-

摘要:

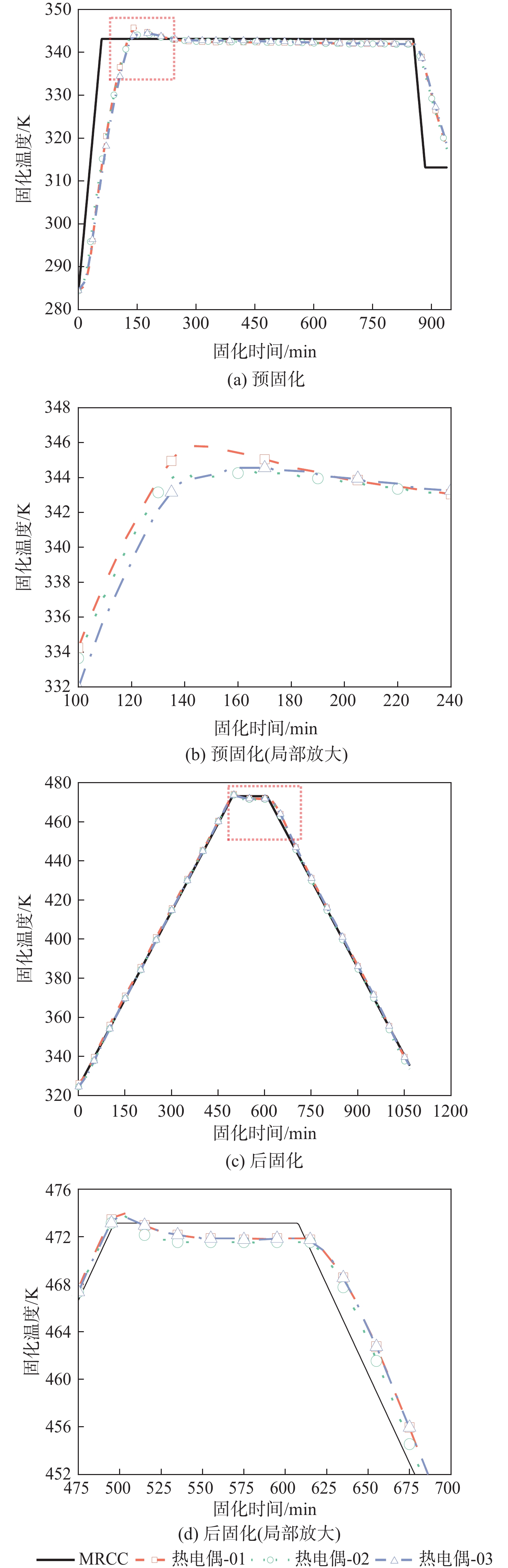

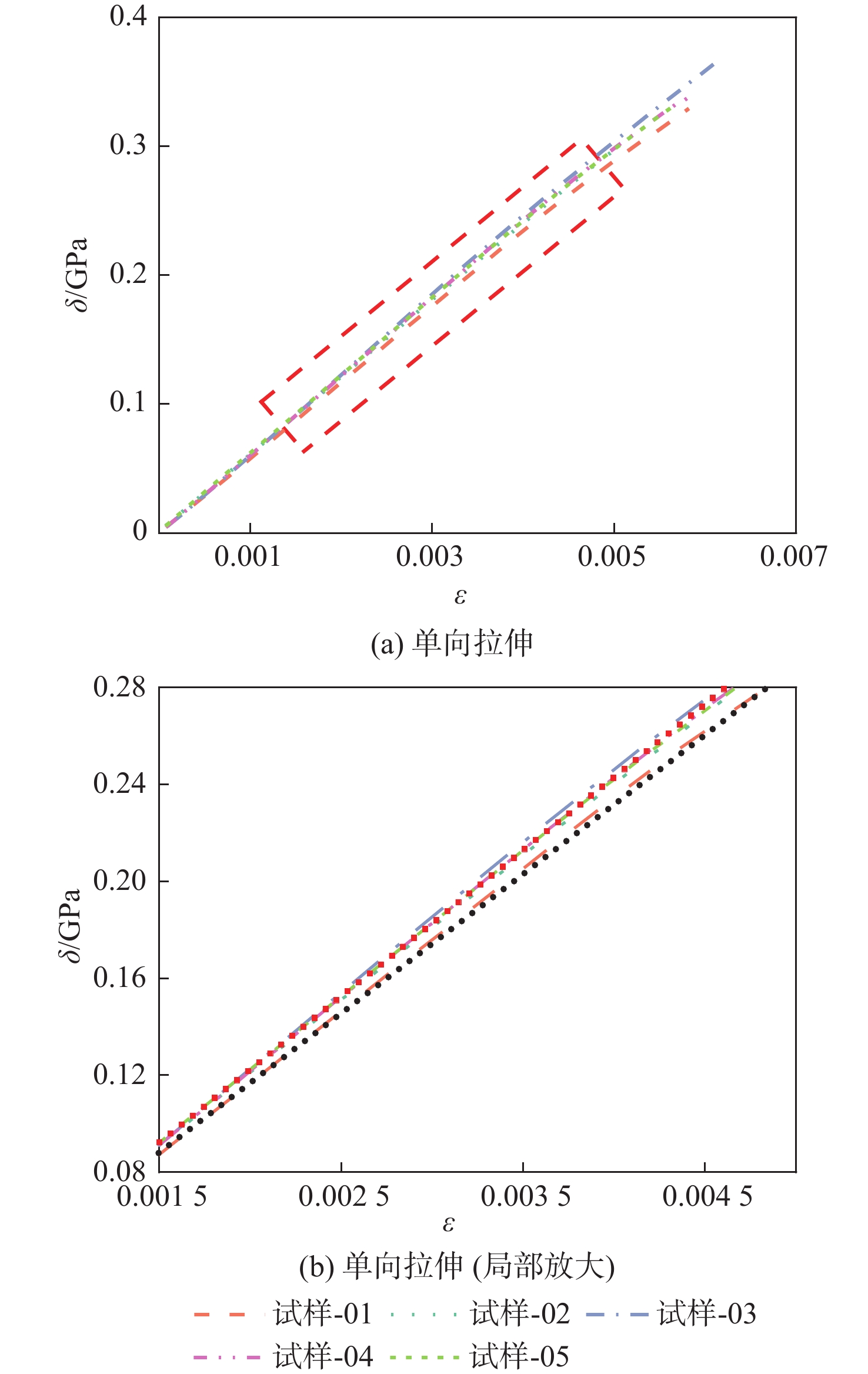

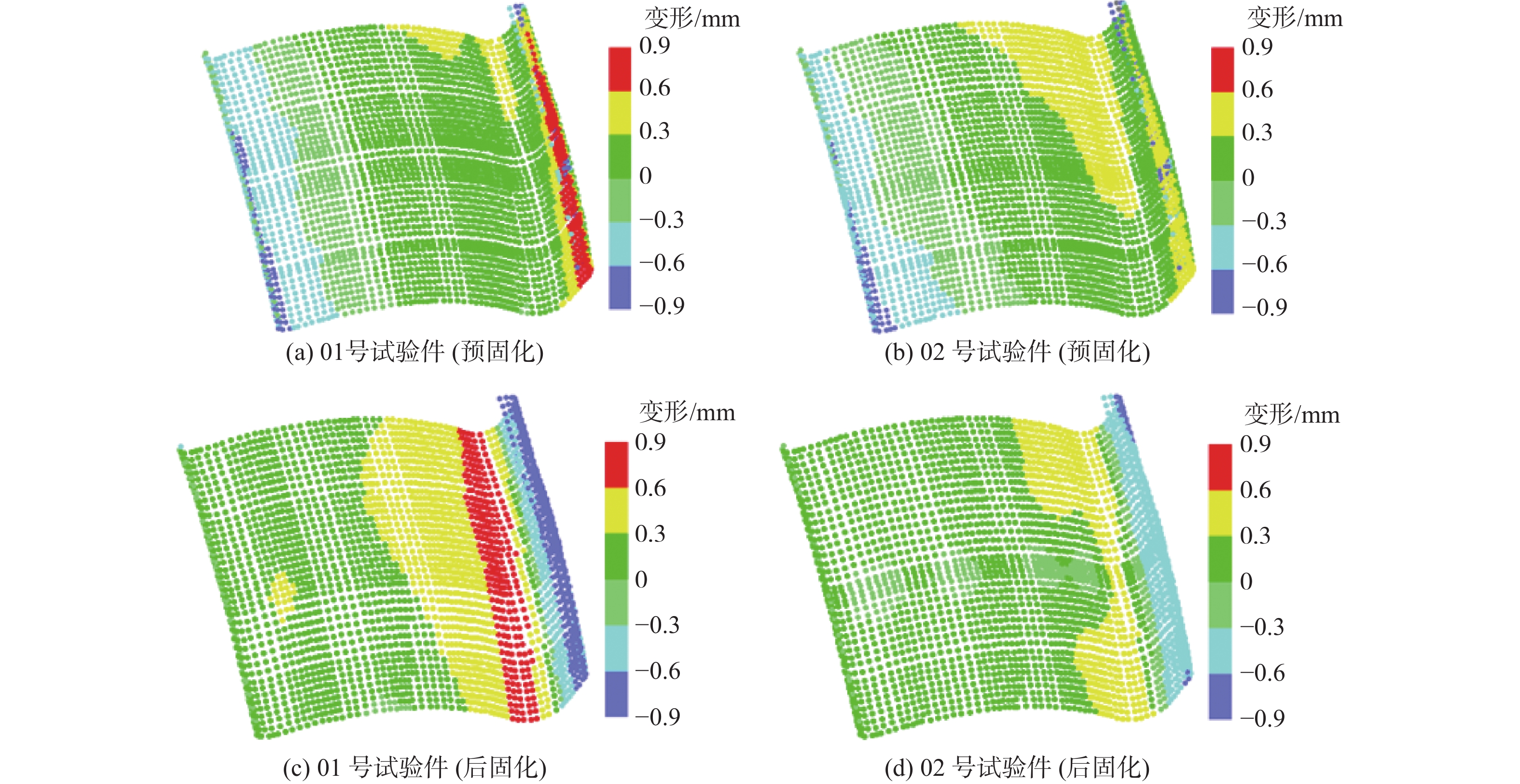

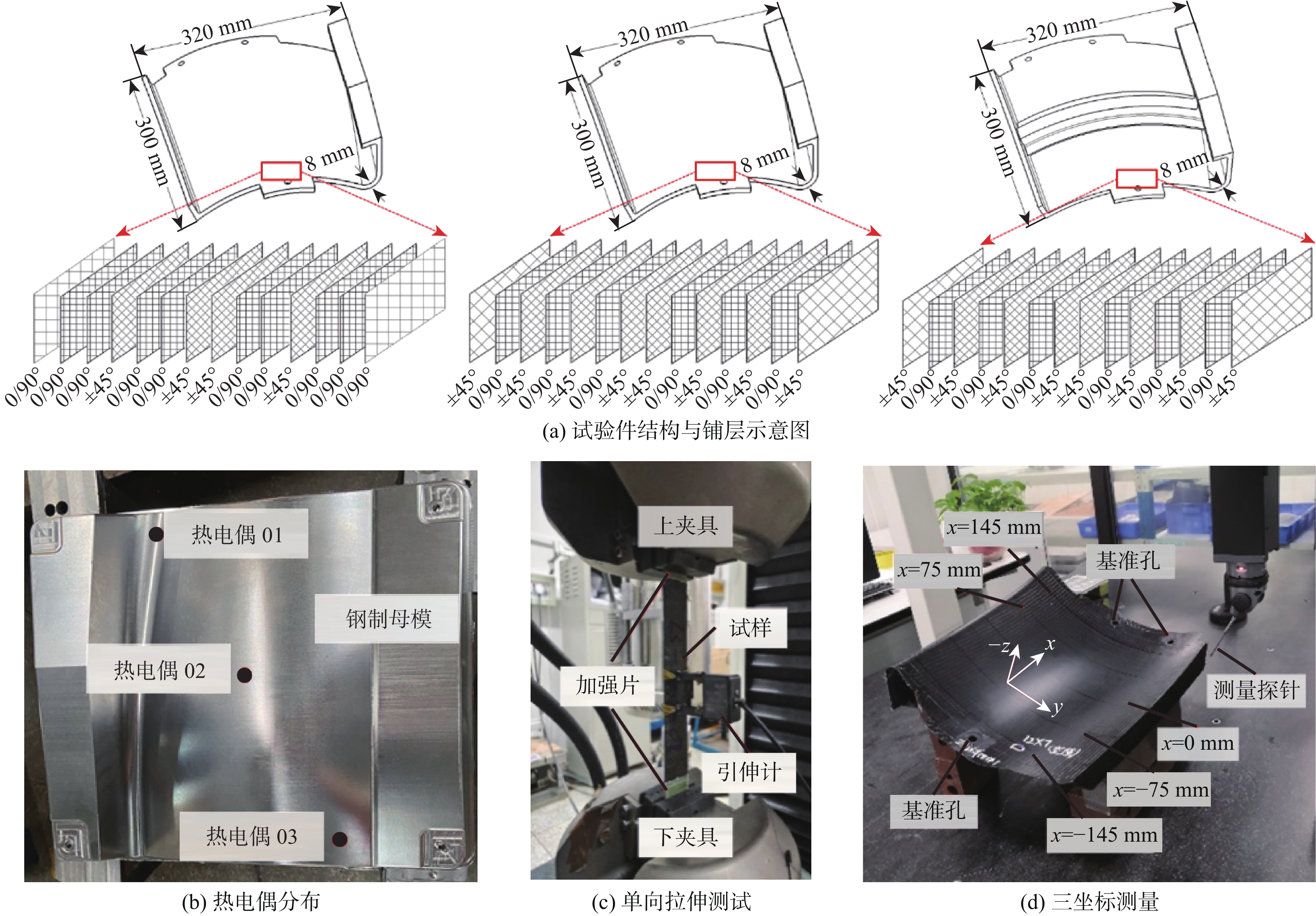

具有低温固化高温使用特点的复合材料工装预浸料,是制造航空航天高精度复合材料成型工装极具潜力的材料之一。为实现其低成本、高精度成型,模具用预浸料一般采用更为复杂的低温预固化和高温后固化组成的2步工艺。模具成型固化应力不仅影响模具初始型面精度,而且在模具热循环使用过程中还可能产生应力松弛,进一步引起模具型面精度变化,进而影响零件成型精度。本文针对碳纤维增强复合材料模具凹凸复杂型面特征,通过试验研究了固化成型阶段和热循环使用过程中模具型面精度变化规律及影响因素。试验结果表明:成型阶段的固化应力及其在使用过程中的应力松弛行为是造成模具型面精度变化的主要因素,且型面偏差随热循环使用周期的增加而逐渐趋于稳定;成型阶段,模具型面偏差主要来源于由热膨胀不匹配、树脂固化收缩及金属母模作用诱导的固化应力,而使用阶段,固化残余应力的松弛行为是引起模具型面偏差的主要原因。研究结果能够帮助理解复合材料模具结构稳定性变化,同时,对于降低复合材料模具制造成本、提高使用寿命,实现复杂高精度复合材料构件的精确制造具有重要意义。

Abstract:Tooling composites prepreg cured at low temperatures and used in high temperature is one of the most promising materials for forming composite tools to manufacture high-precision composite structures in the aerospace field. Tooling composites prepreg utilizes a specially designed two-step method that consists of low-temperature procuring and high-temperature post-curing in order to realize its low cost and high precision manufacture. The curing stress induced in composite tool manufacturing not only affects the accuracy of the initial tool profile, but may produce stress relaxation in the process of thermal recycling, which further causes the change of tool profile accuracy, and then affects the accuracy of components manufacturing. In this paper, the variation rules and influencing factors of profile accuracy of the complex profile characteristics of carbon fiber reinforced composite tools during solidification and thermal recycling were studied by experiments. The results show that the curing stress in the manufacturing process and the stress relaxation in the process of thermal recycling are the main factors that cause the variation of tool profile accuracy, and the profile deviation tends to be stable with the increase of the number of thermal recycling. Subsequent investigation reveals that the primary causes of the tool profile deviation during the manufacturing process are the interaction between the master mold and the composites tool, resin curing shrinkage, and thermal expansion mismatch-induced curing stress. In contrast, the primary cause of the mold surface deviation during the use stage is the relaxation behavior of the residual curing stress. The research results can help to understand the changes in the structural stability of composite tools. Meanwhile, it is of great significance to reduce the manufacturing cost of composite tools, improving the service life of composite tools and realizing the precise manufacturing of complex and high-precision composite components.

-

表 1 复合材料工装预浸料基本力学性能

Table 1. Basic mechanical properties of tooling composite material prepreg

牌号 轴向弹性模量/GPa 面内剪切模量/GPa 面内泊松比 XT-200 56 3.66 0.04 XT-650 59.5 4.35 0.08 -

[1] HASSAN M H, OTHMAN A R, KAMARUDDIN S. A review on the manufacturing defects of complex-shaped laminate in aircraft composite structures[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(9): 4081-4094. [2] 刘振东, 郑锡涛, 范雯静, 等. 固化残余应力对无人机复合材料机翼强度的影响[J]. 航空学报, 2022, 43(6): 526117.LIU Z D, ZHENG X T, FAN W J, et al. Effect of process-induced residual stress on strength of UAV composite wing[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(6): 526117(in Chinese). [3] LIAN J Y, XU Z B, RUAN X D. Analysis and control of cured deformation of fiber-reinforced thermosetting composites: a review[J]. Journal of Zhejiang University: Science A, 2019, 20(5): 311-333. doi: 10.1631/jzus.A1800565 [4] 岳广全, 张博明, 戴福洪, 等. 固化过程中模具与复合材料构件相互作用分析[J]. 复合材料学报, 2010, 27(6): 167-171.YUE G Q, ZHANG B M, DAI F H, et al. Interaction between mold and composite parts during curing process[J]. Acta Materiae Compositae Sinica, 2010, 27(6): 167-171(in Chinese). [5] YANG Q D, WEI K, YANG X J, et al. Microstructures and unique low thermal expansion of Invar 36 alloy fabricated by selective laser melting[J]. Materials Characterization, 2020, 166: 110409. doi: 10.1016/j.matchar.2020.110409 [6] GRANKÄLL T, HALLANDER P, PETERSSON M, et al. The true shape of composite cure tools[J]. Journal of Manufacturing Processes, 2020, 59: 279-286. doi: 10.1016/j.jmapro.2020.08.052 [7] 肖遥, 李东升, 吉康, 等. 大型复合材料航空件固化成型模具技术研究与应用进展[J]. 复合材料学报, 2022, 39(3): 907-925.XIAO Y, LI D S, JI K, et al. Research and application progress of curing tooling technology for large composite aeronautical components[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 907-925(in Chinese). [8] 魏灵航, 安鲁陵, 鲍益东, 等. 基于响应面的框架式复材成型模具轻量化设计[J]. 南京航空航天大学学报, 2020, 52(3): 422-429.WEI L H, AN L L, BAO Y D, et al. Lightweight design of frame molding die for composite materials based on response surface[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2020, 52(3): 422-429(in Chinese). [9] ZHANG G M, WANG J H, NI A Q, et al. Process-induced deformation of L-shaped variable-stiffness composite structures during cure[J]. Composite Structures, 2019, 230: 111461. doi: 10.1016/j.compstruct.2019.111461 [10] 王乾, 关志东, 王仁宇, 等. 结构参数对复合材料V型构件固化变形影响试验及解析分析[J]. 复合材料学报, 2017, 34(12): 2722-2733.WANG Q, GUAN Z D, WANG R Y, et al. Experimental and analytic analysis of the structure parameters on process-induced distortions of V-shaped composite parts[J]. Acta Materiae Compositae Sinica, 2017, 34(12): 2722-2733(in Chinese). [11] KAPPEL E. Forced-interaction and spring-in–relevant initiators of process-induced distortions in composite manufacturing[J]. Composite Structures, 2016, 140: 217-229. doi: 10.1016/j.compstruct.2016.01.016 [12] 贾丽杰, 叶金蕊, 刘卫平, 等. 结构因素对复合材料典型结构件固化变形影响[J]. 复合材料学报, 2013, 30(S1): 261-265.JIA L J, YE J R, LIU W P, et al. Influence of structural factor on curing deformation of typical composite structural part[J]. Acta Materiae Compositae Sinica, 2013, 30(S1): 261-265 (in Chinese). [13] FIORINA M, SEMAN A, CASTANIE B, et al. Spring-in prediction for carbon/epoxy aerospace composite structure[J]. Composite Structures, 2017, 168: 739-745. doi: 10.1016/j.compstruct.2017.02.074 [14] DONG C S. Process-induced deformation of composite T-stiffener structures[J]. Composite Structures, 2010, 92(7): 1614-1619. doi: 10.1016/j.compstruct.2009.11.026 [15] 王雪明, 谢富原. 碳纤维/双马树脂复合材料整体成型过程分层扩展行为实验研究[J]. 航空学报, 2021, 42(2): 424918.WANG X M, XIE F Y. Experimental study on behavior of delamination propagation of carbon fiber/bismaleimide composites during integral forming process[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(2): 424918(in Chinese). [16] 杨晓波, 湛利华, 蒋成标, 等. 模具材料对复合材料制件固化过程应变的影响分析[J]. 南京航空航天大学学报, 2018, 50(1): 24-29.YANG X B, ZHAN L H, JIANG C B, et al. Influence of mould materials on curing process and deformation of composite part[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2018, 50(1): 24-29(in Chinese). [17] LIU X D, GUAN Z D, WANG X D, et al. Study on cure-induced residual stresses and spring-in deformation of L-shaped composite laminates using a simplified constitutive model considering stress relaxation[J]. Composite Structures, 2021, 272: 114203. doi: 10.1016/j.compstruct.2021.114203 [18] BENAVENTE M, MARCIN L, COURTOIS A, et al. Numerical analysis of viscoelastic process-induced residual distortions during manufacturing and post-curing[J]. Composites Part A: Applied Science and Manufacturing, 2018, 107: 205-216. doi: 10.1016/j.compositesa.2018.01.005 [19] BENAVENTE M, MARCIN L, COURTOIS A, et al. Viscoelastic distortion in asymmetric plates during post curing[J]. Composites Part A: Applied Science and Manufacturing, 2017, 103: 122-130. doi: 10.1016/j.compositesa.2017.09.017 [20] HU H X, LI S X, WANG J H, et al. Monitoring the gelation and effective chemical shrinkage of composite curing process with a novel FBG approach[J]. Composite Structures, 2017, 176: 187-194. doi: 10.1016/j.compstruct.2017.04.051 [21] GARSTKA T, ERSOY N, POTTER K D, et al. In situ measurements of through-the-thickness strains during processing of AS4/8552 composite[J]. Composites Part A: Applied Science and Manufacturing, 2007, 38(12): 2517-2526. doi: 10.1016/j.compositesa.2007.07.018 [22] SHAH D B, PATEL K M, PATEL A I, et al. Experimental investigation on spring-back deformation during autoclave curing of parabolic antenna reflectors[J]. Composites Part A: Applied Science and Manufacturing, 2018, 115: 134-146. doi: 10.1016/j.compositesa.2018.09.017 [23] FERNLUND G, POURSARTIP A, TWIGG G, et al. Residual stress, spring-in and warpage in autoclaved composite parts[C]// International Conference on Composite Materials. Vancouver: University of British Columbia, 2003: 1-10. -

下载:

下载: