-

摘要:

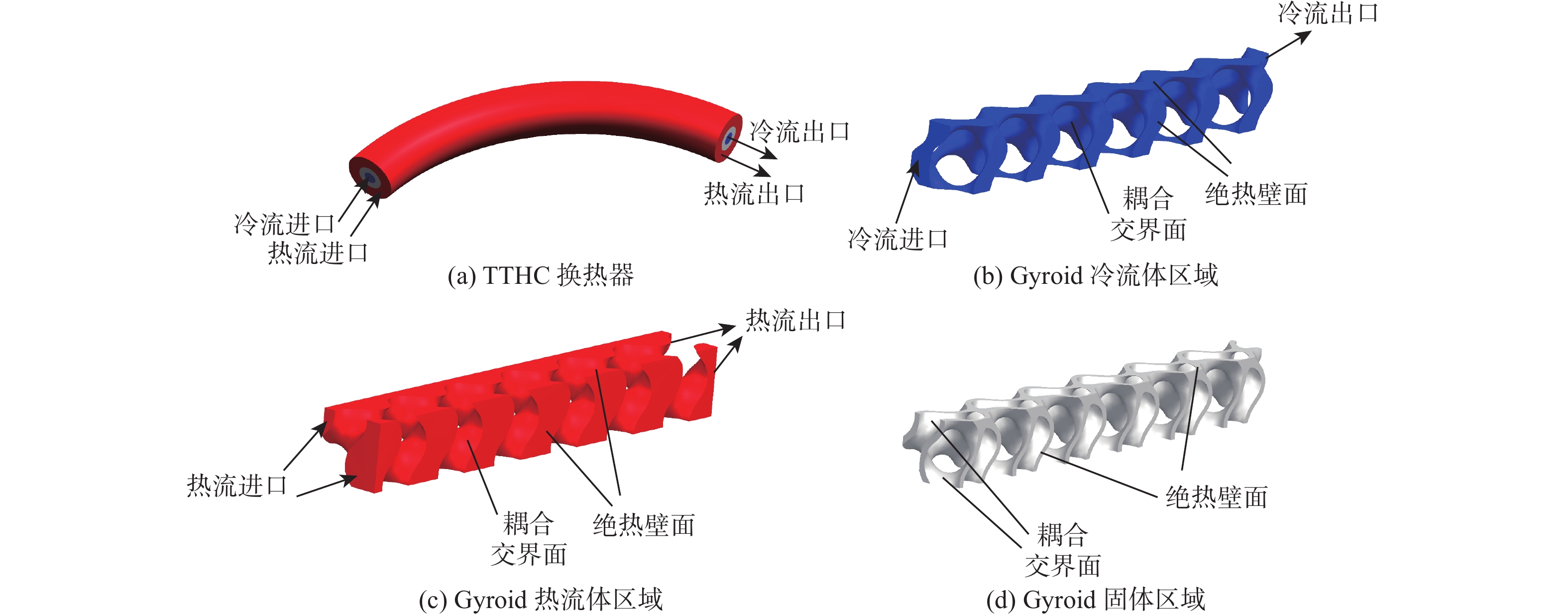

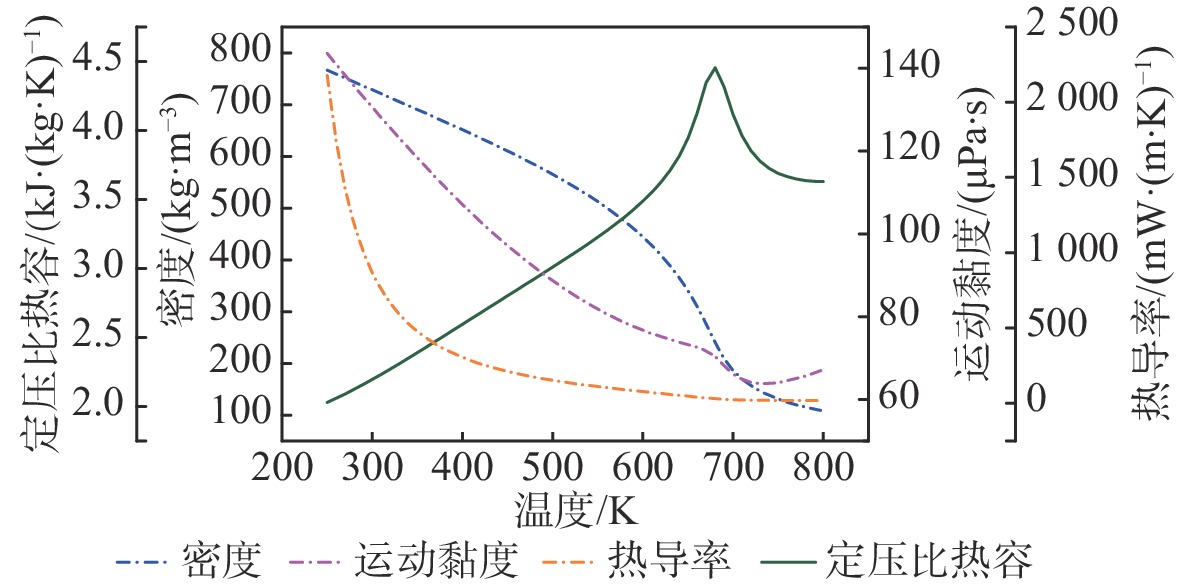

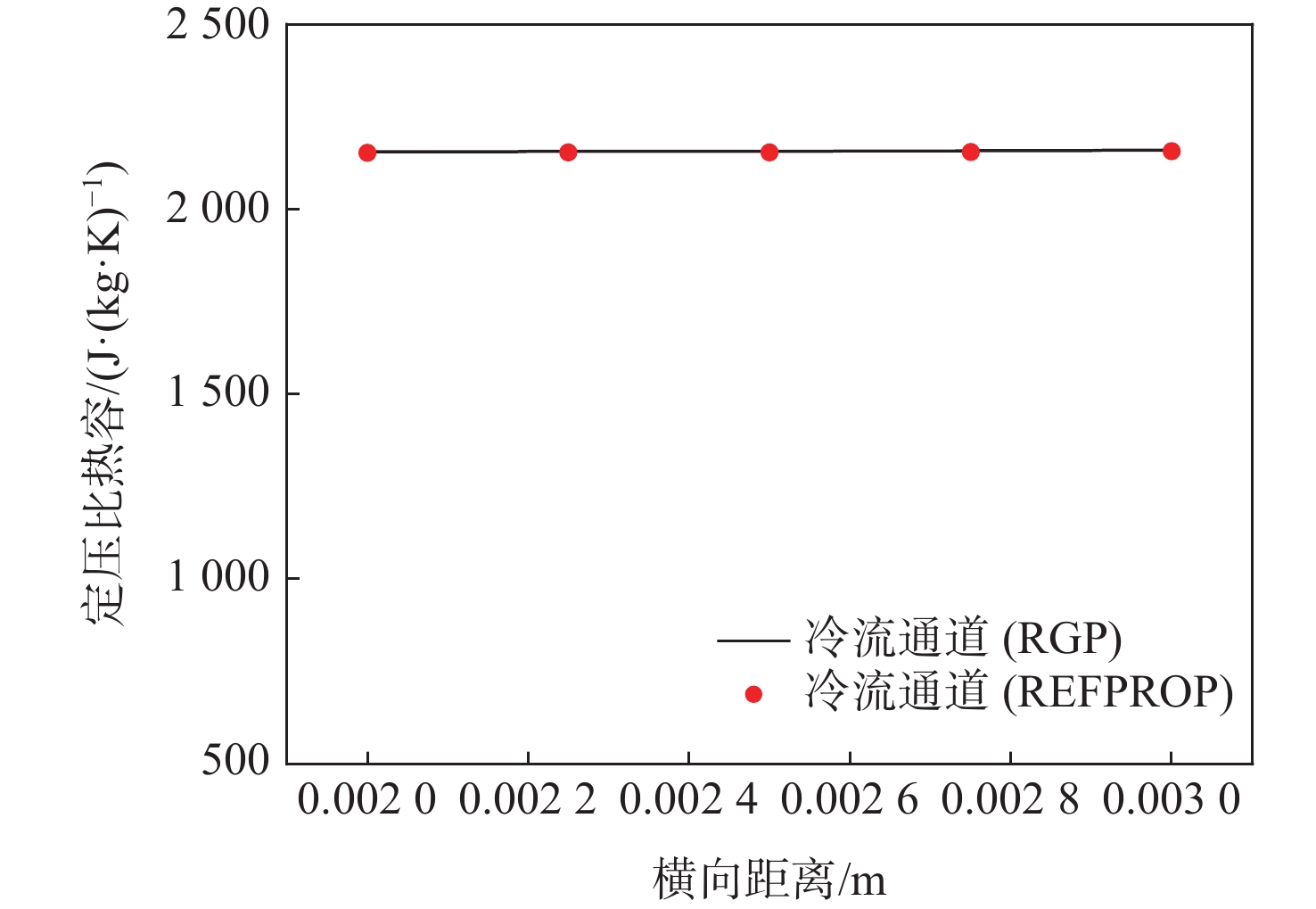

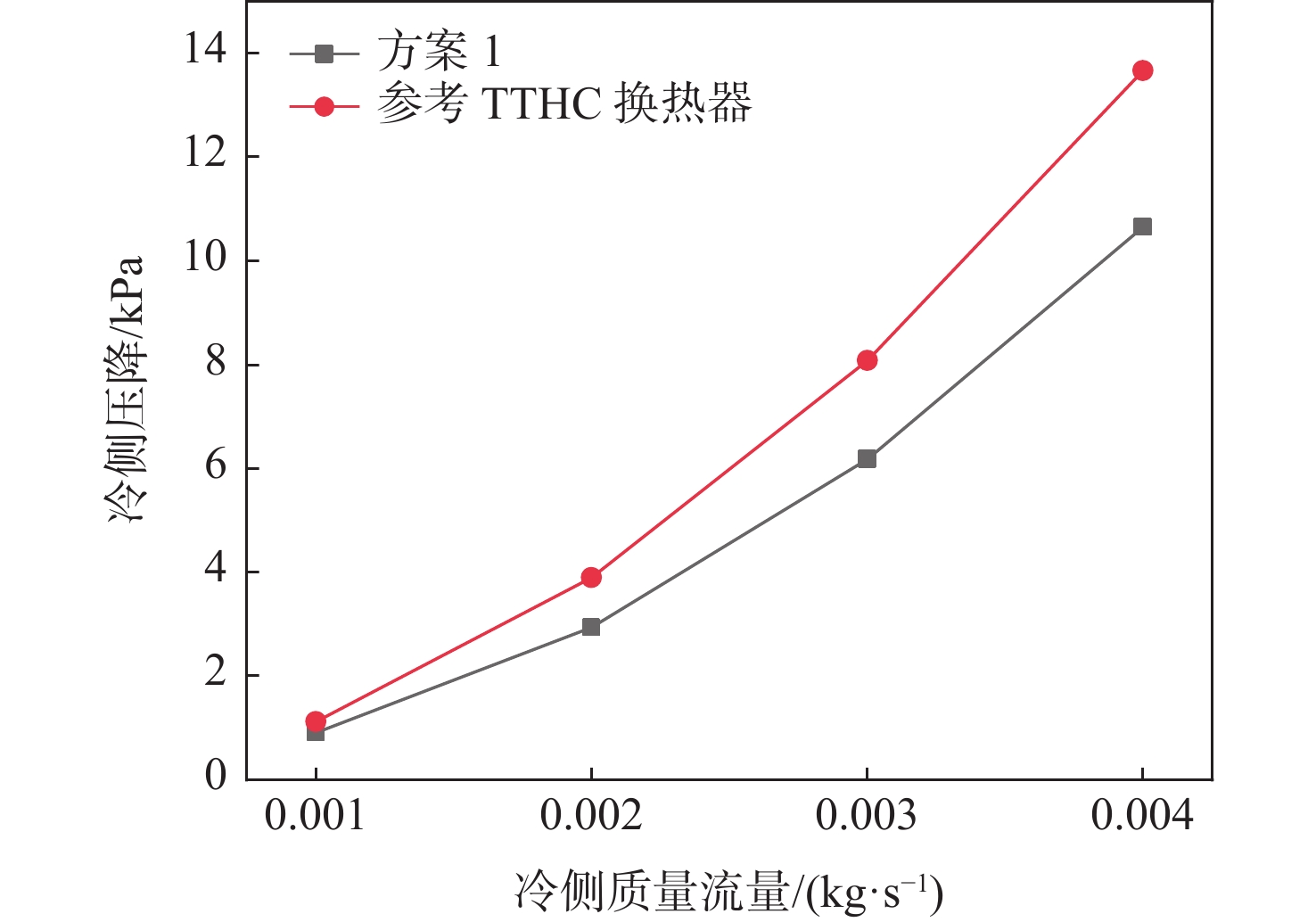

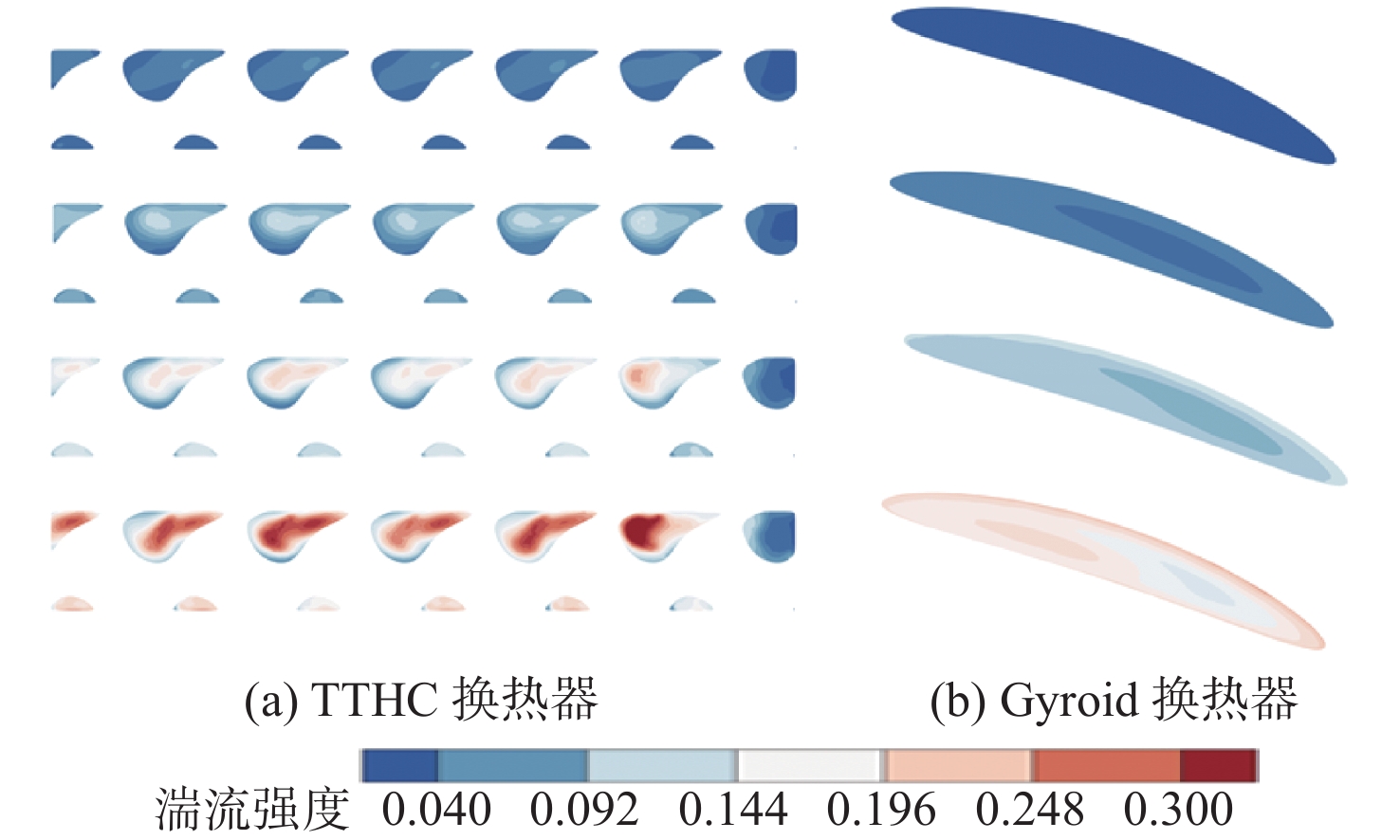

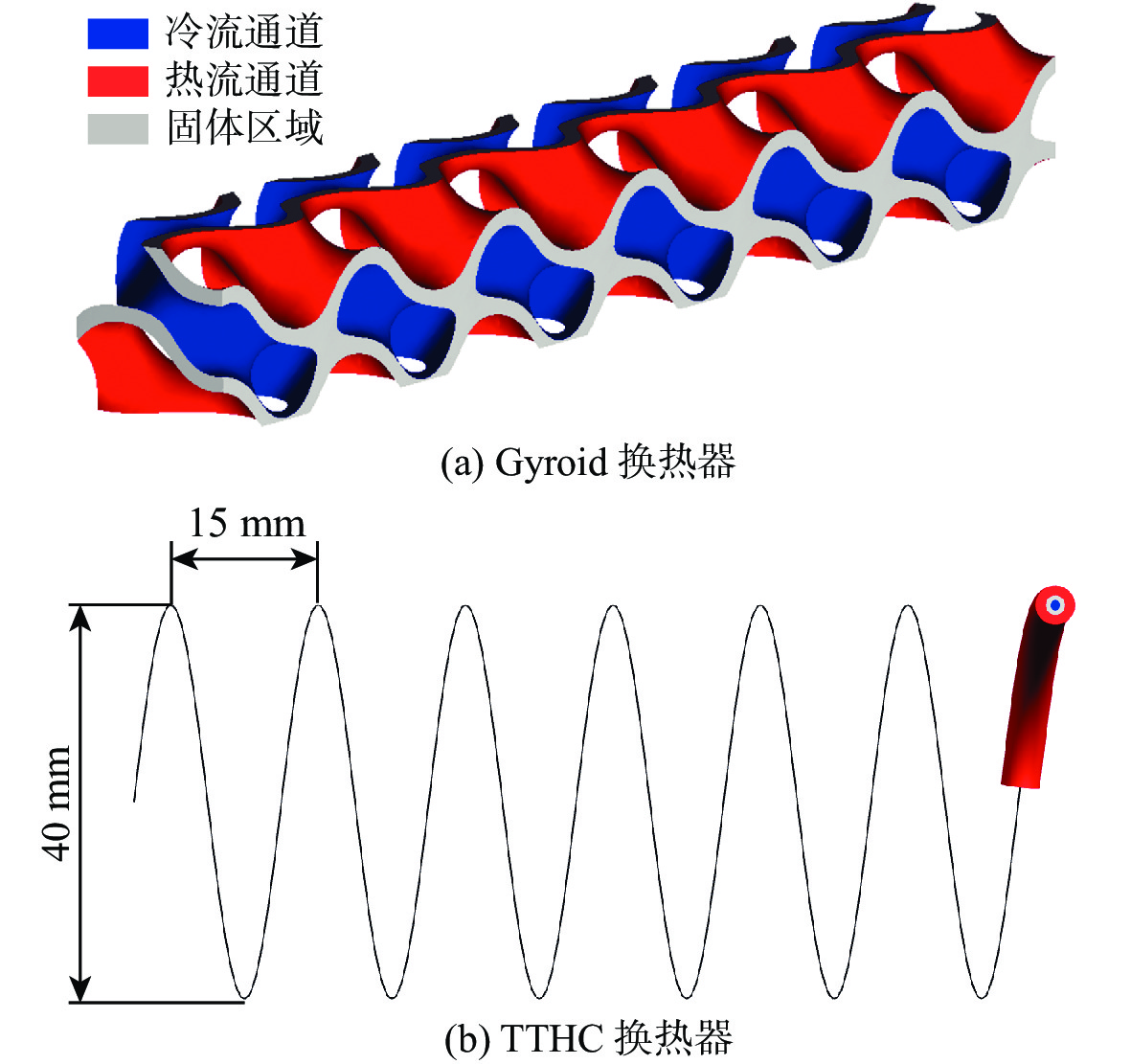

为研究三重周期极小曲面(TPMS)在空气-燃油换热器中的流动换热特性,分析结构参数对换热器性能的影响。采用田口方法,针对壁厚、晶格大小和偏移尺寸3个结构参数,对努塞尔数和摩擦系数进行综合评估,并与参考的螺旋套管(TTHC)换热器性能进行对比。研究得出各个结构参数影响Gyroid换热器努塞尔数和摩擦系数方面的主次顺序,并利用矩阵分析法,确定了最优方案。结果表明:对于热侧出口温度,TTHC换热器比参考的Gyroid换热器最高降低13.13 K;对于压降,TTHC换热器比参考的Gyroid换热器降低3.02 kPa;对于性能评估系数,热侧通道最高为14.72,冷侧通道最高为0.78。

Abstract:In order to study the flow and heat transfer characteristics of triple periodic minimal surfaces (TPMS) in an air-fuel heat exchanger, the influence of structural parameters on the performance of the heat exchanger was analyzed. By using the Taguchi method, the Nusselt number and friction coefficient were comprehensively evaluated for the three structural parameters of wall thickness, unit cell size, and offset size and compared with the performance of a tube-in-tube helical coil (TTHC) heat exchanger. The primary and secondary order of each structural parameter affecting the Nusselt number and friction coefficient of the Gyroid heat exchanger was obtained, and the optimal scheme was determined by using the matrix analysis method. The results show that compared with that of the TTHC heat exchanger, the hot-side outlet temperature of the Gyroid heat exchanger is reduced by up to 13.13 K, and the pressure drop of the Gyroid heat exchanger is reduced by 3.02 kPa. The highest performance evaluation coefficient of the hot-side channel is 14.72, and that of the cold-side channel is 0.78.

-

表 1 边界条件

Table 1. Boundary conditions

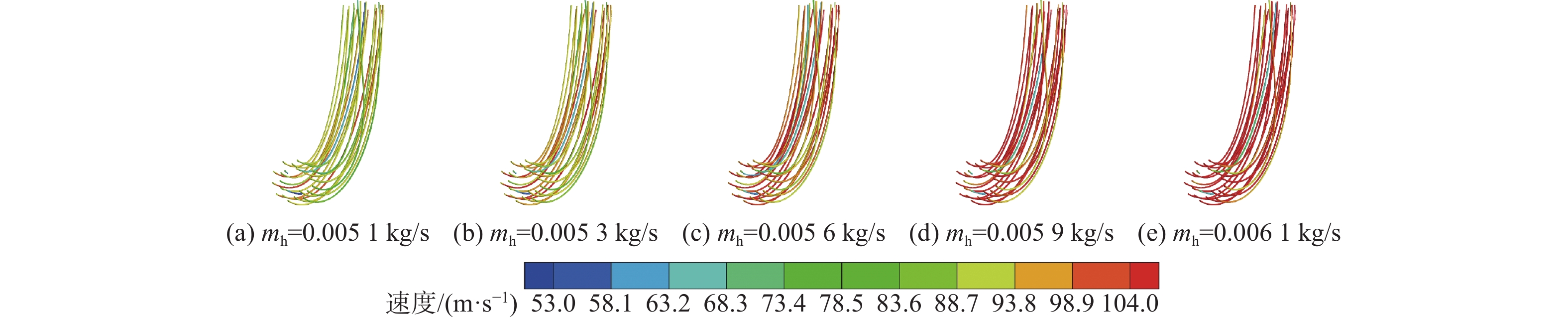

边界 质量流量˙m/(kg·s−1) 进口温度Tin/K 出口压力Pout/MPa 冷侧 0.001,0.002,0.003,0.004 288 4.0 热侧 0.0051 ,0.0053 ,0.0056 ,0.0059 ,0.0061 623 1.0 表 2 结构参数

Table 2. Structural parameters

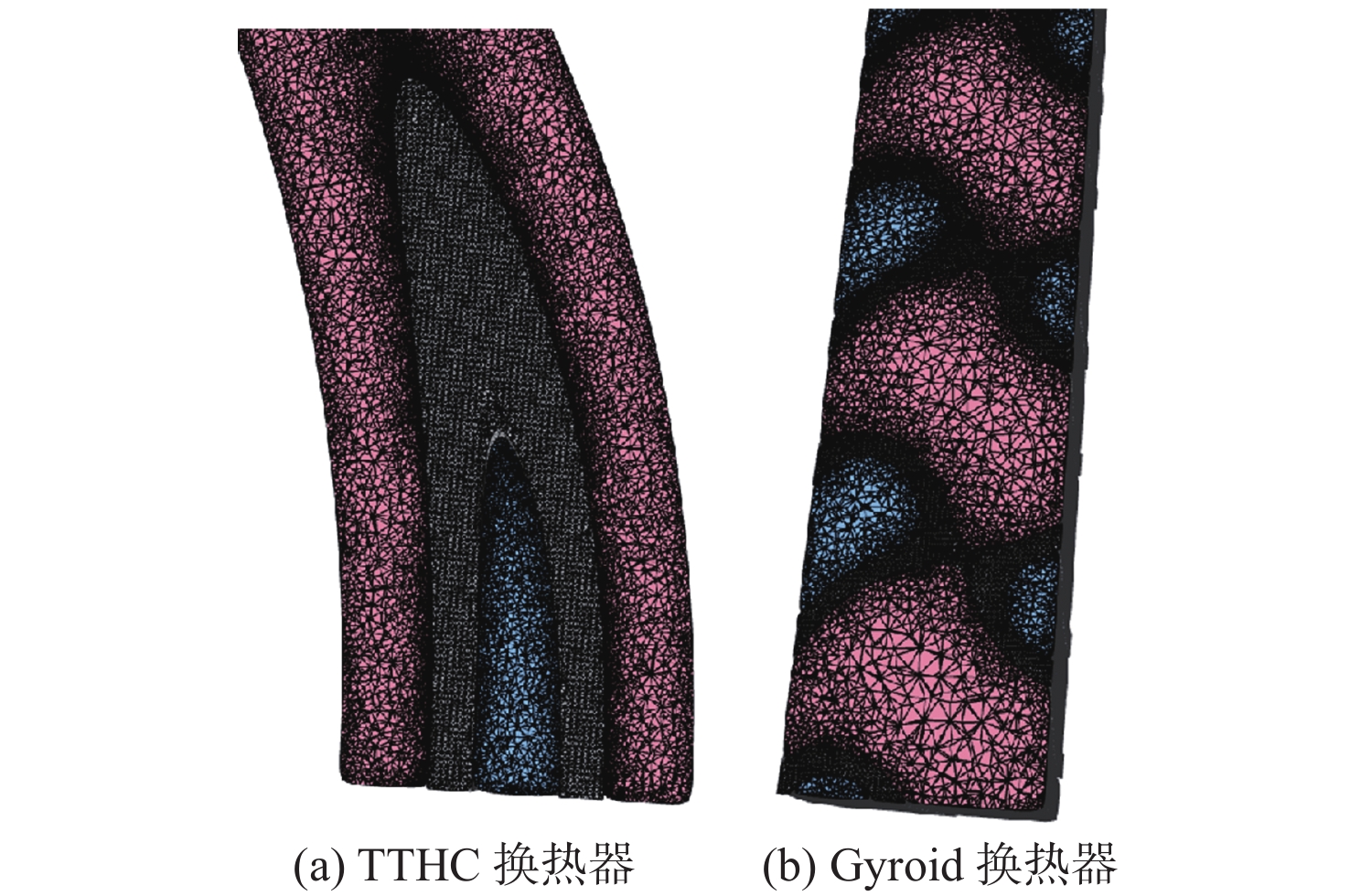

单元晶格大小/mm 结构偏移量/mm 壁厚/mm (5,5,5)

(7,7,7)

(8,8,8)0.2,0.3,0.4 0.3,0.4,0.5 表 3 网格无关性

Table 3. Grid independence

网格数 努塞尔数 摩擦系数 2.1×106 141.838 0.0246 3.1×106 141.842 0.0251 4.1×106 141.844 0.0253 5.1×106 141.841 0.0250 表 4 Gyroid换热器的努塞尔数和摩擦系数及对应的信噪比

Table 4. Nusselt number and friction coefficient of Gyroid heat exchanger and corresponding signal to noise

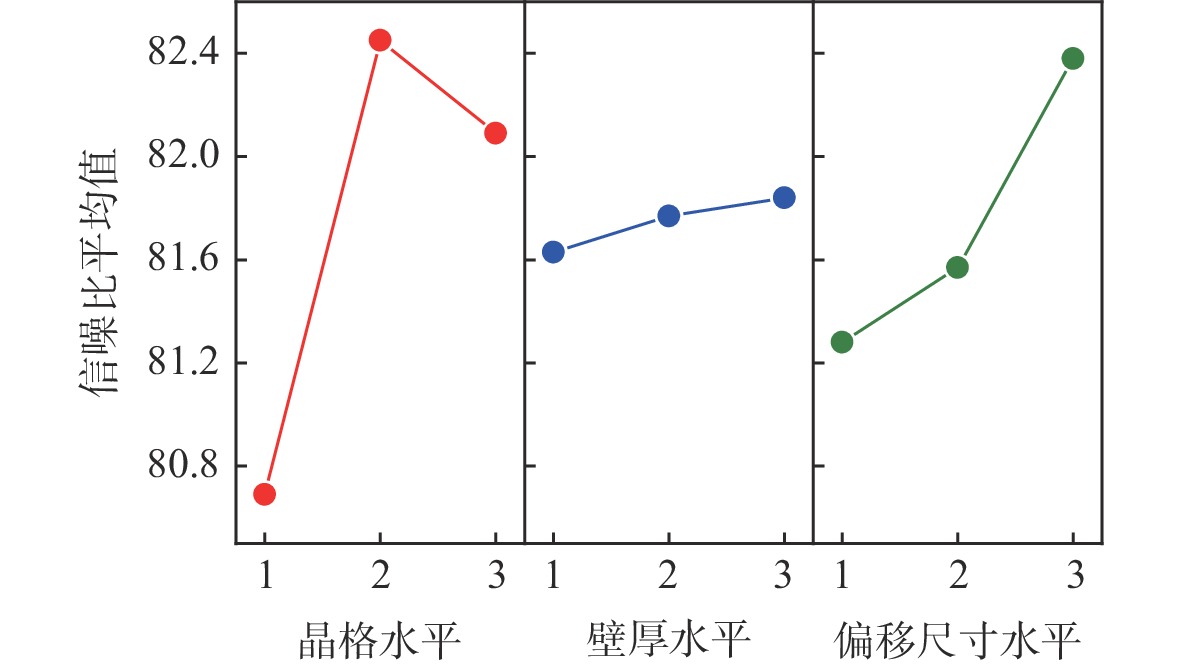

方案 晶格大小/mm 壁厚/mm 偏移尺寸/mm 热侧Nu 冷侧f 信噪比 Nu f 1 5 0.3 0.2 10894.77 1.10 80.74 −0.83 2 5 0.4 0.3 10495.93 1.32 80.42 −2.41 3 5 0.5 0.4 11117.05 2.25 80.92 −7.04 4 7 0.3 0.3 12095.37 1.81 81.65 −5.15 5 7 0.4 0.4 15362.57 1.99 83.73 −5.98 6 7 0.5 0.2 12527.27 1.64 81.96 −4.30 7 8 0.3 0.4 13342.29 1.33 82.50 −2.48 8 8 0.4 0.2 11411.02 1.20 81.15 −1.58 9 8 0.5 0.3 13540.53 1.35 82.63 −2.61 表 5 各个水平下努塞尔数计算结果和相应的信噪比

Table 5. Nusselt number calculation results and corresponding signal to noise at each level

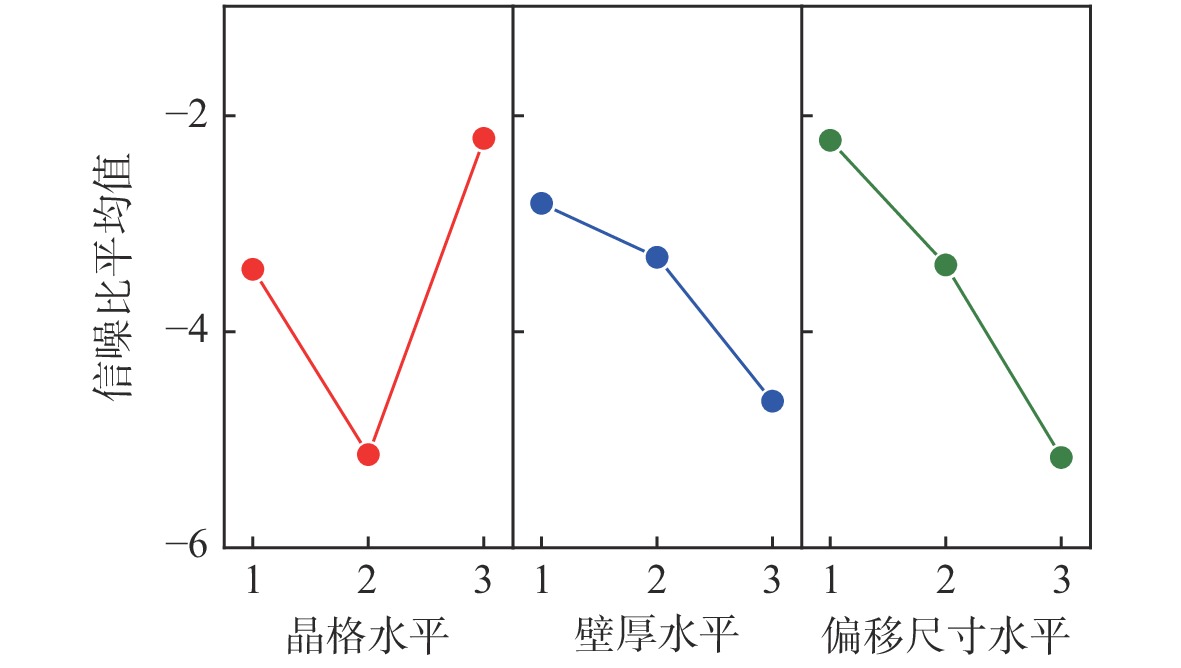

水平 晶格大小/mm 壁厚/mm 偏移尺寸/mm 信噪比 晶格大小 壁厚 偏移尺寸 1 10835.92 12110.81 11611.02 80.69 81.63 81.28 2 13328.40 12423.17 12043.94 82.45 81.77 81.57 3 12764.61 12394.95 13273.97 82.09 81.84 82.38 极差 2492.48 312.36 1662.95 1.76 0.21 1.1 表 6 各个水平下摩擦系数计算结果和相应的信噪比

Table 6. Friction coefficient calculation results and corresponding signal to noise at each level

水平 晶格大小/mm 壁厚/mm 偏移尺寸/mm 信噪比 晶格大小 壁厚 偏移尺寸 1 1.56 1.41 1.31 −3.43 −2.82 −2.24 2 1.81 1.50 1.49 −5.14 −3.32 −3.39 3 1.29 1.75 1.86 −2.22 −4.65 −5.17 极差 0.52 0.34 0.55 2.92 1.83 2.93 表 7 冷热通道的性能评估系数

Table 7. Performance evoluation coefficient for hot and cold channels

方案 冷侧性能评估系数 热侧性能评估系数 1 0.56 11.59 2 0.55 11.42 3 0.78 12.10 4 0.67 11.70 5 0.73 14.72 6 0.70 11.93 7 0.60 10.90 8 0.74 9.13 9 0.50 10.65 -

[1] VLAHINOS M, O’HARA R. Unlocking advanced heat exchanger design and simulation with nTop platform and ANSYS CFX[EB/OL]. https://www.revolutioninsimulation.org/wp-content/uploads/2020/06/WP_HeatExchangerDesignSimulation.pdf. [2] REYNOLDS B W. Simulation of flow and heat transfer in 3D printable triply periodic minimal surface heat exchangers[D]. Christchurch: University of Canterbury, 2020. [3] WADSOE I, HOLMQVIST S. Additively manufactured heat exchangers—development and testing[D]. Lund: Lund University , 2020. [4] KIM J, YOO D J. 3D printed compact heat exchangers with mathematically defined core structures[J]. Journal of Computational Design and Engineering, 2020, 7(4): 527-550. doi: 10.1093/jcde/qwaa032 [5] IYER J, MOORE T, NGUYEN D, et al. Heat transfer and pressure drop characteristics of heat exchangers based on triply periodic minimal and periodic nodal surfaces[J]. Applied Thermal Engineering, 2022, 209: 118192. doi: 10.1016/j.applthermaleng.2022.118192 [6] DIXIT T, AL-HAJRI E, PAUL M C, et al. High performance, microarchitected, compact heat exchanger enabled by 3D printing[J]. Applied Thermal Engineering, 2022, 210: 118339. doi: 10.1016/j.applthermaleng.2022.118339 [7] DHARMALINGAM L K, AUTE V, LING J Z. Review of triply periodic minimal surface (TPMS) based heat exchanger designs[C]//Proceedings of the 19th International Refrigeration and Air Conditioning Conference at Purdue. West Lafayette : Purdue University, 2022. [8] PENG H, GAO F, HU W J. Design, modeling and characterization on triply periodic minimal surface heat exchangers with additive manufacturing[C]//Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium. Austin: University of Texas, 2019, 2325–2337. [9] LI W H, YU G P, YU Z B. Bioinspired heat exchangers based on triply periodic minimal surfaces for supercritical CO2 cycles[J]. Applied Thermal Engineering, 2020, 179: 115686. doi: 10.1016/j.applthermaleng.2020.115686 [10] LI W G, LI W H, YU Z B. Heat transfer enhancement of water-cooled triply periodic minimal surface heat exchangers[J]. Applied Thermal Engineering, 2022, 217: 119198. doi: 10.1016/j.applthermaleng.2022.119198 [11] FEMMER T, KUEHNE A J C, WESSLING M. Estimation of the structure dependent performance of 3-D rapid prototyped membranes[J]. Chemical Engineering Journal, 2015, 273: 438-445. doi: 10.1016/j.cej.2015.03.029 [12] ALTENEIJI M, ALI M I H, KHAN K A, et al. Heat transfer effectiveness characteristics maps for additively manufactured TPMS compact heat exchangers[J]. Energy Storage and Saving, 2022, 1(3): 153-161. doi: 10.1016/j.enss.2022.04.005 [13] LIANG D, SHI C W, LI W H, et al. Design, flow characteristics and performance evaluation of bioinspired heat exchangers based on triply periodic minimal surfaces[J]. International Journal of Heat and Mass Transfer, 2023, 201: 123620. doi: 10.1016/j.ijheatmasstransfer.2022.123620 [14] WEN J, HUANG H R, LI H W, et al. Thermal and hydraulic performance of a compact plate finned tube air-fuel heat exchanger for aero-engine[J]. Applied Thermal Engineering, 2017, 126: 920-928. doi: 10.1016/j.applthermaleng.2017.07.103 [15] LIU P H, WANG R T, LIU S B, et al. Experimental study on the thermal-hydraulic performance of a tube-in-tube helical coil air–fuel heat exchanger for an aero-engine[J]. Energy, 2023, 267: 126626. doi: 10.1016/j.energy.2023.126626 [16] HERRING N R, HEISTER S D. On the use of wire-coil inserts to augment tube heat transfer[J]. Journal of Enhanced Heat Transfer, 2009, 16(1): 19-34. doi: 10.1615/JEnhHeatTransf.v16.i1.20 [17] 杜默, 孟宝, 潘丰, 等. 考虑制造约束的印刷电路板式换热器优化设计[J]. 北京航空航天大学学报, 2022, 48(10): 1994-2005.DU M, MENG B, PAN F, et al. Optimal design of printed circuit heat exchanger considering manufacturing constraints[J]. Journal of Beijing University of Aeronautics and Astronautics, 2022, 48(10): 1994-2005(in Chinese). [18] TANDEL S, RAMMOHAN S. Design for additive manufacturing of high performance heat exchangers[D]. Hamilton: Mcmaster University, 2022: 77-78. [19] JIANG J H, WANG F H, YANG X, et al. Evaluation of the long-term performance of the deep U-type borehole heat exchanger on different geological parameters using the Taguchi method[J]. Journal of Building Engineering, 2022, 59: 105122. doi: 10.1016/j.jobe.2022.105122 [20] 魏效玲, 薛冰军, 赵强. 基于正交试验设计的多指标优化方法研究[J]. 河北工程大学学报(自然科学版), 2010, 27(3): 95-99.WEI X L, XUE B J, ZHAO Q. Optimization design of the stability for the plunger assembly of oil pumps based on multi-target orthogonal test design[J]. Journal of Hebei University of Engineering (Natural Science Edition), 2010, 27(3): 95-99(in Chinese). -

下载:

下载: