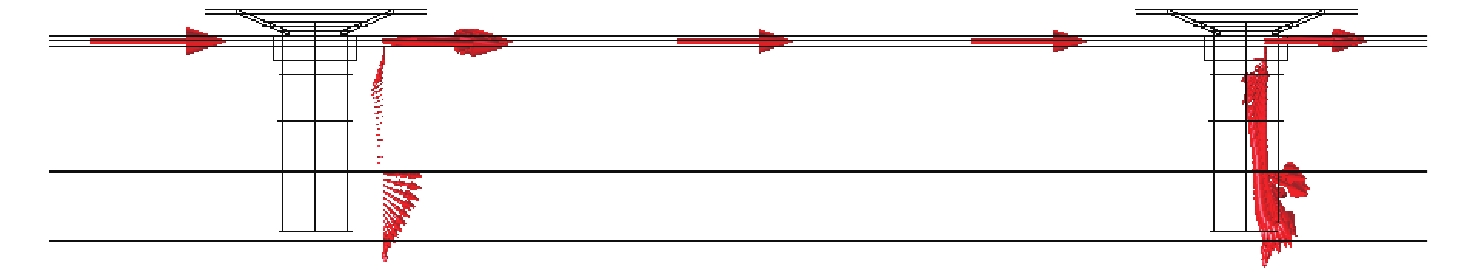

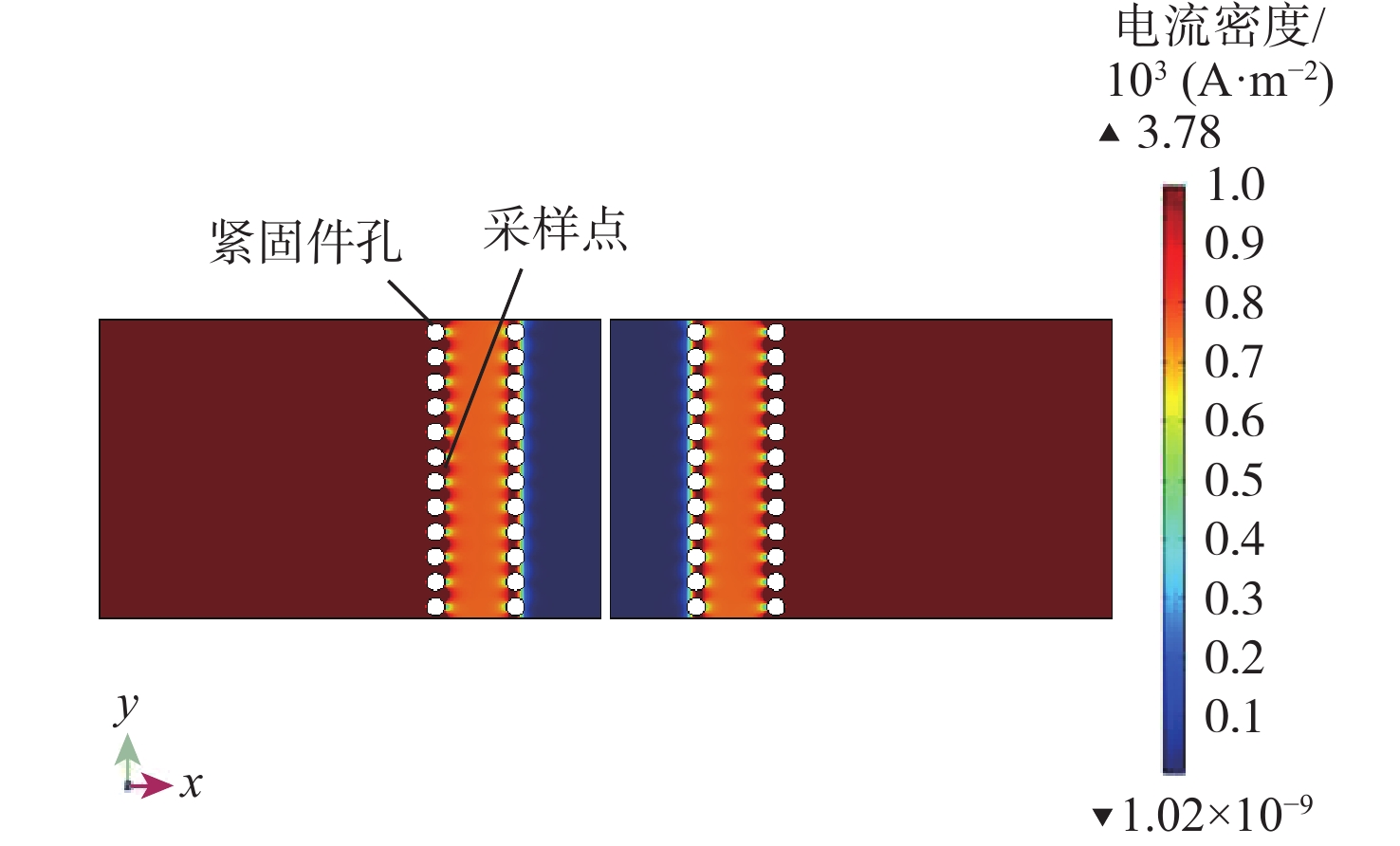

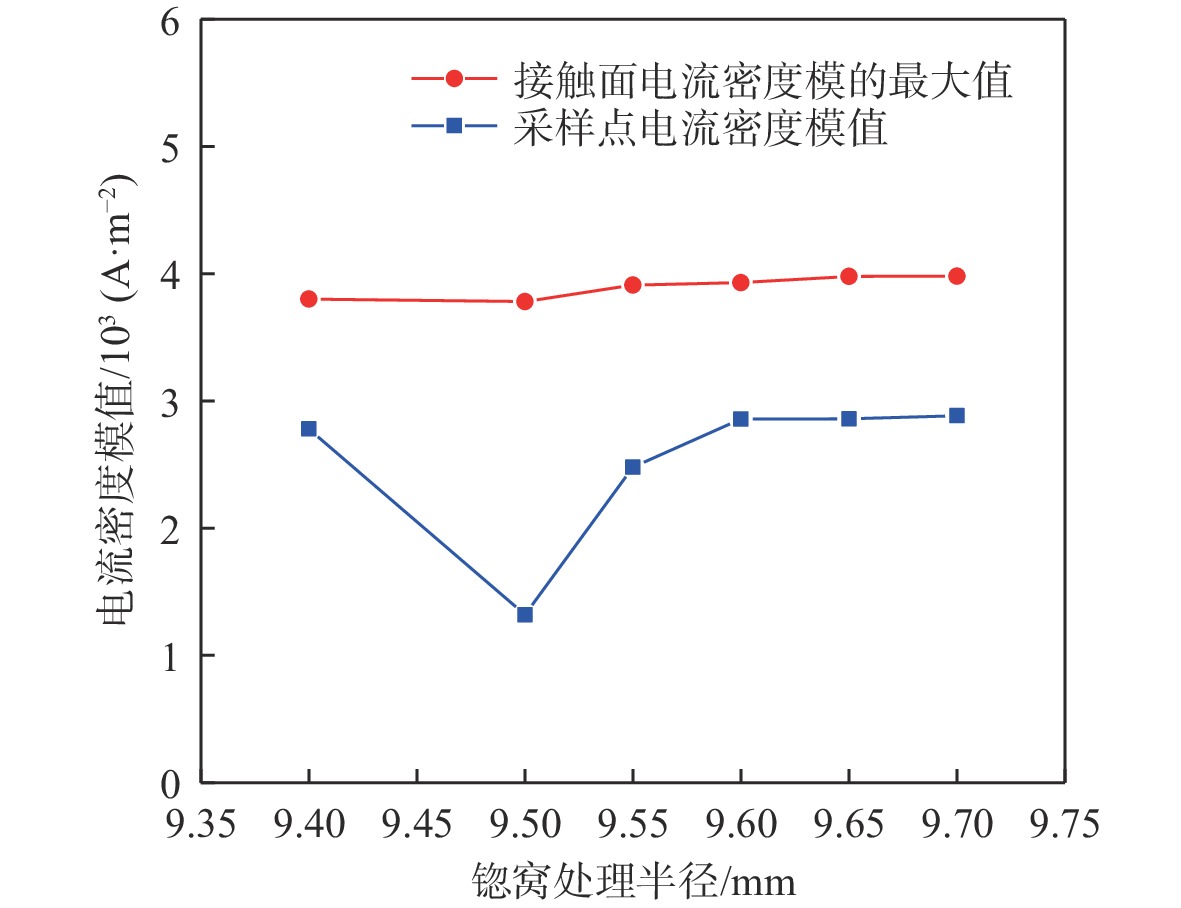

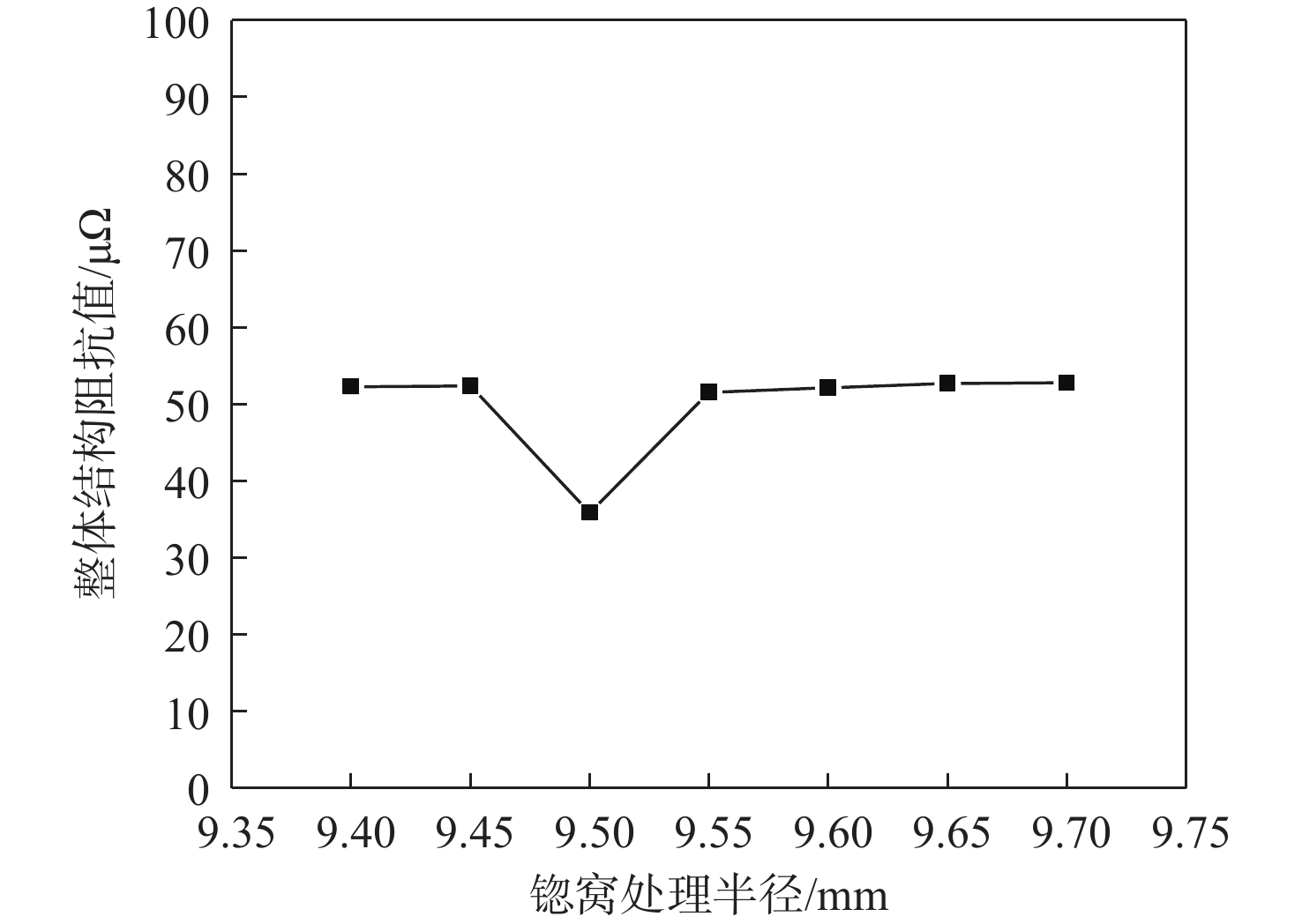

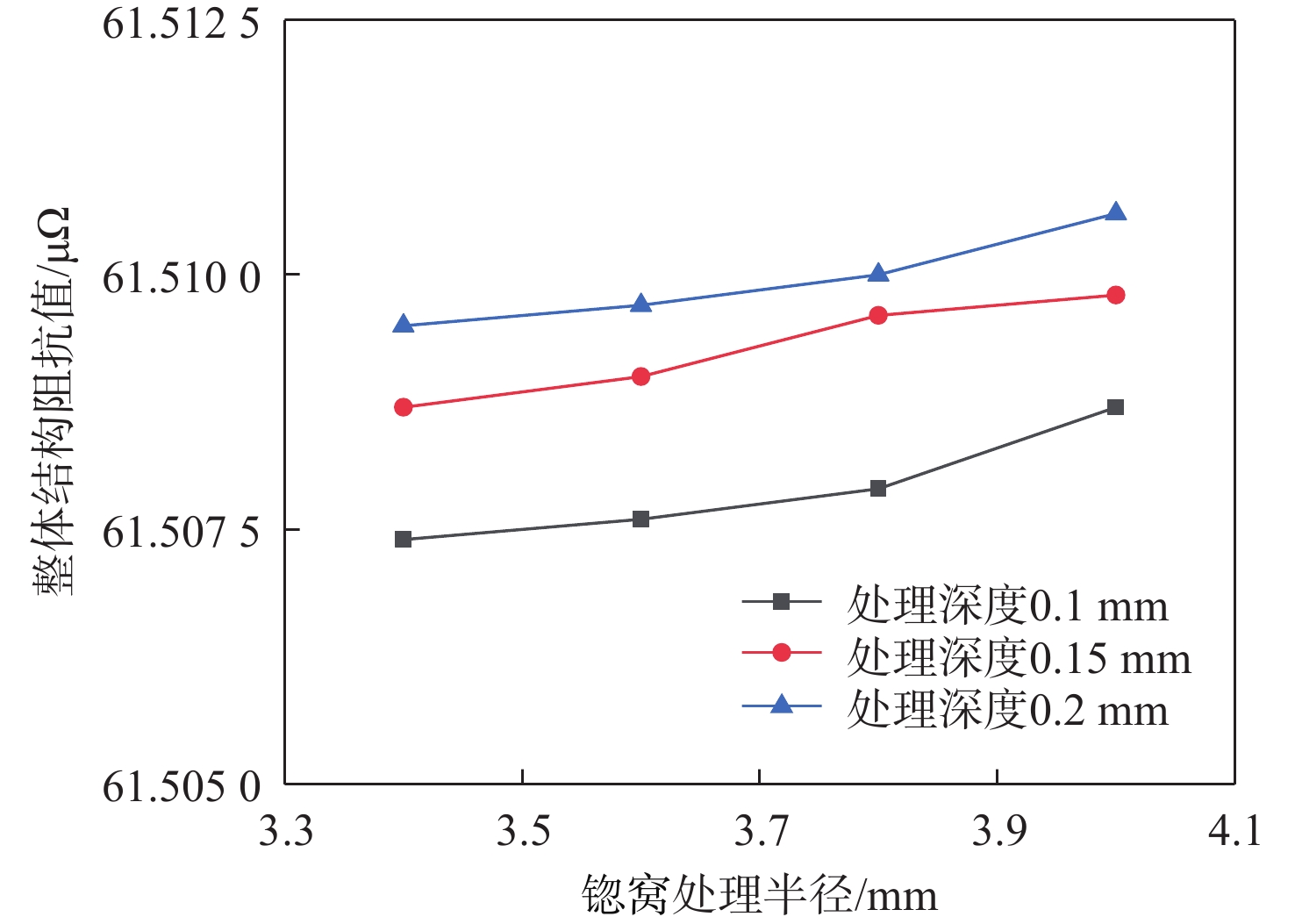

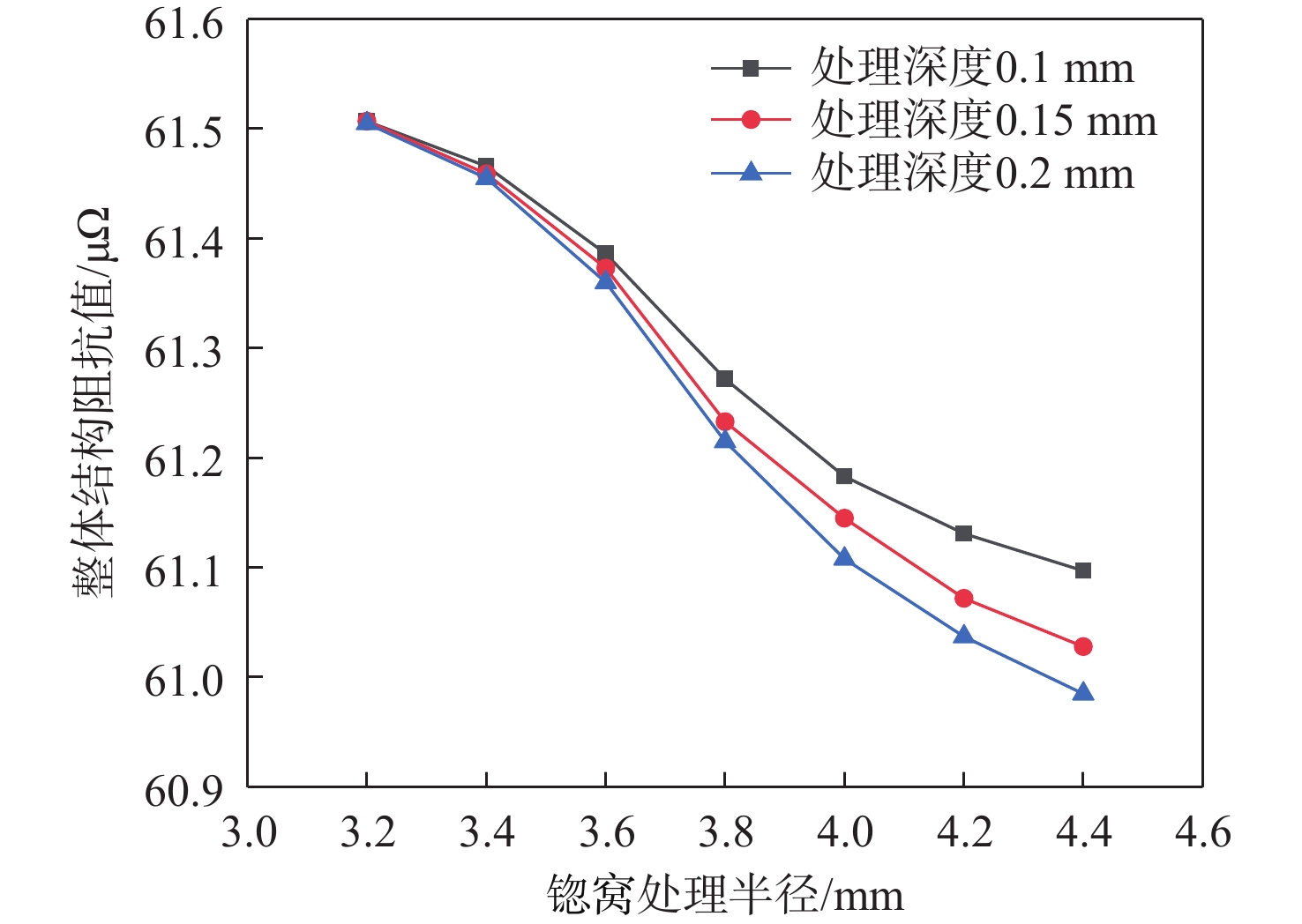

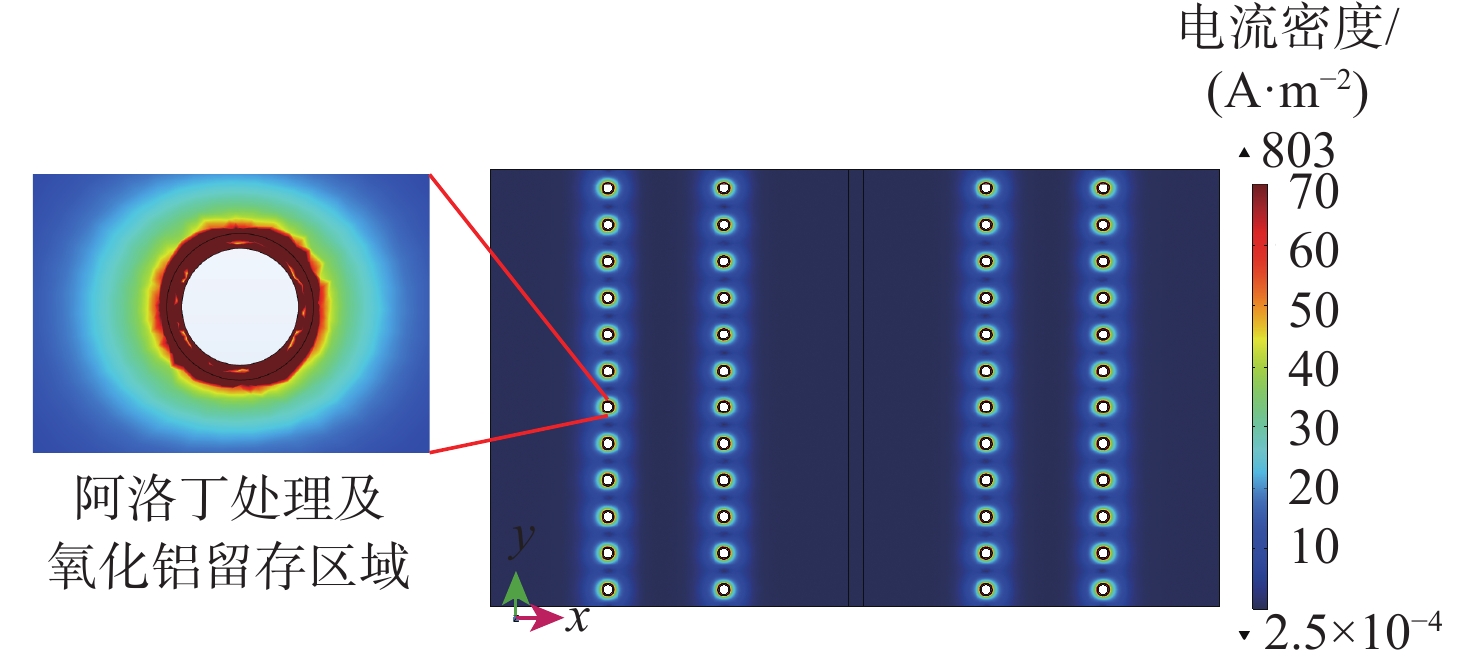

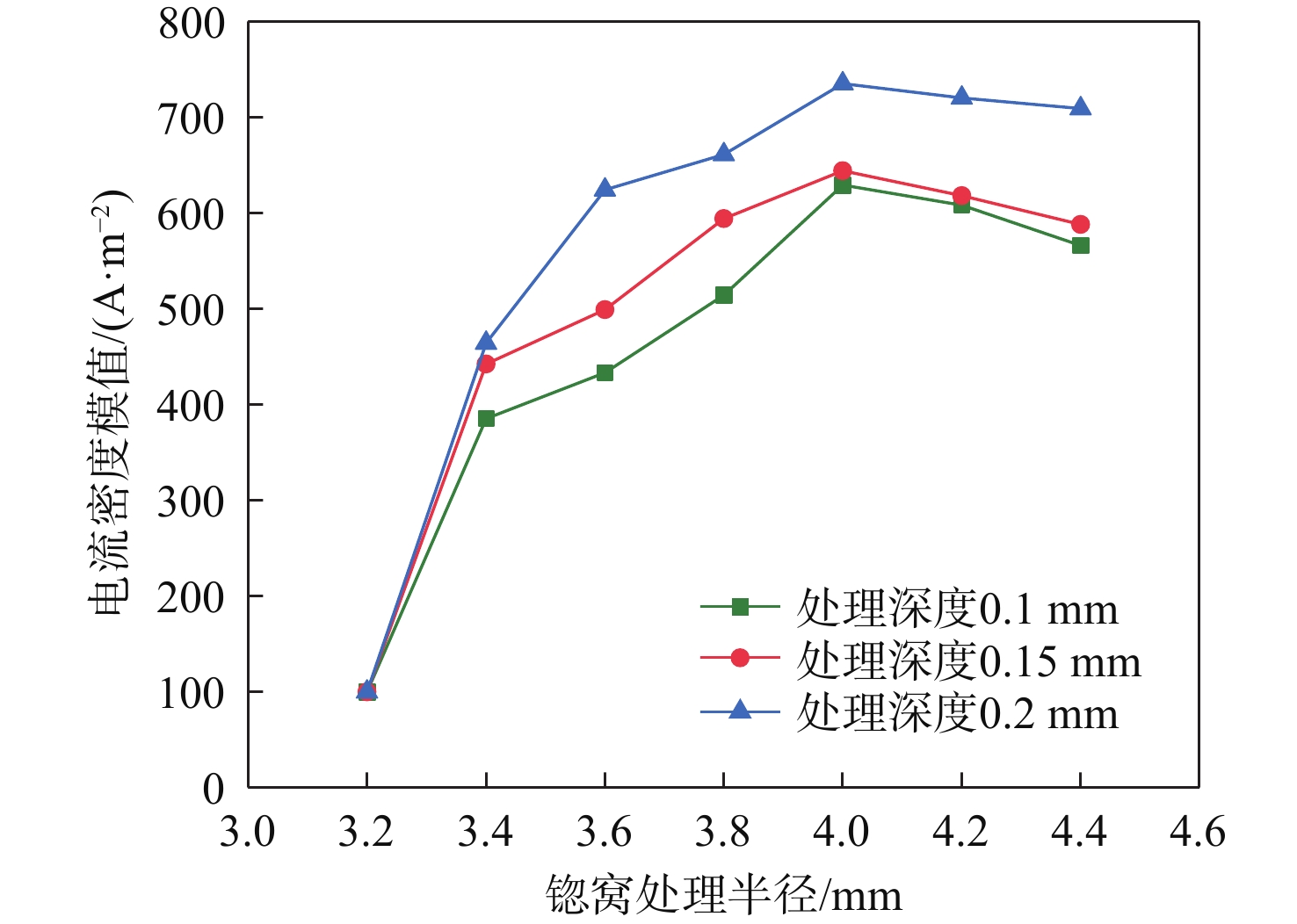

新型商用飞机蒙皮中复合材料的占比越来越高,然而较差的导电性使其需要额外的导电结构实现电流在蒙皮内的流通。为提高蒙皮导电能力,降低复合材料与导电结构的搭接对电流通路的影响,基于各组成结构的电气特性对蒙皮结构进行建模,并利用解析方法分析搭接时可能产生影响的施工工艺。针对蒙皮不同部位各自处理工艺带来的接触面间的电流与整体结构阻抗的变化,分析各结构在装配过程中的施工工艺对飞机蒙皮搭接结构电气特性的影响情况。理论分析与仿真计算结果表明:正确的施工工艺处理方法,尤其是对蒙皮表面树脂与金属连接件氧化膜恰当的处理程度,能够有效减小整体结构阻抗对蒙皮电气性能的影响,并能够为面向现场的施工提供一定的操作建议。

Abstract:Composite materials are increasingly used in modern commercial aircraft skin. However, the poor conductivity makes it necessary to have additional conductive structures to ensure the current flow in the skin. In order to improve the conductivity of the skin and reduce the influence of the bonding between the composite material and the conductive structure on the current path, the skin structure was modeled based on the electrical characteristics of each component structure, and the construction process that may affect the bonding was analyzed by using the analytical method. In view of the changes in the current in the contact surfaces and the overall structural impedance caused by different construction processes applied at different parts of the skin, the influence of the construction process of each structure during assembly on the electrical characteristics of the aircraft skin bonding structure was analyzed. Theoretical analysis and simulation results show that the appropriate construction process, especially the correct treatment of the resin and oxide film of metal connection on the skin surface, can effectively reduce the influence of overall structural impedance on the electrical performance of the skin and provide some operational suggestions in site-oriented construction.

-

Key words:

- aircraft skin /

- composite material /

- bonding structure /

- construction process /

- electrical performance

-

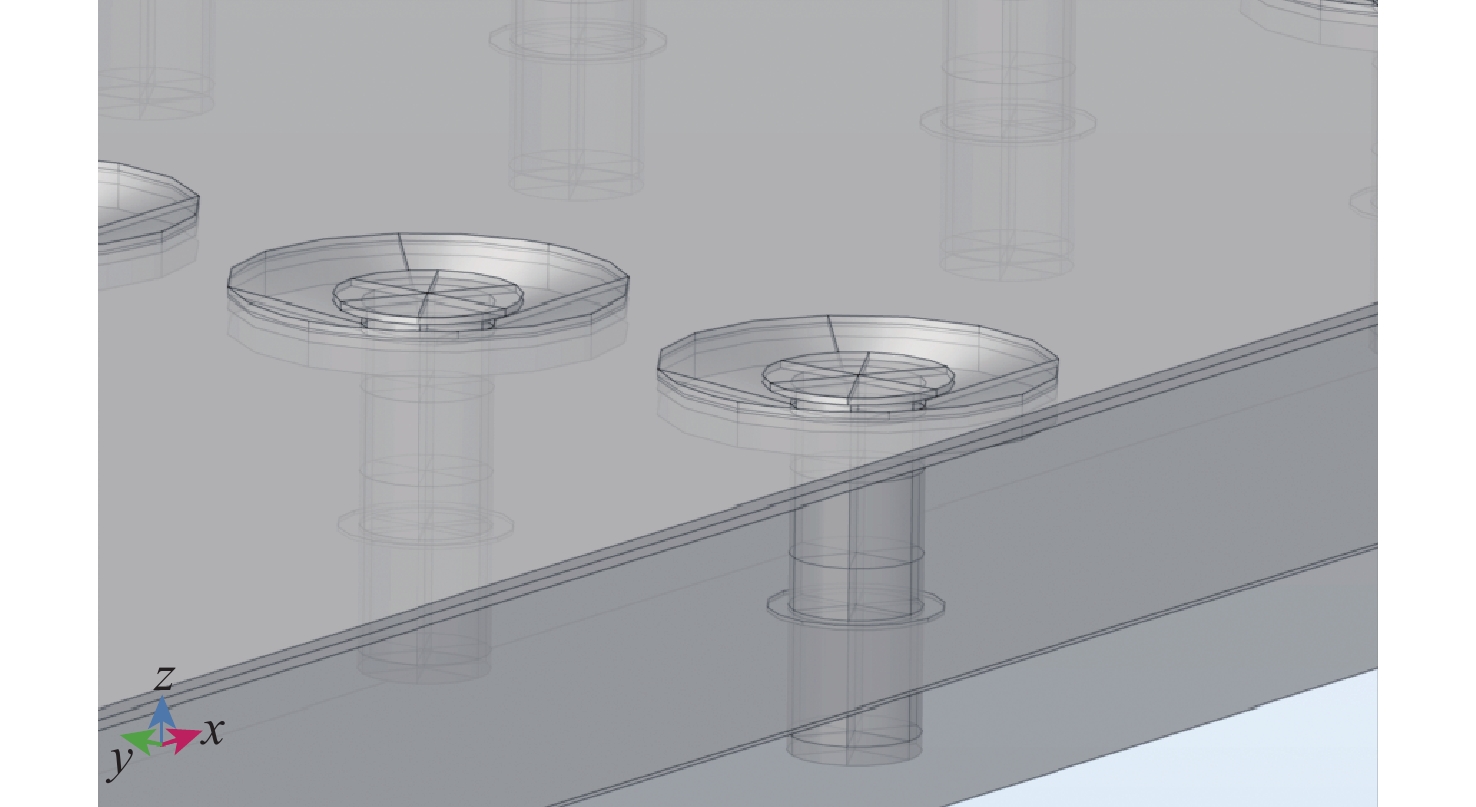

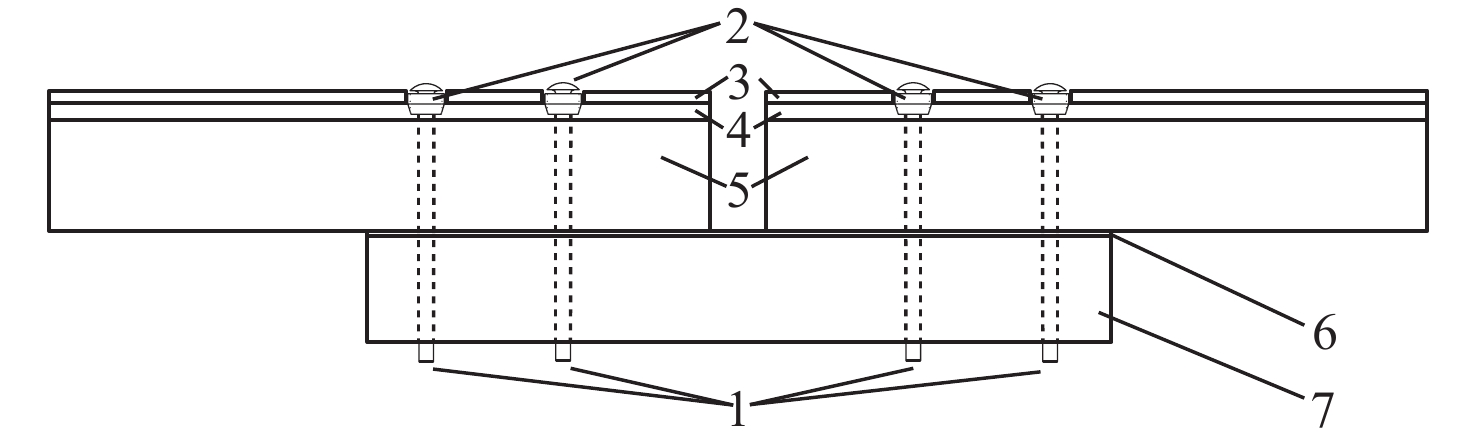

表 1 螺栓与凹形垫圈的尺寸

Table 1. Dimensions of bolts and concave washers

mm 结构 参数 沉头螺栓总长度 18 沉头螺栓螺杆直径 6.4 沉头螺栓头直径 9 沉头螺栓头厚度 0.5 凹形垫圈高度 2.2 凹形垫圈内径 6.45 凹形垫圈外径 19 凹形垫圈厚度 0.4 表 2 各结构件材质及电磁参数

Table 2. Material and electromagnetic parameters of each component

部件名称 材质 电导率/(S·m−1) 延展金属箔 铜 5.998×107 CFRP 碳纤维复合材料 1.5×104 金属氧化膜 氧化铝 0.01 金属连接件 铝 3.03×107 沉头螺栓 钢 4.032×106 凹形垫圈 钛 2.38×106 -

[1] 刘国春, 郭荣辉, 秦文峰. 民用飞机复合材料结构制造与维修[M]. 北京: 清华大学出版社, 2020: 10-11.LIU G C, GUO R H, QIN W F. Manufacture and maintenance of composite structure of civil aircraft[M]. Beijing: Tsinghua University Press, 2020: 10-11(in Chinese). [2] GOLEANU A, DUNAND M, FREYCON A, et al. Search for quasi-optimal current return paths in a composite environment[C]//Proceedings of the 10th International Symposium on Electromagnetic Compatibility. Piscataway: IEEE Press, 2011: 254-259. [3] JONES C E, SZTYKIEL M, PEÑA-ALZOLA R, et al. Grounding topologies for resilient, integrated composite electrical power systems for future aircraft applications[C]//Proceedings of the AIAA/IEEE Electric Aircraft Technologies Symposium. Piscataway: IEEE Press, 2019: 1-15. [4] US Air Force. Military specification, bonding, electrical and lighting protection for aerospace systems: MIL-STD-464A[S]. Washington, D. C. : US Department of Defense, 2002. [5] GOLEANU A L, DUNAND M, GUICHON J M, et al. Towards the conception and optimisation of the current return path in a composite aircraft[C]//Proceedings of the IEEE International Systems Conference. Piscataway: IEEE Press, 2010: 466-471. [6] 张宇. 复合材料飞机的电流回路接地技术研究[J]. 航空科学技术, 2011, 22(6): 27-30. doi: 10.3969/j.issn.1007-5453.2011.06.009ZHANG Y. Research of current return path of composite aircraft[J]. Aeronautical Science & Technology, 2011, 22(6): 27-30(in Chinese). doi: 10.3969/j.issn.1007-5453.2011.06.009 [7] JONES C E, NORMAN P J, GALLOWAY S J, et al. Electrical model of carbon fibre reinforced polymers for the development of electrical protection systems for more-electric aircraft[C]//Proceedings of the 18th European Conference on Power Electronics and Applications. Piscataway: IEEE Press, 2016: 1-10. [8] 易健宏, 杨平, 沈韬. 碳纳米管增强金属基复合材料电学性能研究进展[J]. 复合材料学报, 2016, 33(4): 689-703.YI J H, YANG P, SHEN T. Research progress of electrical properties for carbon nanotubes reinforced metal matrix composites[J]. Acta Materiae Compositae Sinica, 2016, 33(4): 689-703(in Chinese). [9] 郭永超, 高成, 宋双, 等. 不同激励源作用下的碳纤维复合材料的导电性能研究[C]//第22届全国电磁兼容学术会议. 北京: 人民邮电出版社, 2012: 62-66.GUO Y C, GAO C, SONG S, et al. Study of electric properties of carbon fiber composite materials using different excitation[C]//Proceedings of the 22nd National Electromagnetic Compatibility Academic Conference. Beijing: Posts & Telecom Press, 2012: 62-66(in Chinese). [10] LIN Z, SUN X, LIU S, et al. Effect of SnO2 particle size on properties of Ag-SnO2 electrical contact materials prepared by the reductive precipitation method[J]. Advanced Materials Research, 2014, 936: 459-463. doi: 10.4028/www.scientific.net/AMR.936.459 [11] WATTS P C P, HSU W K, BARNES A, et al. High permittivity from defective multiwalled carbon nanotubes in the X-band[J]. Advanced Materials, 2003, 15(7-8): 600-603. [12] CHEN P W, CHUNG D D L. Concrete as a new strain/stress sensor[J]. Composites Part B: Engineering, 1996, 27(1): 11-23. [13] CLINGERMAN M L, WEBER E H, KING J A, et al. Development of an additive equation for predicting the electrical conductivity of carbon-filled composites[J]. Journal of Applied Polymer Science, 2003, 88(9): 2280-2299. doi: 10.1002/app.11938 [14] 张强, 蔡旭龙, 王建宏. 触点制造过程表面膜电阻对接触电阻的影响[J]. 机电元件, 2014, 34(2): 43-47. doi: 10.3969/j.issn.1000-6133.2014.02.009ZHANG Q, CAI X L, WANG J H. Influence of surface film resistance on contact resistance in contact manufacturing process[J]. Electromechanical Components, 2014, 34(2): 43-47 (in Chinese). doi: 10.3969/j.issn.1000-6133.2014.02.009 [15] MALINOWSKI P H, WANDOWSKI T, OSTACHOWICZ W M. Characterisation of CFRP adhesive bonds by electromechanical impedance[C]//Proceedings of the Health Monitoring of Structural and Biological Systems. Bellingham: SPIE, 2014: 906415. [16] MALINOWSKI P H, OSTACHOWICZ W M, BRUNE K, et al. Study of electromechanical impedance changes caused by modifications of CFRP adhesive bonds[J]. Fatigue & Fracture of Engineering Materials & Structures, 2017, 40(10): 1592-1600. [17] 周猛. CFRP锪窝制孔尺寸及误差对连接结构疲劳性能的影响[D]. 天津: 天津大学, 2018: 4-5.ZHOU M. CFRP countersink hole size and error influence of fatigue performance on the connection structure[D]. Tianjin: Tianjin University, 2018: 4-5(in Chinese). [18] 王力强, 吕玲, 胡彦卿, 等. 阿洛丁1200S处理工艺参数对铝合金耐盐雾腐蚀性能的影响[J]. 腐蚀与防护, 2019, 40(12): 912-915. doi: 10.11973/fsyfh-201912009WANG L Q, LÜ L, HU Y Q, et al. Effects of processing parameters in alodine 1200S treatment on salt spray corrosion resistance of Al alloy[J]. Corrosion & Protection, 2019, 40(12): 912-915(in Chinese). doi: 10.11973/fsyfh-201912009 [19] 刘建英, 隋政, 张起浩, 等. 复合材料飞机接地回流网络建模与阻抗分析[J]. 北京航空航天大学学报, 2021, 47(5): 885-893.LIU J Y, SUI Z, ZHANG Q H, et al. Modeling and impedance analysis of composite material aircraft grounded return network[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(5): 885-893(in Chinese). [20] 杨占刚, 隋政, 张起浩, 等. 复合材料飞机接地回流网络网内压降分析[J]. 航空学报, 2022, 43(1): 324859. doi: 10.7527/j.issn.1000-6893.2022.1.hkxb202201037YANG Z G, SUI Z, ZHANG Q H, et al. Voltage drop in composite aircraft grounding and current return network[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(1): 324859(in Chinese). doi: 10.7527/j.issn.1000-6893.2022.1.hkxb202201037 [21] HARRINGTON R F. Field computation by moment methods[M]. New York: Macmillan, 1968. [22] 周琳, 黄江涛, 高正红. 基于离散伴随方程的三维雷达散射截面几何敏感度计算[J]. 航空学报, 2020, 41(5): 623361.ZHOU L, HUANG J T, GAO Z H. Three dimensional radar cross section geometric sensitivity calculation based on discrete adjoint equation[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(5): 623361(in Chinese). [23] BANDINELLI M, MORI A, GALGANI G, et al. A surface PEEC formulation for high-fidelity analysis of the current return networks in composite aircrafts[J]. IEEE Transactions on Electromagnetic Compatibility, 2015, 57(5): 1027-1036. doi: 10.1109/TEMC.2015.2422672 [24] 裴春雨. 碳纳米纤维/环氧树脂基复合材料自感知性能[D]. 大连: 大连理工大学, 2014: 12-14.PEI C Y. Self-sensing properties of carbon nanofiber/epoxy resin matrix composites materials[D]. Dalian: Dalian University of Technology, 2014: 12-14(in Chinese). -

下载:

下载: