Tensile properties of rapid repaired CCF300/QY8911 laminates with broken hole damage

-

摘要:

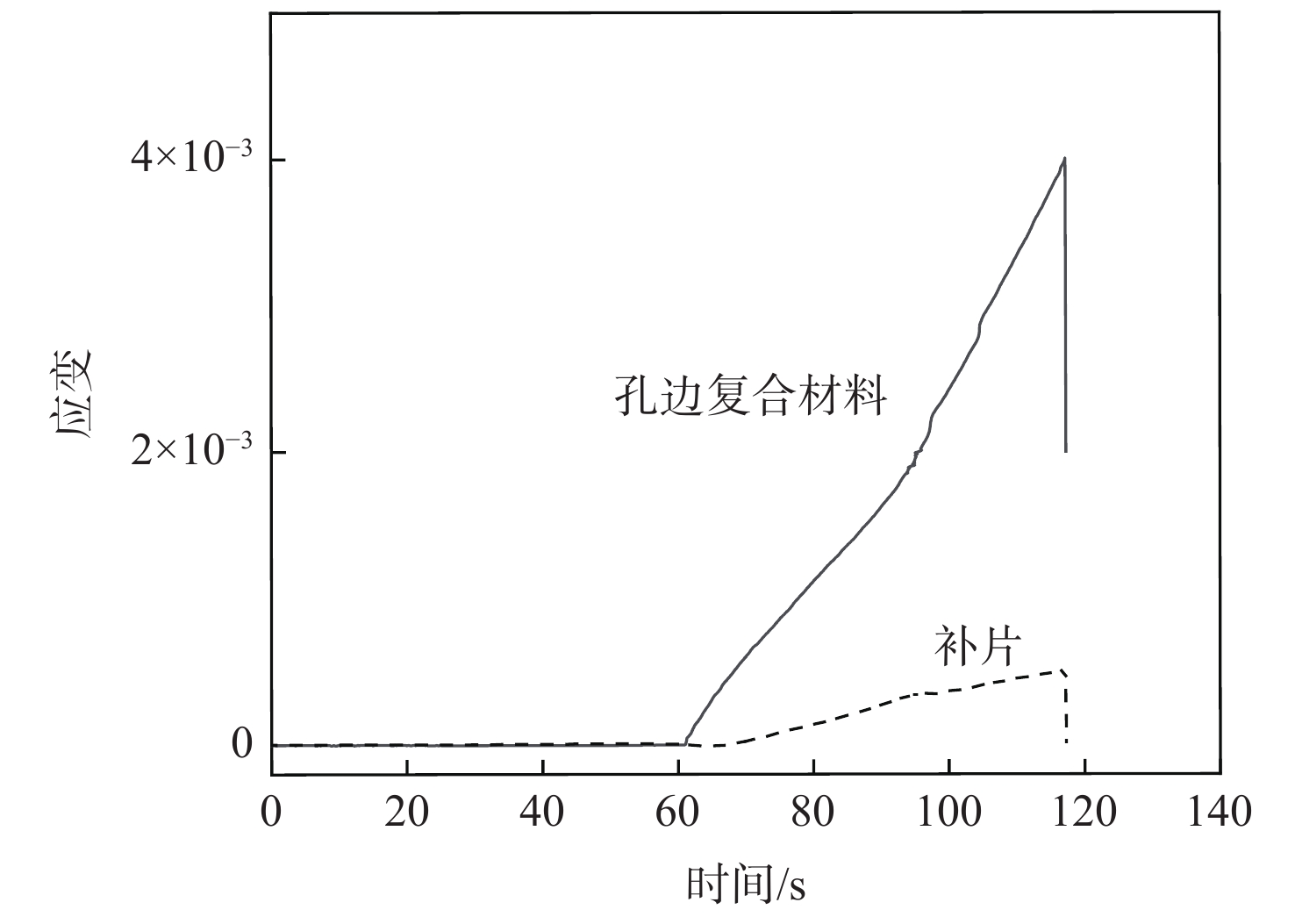

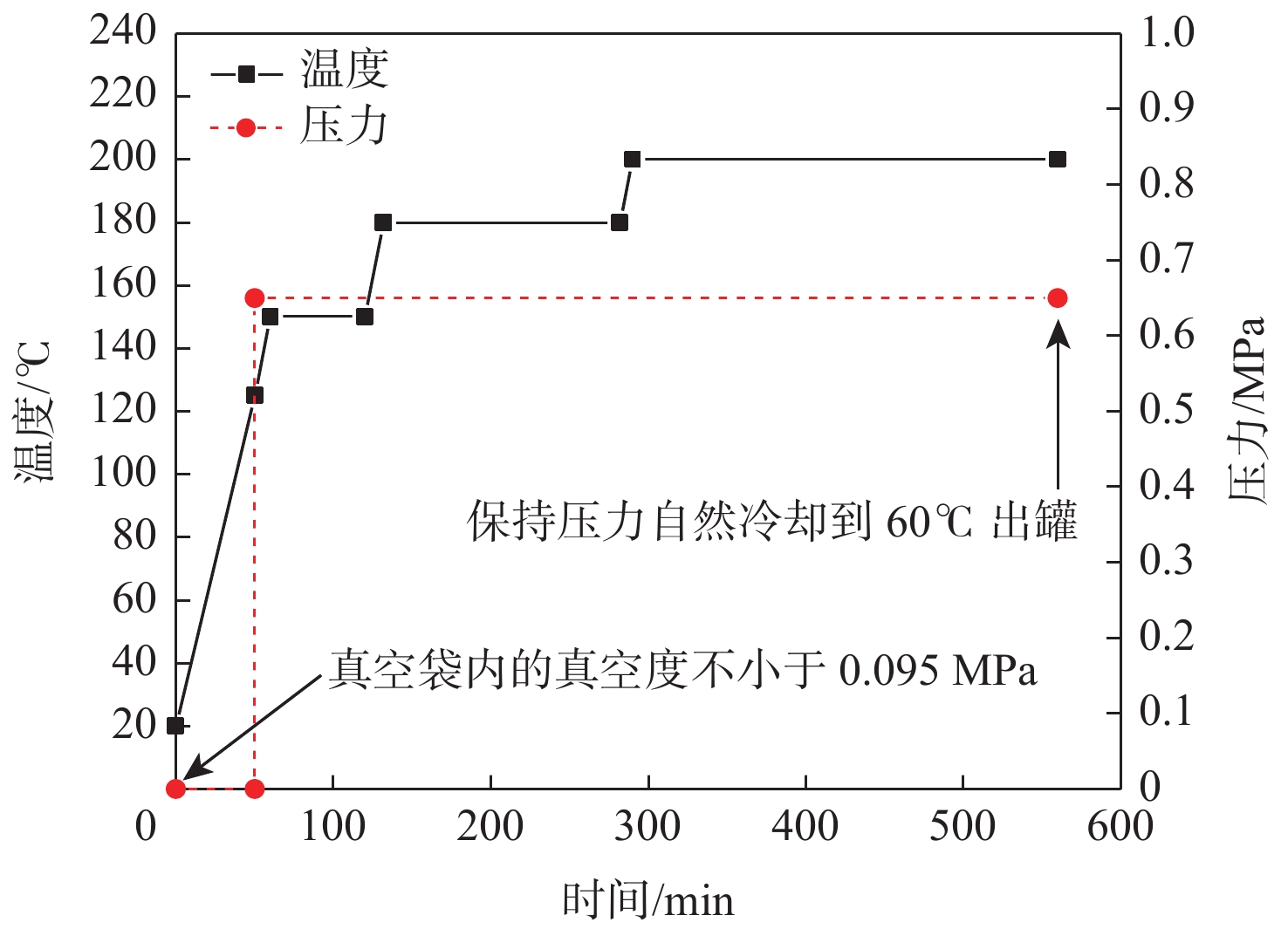

针对CCF300/QY8911复合材料层压板破孔损伤抢修后的拉伸强度影响规律和表征方法问题,通过对原始材料标准试件、含预制损伤试件及通过胶接、铆接和胶铆联合修理后试件的拉伸试验,得到了相应的强度、刚度、损伤模式和重点部位应变数据。结果表明,修理部位与原结构刚度不协调是影响修理强度的主要因素;胶接修理具有较高的连接刚度,其修理强度影响因素主要是铺层间结合强度;铆接修理连接刚度较低,且铆钉受单剪容易被拉脱是影响其修理强度的主要因素;胶铆联合修理综合了胶接修理刚度高和铆接修理能防止层间撕裂的双重优势;综合采用胶铆联合湿装配工艺、增加铆钉直径和在工件背面加装防拉脱垫片可显著提高修理效果,其抗拉强度分别为常规铆接修理和常规胶接修理的161.5%和135.9%。所提的基于线弹性断裂理论的强度恢复率评价方法能更好地从整体上表征修理后结构的真实承载能力。

Abstract:The tensile strength of the CCF300/QY8911 composite laminate after hole damage repair was evaluated using a set of rules and characterization methods. To obtain the necessary data, tensile tests were conducted on standard specimens made from the original material, damaged specimens without repair, and specimens repaired using bonding, riveting, and bonding-riveting joint repair techniques. The corresponding data included strength, stiffness, damage mode, and key point strain. The following conclusions were drawn through comprehensive analysis: the incompatibility between the repair location and the original structure stiffness is the main factor affecting the repair strength; bonding repair has a high connection stiffness, and the main influencing factor of repair strength is the lamina bonding strength;on the other hand, riveting repair, which has a low connection stiffness, is mainly affected by the ease of pulling out the rivet in single shear; bonding-riveting joint repair combines the high stiffness of bonding repair and the dual advantage of riveting repair to prevent interlayer tearing; significantly improving the repair effect by adopting the combined wet assembly process of bonding-riveting, increasing the diameter of rivets, and installing anti-slip pads on the back of the workpiece can achieve a tensile strength of 161.5% and 135.9% higher than the conventional riveting repair and conventional bonding repair, respectively.The method described in this study, which is based on the linear elastic fracture theory, provides a more accurate representation of the real bearing capacity of the restored structure from a comprehensive standpoint.

-

Key words:

- laminates /

- riveting repair /

- bonding repair /

- bonding-riveting joint repair /

- uniaxial tension /

- tensile properties

-

表 1 实验标准及设备

Table 1. Experimental standard and equipment

表 2 材料性能测试结果

Table 2. Experimental results of material properties

试件

编号宽度/

mm厚度/

mm载荷/

kN拉伸

强度/MPa拉伸

模量/GPa破坏

应变1 25.08 1.41 21.4 605 64.7 9216×10−6 2 25.06 1.40 25.3 721 63.8 11036×10−6 3 25.09 1.44 23.7 655 65.2 9944×10−6 4 25.07 1.42 23.4 656 63.6 10333×10−6 5 25.06 1.38 24.4 705 65.1 10686×10−6 6 25.04 1.41 23.5 665 64.4 10173×10−6 表 3 含预制损伤试件的拉伸性能测试结果

Table 3. Tensile properties results of specimens with prefabricated damage

试样

编号宽度/

mm厚度/

mm载荷

峰值/kN拉伸

强度/MPa破坏应变

(孔长轴侧)1 97.66 1.50 21.6 147 4378×10−6 2 97.78 1.49 21.1 145 4387×10−6 3 98.18 1.48 20.1 138 3815×10−6 4 97.77 1.50 19.6 134 3868×10−6 5 97.83 1.50 21.1 144 4245×10−6 表 4 常规铆接修理试件的拉伸性能测试结果

Table 4. Tensile properties results of specimens repaired by simple riveting method

试件形式 试件编号 宽度/mm 厚度/mm 载荷峰值 Ⅰ /

kN拉伸强度 Ⅰ /

MPa载荷峰值 Ⅱ /

kN拉伸强度 Ⅱ /

MPa破坏应变

(孔长轴侧)破坏应变

(金属侧)不锈钢补片 1 98.08 1.48 33.7 232 31.9 220 4326×10−6 122×10−6 2 97.90 1.51 33.7 228 32.8 222 4211×10−6 68.3×10−6 3 98.08 1.44 32.4 229 29.2 207 4256×10−6 82.6×10−6 4 97.97 1.51 35.0 237 32.1 217 4230×10−6 135×10−6 5 98.26 1.45 36.1 253 30.2 212 4469×10−6 121×10−6 钛合金补片 1 98.49 1.50 35.3 239 31.9 216 4386×10−6 259×10−6 2 98.28 1.49 33.0 225 30.7 210 4190×10−6 260×10−6 3 98.03 1.41 35.3 256 30.4 220 4423×10−6 331×10−6 4 98.39 1.48 33.6 231 32.5 224 3995×10−6 240×10−6 5 98.41 1.50 33.7 229 32.5 220 4140×10−6 259×10−6 表 5 改进后铆接修理试件的剩余强度测试结果

Table 5. Residual strength test results of specimens repaired by improved riveting method

试件编号 宽度/mm 厚度/mm 载荷/kN 剩余强度/MPa 1 98.60 1.50 47.90 323.8 2 98.54 1.48 47.53 325.9 3 98.70 1.48 49.62 339.7 4 98.70 1.44 46.44 326.7 5 98.64 1.44 47.99 337.9 表 6 胶接修理试件的剩余强度测试结果

Table 6. Residual strength test results of specimens repaired by bonding method

试件编号 宽度/mm 厚度/mm 载荷/kN 剩余强度/MPa 1 98.84 1.5 39.47 266.2 2 98.4 1.48 40.41 277.5 3 98.2 1.4 40.82 296.9 表 7 胶铆联合修理试件的剩余强度测试结果

Table 7. Residual strength test results of specimens repaired by bonding-riveting joint method

试件编号 宽度/mm 厚度/mm 载荷/kN 剩余强度/MPa 1 99.20 1.48 58.20 396.40 2 98.64 1.46 54.75 380.20 3 98.12 1.50 53.88 366.10 表 8 评价方法改进前后的结构强度恢复率对比

Table 8. Comparison of strength recovery ratio by unimproved and improved evaluation methods

修理方法 修正因子F2 修复强度/

MPa强度恢复

率(旧)/%强度恢复

率(新)/%常规铆接修理 0.601 361.9 35.3 54.2 胶接修理 0.505 430.7 41.9 64.5 改进后的铆接修理 0.428 508.1 49.5 76.1 胶铆联合修理 0.372 584.7 57.0 87.6 -

[1] 魏士礼, 赵艳秦. 民用飞机复合材料翼盒蒙皮损伤外补修理[J]. 机械工程师, 2022(4): 82-84. doi: 10.3969/j.issn.1002-2333.2022.4.jxgcs202204027WEI S L, ZHAO Y Q. External patch repair for damage of composite wing box skin of civil aircraft[J]. Mechanical Engineer, 2022(4): 82-84(in Chinese). doi: 10.3969/j.issn.1002-2333.2022.4.jxgcs202204027 [2] 刘岩松, 张子健, 宋晓晨, 等. 复合材料结构修理技术探究[J]. 航空维修与工程, 2018(11): 76-80. doi: 10.3969/j.issn.1672-0989.2018.11.029LIU Y S, ZHANG Z J, SONG X C, et al. Research on repair technology of composite material structure[J]. Aviation Maintenance & Engineering, 2018(11): 76-80(in Chinese). doi: 10.3969/j.issn.1672-0989.2018.11.029 [3] 贺旺, 曹强, 孙涛. 飞机复合材料修理工艺研究的思路探讨[J]. 航空维修与工程, 2016(4): 57-59.HE W, CAO Q, SUN T. Discussion on the process research of aircraft composite repair[J]. Aviation Maintenance & Engineering, 2016(4): 57-59(in Chinese). [4] 孔磊. 飞机复合材料修理技术研究[J]. 塑料工业, 2019, 47(3): 140-144. doi: 10.3969/j.issn.1005-5770.2019.03.033KONG L. Research on aircraft composite repair technology[J]. China Plastics Industry, 2019, 47(3): 140-144(in Chinese). doi: 10.3969/j.issn.1005-5770.2019.03.033 [5] 聂恒昌, 谭日明, 郭霞, 等. 复合材料层合板机械连接修理拉伸性能[J]. 北京航空航天大学学报, 2016, 42(2): 318-327.NIE H C, TAN R M, GUO X, et al. Tensile performances of mechanically fastened repairs of composite laminates[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(2): 318-327(in Chinese). [6] 杨鹏飞, 樊俊铃, 宁宁, 等. 复合材料矩形开孔损伤螺接修理参数分析[J]. 航空维修与工程, 2021(5): 89-93. doi: 10.3969/j.issn.1672-0989.2021.05.032YANG P F, FAN J L, NING N, et al. Analysis on repair parameters for damaged bolted joints with rectangular holes in composite materials[J]. Aviation Maintenance & Engineering, 2021(5): 89-93(in Chinese). doi: 10.3969/j.issn.1672-0989.2021.05.032 [7] 王航, 李想, 谢宗蕻, 等. 含通孔损伤复材壁板螺接修理接头拉伸性能试验研究[J]. 航空制造技术, 2018, 61(20): 56-62.WANG H, LI X, XIE Z H, et al. Tests on tensile strength of bolted-repaired composite joints[J]. Aeronautical Manufacturing Technology, 2018, 61(20): 56-62(in Chinese). [8] 张阿盈, 许洪明, 陈昊. 复合材料层压板铆接修补剩余强度评估[J]. 机械强度, 2016, 38(1): 105-109.ZHANG A Y, XU H M, CHEN H. Residual strength evaluation of composite laminates repaired by riveted metal patch[J]. Journal of Mechanical Strength, 2016, 38(1): 105-109(in Chinese). [9] 张阿盈, 陈向明, 王力立. 含离散源损伤复合材料加筋板剩余强度及其修理技术研究[J]. 工程与试验, 2018, 58(2): 16-19. doi: 10.3969/j.issn.1674-3407.2018.02.004ZHANG A Y, CHEN X M, WANG L L. Study on residual strength of composite stiffened panel with discrete source damage and repair technique[J]. Engineering & Test, 2018, 58(2): 16-19(in Chinese). doi: 10.3969/j.issn.1674-3407.2018.02.004 [10] 梁凤飞, 金迪, 何勇. 复合材料结构修理研究[J]. 中国胶粘剂, 2019, 28(5): 57-61.LIANG F F, JIN D, HE Y. Research on the maintenance of composite material structure[J]. China Adhesives, 2019, 28(5): 57-61(in Chinese). [11] 王锡然. 复合材料机翼结构胶接修理后强度评估模型研究[D]. 天津: 中国民航大学, 2018.WANG X R. Strength evaluation model of composite wing structure after adhesive repair[D]. Tianjin: Civil Aviation University of China, 2018(in Chinese). [12] 田可可. 复合材料挖补结构性能分析和实验研究[D]. 郑州: 郑州大学, 2021.TIAN K K. Numerical and experimental study on scarf repairment properties of composite material[D]. Zhengzhou: Zhengzhou University, 2021(in Chinese). [13] 王宇灿. 复合材料胶铆混合修理力学特性实验研究[D]. 天津: 中国民航大学, 2019.WANG Y C. Experimental study on mechanical properties of adhesive-rivet hybrid repair of composite materials[D]. Tianjin: Civil Aviation University of China, 2019(in Chinese). [14] 张昂. 碳纤维复合材料的激光清洗机理与表面改性研究[D]. 镇江: 江苏大学, 2019.ZHANG A. Research on laser cleaning mechanism and surface modification of carbon fiber reinforced polymer[D]. Zhenjiang: Jiangsu University, 2019(in Chinese). [15] 李俊磊. 基于激光表面处理的民机复合材料结构胶结修理研究[D]. 广汉: 中国民用航空飞行学院, 2016.LI J L. Civil aircraft composite structure based on laser surface treatment[D]. Guanghan: Civil Aviation Flight University of China, 2016(in Chinese). [16] 邹维杰. 复合材料层合板机械修理研究[D]. 南京: 南京航空航天大学, 2018.ZOU W J. Research on mechanical repair of composite laminates[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018(in Chinese). [17] 王瑞峰. 复合材料胶铆混合连接与胶接修理的力学性能对比研究[D]. 天津: 中国民航大学, 2016.WANG R F. A comparative study of mechanical property of bonded repair and adhesive-rivet hybrid repair of composite laminate[D]. Tianjin: Civil Aviation University of China, 2016(in Chinese). [18] 原志翔. 复合材料胶铆混合修理损伤特性实验研究[D]. 天津: 中国民航大学, 2020.YUAN Z X. Experimental study on damage properties of adhesive-rivet hybrid repair of composite materials[D]. Tianjin: Civil Aviation University of China, 2020(in Chinese). [19] 徐航. 复合材料胶铆混合修理优化设计[D]. 天津: 中国民航大学, 2015.XU H. Optimal design of composite material adhesive-rivet hybrid repair[D]. Tianjin: Civil Aviation University of China, 2015(in Chinese). [20] ASTM. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039—2017[S]. West Conshohocken: ASTM International, 2017. [21] 中国飞机强度研究所、中国航空综合技术研究所、中国航空工业第601 研究所,等. 飞机复合材料结构机械连接设计要求: HB 7709[S]. 北京: 国防科学技术工业委员会, 2003.Aircraft Strength Research Institute of China, China Aero-poly Technology Establishment, AVIC Shenyang Aircraft Design & Research Institute, et al. Design requirements of mechanically fastened joint of composite structure for airplane: HB 7099[S]. Beijing: Commission of Science, Technology and Industry for National Defense, 2003(in Chinese). [22] USHAKOV A, STEWART A, MISHULIN I. Probabilistic design of damage tolerant composite aircraft structures[R]. Washington, D. C. : US Department of Transportation, 2002. [23] 王辰, 贺尔铭, 赵志彬, 等. 民机复合材料结构修理容限确定方法研究[J]. 西北工业大学学报, 2020, 38(4): 695-704. doi: 10.3969/j.issn.1000-2758.2020.04.002WANG C, HE E M, ZHAO Z B, et al. Method for determining repair tolerance of civil aircraft composite structure[J]. Journal of Northwestern Polytechnical University, 2020, 38(4): 695-704(in Chinese). doi: 10.3969/j.issn.1000-2758.2020.04.002 [24] 中国人民解放军空军第一研究所. 飞机战伤评估与修理技术手册编制要求: GJB 3897—99[S]. 北京: 中国人民解放军总装备部, 1999.Air Force First Research Institute of PLA. Requirements for developing technical manuals for aircraft battle damage assessment and repair: GJB 3897—99[S]. Beijing: PLA General Armament Department, 1999(in Chinese). [25] FLCMC/HIAM Technical Data Section. Detail specification manuals, technical-aircraft battle damage assessment and repair: MIL-DTL-87158D[S]. Washington, D. C. : US Department of Defense, 2016. [26] 中国航空研究院. 军用飞机疲劳·损伤容限·耐久性设计手册 第三册 损伤容限设计[M]. 北京: 中国航空研究院, 1994: 328-335.Chinese Aeronautical Establishment. Fatigue, damage tolerant and durability design for military airplane. Volume Ⅲ. Damage tolerant design[M]. Beijing: Chinese Aeronautical Establishment, 1994: 328-335(in Chinese). [27] JOHN G A. Design manual for impact damage tolerant aircraft structure: AGARD-AG-238[R]. Washington, D. C. : AGARD, 1981: 161-168. [28] 中国航空研究院. 应力强度因子手册(增订版)[M]. 北京: 科学出版社, 1993: 3-9.Chinese Aeronautical Establishment. Stress intensity factors handbook(revised and enlarged edition)[M]. Beijing: Science Press, 1993: 3-9(in Chinese). [29] 航空航天工业部科学技术研究院. 飞机结构耐久性及损伤容限设计手册 第三册 飞机结构的损伤容限设计[M]. 北京: 航空航天工业部科学技术研究院, 1989.Academy of Science and Technology Ministry of Aerospace Industry. Durability and damage tolerant design for airplane structure. Volume Ⅲ. Damage tolerant design for airplane structure[M]. Beijing: Academy of Science and Technology Ministry of Aerospace Industry, 1989(in Chinese). -

下载:

下载: