-

摘要:

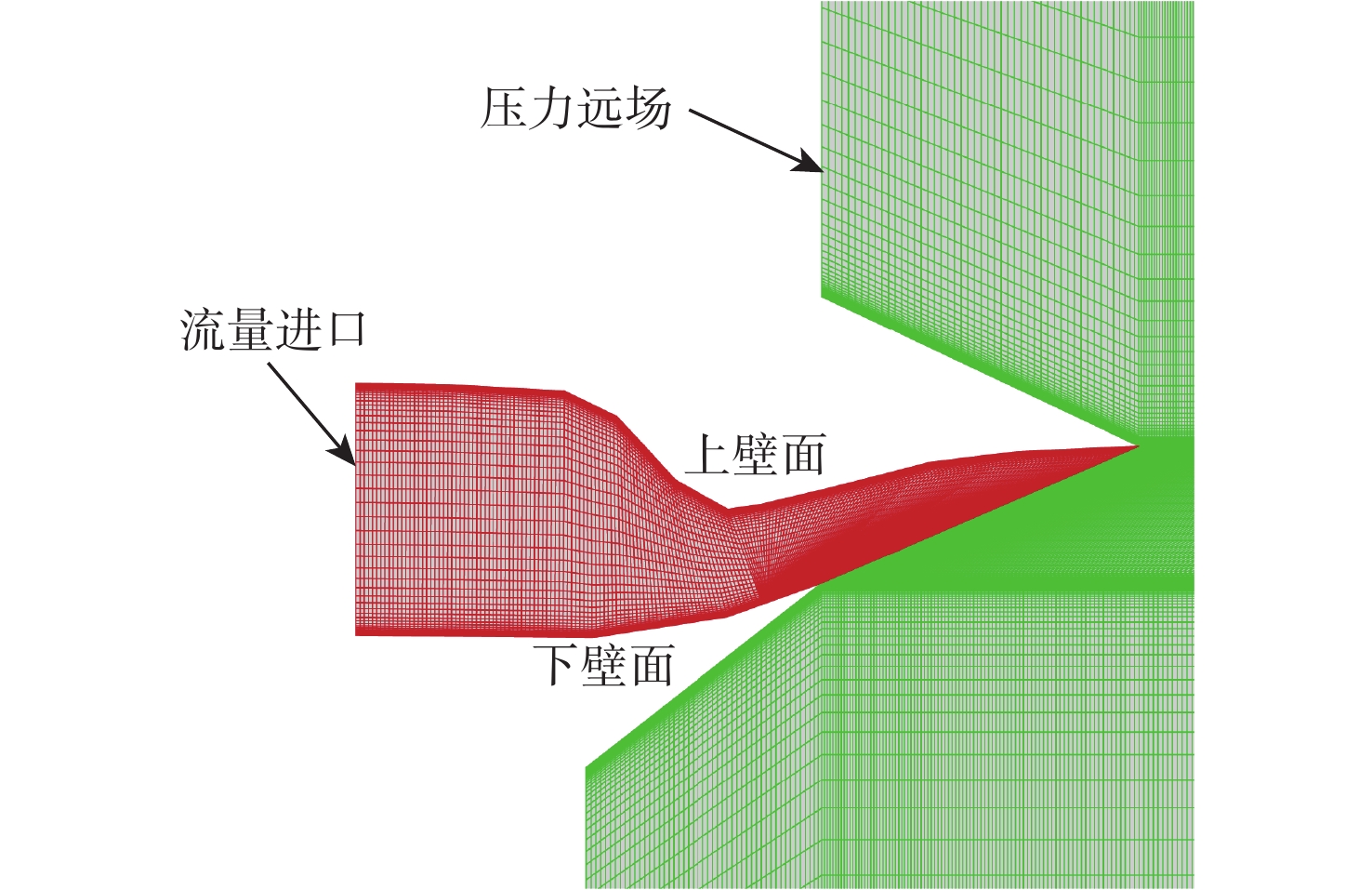

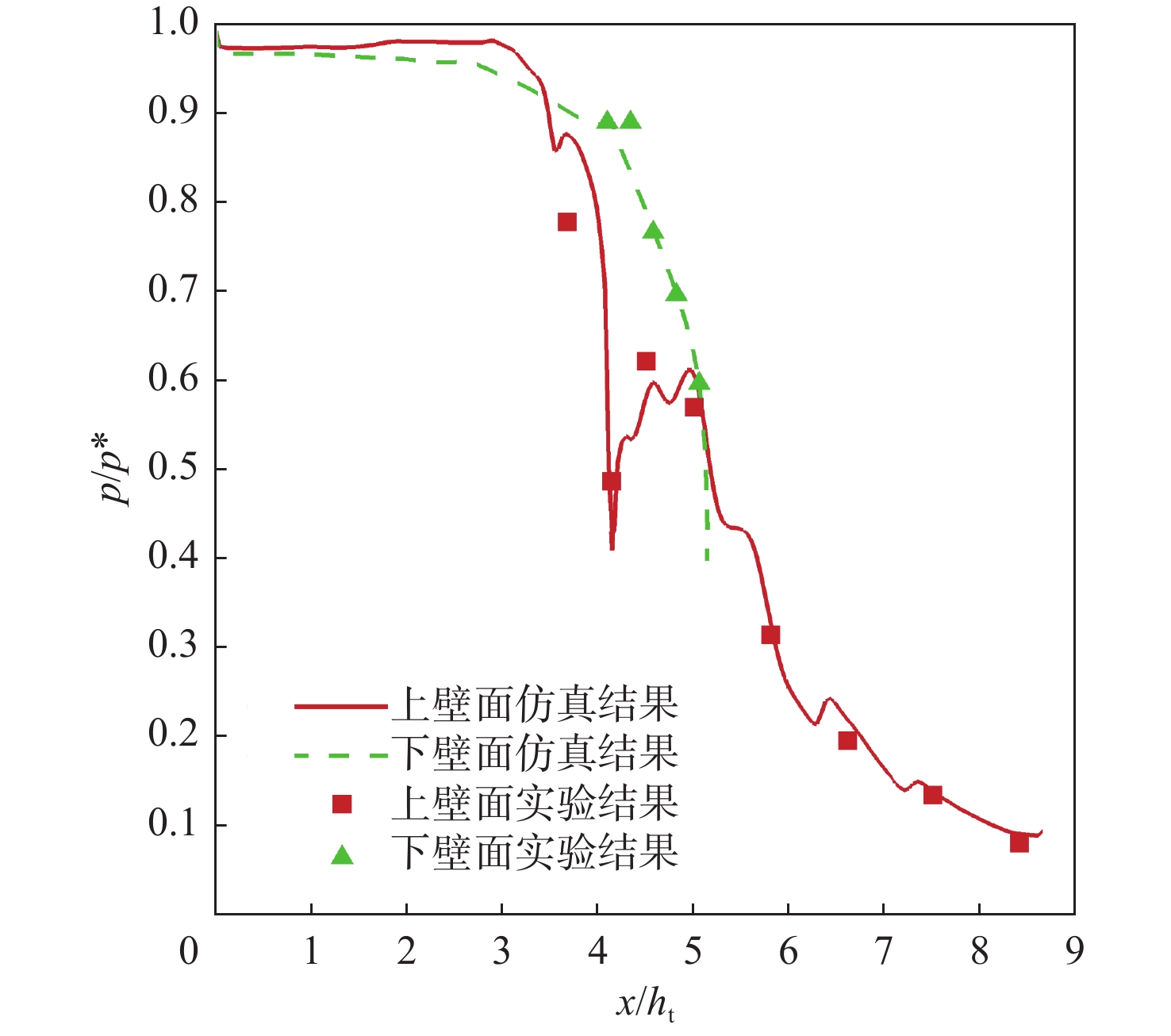

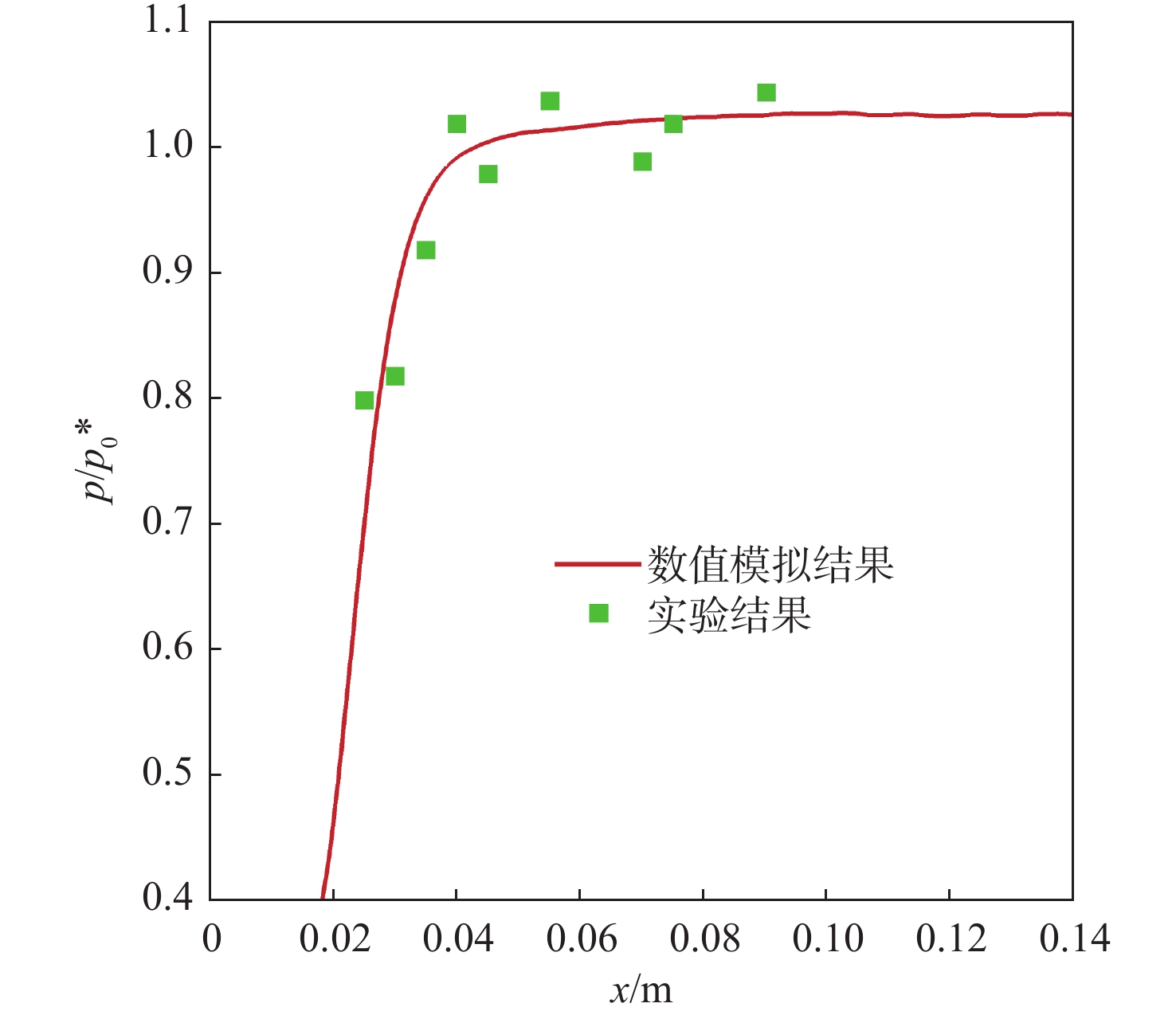

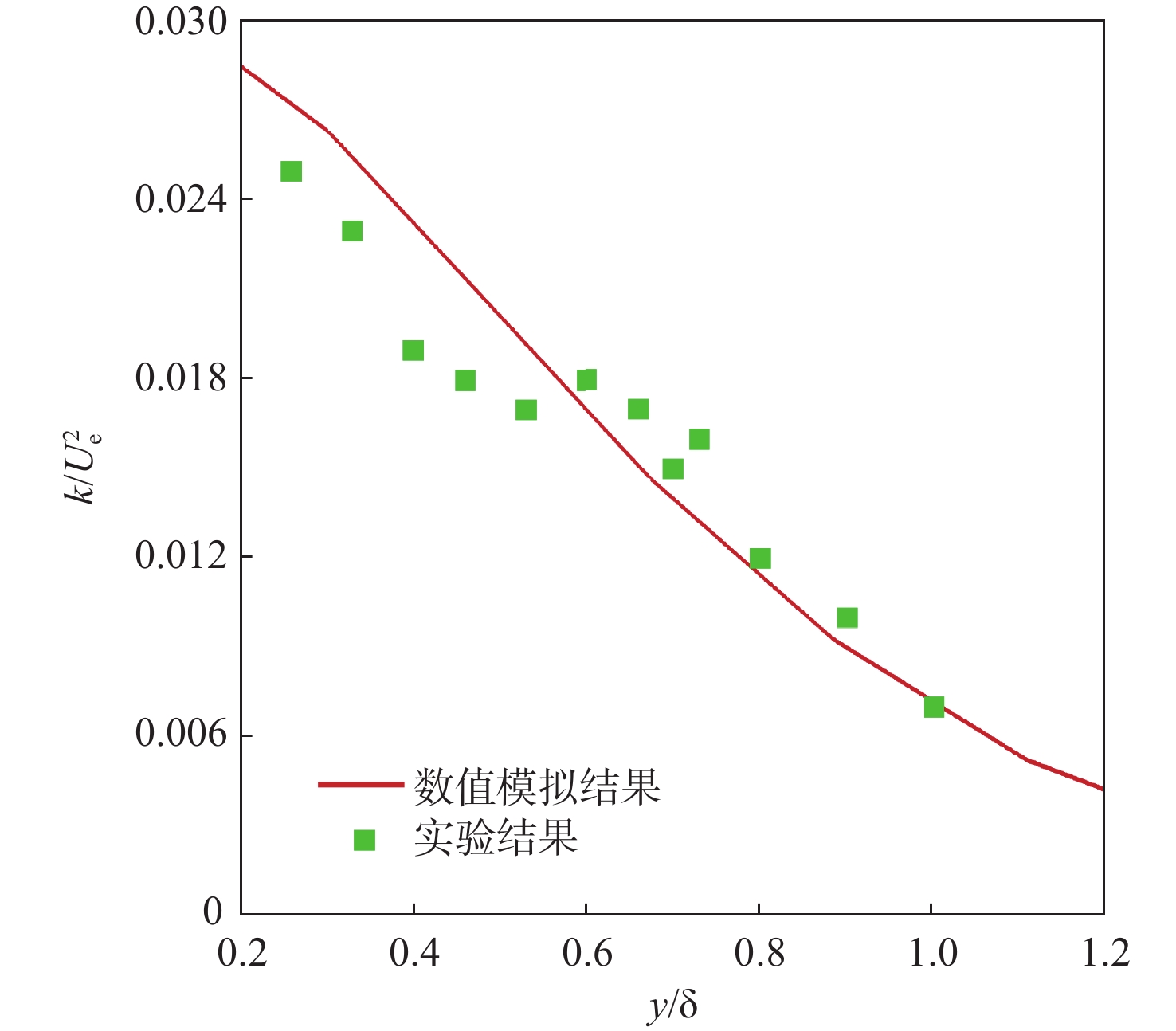

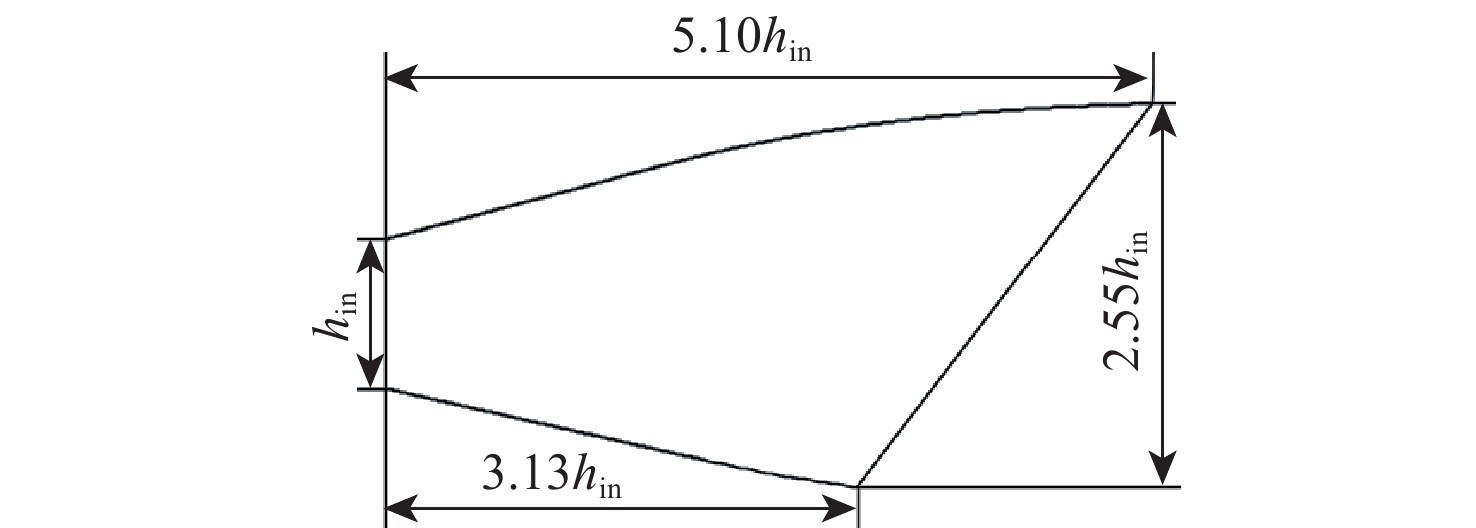

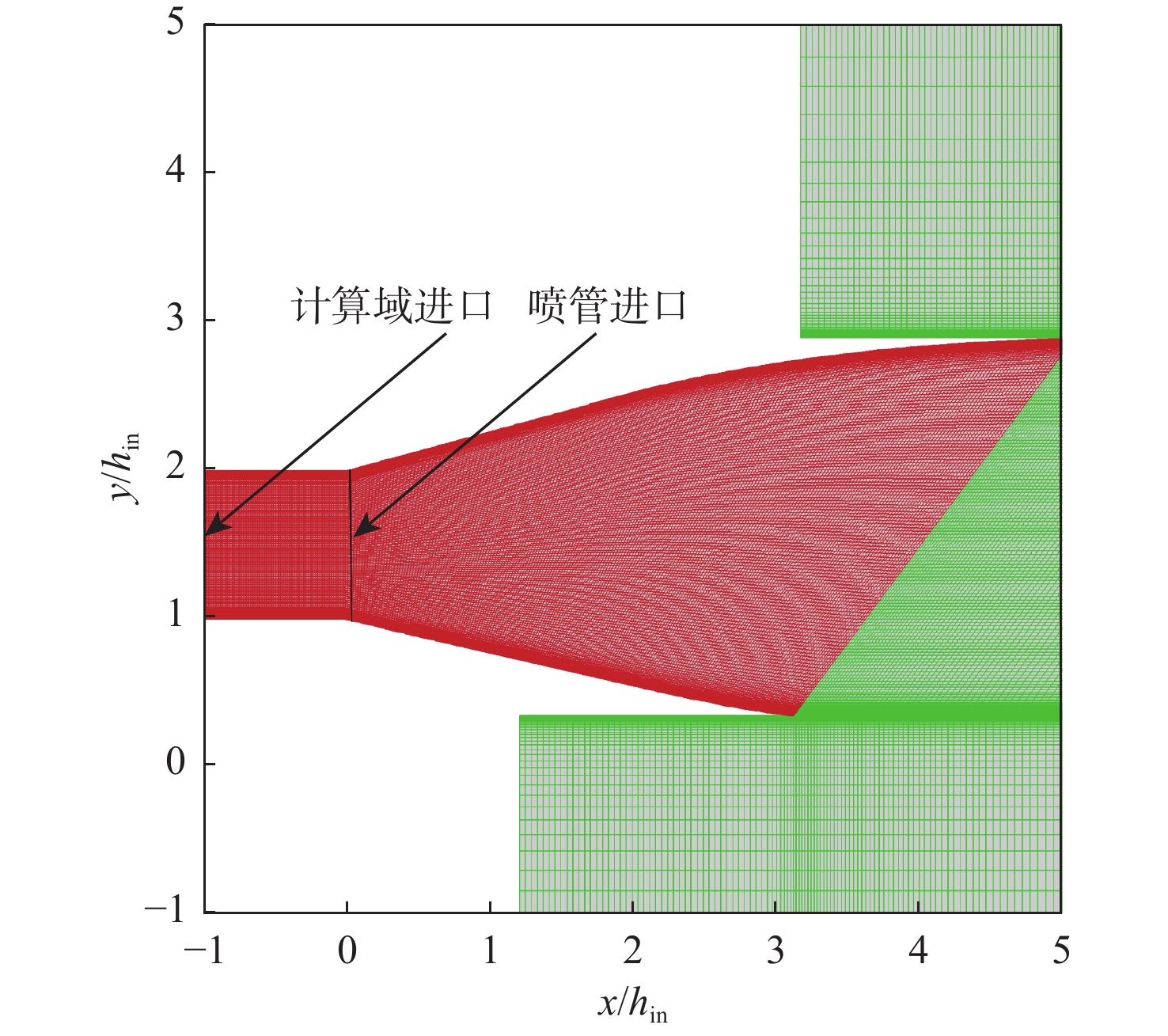

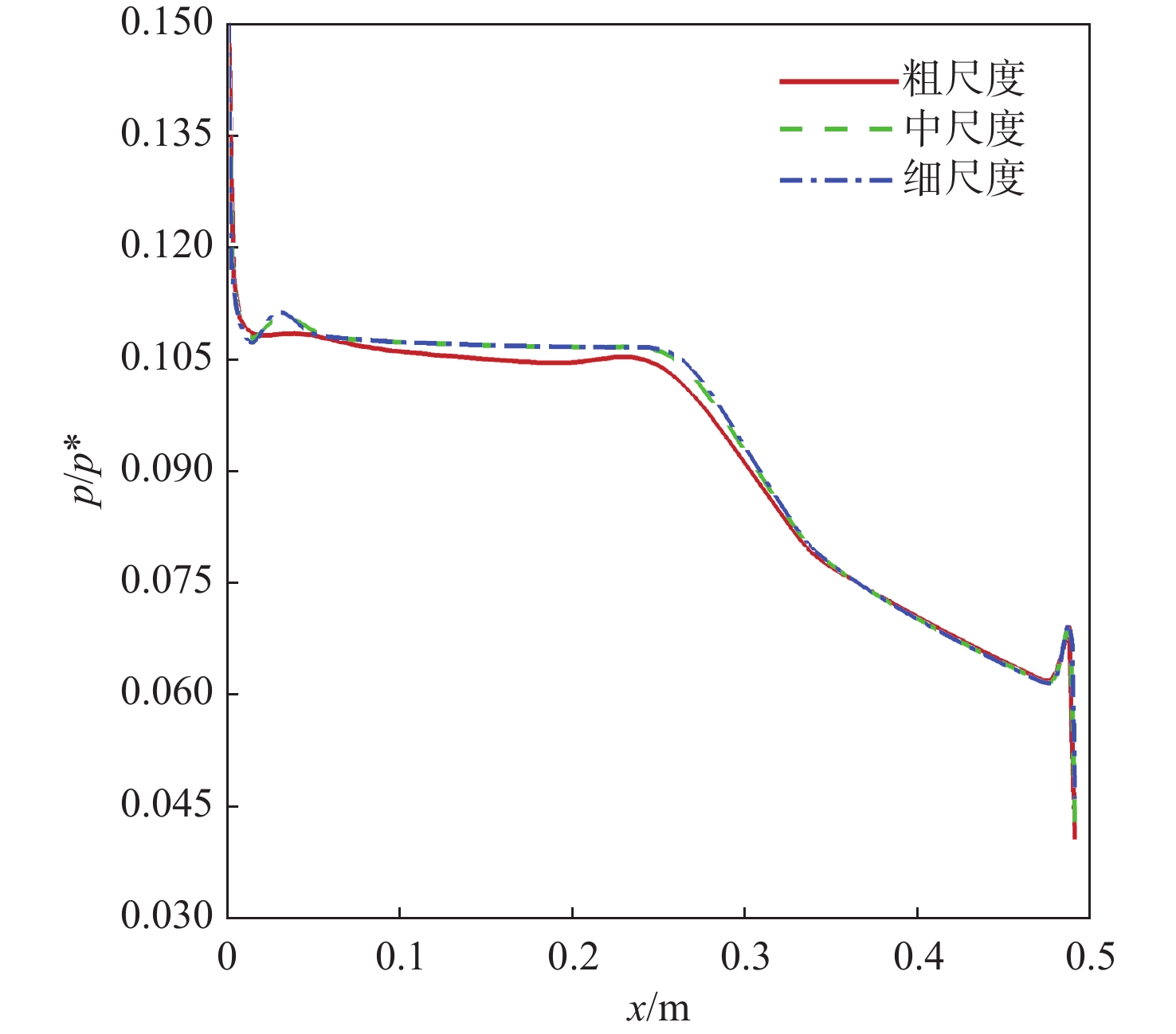

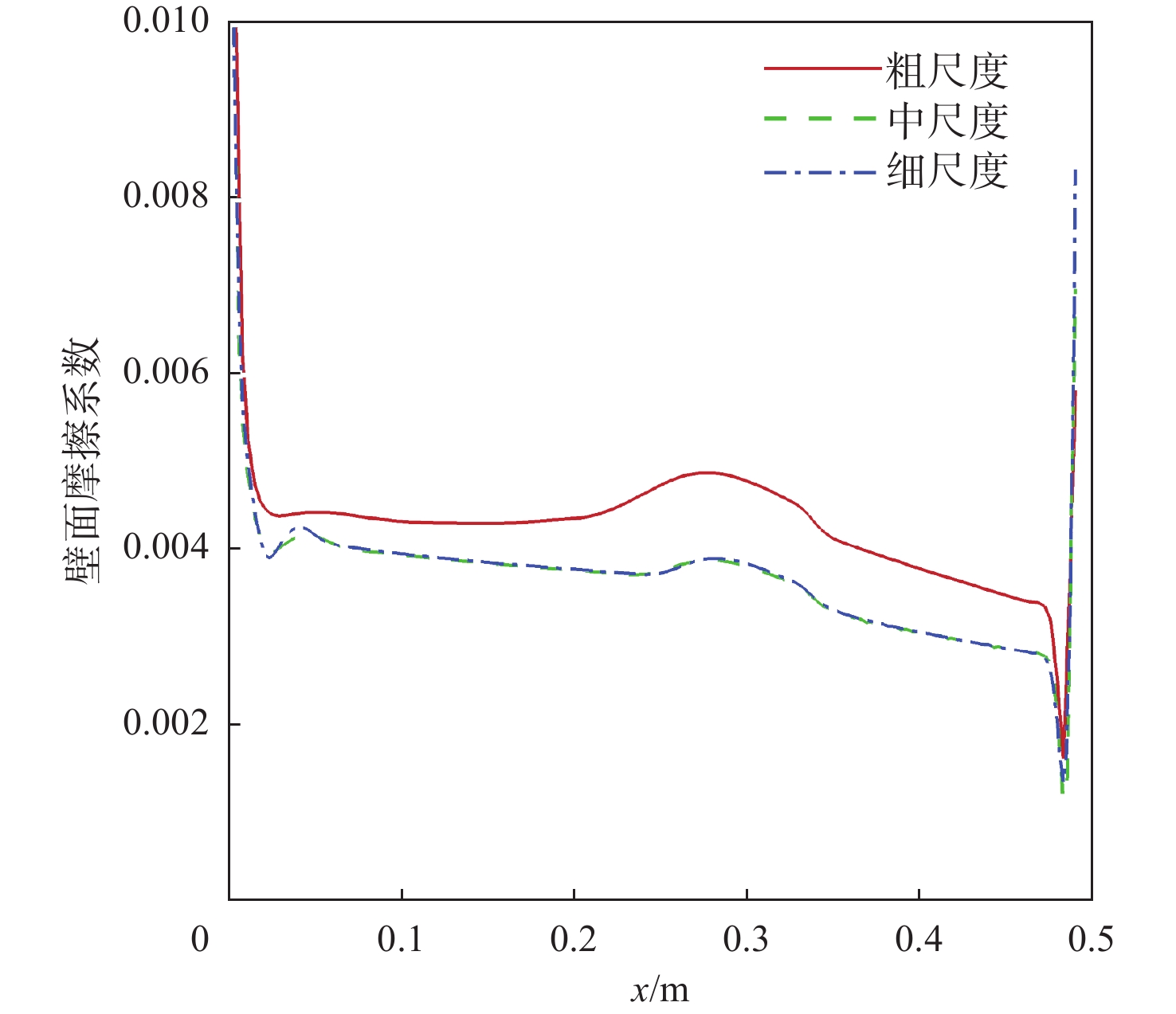

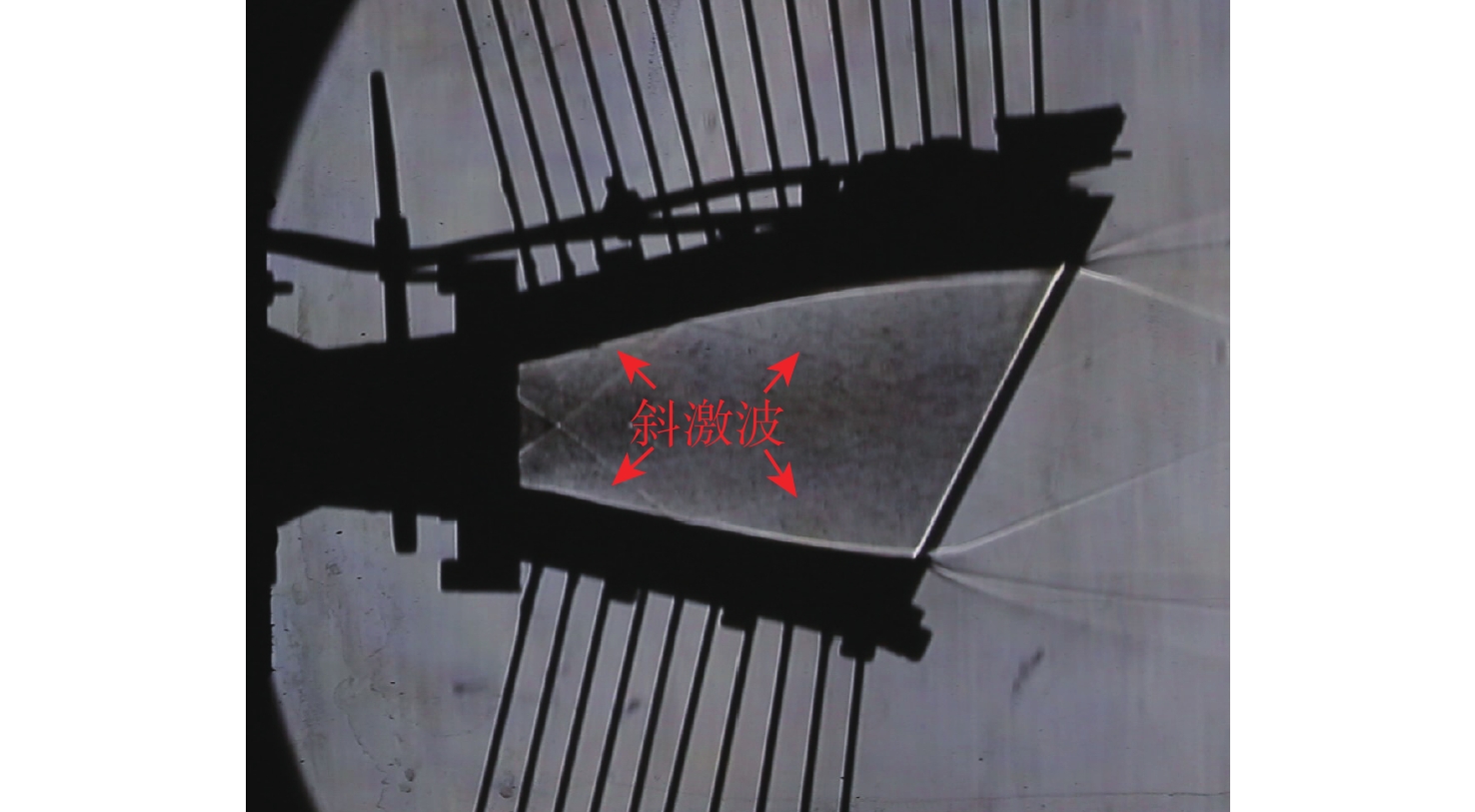

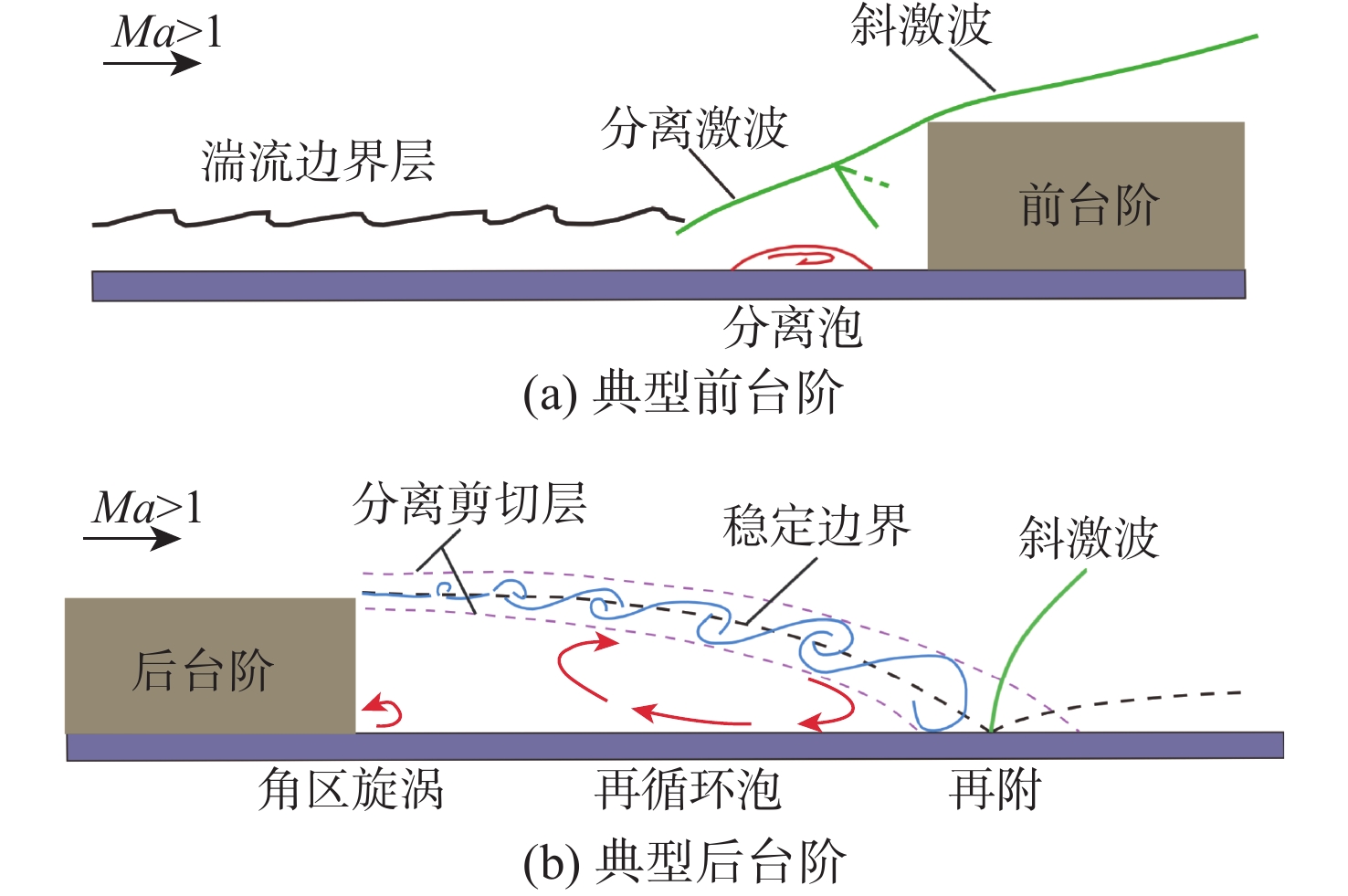

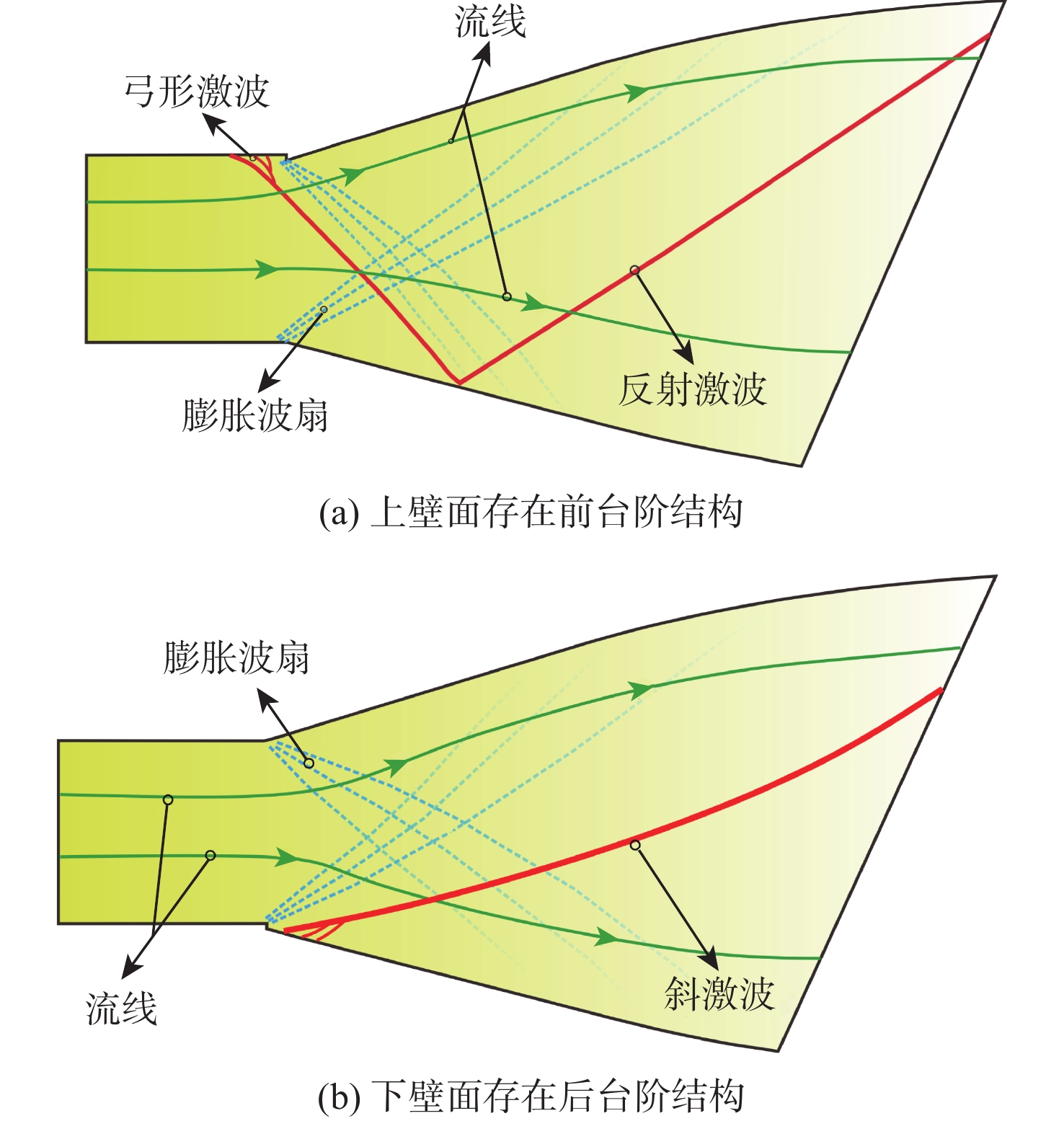

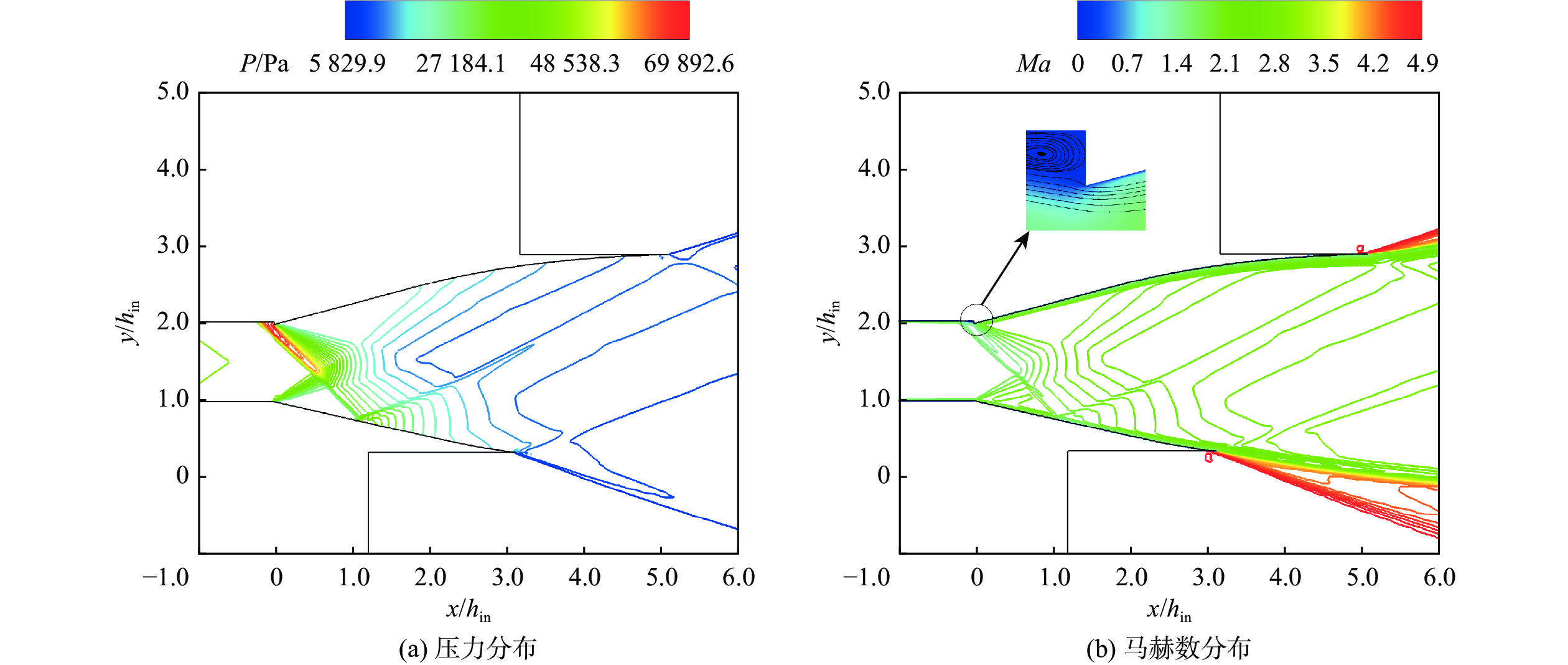

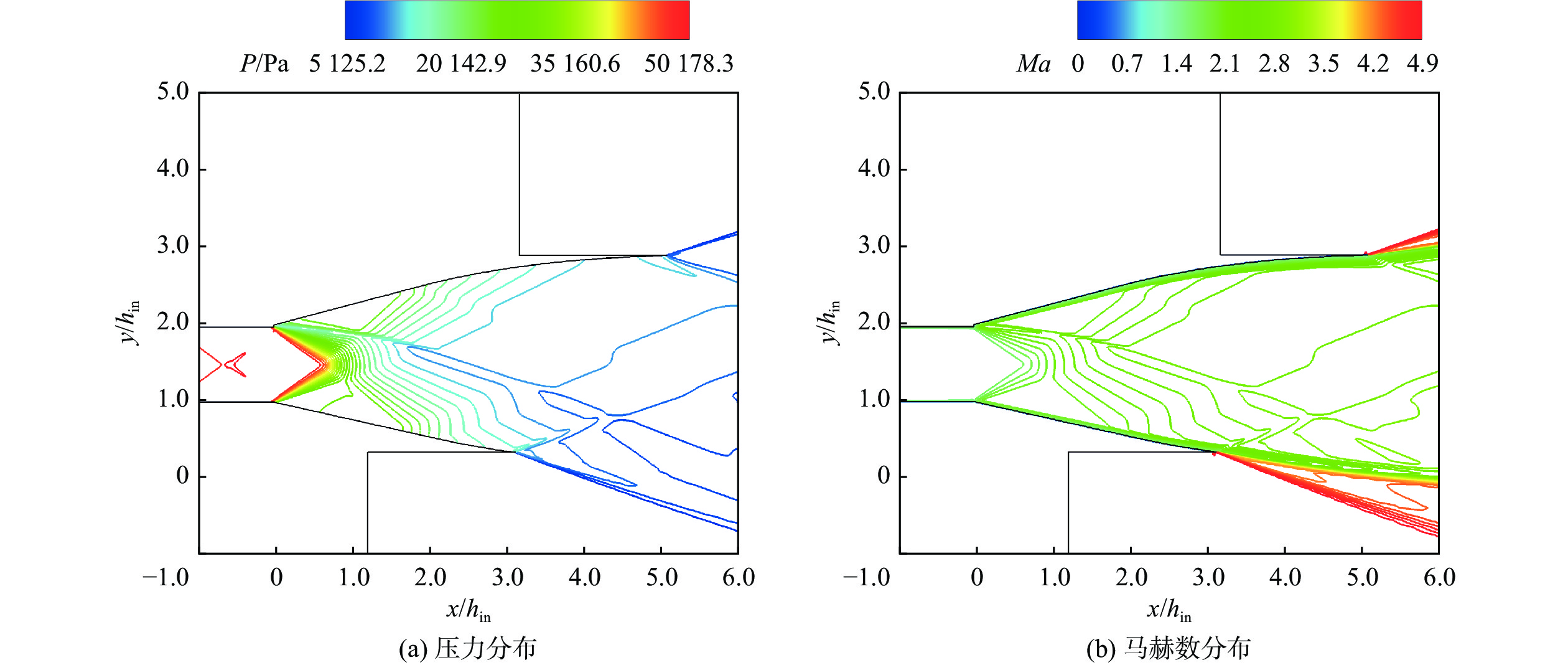

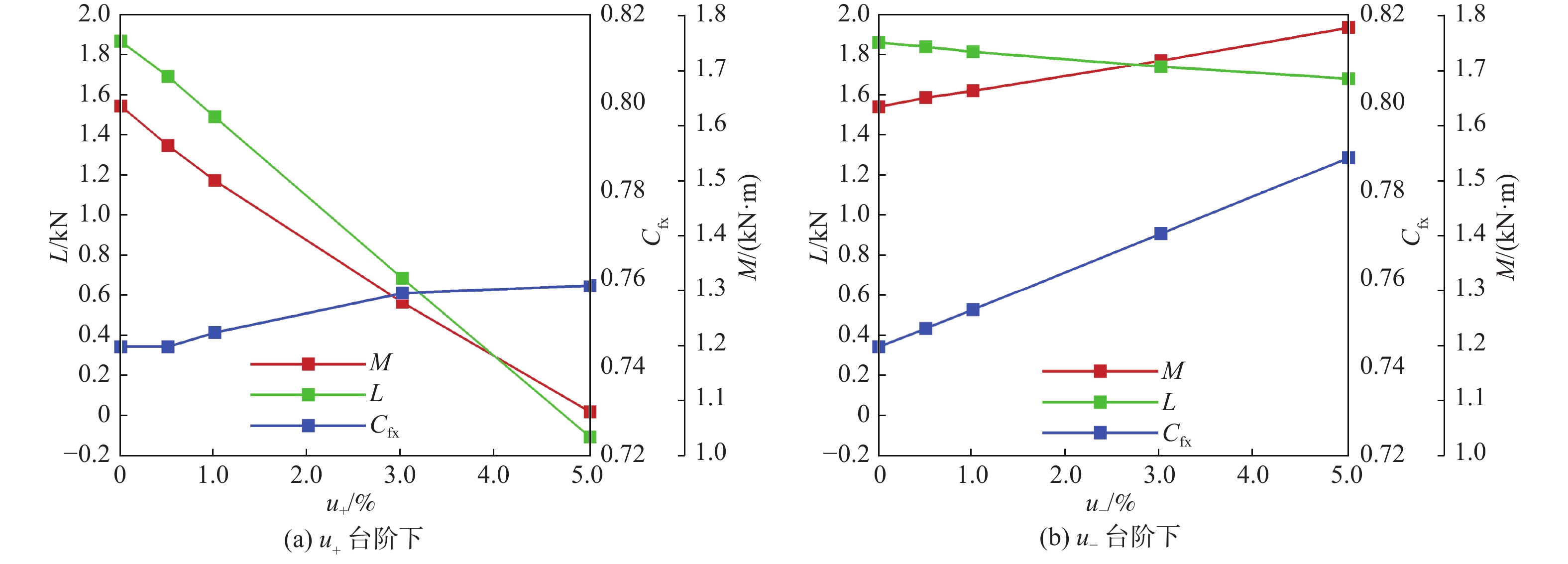

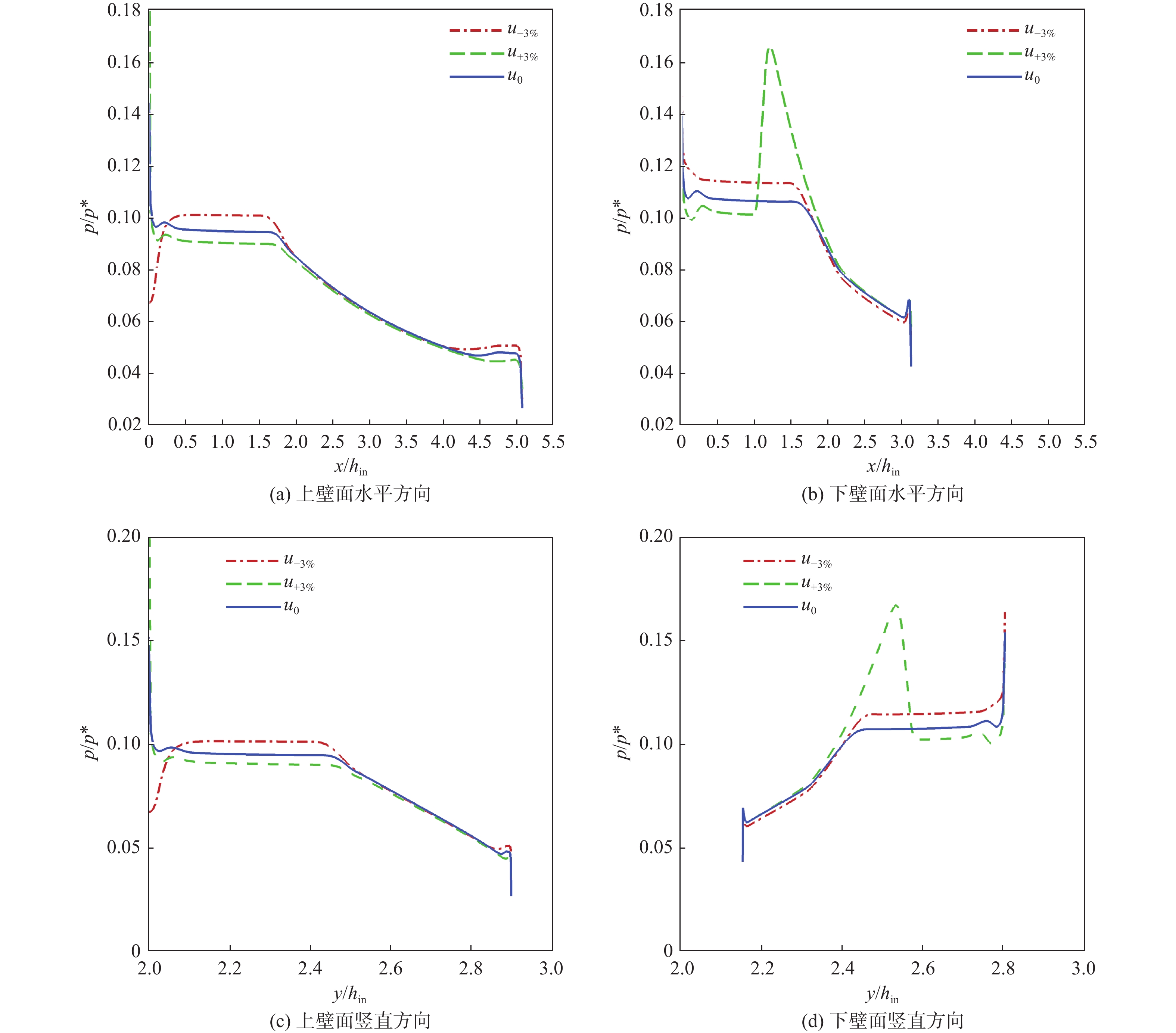

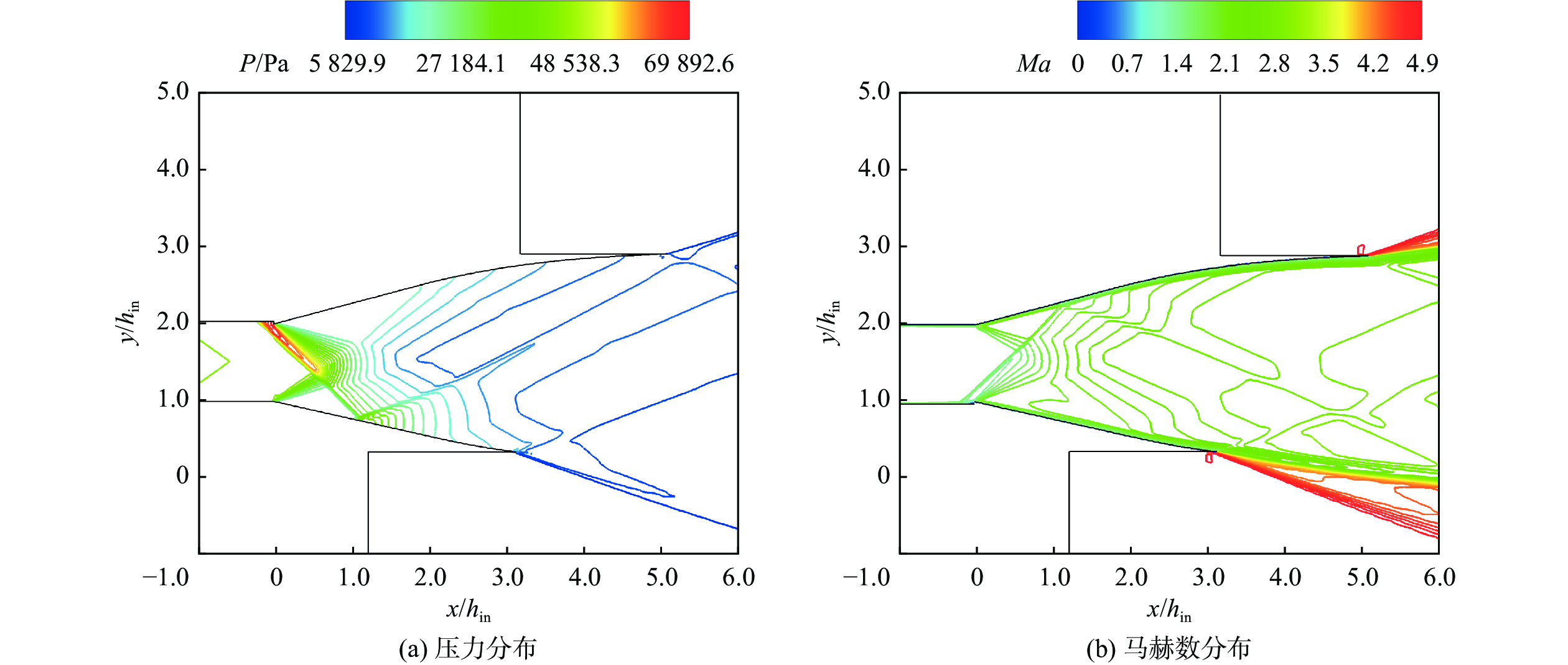

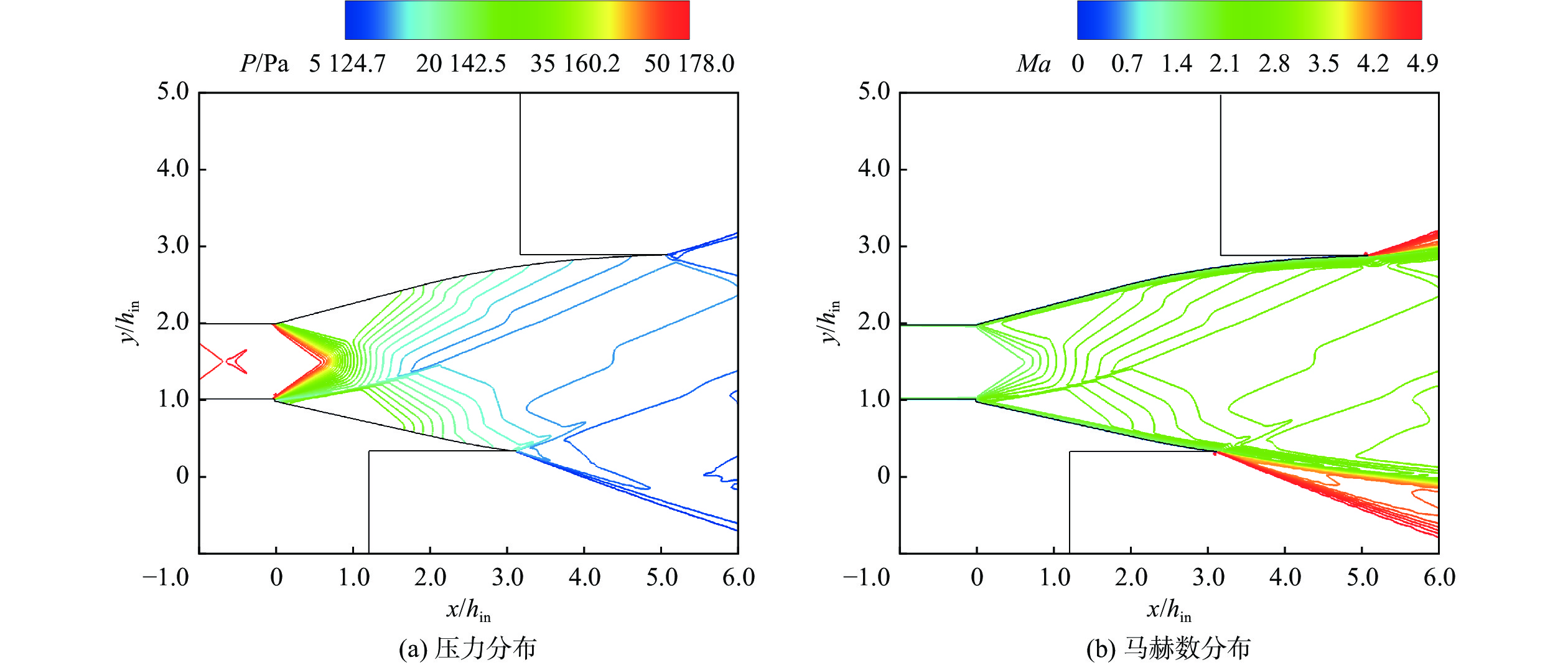

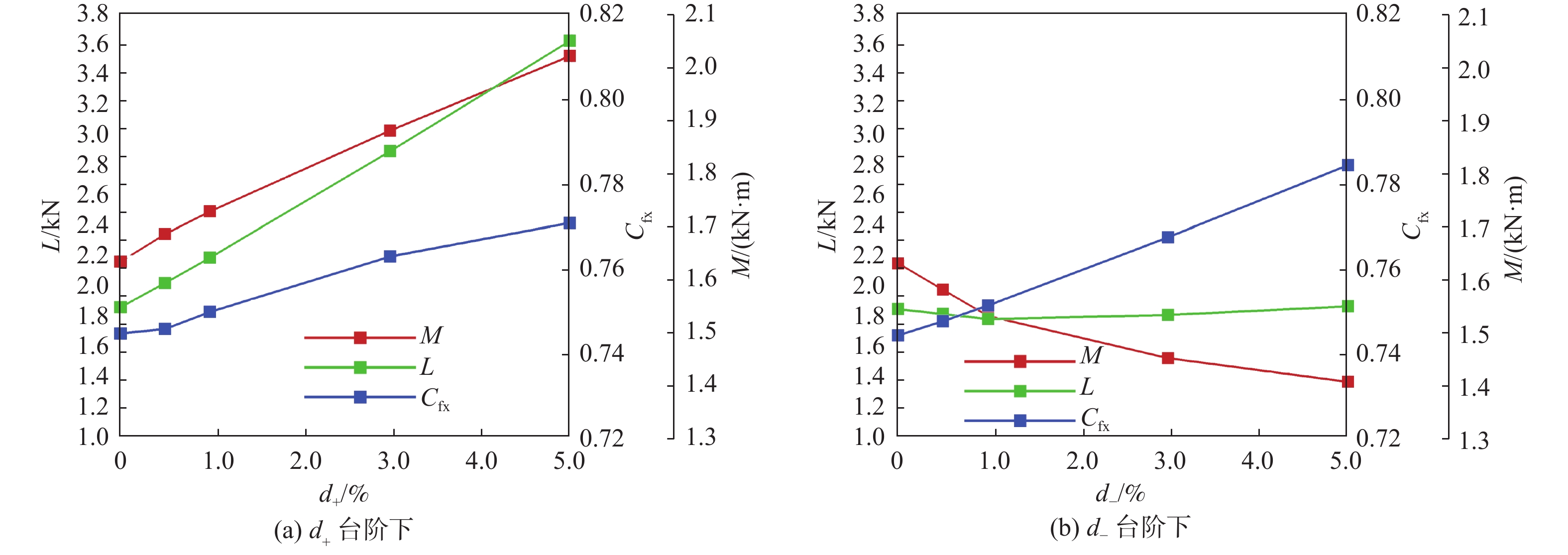

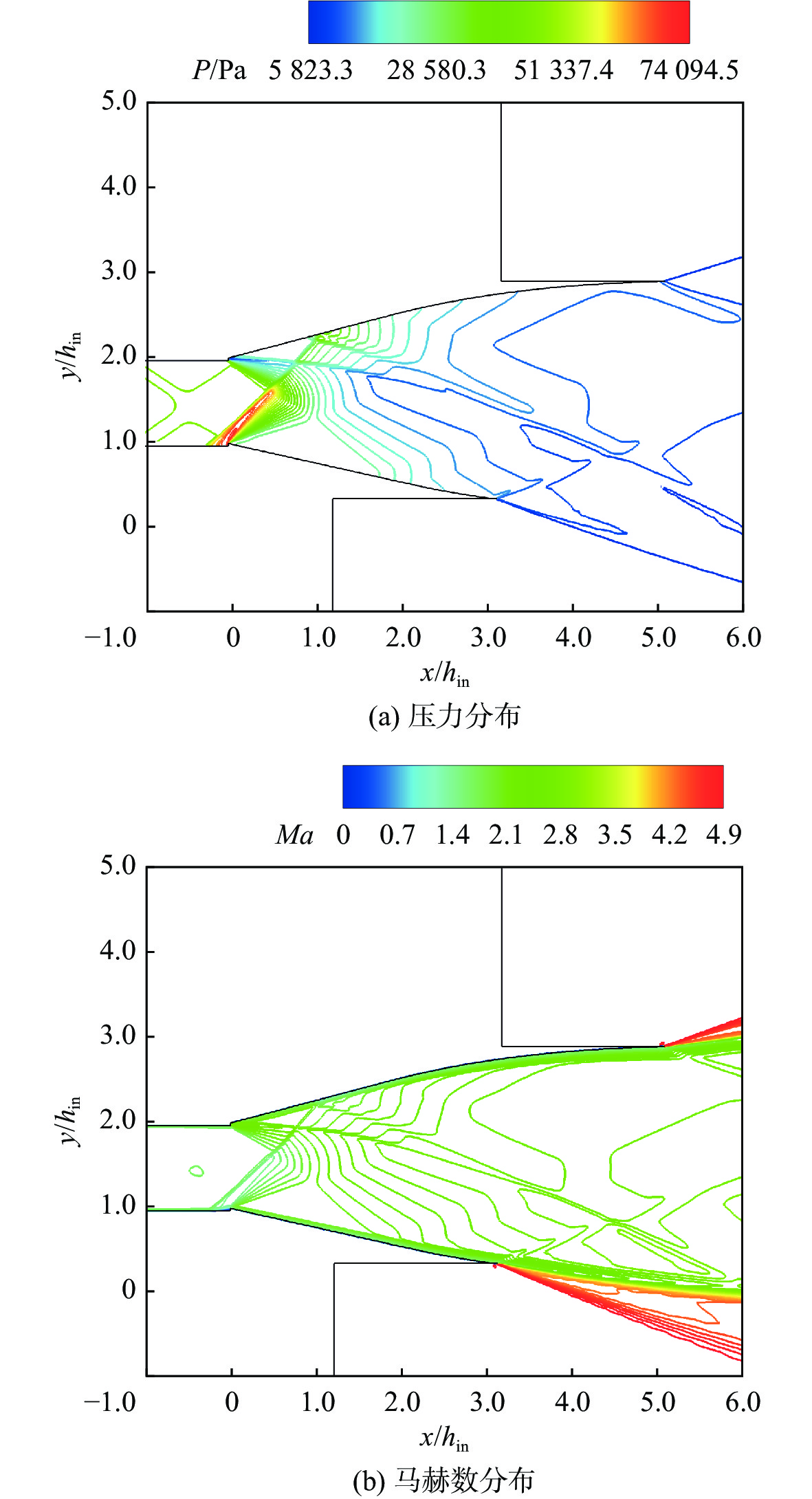

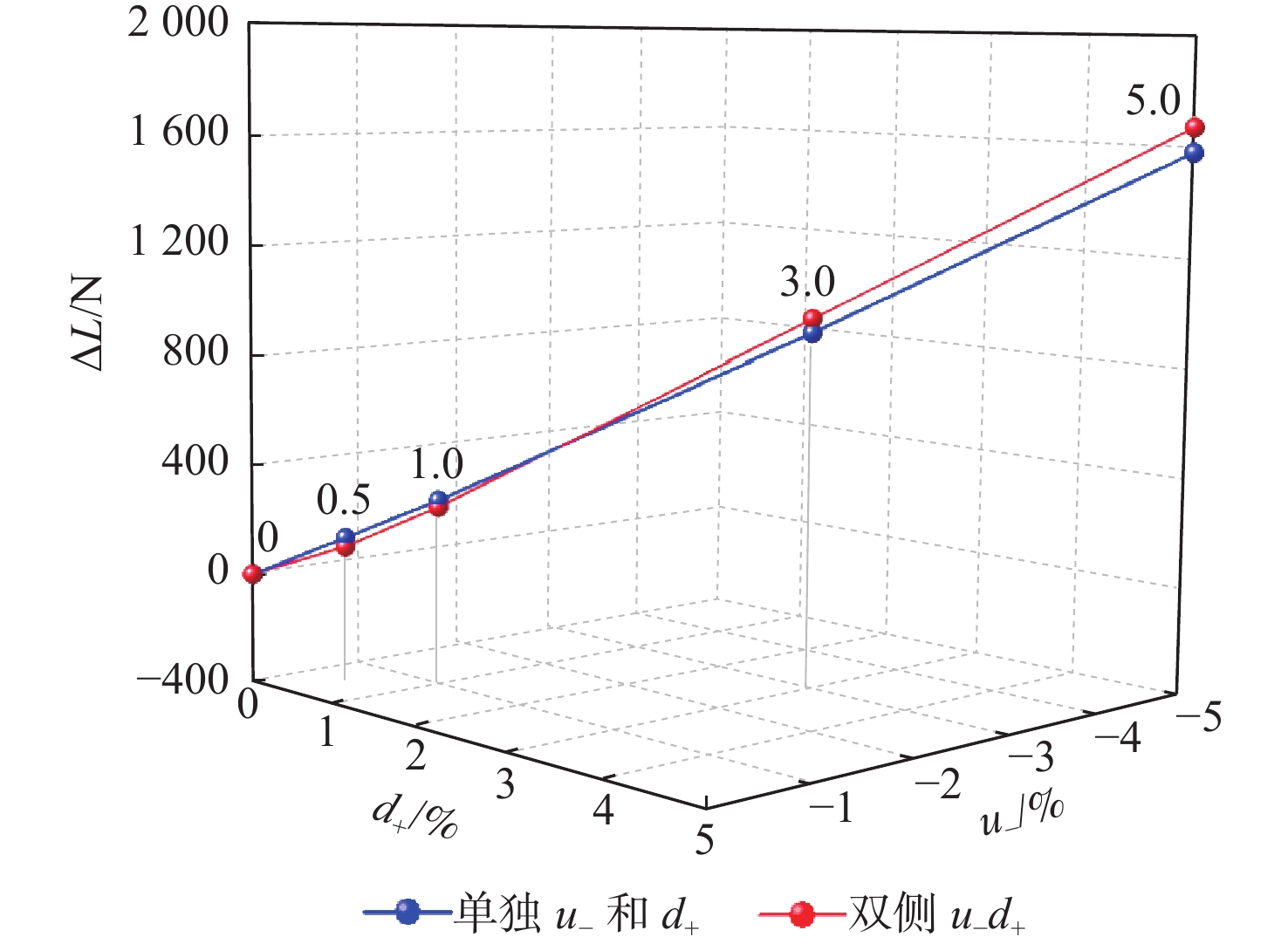

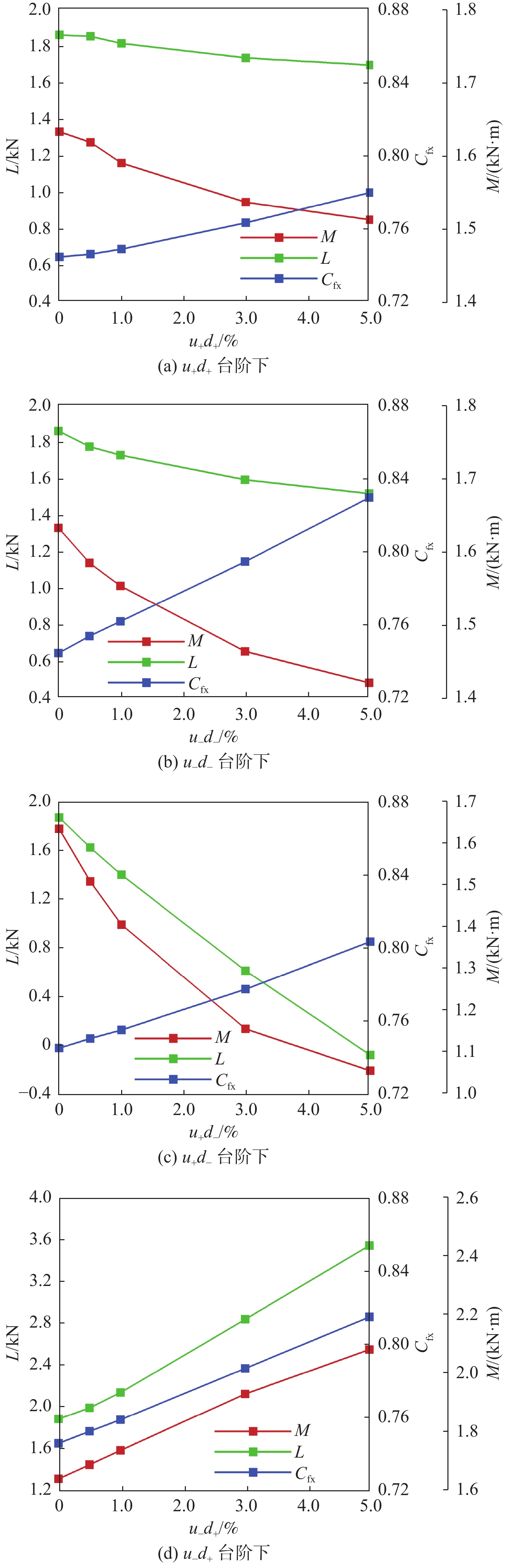

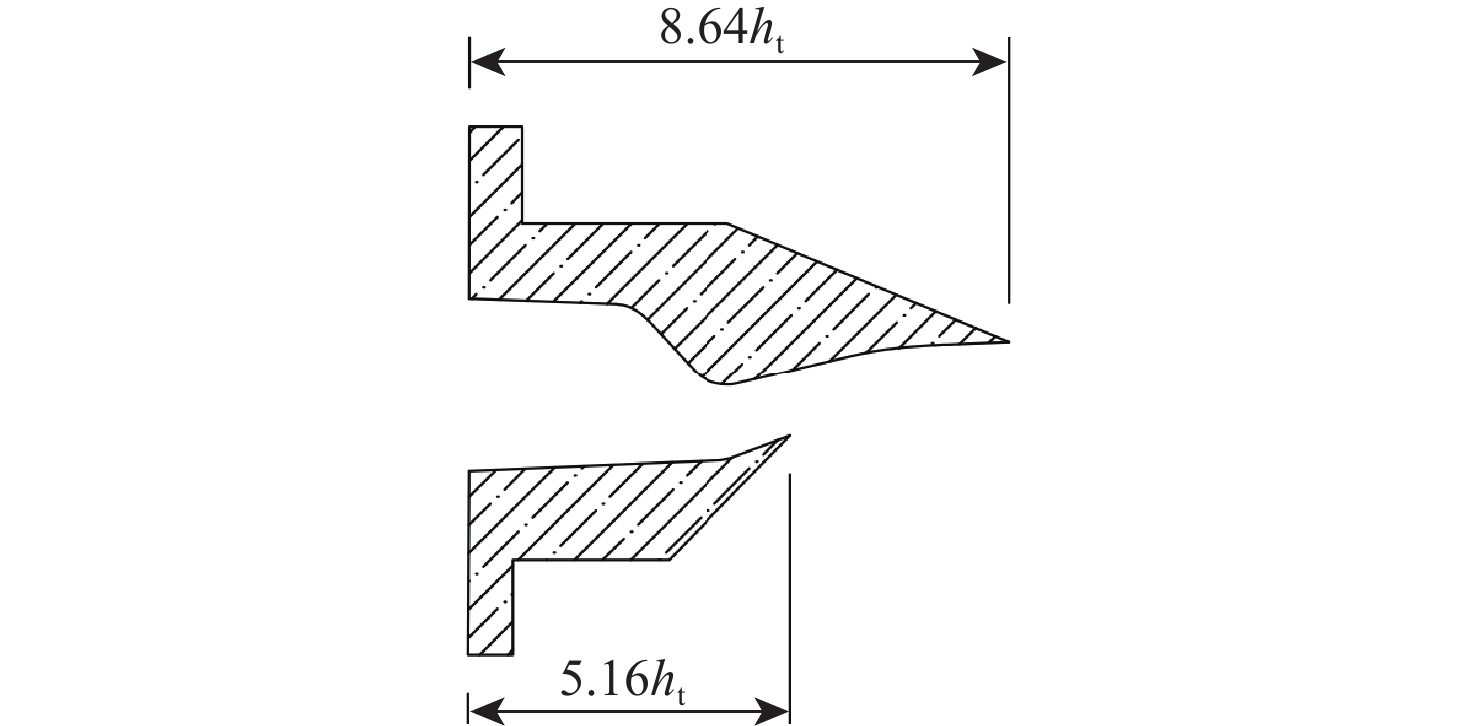

为了探究进口拐角波系对超燃冲压发动机喷管的壁面压力分布作用机制,考虑进口拐角波系对超燃冲压发动机尾喷管性能的影响,开展不同拐角波及其强度对喷管气动参数影响的数值模拟分析。进行数值方法有效性和网格无关性验证,利用不同的前后台阶来形成进口拐角波系,研究了不同波系和波系强度对喷管气动性能的影响。结果表明,进口拐角波系造成的进口非均匀对喷管气动性能造成显著影响,其中推力系数在上下壁面存在后台阶时最大增加13.98%,升力在下壁面前台阶时提高94.32%,而俯仰力矩则在上壁面前台阶、下壁面后台阶时最多降低35.47%。当喷管进口存在单侧前台阶时,随台阶高度增加,升力与俯仰力矩的变化趋势一致;而喷管进口存在单侧后台阶时,结论相反。此外,壁面台阶对喷管性能的影响是相互独立的,且基本符合线性叠加原理。

Abstract:In order to explore the mechanism of the effect of inlet corner wave system on the wall pressure distribution of scramjet nozzle and investigate the influence of the inlet corner wave system on the performance of a scramjet nozzle, the numerical simulation and analysis of the influence of different corner waves and their intensity on the aerodynamic parameters of the nozzle were carried out. The effectiveness of the numerical method and the grid independence were verified. Different forward/backward steps were used to form the inlet corner wave system, and the influence of different wave systems and wave system intensities on the aerodynamic performance of the nozzle was studied. The results show that the inlet non-uniformity caused by the inlet corner wave system has a significant impact on the aerodynamic performance of the nozzle, in which the thrust coefficient can be increased by 13.98% at most when there is a backward step on the upper and lower walls, and the lift can be increased by 94.32% when there is a forward step on the lower wall. However, the pitching moment can be reduced by 35.47% at most when there is a forward step on the upper wall and a backward step on the lower wall. When there is a single-sided forward step at the nozzle inlet, the changing trend of lift and pitching moment is consistent with the increase in step height; when there is a single-sided backward step at the nozzle inlet, the conclusion is different. In addition, the influence of wall steps on nozzle performance is independent of each other and basically conforms to the linear superposition principle.

-

Key words:

- scramjet /

- nozzle /

- expansion wave/shock wave /

- forward/backward steps /

- aerodynamic performance

-

表 1 计算域进出口流动参数

Table 1. Flow conditions of inlet and outlet in calculation domain

参数 数值 计算域进口马赫数Main 1.76 计算域进口静压Pin/Pa 45454.52 计算域进口静温Tin/K 1 821.97 环境压力Pe/Pa 3 466.0 环境温度Te/K 219.57 巡航马赫数Ma0 5.00 巡航高度H/km 23.00 -

[1] ORTON G F, SCUDERIT L F, SANGER P W, et al. Airbreathing hypersonic aircraft and transatmospheric vehicles[M]. Reston: American Institute of Aeronautics and Astronautics, Inc., 1997. [2] FRY R S. A century of ramjet propulsion technology evolution[J]. Journal of Propulsion and Power, 2004, 20(1): 27-58. doi: 10.2514/1.9178 [3] FERRI A. Review of scramjet propulsion technology[J]. Journal of Aircraft, 1968, 5(1): 3-10. doi: 10.2514/3.43899 [4] FALEMPIN F H. Scramjet developments in France[M]. Reston: American Institute of Aeronautics and Astronautics, Inc., 2000. [5] JOHNSTON P J , CUBBAGE J M , WEIDNER J P . Studies of engine-airframe integration on hypersonic aircraft[J]. Journal of Aircraft, 1970, 8(7): 495-501. [6] MO J W, XU J L, GU R, et al. Design of an asymmetric scramjet nozzle with circular to rectangular shape transition[J]. Journal of Propulsion and Power, 2014, 30(3): 812-819. doi: 10.2514/1.B34949 [7] LANDSBERG W O, WHEATLEY V, SMART M K, et al. Performance of high Mach number scramjets - Tunnel vs flight[J]. Acta Astronautica, 2018, 146: 103-110. doi: 10.1016/j.actaastro.2018.02.031 [8] LU X, YUE L J, XIAO Y B, et al. Design of scramjet nozzle employing streamline tracing technique[C]// Proceedings of the 16th AIAA/DLR/DGLR International Space Planes and Hypersonic Systems and Technologies Conference. Reston: AIAA, 2009: AIAA2009-7248. [9] HIRAIWA T, TOMIOKA S, UEDA S, et al. Performance variation of scramjet nozzle at various nozzle pressure ratios[J]. Journal of Propulsion and Power, 1995, 11(3): 403-408. doi: 10.2514/3.23858 [10] 张晓源, 覃粒子, 刘宇. 非均匀入口与化学非平衡效应对尾喷管性能的影响研究[J]. 推进技术, 2014, 35(2): 166-171.ZHANG X Y, QIN L Z, LIU Y. Non-uniform entrance and non-equilibrium chemical effects on scramjet nozzle performance[J]. Journal of Propulsion Technology, 2014, 35(2): 166-171 (in Chinese). [11] 全志斌, 徐惊雷, 李斌, 等. 超燃冲压发动机尾喷管非均匀进口的冷流试验与数值模拟[J]. 航空学报, 2013, 34(10): 2308-2315.QUAN Z B, XU J L, LI B, et al. Cold flow experiment and numerical simulation on nonuniform entrance flow of scramjet nozzle[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(10): 2308-2315 (in Chinese). [12] 张璞, 徐惊雷, 全志斌. 激波/膨胀波造成的非均匀进口对单边膨胀喷管性能的影响及对比研究[C]//第七届全国高超声速科技学术会议. 北京: 中国力学 学会, 2014.ZHANG P, XU J L, QUAN Z B. Effect of shock/expansion wave induced non-uniform inlet on performance of unilateral expansion nozzle and comparative study[C]//The 7th Hypersonic Science and Technology Conference. Beijing: Chinese Society of Mechanics, 2014(in Chinese). [13] 陈以勒, 俞凯凯, 徐惊雷. 超燃冲压发动机尾喷管进口气流角畸变研究[J]. 推进技术, 2021, 42(12): 2694-2702.CHEN Y L, YU K K, XU J L. Effects of inlet flow angle distortion on scramjet nozzle[J]. Journal of Propulsion Technology, 2021, 42(12): 2694-2702 (in Chinese). [14] MO J W, XU J L, QUAN Z B, et al. Design and cold flow test of a scramjet nozzle with nonuniform inflow[J]. Acta Astronautica, 2015, 108: 92-105. doi: 10.1016/j.actaastro.2014.12.005 [15] GAFFNEY R L Jr. Design of a Mach-15 total-enthalpy nozzle with non-uniform inflow using rotatioanl MOC[C]//Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit. Reston: AIAA, 2005: AIAA2005-691. [16] BARE E A, CAPONE F J. Static internal performance of convergent single-expansion-ramp nozzles with various combinations of internal geometric parameters[R]. Washington: National Aeronautics and Space Administration, 1989. [17] ARAI T, SUGIYAMA H, HOMAREDA M, et al. Turbulence characteristics of supersonic boundary layer past a backward facing step[C]// Proceedings of the International Aerospace Planes and Hypersonics Technologies. Reston: AIAA, 1995. [18] 陈以勒, 俞凯凯, 徐惊雷. 几何尺寸约束的超燃冲压发动机推力喷管设计[J]. 航空学报, 2021, 42(6): 124259.CHEN Y L, YU K K, XU J L. New design method for scramjet nozzles with strong geometric constraints[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(6): 124259 (in Chinese). -

下载:

下载: