Numerical study on heat transfer of supercritical RP-3 aviation kerosene in twisted spiral tubes

-

摘要:

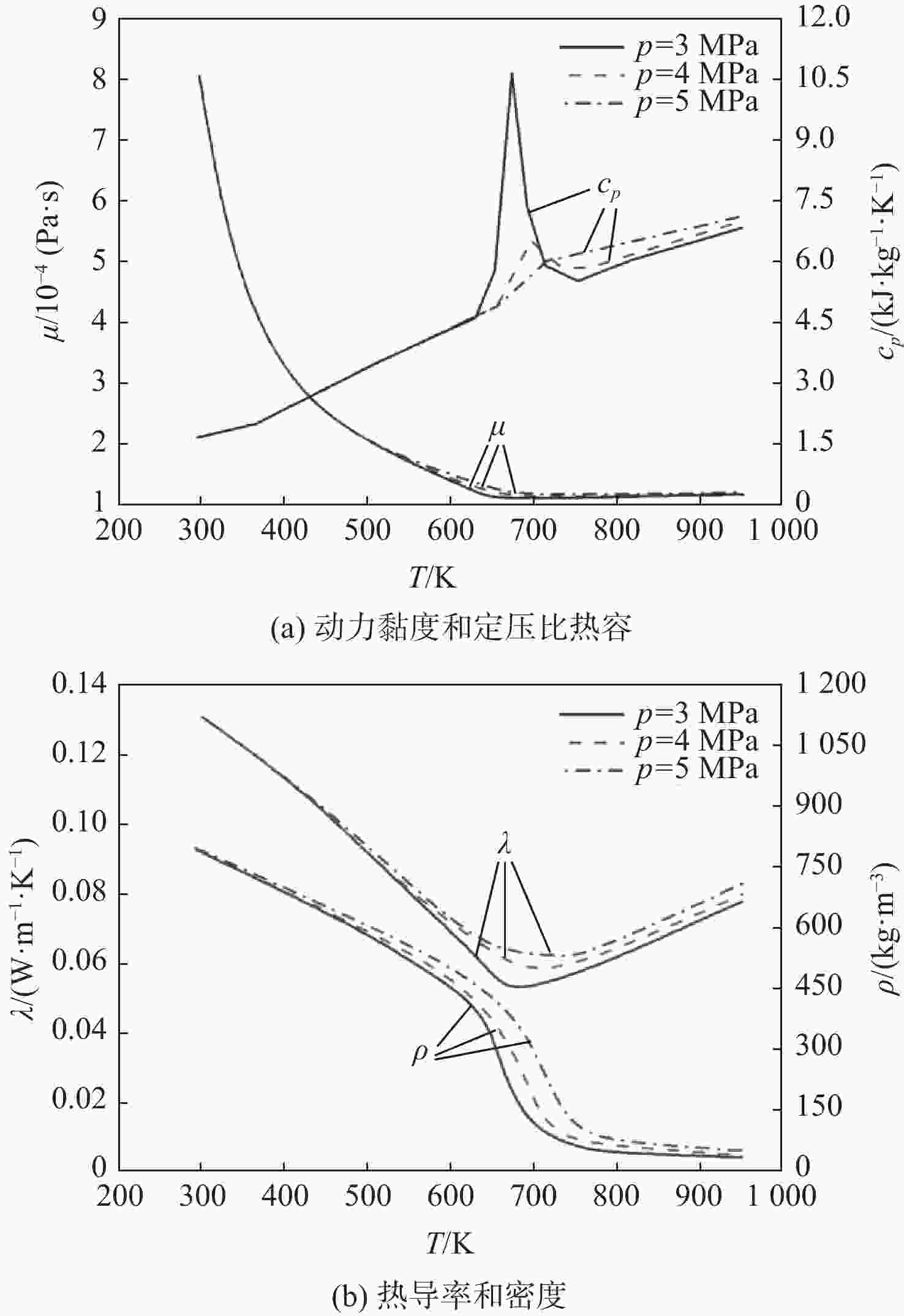

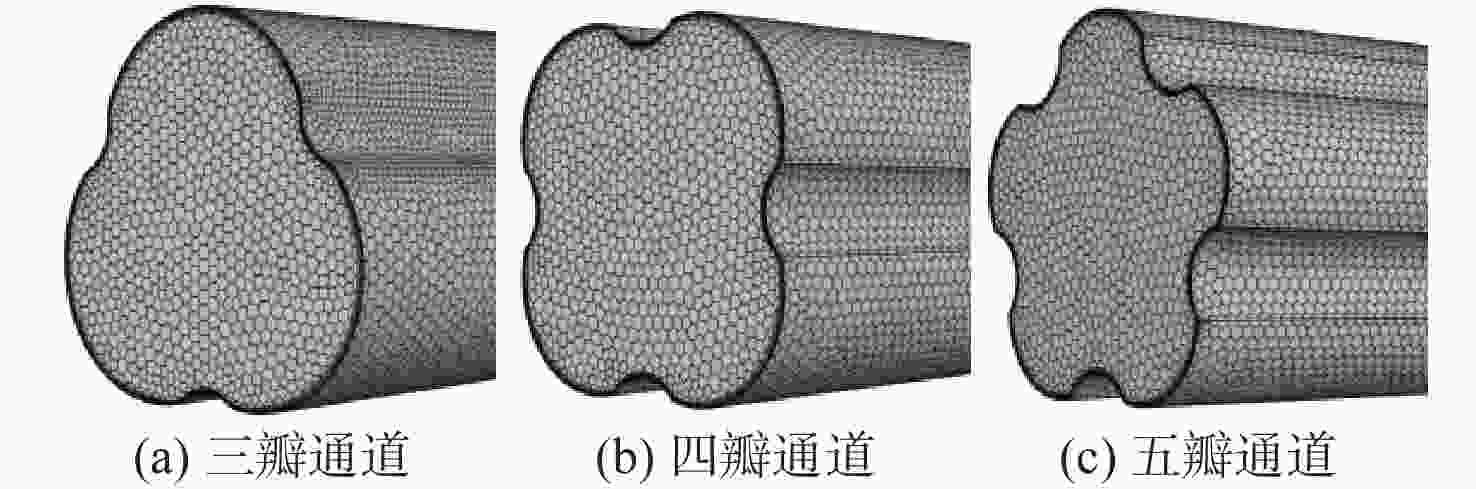

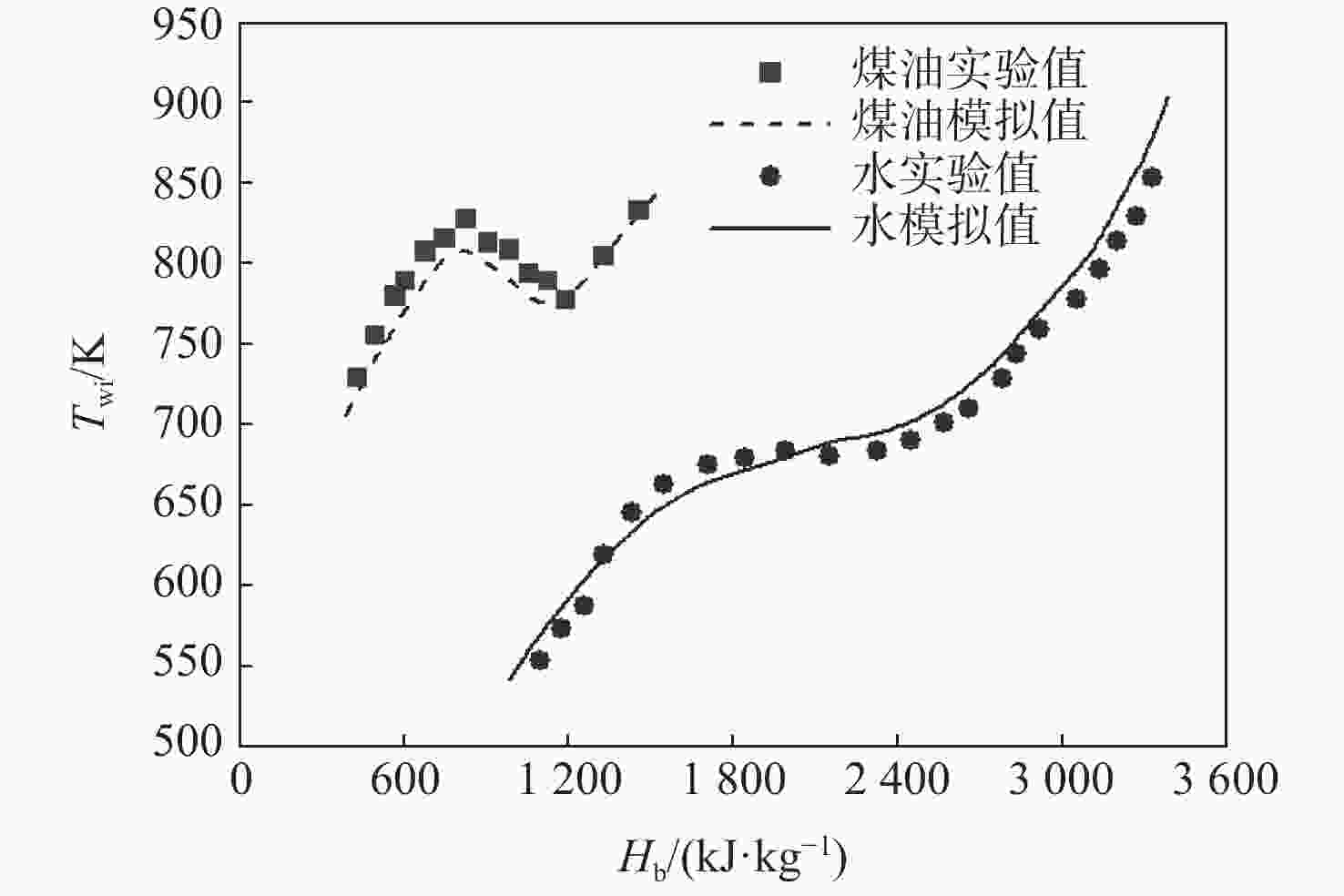

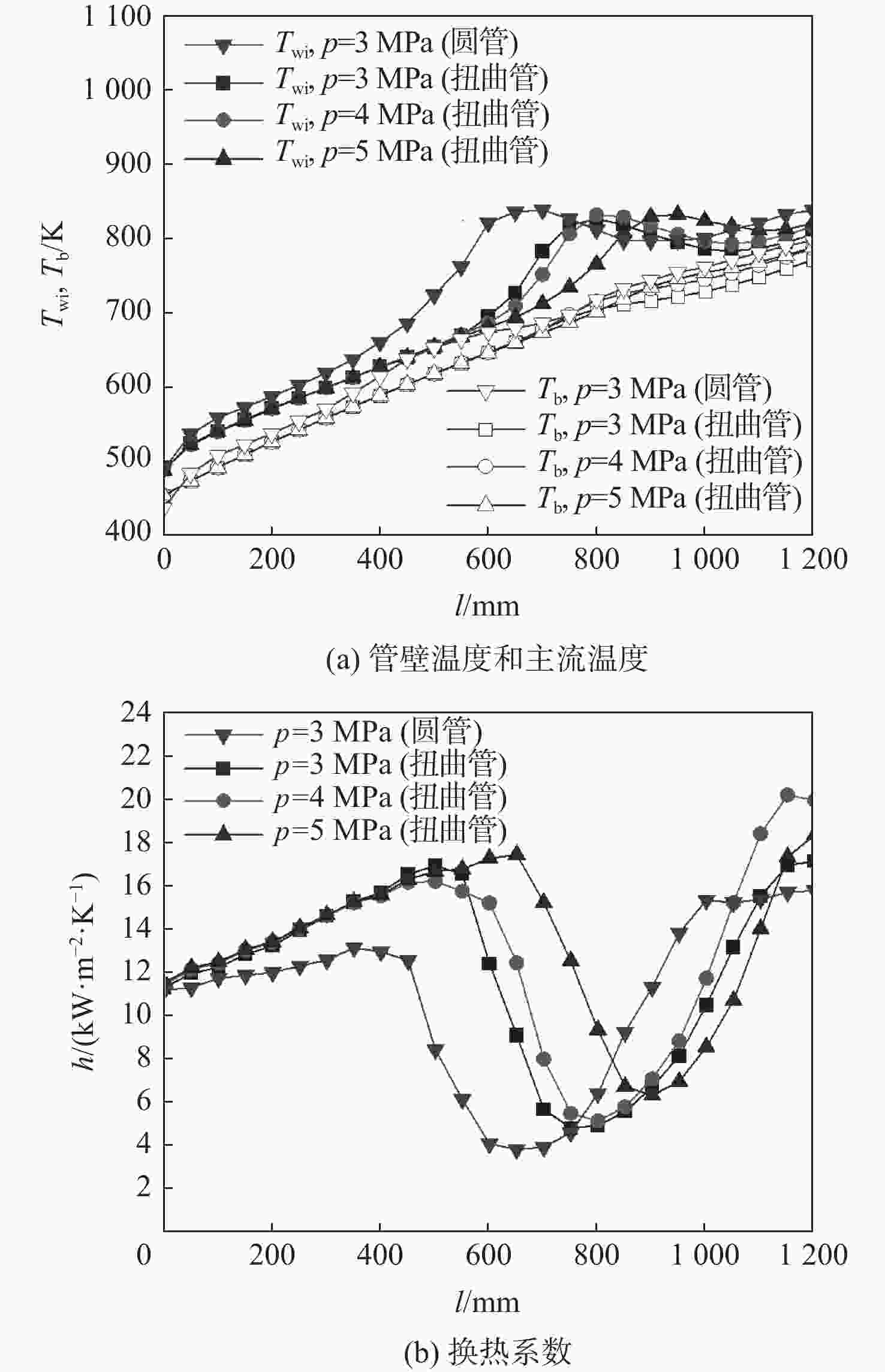

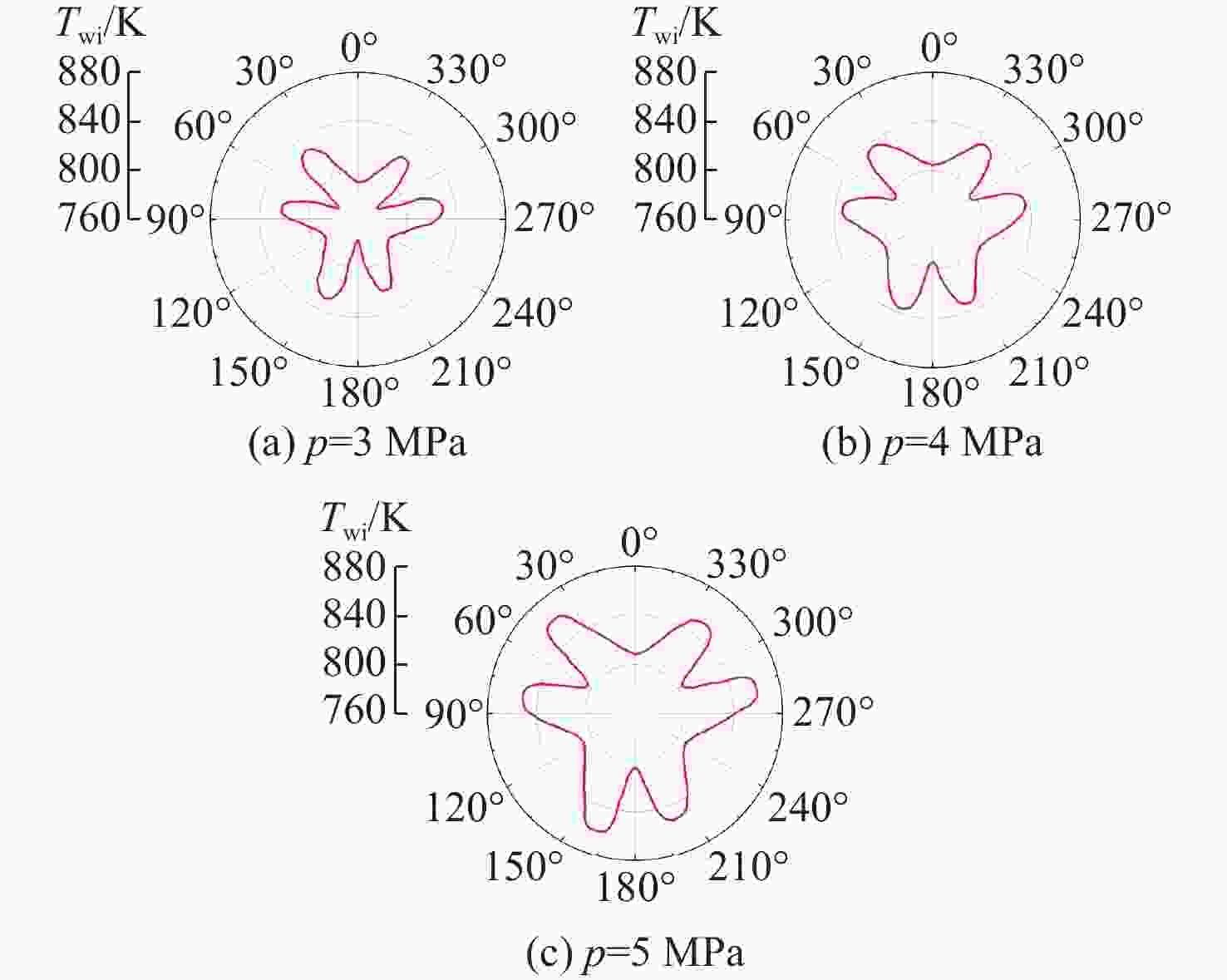

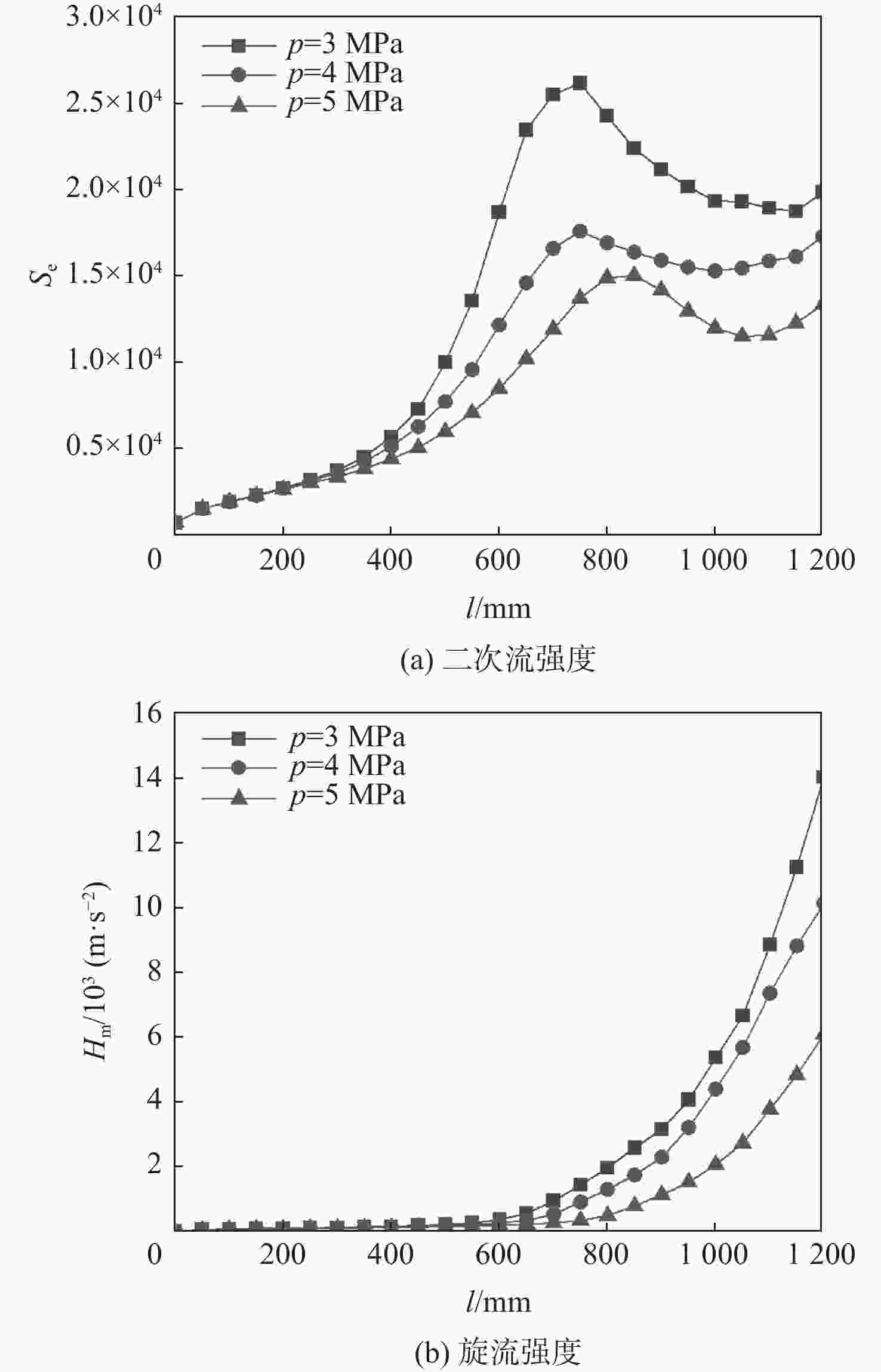

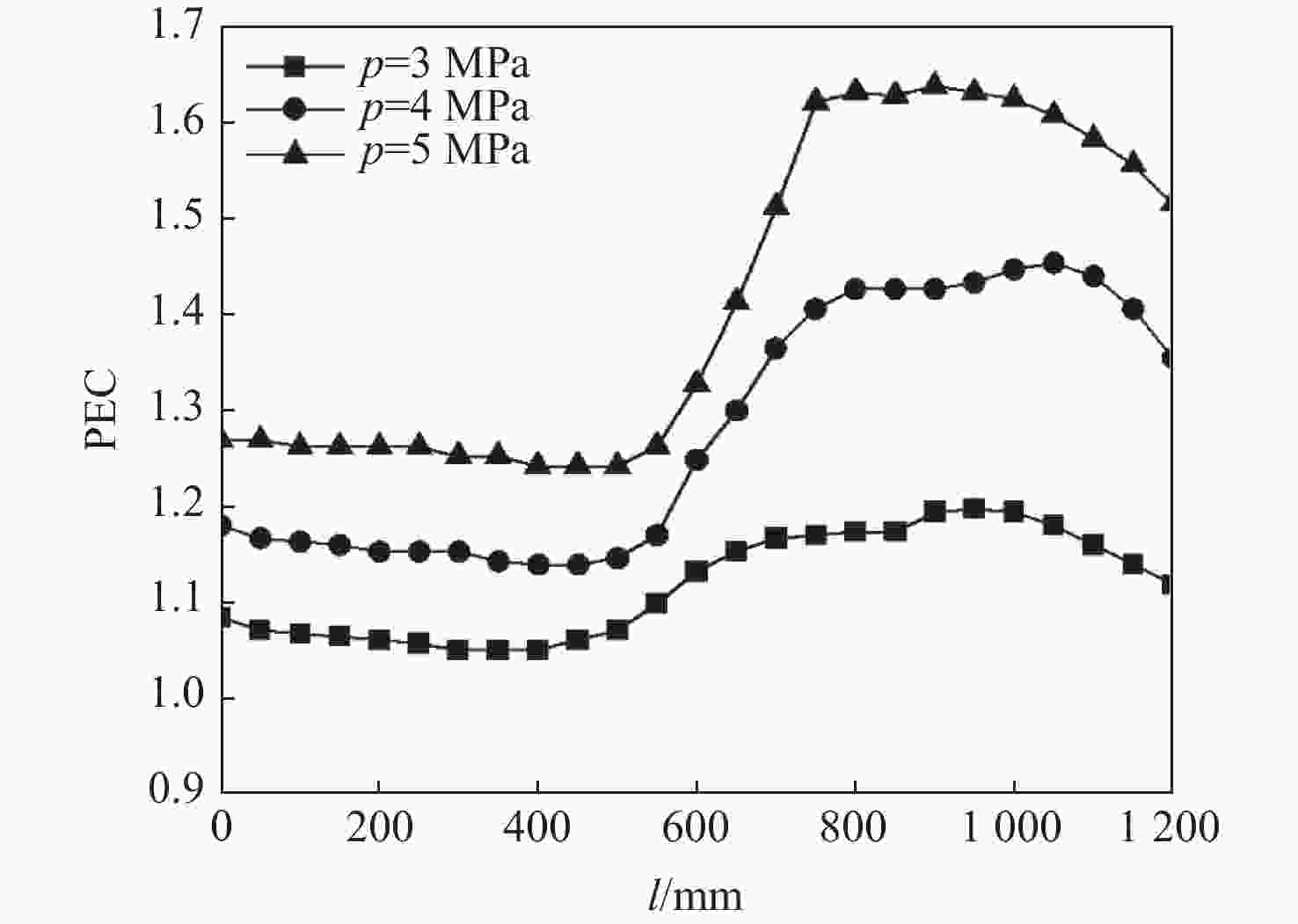

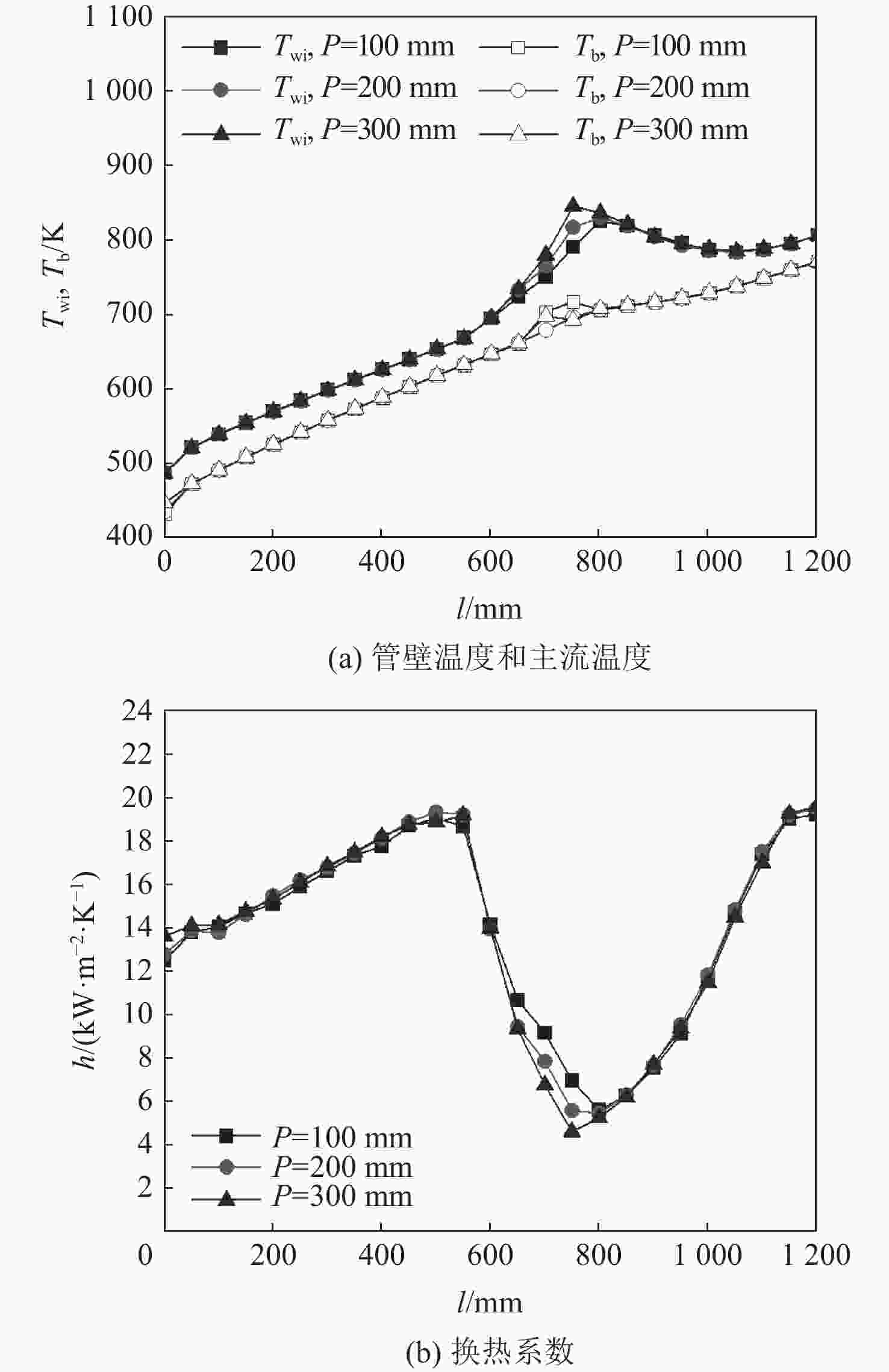

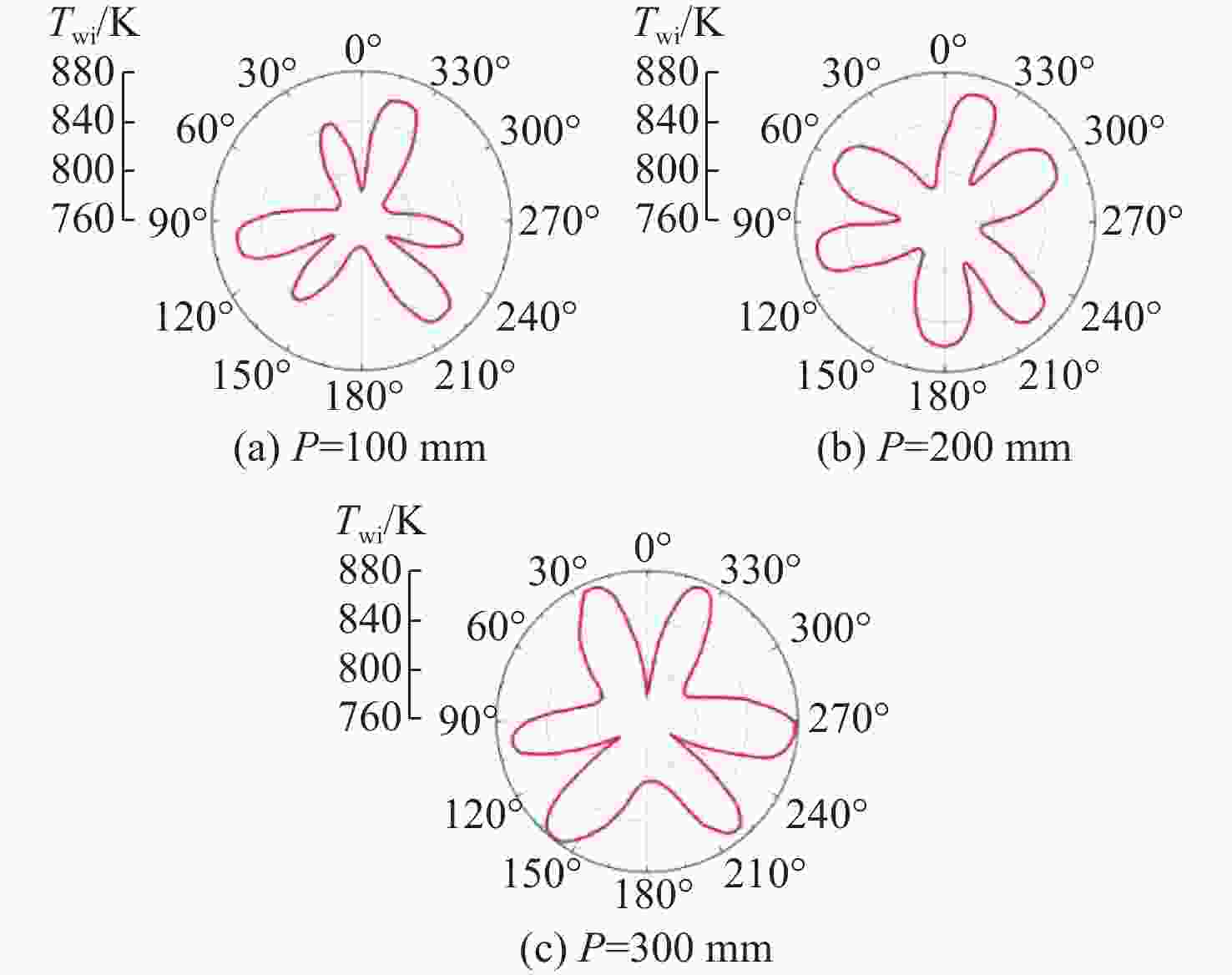

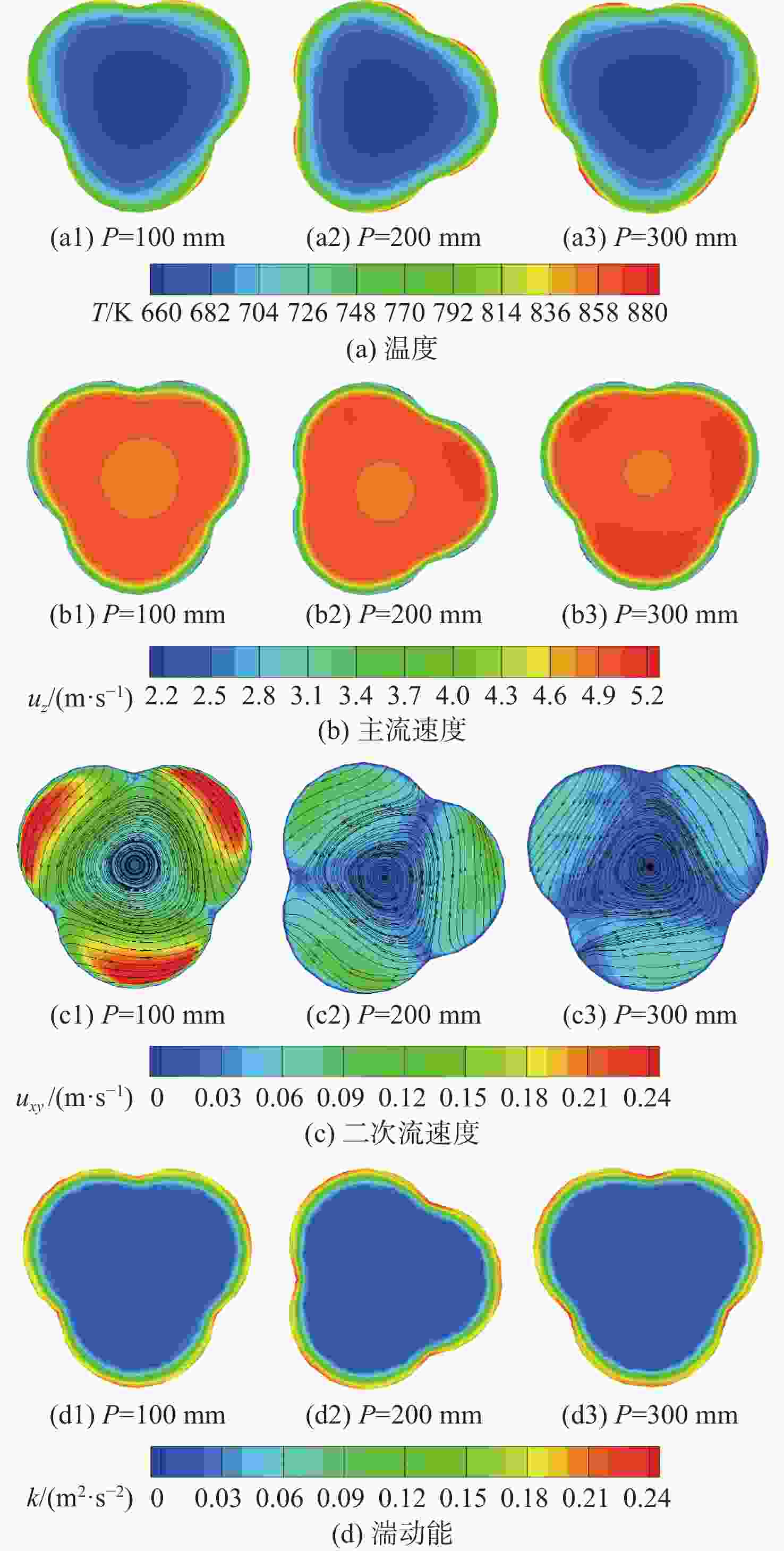

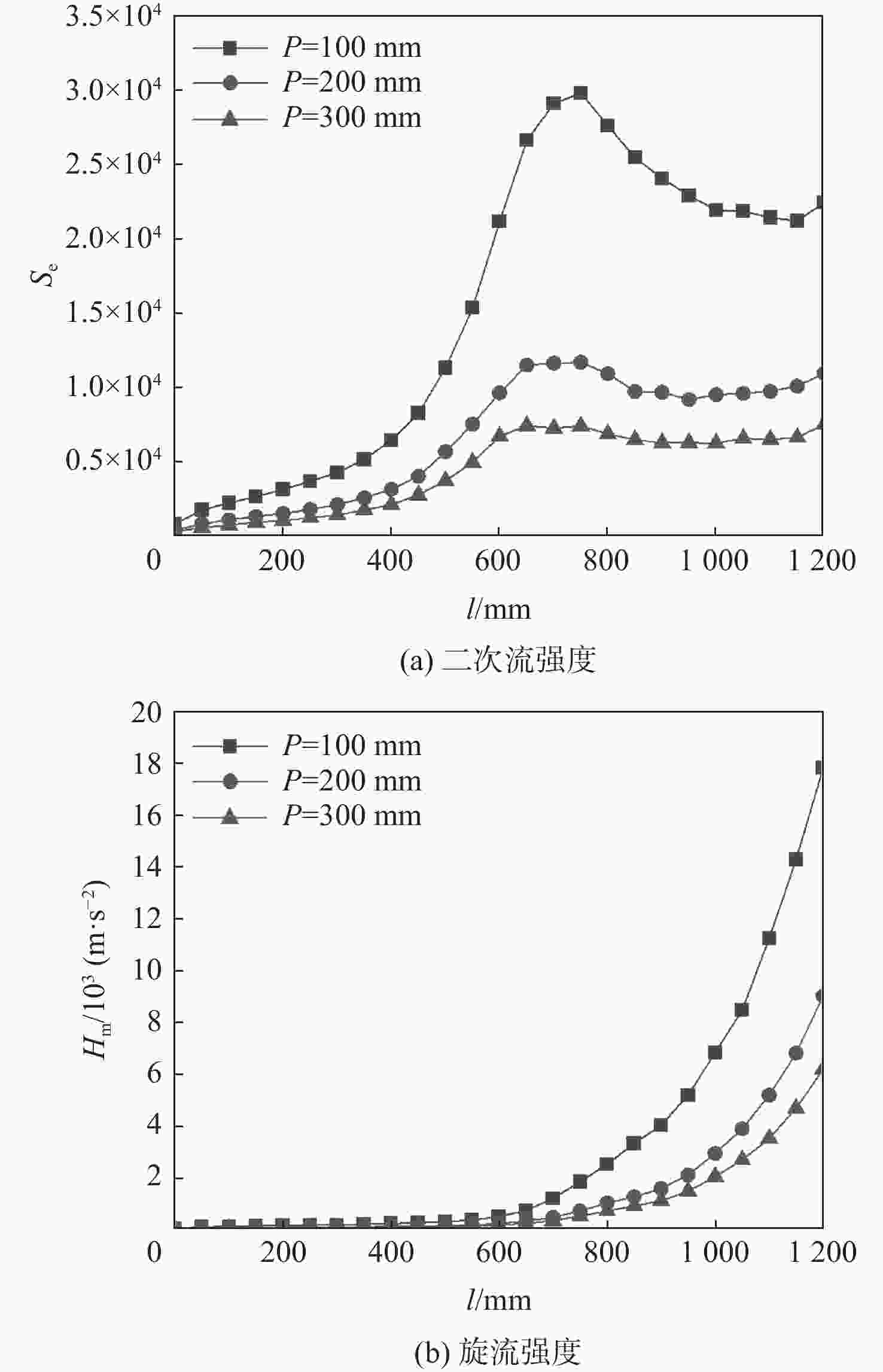

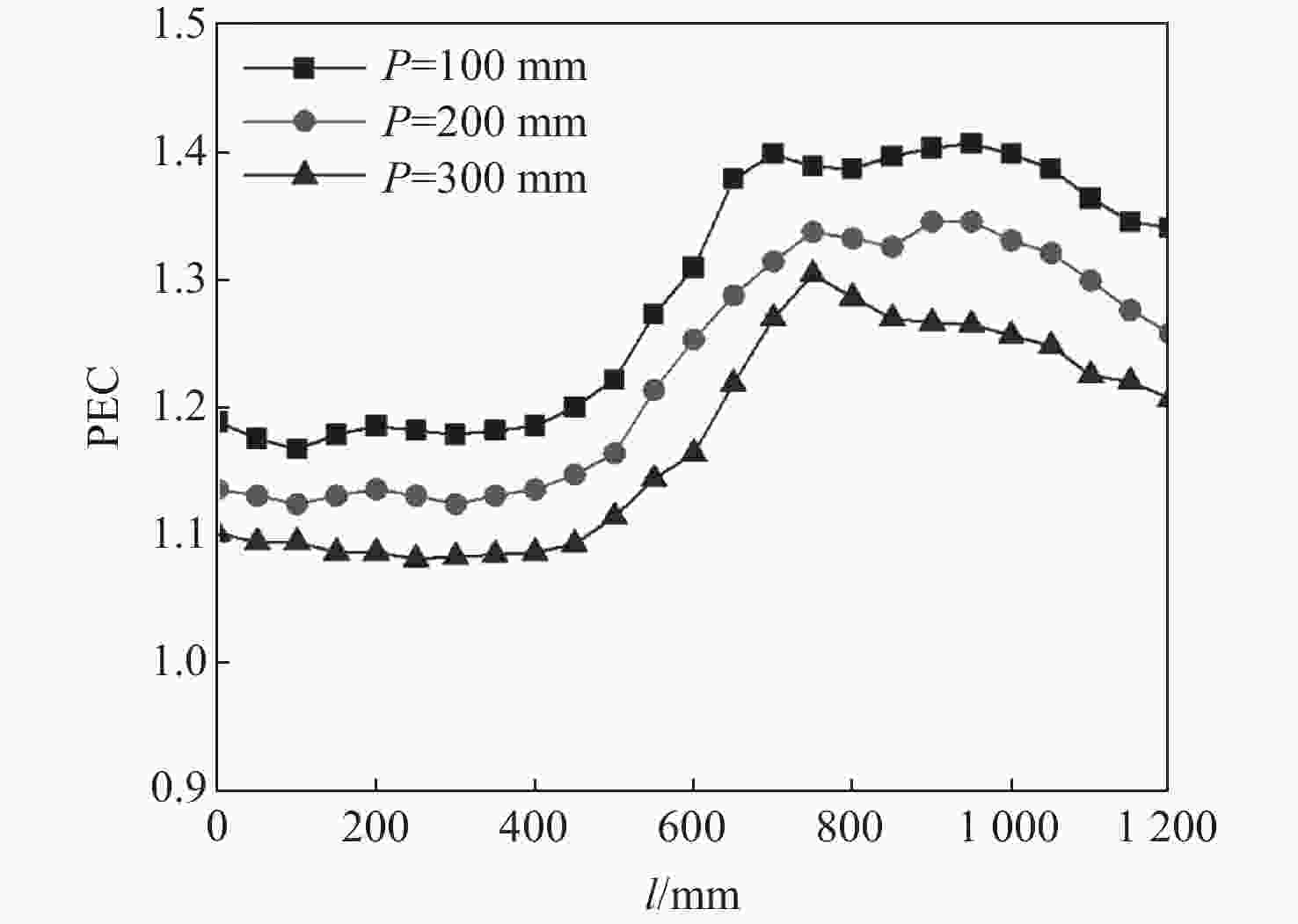

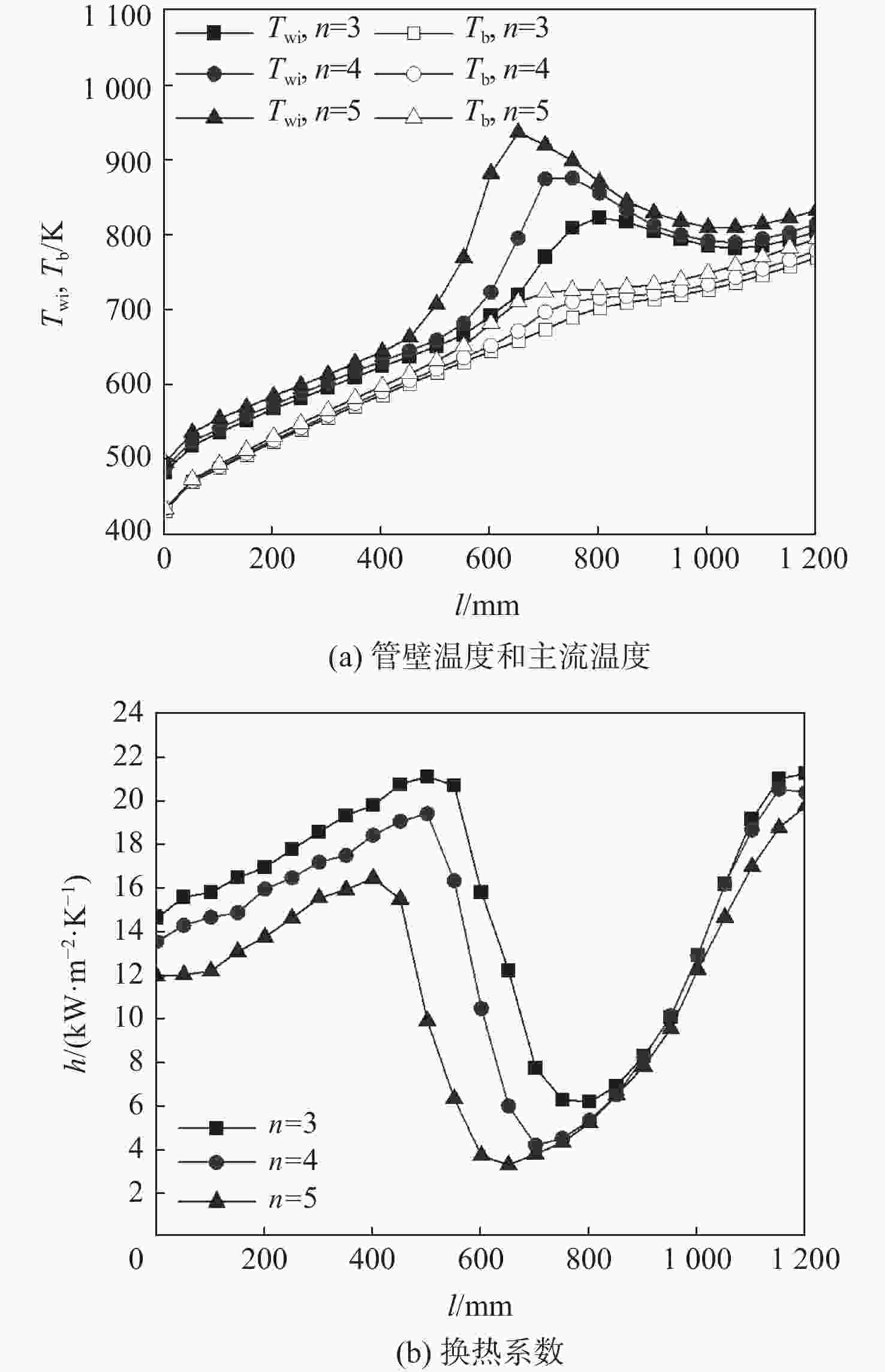

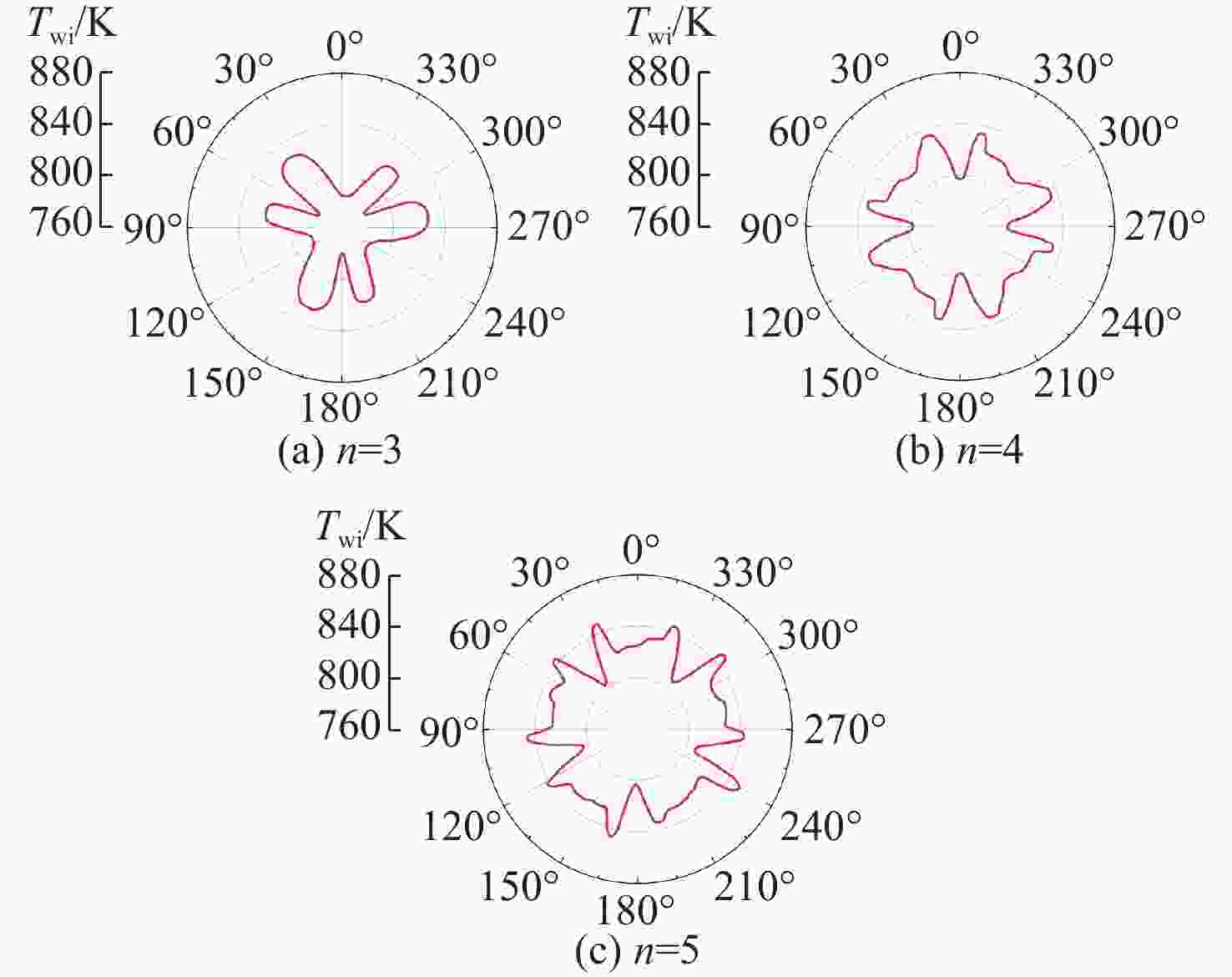

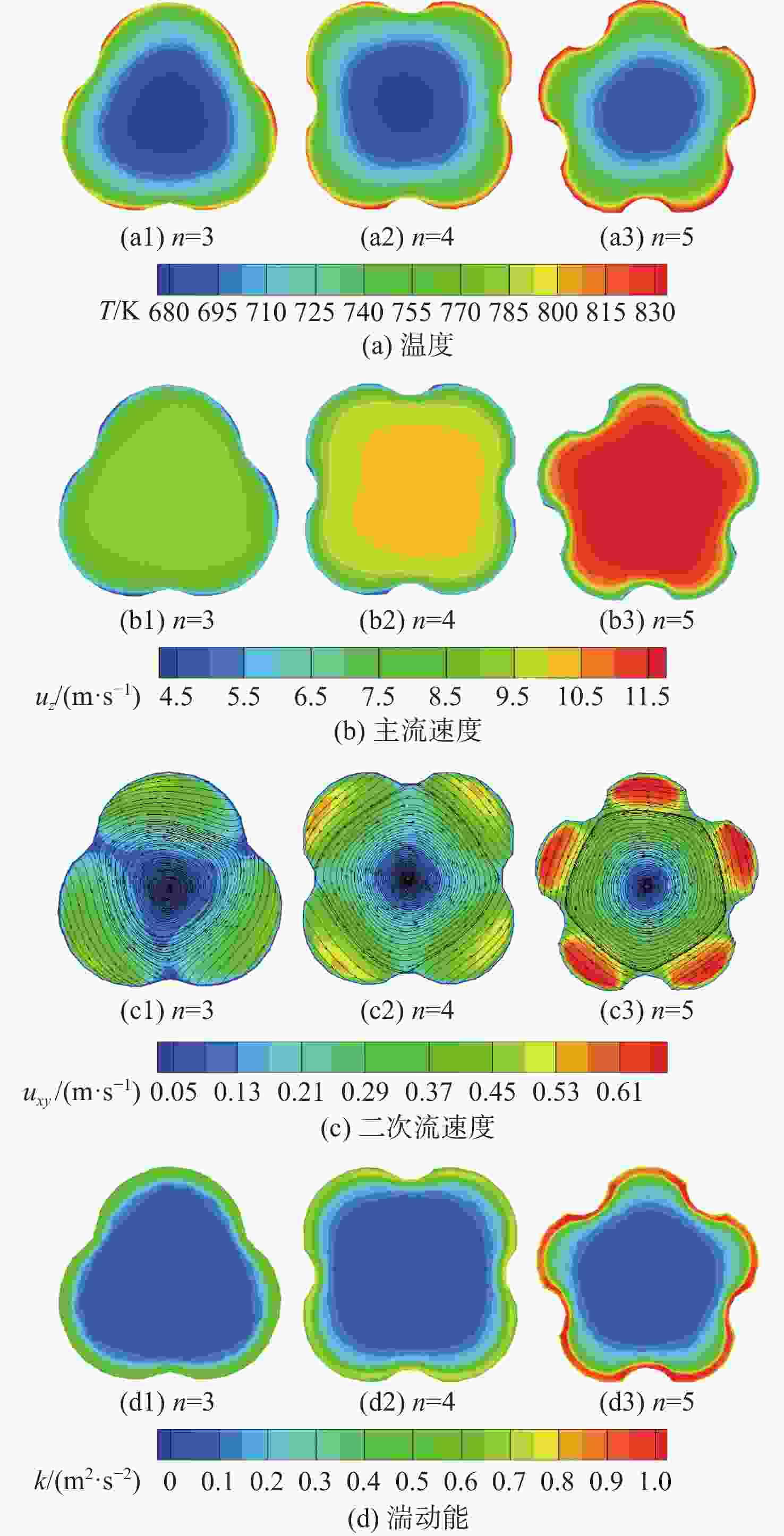

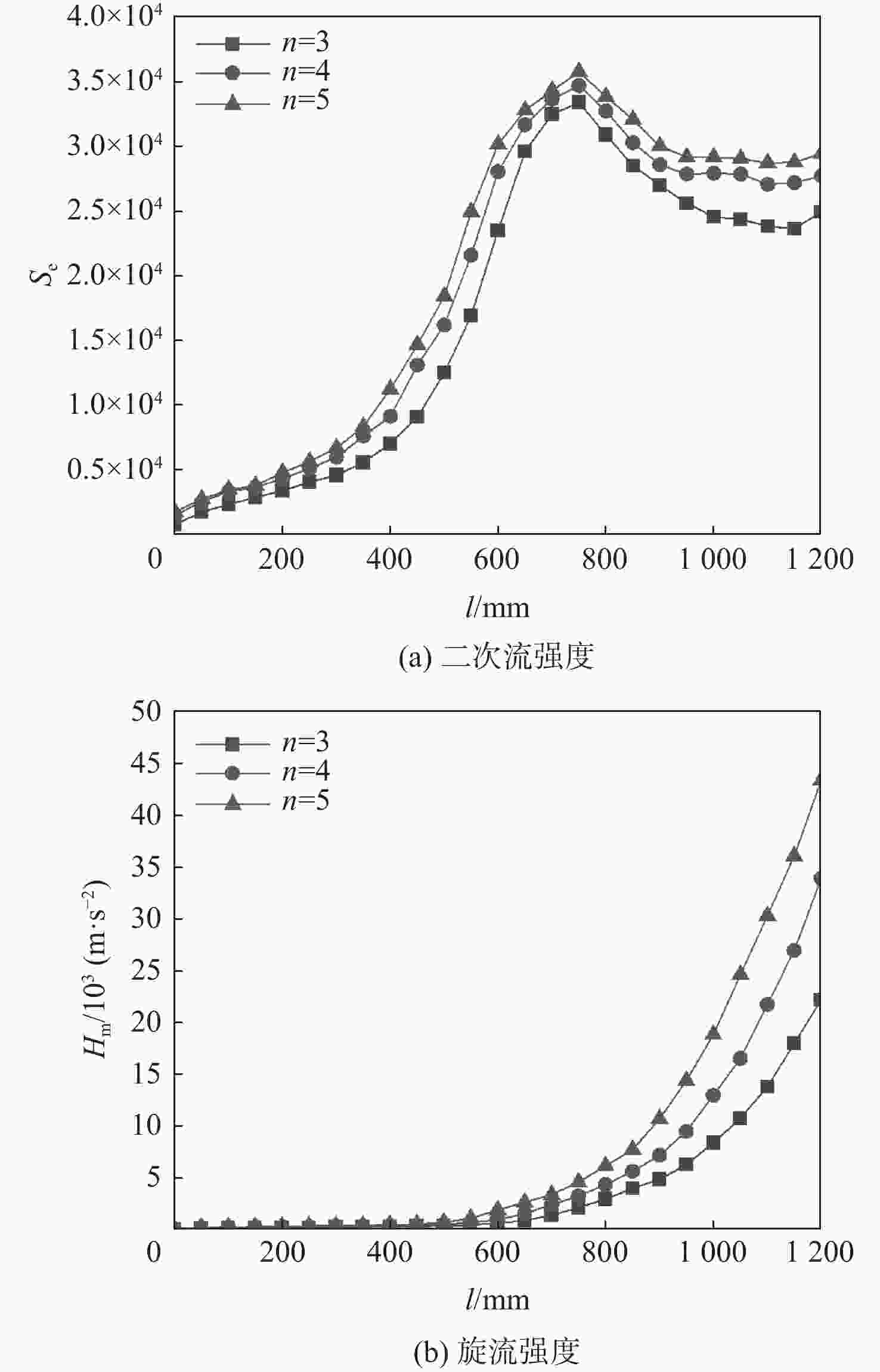

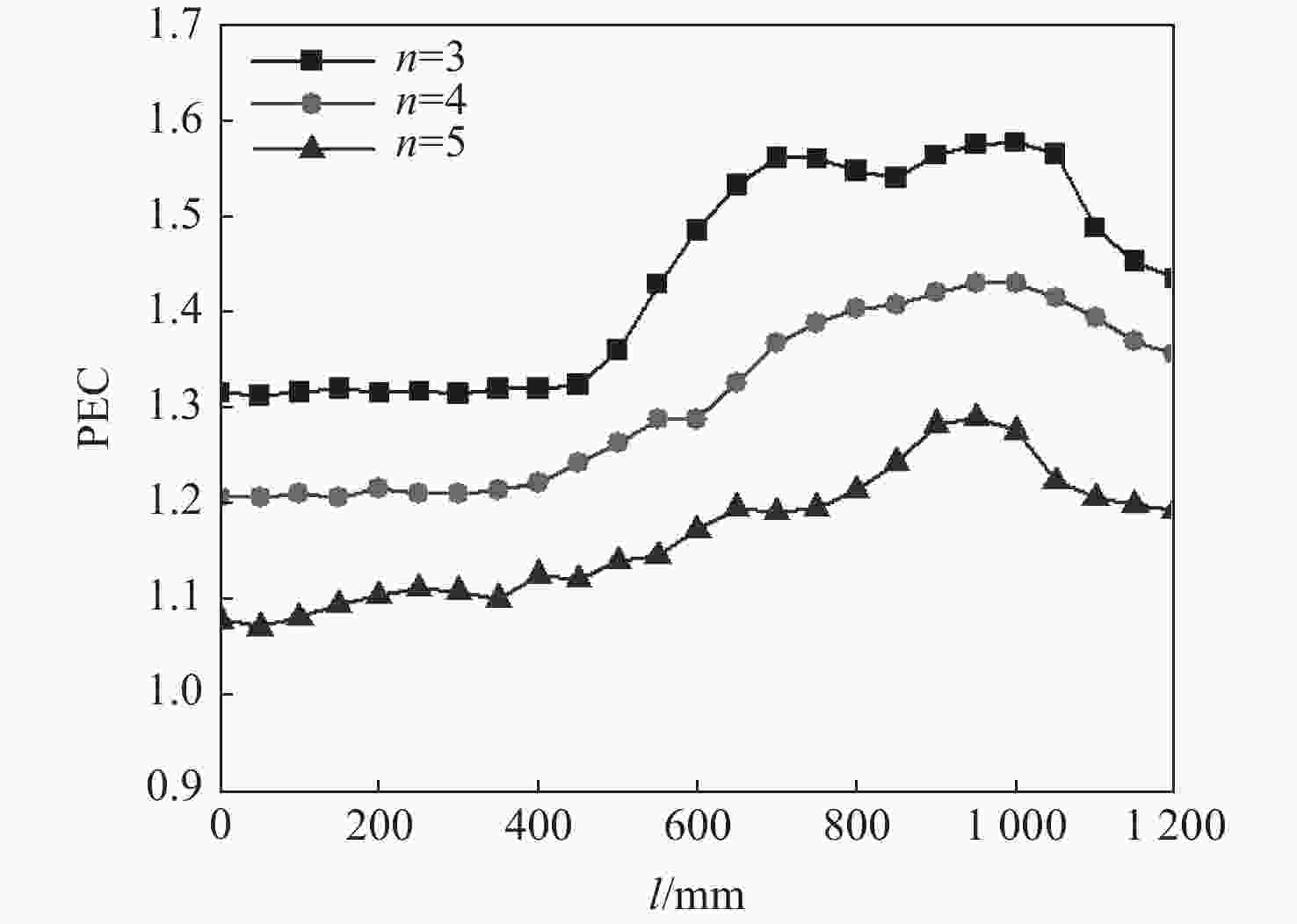

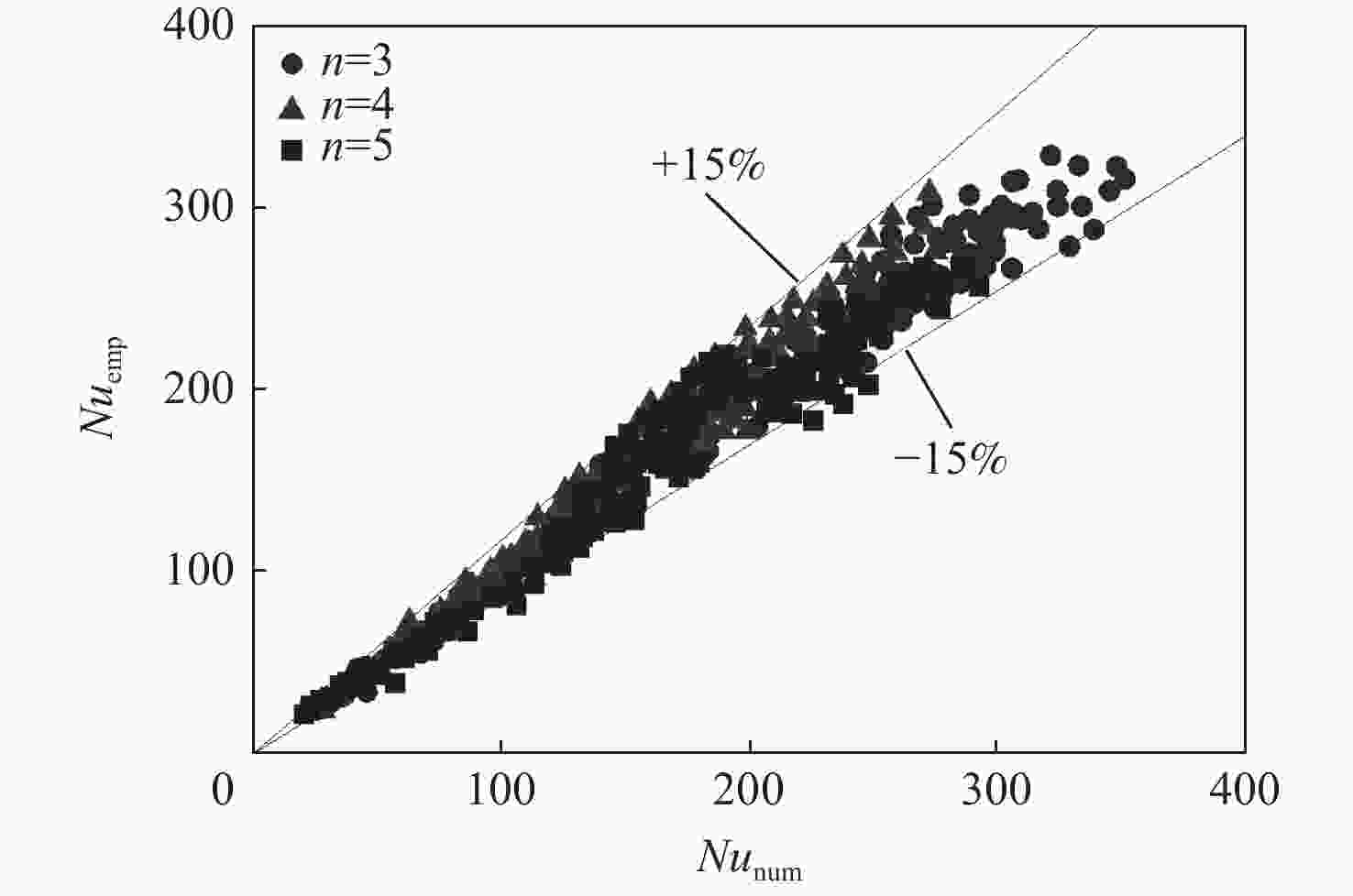

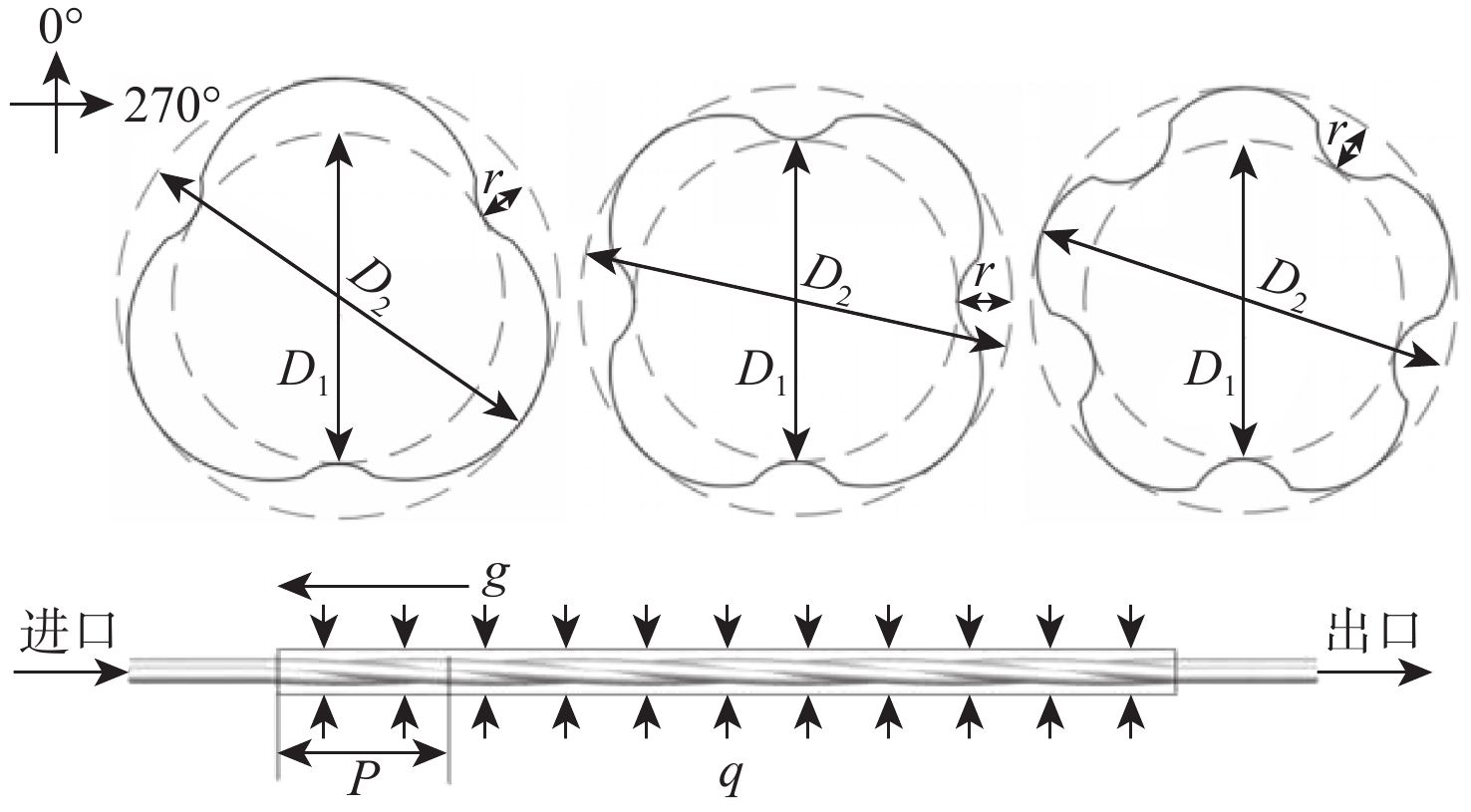

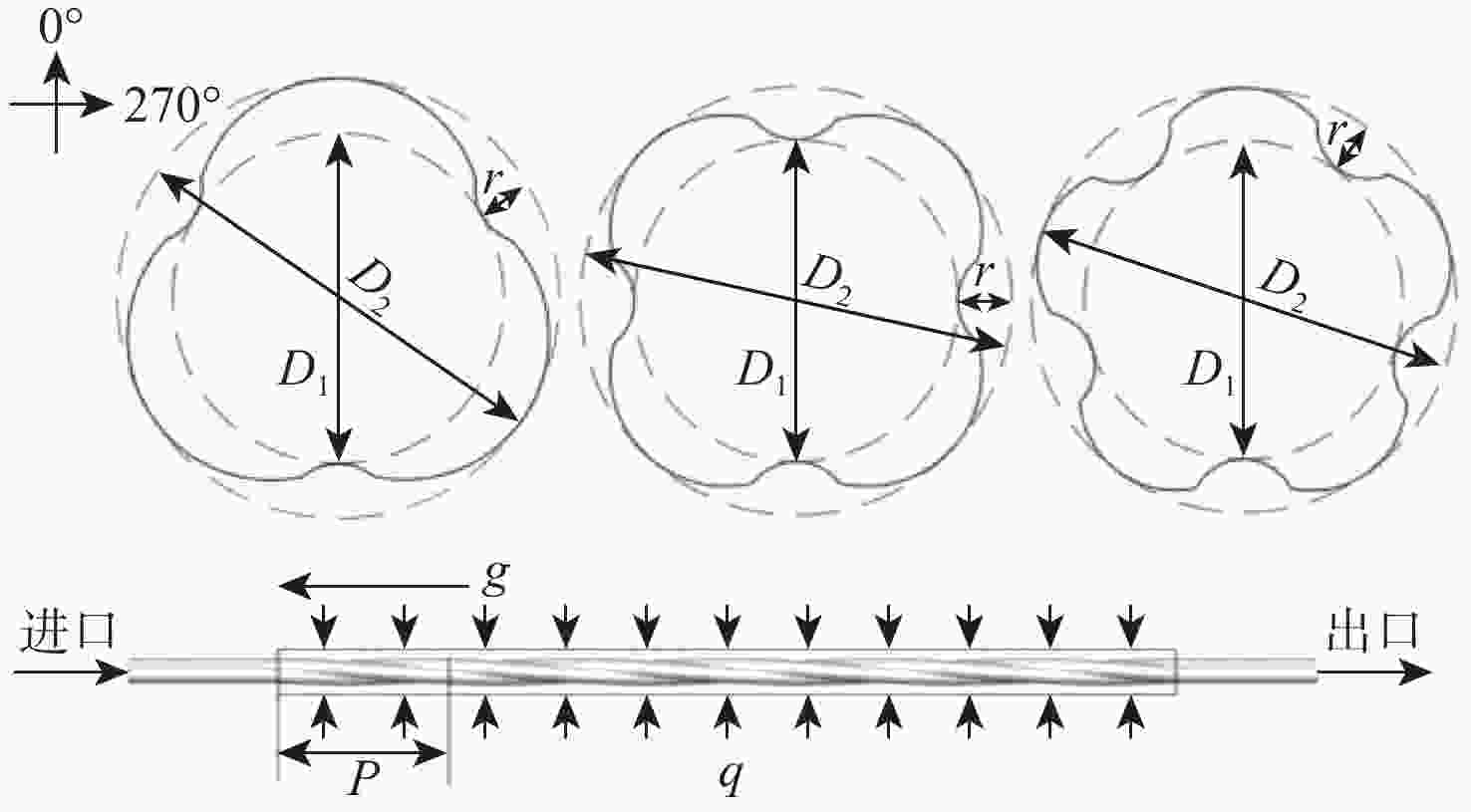

面向空-油换热器的通道结构改进问题,进行扭曲螺旋管中超临界RP-3航空煤油换热数值研究,着重探究煤油压力、螺旋节距和花瓣数目对换热的影响。讨论管壁温度和换热系数沿流动方向的变化情况,通过通道截面温度、主流流速、二次流流速和湍动能云图揭示壁温的周向分布特征和机制。基于旋流强度和二次流强度的轴向演变考察了旋流对换热的影响。与圆管比较,通过综合评价因子(PEC)表征扭曲螺旋管的增强换热效果。建立三瓣、四瓣、五瓣通道的换热关联式。结果表明:管壁温度达到拟临界温度后观察到高传热热阻类气膜引起的传热恶化问题,花瓣内出现2个非对称的壁温波形;提高煤油压力、增大螺旋节距、减少花瓣数目均使旋流效应减弱;PEC处于1.05~1.65的范围,煤油压力越高、螺旋节距越小、花瓣数目越少,越有利于提升扭曲螺旋管的综合换热作用。

Abstract:To enhance the channel structure of air-fuel heat exchangers, numerical studies of the heat transfer of supercritical RP-3 aviation kerosene in twisted spiral tubes were carried out. The study focused on examining the impact of petal number, spiral pitch, and kerosene pressure on heat transmission. The circumferential distribution characteristic and mechanism of wall temperature were revealed through the distributions of channel-section temperature, bulk flow velocity, secondary flow velocity, and turbulent kinetic energy. Axial evolutions of swirl intensity and secondary flow intensity were used to investigate the swirl flow effect on heat transfer. Compared with circular tubes, the enhanced heat transfer effect of twisted spiral tubes was characterized by the comprehensive heat transfer coefficient performance evaluation criteria(PEC). The heat transfer correlations for twisted spiral tubes with three, four, and five lobes were proposed. The findings demonstrated that two asymmetric wall temperature waveforms emerge within the petals when the wall temperature approaches the pseudo-critical temperature, indicating heat transfer deterioration brought on by the gas-like coating with significant heat transfer resistance. Increasing kerosene pressure, increasing spiral pitch, and reducing the petal number all weaken the swirl flow effect. The PEC ranges from 1.05 to 1.65, and the higher the kerosene pressure, the smaller the spiral pitch, and the fewer petals, the more favorable it is to enhance the comprehensive heat transfer effect of twisted spiral tubes.

-

Key words:

- twisted spiral tube /

- supercritical kerosene /

- heat transfer deterioration /

- swirl flow /

- secondary flow

-

表 1 压力为3 MPa时分段线性拟合的热物性

Table 1. Thermophysical properties of a piecewise linear fitting at a pressure of 3 MPa

ρ/(kg·m−3) cp/(kJ·kg−1·K−1) λ/(W·m−1·K−1) μ/10−4(Pa·s) −1.03T+300.22(T∈[295,515] K) 0.0047 T−1.37(T∈[295,361] K)− 0.00018 T+0.054(T∈[295,409] K)−0.072T+21.32(T∈[295,324] K) −1.4T+720.89(T∈[515,619] K) 0.0098 T−3.55(T∈[361,627] K)−0.00022 T+0.092(T∈[409,659] K)−0.049T+15.9(T∈[324,350] K) −3T+ 1859.52 (T∈[619,650] K)0.051T−32.06(T∈[627,651] K) −0.000095 T+0.063(T∈[659,680] K)−0.031T+10.69(T∈[350,389] K) −5.08T+ 3302.32 (T∈[650,681] K)0.23T−148.43(T∈[651,672] K) −0.0013 T+0.88(T∈[680,721] K)−0.018T+6.99(T∈[389,428] K) −2.3T+ 1569.14 (T∈[681,709] K)−0.18T+123.6(T∈[672,690] K) 0.000088 T−0.063(T∈[721,814] K)−0.01T+4.44(T∈[428,500] K) −0.99T+702.92(T∈[709,754] K) −0.066T+45.37(T∈[690,712] K) 0.00011 T−0.087(T∈[814,950] K)−0.0062 T+3.12(T∈[500,646] K)−0.31T+233.59(T∈[754,799] K) −0.01T+7.4(T∈[712,751] K) 0.000092 T−0.06(T∈[646,950] K)−0.082T+65.95(T∈[799,950] K) 0.0078 T−5.87(T∈[751,821] K)0.0059 T−4.88(T∈[821,950] K)表 2 网格无关性分析

Table 2. Mesh independence analysis

花瓣数 网格数量 Tout/K uout/(m·s−1) 3 2.10×106 751.23 13.55 3 3.25×106 754.62 14.23 3 4.10×106 754.59 14.35 4 2.25×106 775.24 12.45 4 3.30×106 778.65 13.73 4 4.20×106 778.89 13.54 5 2.40×106 793.07 11.51 5 3.45×106 795.17 12.93 5 4.65×106 794.96 12.24 -

[1] 杜长河, 高银峰, 李洪伟, 等. 高温高压工况下NASA C3X涡轮叶片旋流冷却和冲击冷却的性能对比研究[J]. 东北电力大学学报, 2022, 42(5): 55-64.DU C H, GAO Y F, LI H W, et al. Comparative study on swirl cooling and lmpingement cooling performance for NASA C3X vane under high parameter conditions[J]. Journal of Northeast Electric Power University, 2022, 42(5): 55-64(in Chinese). [2] 温奇, 裴鑫岩, 田鸿宇, 等. 空-油换热器对变循环航空发动机总体性能的影响研究[J]. 推进技术, 2023, 44(2): 2202035.WEN Q, PEI X Y, TIAN H Y, et al. Overall performance evaluation of variable cycle aero-engine based on air-fuel heat exchanger[J]. Journal of Propulsion Technology, 2023, 44(2): 2202035(in Chinese). [3] PU H, CHANG H T, WANG J Z, et al. Experimental investigation and analysis of convective heat transfer to supercritical pressure aviation kerosene RP-3 in vertical miniature tubes based on the pseudo-boiling theory[J]. Applied Thermal Engineering, 2023, 219: 119651. doi: 10.1016/j.applthermaleng.2022.119651 [4] LEI Z L, BAO Z W. Experimental investigation on laminar heat transfer performances of RP-3 at supercritical pressure in the helical coiled tube[J]. International Journal of Heat and Mass Transfer, 2022, 185: 122326. doi: 10.1016/j.ijheatmasstransfer.2021.122326 [5] LIU X Y, YANG Z Q, MIAO R P, et al. Experimental study on flow excursion instability of supercritical hydrocarbon fuel in scramjet regenerative cooling parallel channels[J]. Chinese Journal of Aeronautics, 2023, 36(1): 201-215. doi: 10.1016/j.cja.2022.09.024 [6] 刘东洋, 乔柏铖, 闵敬春. 螺旋管空油换热器空气流动换热特性数值研究[J]. 工程热物理学报, 2023, 44(5): 1383-1389.LIU D Y, QIAO B C, MIN J C. Numerical study on air flow and heat transfer of a spiral tube air-fuel heat exchanger[J]. Journal of Engineering Thermophysics, 2023, 44(5): 1383-1389(in Chinese). [7] LIU P H, WANG R T, LIU S B, et al. Experimental study on the thermal-hydraulic performance of a tube-in-tube helical coil air–fuel heat exchanger for an aero-engine[J]. Energy, 2023, 267: 126626. doi: 10.1016/j.energy.2023.126626 [8] WEN J, HUANG H R, FU Y C, et al. Heat transfer performance of aviation kerosene RP-3 flowing in a vertical helical tube at supercritical pressure[J]. Applied Thermal Engineering, 2017, 121: 853-862. doi: 10.1016/j.applthermaleng.2017.04.055 [9] FU Y C, WEN J, TAO Z, et al. Experimental research on convective heat transfer of supercritical hydrocarbon fuel flowing through U-turn tubes[J]. Applied Thermal Engineering, 2017, 116: 43-55. doi: 10.1016/j.applthermaleng.2017.01.058 [10] 赵晋杰, 雷志良, 鲍泽威, 等. S型管内超临界航空煤油的裂解与结焦研究[J]. 推进技术, 2021, 42(3): 692-700.ZHAO J J, LEI Z L, BAO Z W, et al. Pyrolysis and coking deposition of aviation kerosene under supercritical conditions in S-bend tubes[J]. Journal of Propulsion Technology, 2021, 42(3): 692-700(in Chinese). [11] 王彦红, 李雨健, 李洪伟, 等. S型通道内超临界RP-3航空煤油换热特性研究[J]. 工程热物理学报, 2022, 43(9): 2442-2450.WANG Y H, LI Y J, LI H W, et al. Research on heat transfer characteristics of supercritical RP-3 aviation kerosene in a S-shaped channel[J]. Journal of Engineering Thermophysics, 2022, 43(9): 2442-2450(in Chinese). [12] 王彦红, 李雨健, 李洪伟, 等. 超临界压力下竖直蛇形管内RP-3燃料换热特性数值研究[J]. 推进技术, 2022, 43(12): 267-275.WANG Y H, LI Y J, LI H W, et al. Numerical research on heat transfer characteristics of supercritical-pressure RP-3 fuel in a vertical serpentine tube[J]. Journal of Propulsion Technology, 2022, 43(12): 267-275(in Chinese). [13] XU K K, SUN X, MENG H. Conjugate heat transfer, endothermic fuel pyrolysis and surface coking of aviation kerosene in ribbed tube at supercritical pressure[J]. International Journal of Thermal Sciences, 2018, 132: 209-218. doi: 10.1016/j.ijthermalsci.2018.06.008 [14] 黄世璋, 朱强华, 高效伟. 碳氢燃料在波纹管内的超临界裂解传热特性[J]. 推进技术, 2019, 40(1): 95-106.HUANG S Z, ZHU Q H, GAO X W. Supercritical heat transfer characteristics of hydrocarbon fuel with pyrolysis in corrugated tubes[J]. Journal of Propulsion Technology, 2019, 40(1): 95-106(in Chinese). [15] 苏桐, 刘滟钰, 张咏鸥. 超临界LNG在螺旋形微通道中的流动传热特性[J]. 舰船科学技术, 2022, 44(10): 61-67. doi: 10.3404/j.issn.1672-7649.2022.10.012SU T, LIU Y Y, ZHANG Y O. Flow and heat transfer of supercritical LNG in spiral microchannel[J]. Ship Science and Technology, 2022, 44(10): 61-67(in Chinese). doi: 10.3404/j.issn.1672-7649.2022.10.012 [16] TANG X Y, ZHU D S. Experimental and numerical study on heat transfer enhancement of a rectangular channel with discontinuous crossed ribs and grooves[J]. Chinese Journal of Chemical Engineering, 2012, 20(2): 220-230. doi: 10.1016/S1004-9541(12)60382-6 [17] MARYAN F N, HOSSEIM T R, MOUSA F. Analysis of a twisted double-pipe heat exchanger with lobed cross-section as a novel heat storage unit for solar collectors using phase-change material[J]. International Communications in Heat and Mass Transfer, 2021, 128: 105598. doi: 10.1016/j.icheatmasstransfer.2021.105598 [18] LIAW K L, KURNIA J C, PUTRA Z A, et al. Enhanced turbulent convective heat transfer in helical twisted Multilobe tubes[J]. International Journal of Heat and Mass Transfer, 2023, 202: 123687. doi: 10.1016/j.ijheatmasstransfer.2022.123687 [19] LIAW K L, KURNIA J C, SASMITO A P. Laminar convective heat transfer in helical twisted multilobe tubes[J]. Case Studies in Thermal Engineering, 2022, 39: 102459. doi: 10.1016/j.csite.2022.102459 [20] FU Y C, HUANG H R, WEN J, et al. Experimental investigation on convective heat transfer of supercritical RP-3 in vertical miniature tubes with various diameters[J]. International Journal of Heat and Mass Transfer, 2017, 112: 814-824. doi: 10.1016/j.ijheatmasstransfer.2017.05.008 [21] WANG Y H, LU Y N, LI S F, et al. Numerical study on non-uniform heat transfer deterioration of supercritical RP-3 aviation kerosene in a horizontal tube[J]. Chinese Journal of Chemical Engineering, 2020, 28(6): 1542-1557. doi: 10.1016/j.cjche.2020.03.037 [22] WEN J, HUANG H R, JIA Z X, et al. Buoyancy effects on heat transfer to supercritical pressure hydrocarbon fuel in a horizontal miniature tube[J]. International Journal of Heat and Mass Transfer, 2017, 115: 1173-1181. doi: 10.1016/j.ijheatmasstransfer.2017.08.116 [23] NAJAFIAN M, ESMAEILI A, NIKKHOO A, et al. Numerical study of heat transfer and fluid flow of supercritical water in twisted spiral tubes[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2022, 44(3): 6433-6455. doi: 10.1080/15567036.2022.2098421 -

下载:

下载: