Effect of flow stress calculation on formability of aluminum alloy warm sheet hydroforming

-

摘要:

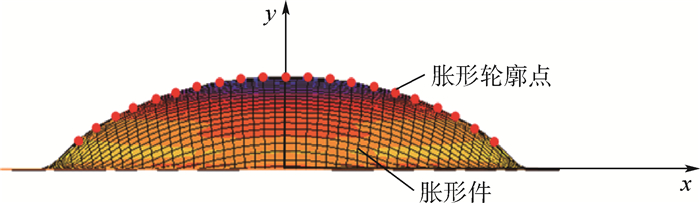

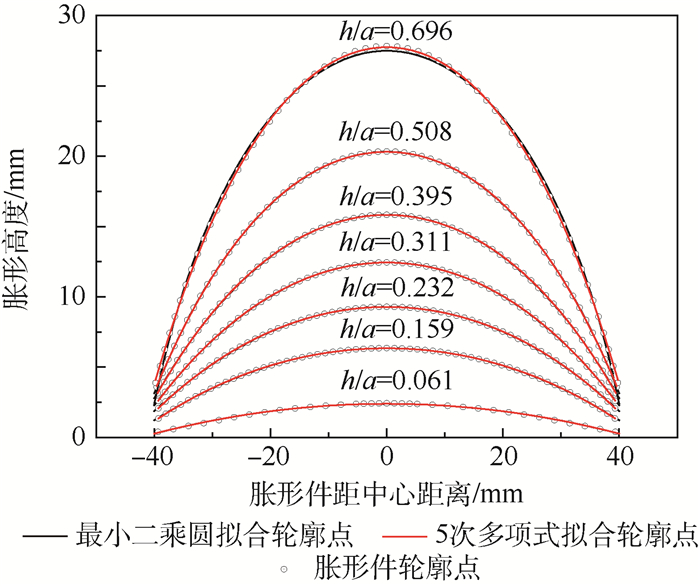

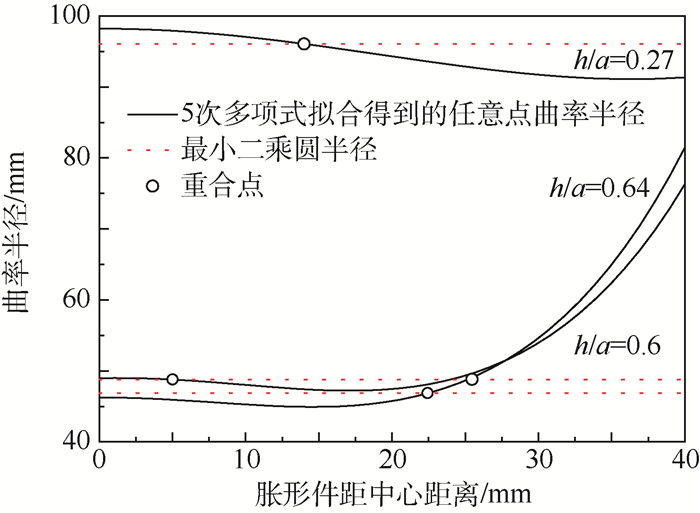

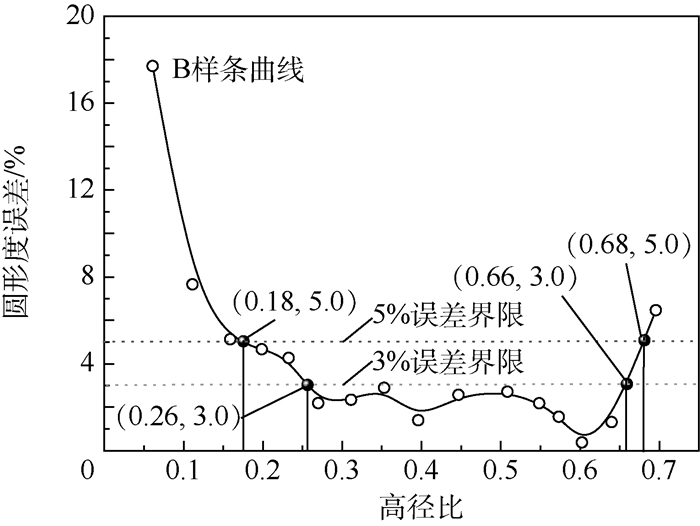

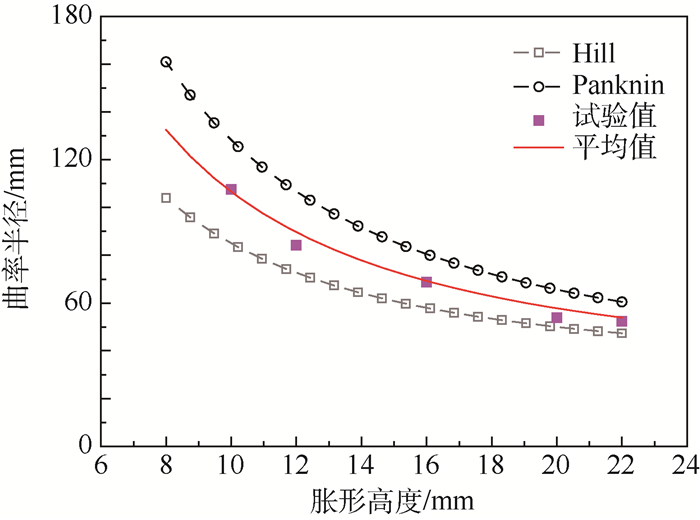

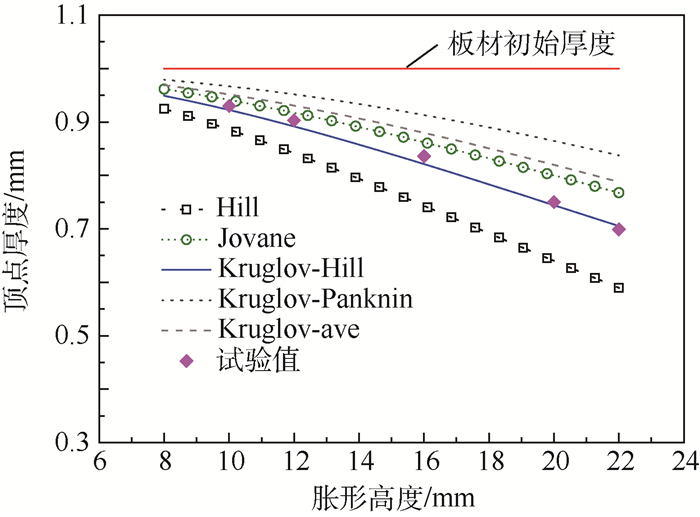

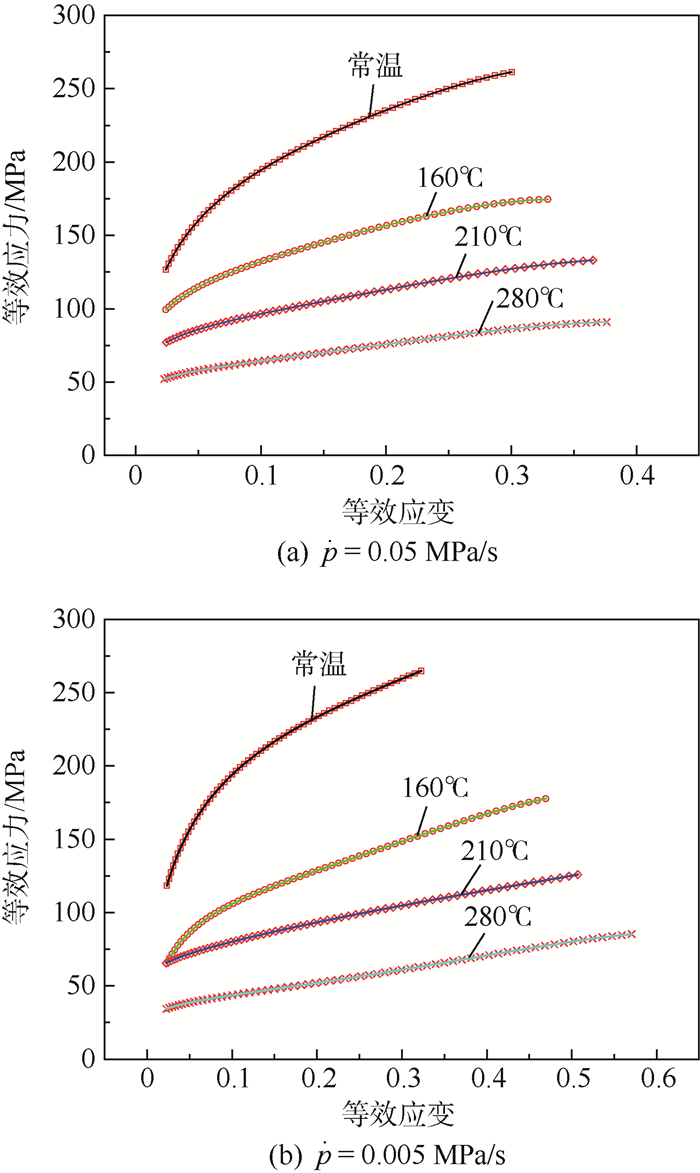

为研究流动应力计算对铝合金板材充液热成形性能的影响,进行了板材热态胀形试验,得到了不同直径的胀形高度-压力曲线。结合三坐标测量仪测得的胀形零件轮廓数据,拟合出了最小二乘圆(LSCF)半径,发现在高径比(

h /a )范围(0.18 <h /a ≤0.68)内,对应的曲率半径与圆形半径之间的圆形度误差为5%。为获取更为精确的应力-应变曲线,通过对现有曲率半径和厚度理论模型进行比较,结合流动应力计算,发现Hill及Panknin曲率半径模型的平均值及Kruglov-Hill厚度模型最符合试验数据。利用组合模型计算胀形试验所得到的胀形高度-压力曲线,得到了不同温度、不同压力率下的应力-应变曲线。结果表明,210℃时方向异性(轧制方向及垂直方向)对铝合金7075-O胀形件曲率半径的影响很小;同时,压力率可影响其应力-应变曲线。Abstract:In order to research the influence of flow stress calculation on formability of aluminum alloy warm sheet hydroforming, warm sheet bulging test was carried out to obtain bulging height-pressure curves with different bulging diameters in this study. Based on the data of bulging parts profile measured by three coordinate measuring machine, the least square circle fit (LSCF) radius were fitted, and it was found that when the height-diameter ratio

h /a was in the range of 0.18 <h /a ≤ 0.68, the corresponding value of roundness error between the radius of curvature and the circle radius was 5%. By comparing the existing theoretical models for radius of curvature and thickness, which is combined with flow stress calculation, it was found that the average value of radius of curvature model Hill and Panknin, and the thickness model Kruglov-Hill are in the most accordance with experimental data. The combination model was used to calculate the bulging height-pressure curves obtained by bulging test, and then the stress-strain curves with different temperatures and pressure rates were obtained. It was found that there was a little impact on radius of curvature for different directions (rolling direction and vertical direction) of the bulging parts formed with 7075-O aluminum alloy at 210℃, while the pressure rate can affect the stress-strain curves.-

Key words:

- warm sheet hydroforming /

- flow stress /

- formability /

- stress-strain curve /

- pressure rate

-

成分 Zn Mg Cu Mn Cr Fe Si Ti 其他 Al 含量/% 5.1 2.1 1.2 0.3 0.18 0.5 0.4 0.2 0.2 余量 表 2 不同胀形高度时试验测量数据和有限元拟合数据胀形件轮廓最小二乘圆半径对比

Table 2. Comparison of LSCF radius of bulging parts profile based on experimental measurment data and finite element fitting data with different bulging heights

mm 胀形高度 轧制方向 垂直方向 有限元拟合最小二乘圆半径 圆心(y, z) 最小二乘圆半径 圆心(x, z) 最小二乘圆半径 10 (-94.73, -159.32) 107.16 (108.77, -160.12) 107.95 103.77 12 (-91.72, -133.30) 84.18 (113.19, -133.25) 84.13 83.75 16 (-97.33, -114.89) 68.79 (117.74, -114.77) 68.66 67.79 20 (-91.99, -94.10) 53.70 (117.51, -94.30) 53.90 55.15 22 (-92.85, -91.94) 52.35 (120.50, -91.92) 52.32 52.14 表 3 不同顶点曲率半径及顶点厚度解析模型

Table 3. Analytical model for different vertex radius of curvature and vertex thickness

顶点曲率半径 顶点厚度 模型 表达式 模型 表达式 Hill

Jovane

Panknin

Hill

Kruglov

注:rc—胀形半径; hd—胀形高度; rf—胀形圆角半径; t(td)—顶点厚度; t0—板材初始厚度。 表 4 胀形高度-压力曲线5次多项式拟合

Table 4. Five-order polynomial fitting of bulging height-pressure curves

温度 压力率/(MPa·s-1) 5次多项式拟合 A0 A1 A2 A3 A4 A5 常温 0.05 0.003 -0.011 0.068 -0.005 1.94×10-4 -3.19×10-6 0.005 -0.022 -0.014 0.061 -0.004 8.73×10-5 -7.88×10-7 160℃ 0.05 -0.044 0.092 0.029 -0.003 1.08×10-4 -2.05×10-6 0.005 0.013 -0.027 0.034 -0.002 4.92×10-5 -5.29×10-7 210℃ 0.05 0.001 0.080 0.018 -0.001 6.23×10-5 -1.09×10-6 0.005 -0.038 0.116 0.002 6.23×10-5 -9.21×10-6 1.52×10-7 280℃ 0.05 -0.015 0.065 0.011 -9.99×10-4 4.69×10-5 -8.76×10-7 0.005 -0.013 0.046 0.006 -4.22×10-4 1.55×10-5 -2.25×10-7 -

[1] SELLARS C M, MCTEGART W J.On the mechanism of hot deformation[J].Acta Metallurgica, 1966, 14(9):1136-1138. doi: 10.1016/0001-6160(66)90207-0 [2] HOULSBY G T, PUZRIN A M.Principles of hyperplasticity[M].London:Springer-Verlag, 2006:19-28. [3] KOC M, BILLUR E, CORA O N.An experimental study on the comparative assessment of hydraulic bulge test analysis methods[J].Materials and Design, 2011, 32(1):272-281. doi: 10.1016/j.matdes.2010.05.057 [4] LANG L H, CAI G S, LIU K N, et al.Investigation on the effect of through thickness normal stress on forming limit at elevated temperature by using modified M-K model[J].International Journal of Material Forming, 2015, 8(2):211-228. doi: 10.1007/s12289-014-1161-3 [5] NURCHESHMEH M, GREEN D E.Influence of out-of-plane compression stress on limit strains in sheet metals[J].International Journal of Material Forming, 2012, 5(3):213-226. doi: 10.1007/s12289-011-1044-9 [6] LANG L H, LIU B S, LI T, et al.Experimental investigation on hydromechanical deep drawing of aluminum alloy with heated media[J].Steel Research International, 2012, 83(3):230-237. doi: 10.1002/srin.v83.3 [7] 马高山.5A90铝锂合金板材热成形有限元模拟与试验研究[D].北京: 北京航空航天大学, 2008: 37-46.MA G S.FEM simulation and experimental research on hot forming of 5A90 Al-Li alloy sheet[D].Beijing: Beihang University, 2008: 37-46(in Chinese). [8] LIU B S, LANG L H, ZENG Y S, et al.Forming characteristic of sheet hydroforming under the influence of through-thickness normal stress[J].Journal of Materials Processing Technology, 2012, 212(9):1875-1884. doi: 10.1016/j.jmatprotec.2012.03.021 [9] HOFFMANNER A L.Development of workability testing techniques: F33615-67-C-1466[R].Cleveland: Interim Report on Air Force Contract, 1967. [10] GROCHE P, HUBER R, DOERR J, et al.Hydromechanical deep-drawing of aluminium-alloys at elevated temperatures[J].CIRP Annals, 2002, 51(1):215-218. doi: 10.1016/S0007-8506(07)61502-9 [11] KAYA S, ALTAN T, GROCHE P, et al.Determination of the flow stress of magnesium Az31-O sheet at elevated temperatures using the hydraulic bulge test[J].International Journal of Machine Tools and Manufacture, 2008, 48(5):550-557. doi: 10.1016/j.ijmachtools.2007.06.011 [12] MAHABUNPHACHAI S, KOC M.Investigations on forming of aluminum 5052 and 6061 sheet alloys at warm temperatures[J].Materials and Design, 2010, 31(5):2422-2434. doi: 10.1016/j.matdes.2009.11.053 [13] LANG L H, WANG Z R, KANG D C, et al.Hydroforming highlights:Sheet hydroforming and tube hydroforming[J].Journal of Materials Processing Technology, 2004, 151(1-3):165-177. doi: 10.1016/j.jmatprotec.2004.04.032 [14] SIEGERT K, JAGER S, VULCAN M.Pneumatic bulging of magnesium AZ 31 sheet metals at elevated temperatures[J].CIRP Annals, 2003, 52(1):241-244. doi: 10.1016/S0007-8506(07)60575-7 [15] STRANO M, ALTAN T.An inverse energy approach to determine the flow stress of tubular materials for hydroforming applications[J].Journal of Materials Processing Technology, 2004, 146(1):92-96. doi: 10.1016/j.jmatprotec.2003.07.016 [16] 刘宝胜.板材充液热成形机理及关键技术研究[D].北京: 北京航空航天大学, 2012: 95-105.LIU B S.Research on forming mechanism and key technologies of warm sheet hydroforming[D].Beijing: Beihang University, 2012: 95-105(in Chinese). [17] GOTOH M, CHUNG T, IWATA N.Effect of out-of-plane stress on the forming limit strain of sheet metals[J].JSME International Journal Series A:Mechanics and Material Engineering, 1995, 38(1):123-132. doi: 10.1299/jsmea1993.38.1_123 [18] GUTSCHER G, WU H C, NGAILE G.Determination of flow stress for sheet metal forming using the viscous pressure bulge (VPB) test[J].Journal of Materials Processing Technology, 2004, 146(1):1-7. doi: 10.1016/S0924-0136(03)00838-0 [19] PRATT V.Direct least-squares fitting of algebraic surfaces[J].Computer Graphics, 1987, 21(4):145-152. doi: 10.1145/37402 [20] PEIRS J, VERLEYSEN P, VAN PAEPEGEM W, et al.Determining the stress-strain behaviour at large strains from high strain rate tensile and shear experiments[J].International Journal of Impact Engineering, 2011, 38(5):406-415. doi: 10.1016/j.ijimpeng.2011.01.004 [21] LANG L H, DU P M, LIU B S, et al.Pressure rate controlled unified constitutive equations based on microstructure evolution for warm hydroforming[J].Journal of Alloys and Compounds, 2013, 574:41-48. doi: 10.1016/j.jallcom.2013.03.134 期刊类型引用(24)

1. 刘海瑞,武宪威,李鹏,钱征华,李锟. 基于APSO-LSSVM的航空发动机轴承故障诊断及寿命预测. 测控技术. 2024(01): 70-76 .  百度学术

百度学术2. 章宗沈,施继忠,高清平,孙剑锋. 基于多尺度CNN和BiLSTM-Attention的轴承故障诊断模型. 浙江师范大学学报(自然科学版). 2024(03): 281-289 .  百度学术

百度学术3. 刘信良,陈国宁,苏化,王静秋,王晓雷. 一个用于磨粒图像快速分类的轻量化CNN模型. 润滑与密封. 2024(10): 102-107 .  百度学术

百度学术4. 刘秀丽,徐小力. 基于特征金字塔卷积循环神经网络的故障诊断方法. 上海交通大学学报. 2022(02): 182-190 .  百度学术

百度学术5. 王红珂,刘啸天,林磊,孙海涛,吕云鹤,张晏玮,薛飞. 机器学习在材料服役性能预测中的应用. 装备环境工程. 2022(01): 11-19 .  百度学术

百度学术6. 曹明,黄金泉,周健,陈雪峰,鲁峰,魏芳. 民用航空发动机故障诊断与健康管理现状、挑战与机遇Ⅰ:气路、机械和FADEC系统故障诊断与预测. 航空学报. 2022(09): 9-41+2 .  百度学术

百度学术7. 吴庆涛,韩春松,丁传东. SVM用于非线性系统故障诊断. 齐齐哈尔大学学报(自然科学版). 2021(03): 22-24+61 .  百度学术

百度学术8. 孟亚峰,王涛,李泽西,蔡金燕,朱赛,韩春辉. 改进自适应人工免疫算法求解函数优化问题. 北京航空航天大学学报. 2021(05): 894-903 .  本站查看

本站查看9. 卞景艺,刘秀丽,徐小力,吴国新. 基于多尺度深度卷积神经网络的故障诊断方法. 振动与冲击. 2021(18): 204-211 .  百度学术

百度学术10. 赵柄锡,冀大伟,袁奇,李浦,葛庆. 采用时域与时频域联合特征空间的转子系统碰磨故障诊断. 西安交通大学学报. 2020(01): 75-84 .  百度学术

百度学术11. 潘礼正,朱大帅,佘世刚. 基于WP-ICA及SVM的齿轮故障诊断研究. 计算机仿真. 2020(01): 411-416+483 .  百度学术

百度学术12. 张海涛. 基于在线油液监测的船舶发动机故障分析. 机械设计与制造工程. 2020(03): 113-116 .  百度学术

百度学术13. 冀丰偲,余云松,张早校. LDA_SVM方法在化工过程故障诊断中的应用. 高校化学工程学报. 2020(02): 487-494 .  百度学术

百度学术14. 周超,曹春平,孙宇. 利用GS优化SM-SVM的滚动轴承故障诊断方法研究. 机械设计与制造. 2020(06): 16-19 .  百度学术

百度学术15. 常鹏,胡军,贺石中,庞晋山,李秋秋,张驰. 基于光谱分析技术的风机齿轮箱系统维护策略研究. 润滑与密封. 2019(01): 115-118 .  百度学术

百度学术16. 徐萌,席泽西,王雍赟,李晓露. 基于集成学习的航空发动机故障诊断方法. 中国民航大学学报. 2019(02): 29-33+42 .  百度学术

百度学术17. 任松,徐雪茹,欧阳汛,赵云峰,王小书. 基于分层模糊支持向量机的油液磨粒自动识别. 润滑与密封. 2019(05): 1-8 .  百度学术

百度学术18. 谷远利,张源,芮小平,陆文琦,李萌,王硕. 基于免疫算法优化LSSVM的短时交通流预测. 吉林大学学报(工学版). 2019(06): 1852-1857 .  百度学术

百度学术19. 张帅,杜军,严智. 基于输出层增强的LSTM发动机排气温度模型. 电子测量与仪器学报. 2019(08): 124-132 .  百度学术

百度学术20. 左奎军,李艳军,曹愈远,王宏宇. 改进的AdaBoost-SVM算法用于无人机目标跟踪. 武汉理工大学学报(交通科学与工程版). 2019(06): 1113-1119 .  百度学术

百度学术21. 李刚,杨传健,贾会星. 基于小波特征值容差阈值随机仿真的故障判别方法. 电子测量与仪器学报. 2018(09): 42-47 .  百度学术

百度学术22. 皮骏,马圣,贺嘉诚,孔庆国,马龙. 遗传算法优化的SVM在航空发动机磨损故障诊断中的应用. 润滑与密封. 2018(10): 89-97 .  百度学术

百度学术23. 谢堃,崔迪,王一博. 高性能航空金属材料抗磨损性能研究. 中国金属通报. 2018(07): 78-79 .  百度学术

百度学术24. 李运,杨世海,吴佳佳,顾伯忠. 基于SVM观测器的新异类故障检测方法及应用. 振动.测试与诊断. 2021(02): 292-298+411 .  百度学术

百度学术其他类型引用(16)

-

下载:

下载:

百度学术

百度学术