-

摘要:

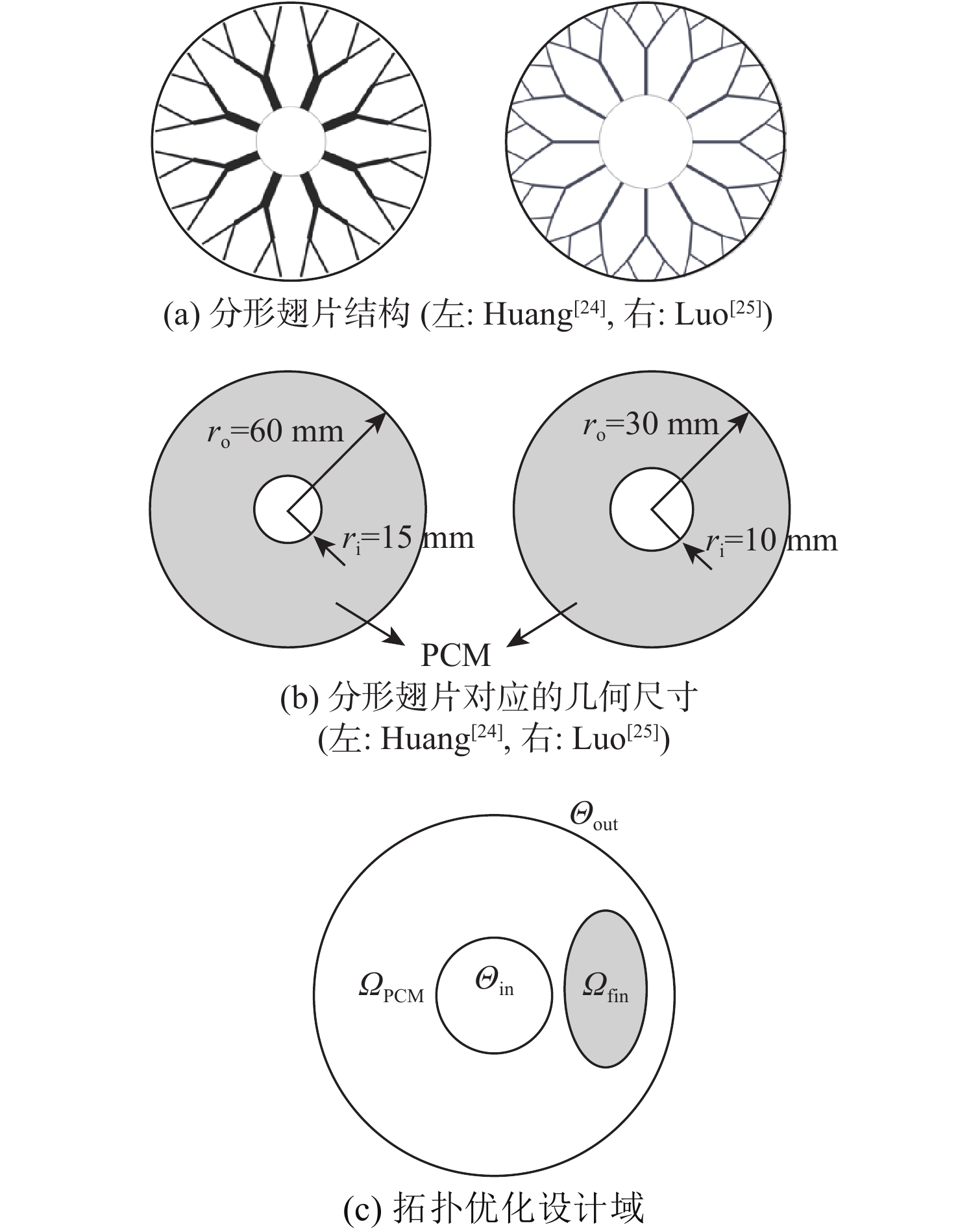

为强化翅片管式储能系统的传热速率和相变材料域的温度均匀性,基于带惩罚的固体各向同性材料方法,以两种分形结构和对应翅片体积分数为参数,采用月桂酸为相变材料,进行了拓扑优化设计,并对比研究了拓扑优化的强化导热效果和温度均匀性。研究表明:壁面温度20 ℃时,拓扑优化有更好的导热效果,比分形优化分别减少21.18%和12.68%的总凝固时间,相变材料温度最高降低了7.33 ℃和4.30 ℃,平均降低了0.98 ℃和3.85 ℃;拓扑优化也具备更好的温度均匀性,相变材料平均方差分别为对应分形的33.38%和72.13%;壁温偏离拓扑的设计参数时,其热性能也基本未发生改变。以上结果传导为翅片设计提供了一定参考。

Abstract:In order to improve the temperature uniformity of the phase change material domain and the heat transfer rate of the finned tube energy storage system, two types of fractal structures and their corresponding fin volume fraction were used as design parameters, and lauric acid was used as the phase change material to carry out topology optimization design. This was done using the Solid Isotropic Material with Penalty method. The thermal conductivity enhancement and temperature uniformity of topology optimization are compared. The findings indicate that the topology optimization has a better thermal conductivity impact and can shorten the overall solidification time by 21.18% and 12.68%, respectively, when the wall temperature is 20 ℃. The phase change material temperature is reduced by 7.33 ℃ and 4.30 ℃, 0.98 ℃ and 3.85 ℃ on average. At the same time, the topology optimization also has better temperature uniformity, and the average variance of phase change material is 33.38% and 72.13% of the corresponding fractal, respectively. When the wall temperature deviates from the design parameters of the topology, the thermal performance does not change. This study provides some reference for fin design.

-

表 1 树状分形的尺寸

Table 1. Dimensions of a tree fractal

表 2 材料热物性参数

Table 2. Thermal properties of material

ρ/(kg∙m−3) cp/(kJ∙kg−1∙℃−1) k/(W∙m−1∙℃−1) L/(kJ∙kg−1)

(月桂酸)Tm/℃

(月桂酸)月桂酸 铝 月桂酸 铝 月桂酸 铝 1007 (固)/862(液)2730 1.7(固)/2.4(液) 0.896 0.22(固)/0.147(液) 167 178 42~48 -

[1] KABIR M, GEMEDA T, PRELLER E, et al. Design and development of a PCM-based two-phase heat exchanger manufactured additively for spacecraft thermal management systems[J]. International Journal of Heat and Mass Transfer, 2021, 180: 121782. doi: 10.1016/j.ijheatmasstransfer.2021.121782 [2] TATSIDJODOUNG P, LE PIERRÈS N, LUO L G. A review of potential materials for thermal energy storage in building applications[J]. Renewable and Sustainable Energy Reviews, 2013, 18: 327-349. doi: 10.1016/j.rser.2012.10.025 [3] WANG S S, XING Y M, HAO Z L, et al. Experimental study on the thermal performance of PCMs based heat sink using higher alcohol/graphite foam[J]. Applied Thermal Engineering, 2021, 198: 117452. doi: 10.1016/j.applthermaleng.2021.117452 [4] HOU X, XING Y M, HAO Z L. Multi-objective optimization of a composite phase change material-based heat sink under non-uniform discrete heating[J]. Applied Thermal Engineering, 2021, 197: 117435. doi: 10.1016/j.applthermaleng.2021.117435 [5] JÄCKEL R, TAPIA F, GUTIÉRREZ-URUETA G, et al. Design of an aeronautic pitot probe with a redundant heating system incorporating phase change materials[J]. Flow Measurement and Instrumentation, 2020, 76: 101817. doi: 10.1016/j.flowmeasinst.2020.101817 [6] SHANMUGASUNDARAM V, RAMALINGAM M, DONOVAN B, et al. Aircraft based pulsed power system thermal management options with energy storage[C]//Proceedings of the 4th International Energy Conversion Engineering Conference and Exhibit (IECEC). Reston: AIAA, 2006: AIAA2006-4025. [7] SHANMUGASUNDARAM V, RAMALINGAM M, DONOVAN B. Thermal management system with energy storage for an airborne laser power system application[C]//Proceedings of the 5th International Energy Conversion Engineering Conference and Exhibit (IECEC). Reston: AIAA, 2007: AIAA2007-4817. [8] VELRAJ R, SEENIRAJ R, HAFNER B, et al. Heat transfer enhancement in a latent heat storage system[J]. Solar Energy, 1999, 65: 171-180. doi: 10.1016/S0038-092X(98)00128-5 [9] BABAPOOR A, AZIZI M, KARIMI G. Thermal management of a Li-ion battery using carbon fiber-PCM composites[J]. Applied Thermal Engineering, 2015, 82(2): 281-290. [10] OPOLOT M, ZHAO C R, LIU M, et al. Influence of cascaded graphite foams on thermal performance of high temperature phase change material storage systems[J]. Applied Thermal Engineering, 2020, 180: 115618. doi: 10.1016/j.applthermaleng.2020.115618 [11] ZHANG H, LI X Y, LIU L Q, et al. Experimental investigation on paraffin melting in high porosity copper foam under centrifugal accelerations[J]. Applied Thermal Engineering, 2020, 178: 115504. doi: 10.1016/j.applthermaleng.2020.115504 [12] ALGARNI S, MELLOULI S, ALQAHTANI T, et al. Experimental investigation of an evacuated tube solar collector incorporating nano-enhanced PCM as a thermal booster[J]. Applied Thermal Engineering, 2020, 180: 115831. doi: 10.1016/j.applthermaleng.2020.115831 [13] XU H T, WANG N, ZHANG C Y, et al. Optimization on the melting performance of triplex-layer PCMs in a horizontal finned shell and tube thermal energy storage unit[J]. Applied Thermal Engineering, 2020, 176: 115409. doi: 10.1016/j.applthermaleng.2020.115409 [14] MAHDI J M, LOHRASBI S, GANJI D D, et al. Accelerated melting of PCM in energy storage systems via novel configuration of fins in the triplex-tube heat exchanger[J]. International Journal of Heat and Mass Transfer, 2018, 124: 663-676. doi: 10.1016/j.ijheatmasstransfer.2018.03.095 [15] KATESHIA J, LAKHERA V J. Analysis of solar still integrated with phase change material and pin fins as absorbing material[J]. Journal of Energy Storage, 2021, 35: 102292. doi: 10.1016/j.est.2021.102292 [16] AGYENIM F, HEWITT N, EAMES P, et al. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS)[J]. Renewable and Sustainable Energy Reviews, 2010, 14(2): 615-628. doi: 10.1016/j.rser.2009.10.015 [17] SHEIKHOLESLAMI M, LOHRASBI S, GANJI D D. Numerical analysis of discharging process acceleration in LHTESS by immersing innovative fin configuration using finite element method[J]. Applied Thermal Engineering, 2016, 107: 154-166. doi: 10.1016/j.applthermaleng.2016.06.158 [18] YU C, WU S C, HUANG Y P, et al. Charging performance optimization of a latent heat storage unit with fractal tree-like fins[J]. Journal of Energy Storage, 2020, 30: 101498. doi: 10.1016/j.est.2020.101498 [19] BENDSØE M P. Optimal shape design as a material distribution problem[J]. Structural Optimization, 1989, 1(4): 193-202. doi: 10.1007/BF01650949 [20] BRUNS T E. Topology optimization of convection-dominated, steady-state heat transfer problems[J]. International Journal of Heat and Mass Transfer, 2007, 50(15-16): 2859-2873. doi: 10.1016/j.ijheatmasstransfer.2007.01.039 [21] PIZZOLATO A, SHARMA A, MAUTE K, et al. Topology optimization for heat transfer enhancement in Latent Heat Thermal Energy Storage[J]. International Journal of Heat and Mass Transfer, 2017, 113: 875-888. doi: 10.1016/j.ijheatmasstransfer.2017.05.098 [22] PIZZOLATO A, SHARMA A, MAUTE K, et al. Design of effective fins for fast PCM melting and solidification in shell-and-tube latent heat thermal energy storage through topology optimization[J]. Applied Energy, 2017, 208: 210-227. doi: 10.1016/j.apenergy.2017.10.050 [23] TIAN Y, LIU X L, XU Q, et al. Bionic topology optimization of fins for rapid latent heat thermal energy storage[J]. Applied Thermal Engineering, 2021, 194: 117104. doi: 10.1016/j.applthermaleng.2021.117104 [24] HUANG Y P, LIU X D. Charging and discharging enhancement of a vertical latent heat storage unit by fractal tree-shaped fins[J]. Renewable Energy, 2021, 174: 199-217. doi: 10.1016/j.renene.2021.04.066 [25] LUO X M, GU J A, MA H Q, et al. Numerical study on enhanced melting heat transfer of PCM by the combined fractal fins[J]. Journal of Energy Storage, 2022, 45: 103780. doi: 10.1016/j.est.2021.103780 [26] ZHOU M, ROZVANY G. The COC algorithm, Part II: Topological, geometrical and generalized shape optimization[J]. Computer Methods in Applied Mechanics and Engineering, 1991, 89(1-3): 309-336. doi: 10.1016/0045-7825(91)90046-9 [27] LAZAROV B S, SIGMUND O. Filters in topology optimization based on Helmholtz-type differential equations[J]. International Journal for Numerical Methods in Engineering, 2011, 86(6): 765-781. doi: 10.1002/nme.3072 [28] WANG F W, LAZAROV B S, SIGMUND O. On projection methods, convergence and robust formulations in topology optimization[J]. Structural and Multidisciplinary Optimization, 2011, 43(6): 767-784. doi: 10.1007/s00158-010-0602-y [29] Guo L H, Tang W C. Deep Study and Improvement of the Globally Convergent Version of MMA[J]. Applied Mechanics and Materials, 2014, 635: 1666-1670. [30] SHMUELI H, ZISKIND G, LETAN R. Melting in a vertical cylindrical tube: numerical investigation and comparison with experiments[J]. International Journal of Heat and Mass Transfer, 2010, 53(19-20): 4082-4091. doi: 10.1016/j.ijheatmasstransfer.2010.05.028 [31] ISMAIL K A R, ALVES C L F, MODESTO M S. Numerical and experimental study on the solidification of PCM around a vertical axially finned isothermal cylinder[J]. Applied Thermal Engineering, 2001, 21(1): 53-77. doi: 10.1016/S1359-4311(00)00002-8 -

下载:

下载: