Energy consumption of condensation-hydrogenation process to prepare alkanes from lignocellulose biomass

-

摘要:

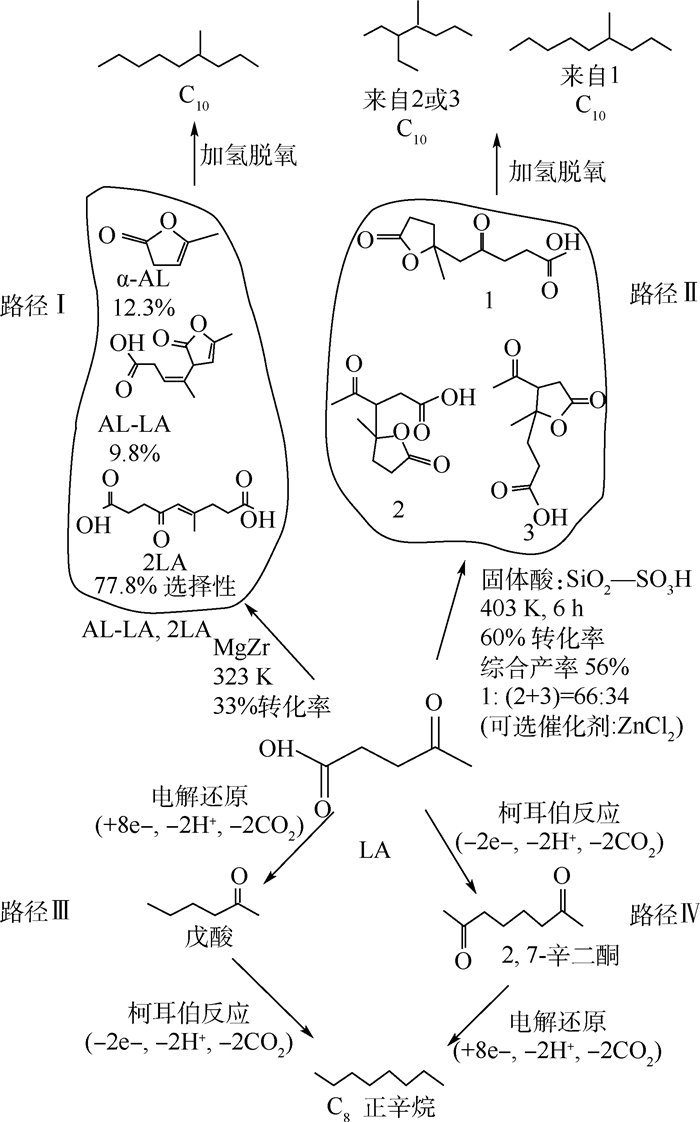

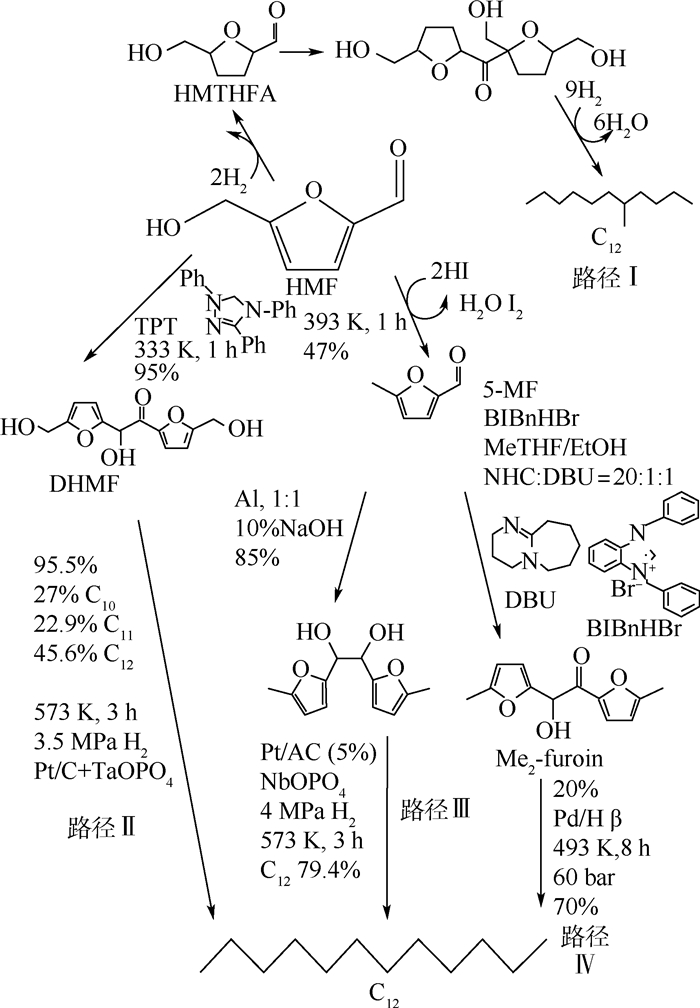

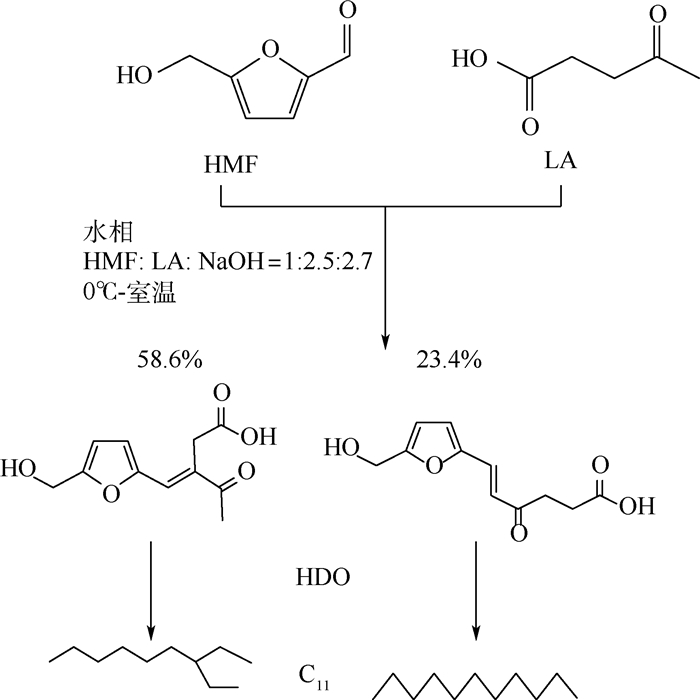

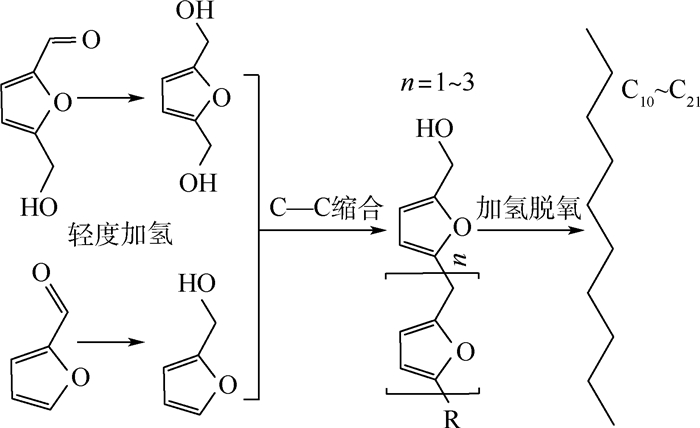

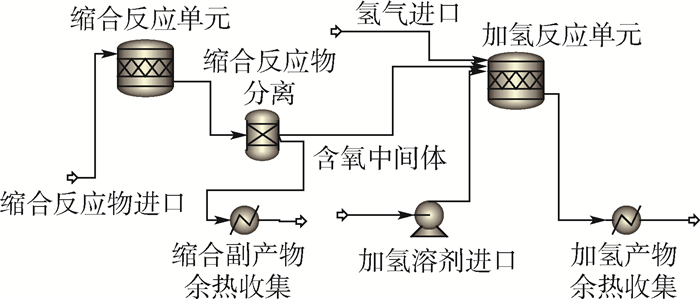

随着纤维素原料制备糠醛、5-羟甲基糠醛、乙酰丙酸平台化合物技术的日益成熟,平台化合物再利用技术成为国际热点。通过研究平台化合物自缩合与交叉缩合工艺特点,以及后续加氢制备合成航油烷烃的可行路径,设计了利用2条纤维素生物质平台化合物全组分制备航油的工艺,通过能耗分析与评价,确定了每条工艺路线中的主要能耗单元及主要输入的耗能物质。结果表明:糠醛-乙酰丙酸交叉缩合加氢工艺相比糠醛自缩合加氢工艺、5-羟甲基糠醛自缩合加氢工艺在热耗、氢耗等方面有明显优势。为实现秸秆的全组分利用,提出糠醛-乙酰丙酸交叉缩合加氢联合5-羟甲基糠醛自缩合加氢工艺,根据目前的工艺技术,航油收率可达19.6%。

Abstract:With the increasing maturity of technology for preparing furfural, 5-hydroxymethylfurfural, levulinic acid from lignocellulose biomass, platform compounds reuse technology has become an international hot spot. By studying the characteristics of the self-condensation and cross-condensation processes of platform compounds, as well as the feasible paths for subsequent hydrogenation to prepare synthetic jet fuel alkanes, two processes for preparing jet fuel with the full component use of lignocellulose biomass derived platform compounds were designed. Through energy consumption analysis and evaluation, the main energy consumption units and main input energy consumption materials in each process route were determined. Furfural-levulinic acid cross-condensation hydrogenation process compared with furfural self-condensation hydrogenation process and 5-hydroxymethyl furfural self-condensation hydrogenation process has obvious advantages in terms of heat consumption and hydrogen consumption. In order to realize the full-component utilization of straw, furfural-levulinic acid cross-condensation hydrogenation is combined with 5-hydroxymethylfurfural self-condensation hydrogenation process, and according to the current process technology, the jet fuel yield can reach 19.6%.

-

Key words:

- platform compounds /

- condensation /

- hydrogenation /

- energy consumption analysis /

- alternative jet fuel

-

表 1 三种纤维素类生物质前驱体缩合-加氢制备航油烷烃的方法

Table 1. Three ways of alkanes production by condensation and hydrogenation of precursors derived from lignocellulose-derived chemicals

平台化合物 类别 缩合过程 加氢过程 综合收率/% 参考文献 缩合收率/% 催化剂 温度/℃ 产物烷烃碳数 理论氢耗/g 加氢收率/% 催化剂 温度/℃ FF Zn催化FF二聚 98.51 还原剂Zn 50 10 0.103 61.26 Pt/C 300 60.35 [11] HMF TPT催化HMF二聚 95 TPT 60 12 0.103 49.92 Pd/C 250 47.42 [4] FF、LA LA-FF交叉缩合 79.21 NaOH 50 15、10 0.111 52.23 Ru/C

Ru/Al2O3300 41.37 [22-23] 注:缩合收率=缩合产物质量/平台化合物的质量×100%;加氢收率=烷烃质量/缩合产物质量×100%;理论氢耗=每克缩合产物加氢过程理论耗氢质量;综合收率=缩合收率×加氢收率×100%。 表 2 基于ASPEN PLUS模拟的各缩合-加氢路径的能耗情况

Table 2. Energy consumption of different pathways in condensation and hydrogenation by ASPEN PLUS simulation

路径 缩合单元 反应物组成/% 产物组成/% 反应条件 化学反应热/(kJ·mol-1) 热负荷/(J·g-1) LA-FF

缩合加氢FF 1.85 C10中间体 0.17 50℃ 1atm -106.35(参考组分:LA) 9 020.25 LA 1.12 C15中间体 2.17 NaOH 1.13 其他 97.66 H2O 95.9 FF自缩

合加氢FF 5.78 C10中间体 5.69 50℃ 1atm 413.35(参考组分:FF) 9 886.19 Zn 3.94 其他 94.31 NaOH 9.03 H2O 81.25 HMF自缩

合加氢HMF 100 C12中间体 95 60℃ 1atm 81.44(参考组分:HMF) 1 451.1 TPT 其他 5 KOtBu 路径 加氢单元 反应物组成/% 产物组成/% 反应条件 化学反应热/(kJ·mol-1) 热负荷/(J·g-1) LA-FF

缩合加氢含氧中间体 32.23 C10烷烃 1.17 300℃ 4 MPa -1 186.01(参考组分:含氧中间体) 2 836.74 甲醇 64.24 C15烷烃 15.67 催化剂 其他 83.16 H2 3.53 FF自缩合加氢 含氧中间体 1.9 C10烷烃 1.16 300℃ 10 MPa -1 317.28

(参考组分:含氧中间体)112 654.2 水 97.9 其他 98.84 Pt/C 固体酸 H2 0.2 HMF自缩合加氢 含氧中间体 0.59 C12烷烃 0.29 250℃ 4.2 MPa -1 105.91(参考组分:含氧中间体) 61 555.36 醋酸 99.35 其他 99.71 Pd/C La(OTf)3 H2 0.06 路径 泵单元 余热收集单元 电功/(J·g-1) 缩合副产物余热/(J·g-1) 加氢产物余热/(J·g-1) LA-FF缩合加氢 62.99 -7 780.66 -6 962.93 FF自缩合加氢 2 825.2 -2 287.26 -94 188.84 HMF自缩合加氢 4 289.59 -7.56 -58 110.59 注:表中各单元能耗基准为各路径生成每克航油产物所消耗的能量,正值表示吸热,负值表示放热;1 atm=1.013 25×105 Pa。 表 3 基于航油产物的各缩合-加氢路径能耗汇总

Table 3. Energy consumption of different pathways in condensation and hydrogenation based on alkanes products

基准 路径 反应热耗/kJ 电耗/J (反应热耗+电耗)/J 余热收集/J 加氢氢耗/g 基于每克航油产物 LA-FF

缩合加氢考虑C10与C15 11 856.99 62.99 11 919.98 -14 743.59 0.142 3 只考虑C10 171 165.14 909.31 172 074.45 -212 835.52 2.054 3 只考虑C15 12 739.48 67.68 12 807.16 -15 840.93 0.152 9 FF自缩合加氢 122 540.42 2 825.20 125 365.62 -96 476.10 0.141 7 HMF自缩合加氢 63 006.46 4 289.59 67 296.05 -58 118.15 0.153 8 基于每焦耳航油产物 LA-FF

缩合加氢考虑C10与C15 0.27 0.001 4 0.27 -0.34 只考虑C10 3.87 0.020 6 3.89 -4.81 只考虑C15 0.29 0.001 5 0.29 -0.36 FF自缩合加氢 2.77 0.063 9 2.83 -2.18 HMF自缩合加氢 1.43 0.097 2 1.53 -1.32 / 注:LA-FF缩合加氢路径航油产物同时包含C10和C15烷烃,表中给出了只考虑C10或C15航油的情况;LHVC10=44.24 kJ/g, LHVC12=44.11 kJ/g, LHVC15=43.98 kJ/g。 表 4 各种工艺缩合-加氢过程的能耗指标

Table 4. Energy consumption indexes of condensation and hydrogenation of various processes

工艺 航油产率 热耗+电耗 氢耗 基于每克秸秆/g 基于每克秸秆/J 基于每克秸秆/kJ 基于每克航油/kJ 基于每焦耳航油/J 基于每克秸秆/g 基于每克航油/g 基于每焦耳航油/g LA-FF缩合 0.094 2 4 144.79 1.12 11.92 0.27 0.013 4 0.142 3 3.234 3 FF自缩合 0.085 6 3 785.62 10.73 125.37 2.83 0.012 1 0.141 7 3.202 7 HMF自缩合 0.145 9 6 436.19 9.82 67.30 1.53 0.022 4 0.153 8 3.487 8 LA-FF缩合与HMF自缩合结合 0.196 0 8 634.23 7.97 40.68 0.92 0.029 1 0.148 3 3.366 1 FF自缩合与HMF自缩合结合 0.231 5 10 221.82 20.55 88.76 2.01 0.034 6 0.149 4 3.382 3 -

[1] HUBER G W, CHHEDA J N, BARRETT C J, et al. Production of liquid alkanes by aqueous-phase processing of biomass-derived carbohydrates[J]. Science, 2005, 308(5727): 1446-1450. doi: 10.1126/science.1111166 [2] CHHEDA J N, DUMESIC J A. An overview of dehydration, aldol-condensation and hydrogenation processes for production of liquid alkanes from biomass-derived carbohydrates[J]. Catalysis Today, 2007, 123(1-4): 59-70. doi: 10.1016/j.cattod.2006.12.006 [3] MARISCAL R, MAIRELES-TORRES P, OJEDA M, et al. Furfural: A renewable and versatile platform molecule for the synthesis of chemicals and fuels[J]. Energy & Environmental Science, 2016, 9(4): 1144-1189. [4] ZANG H J, WANG K, ZHANG M C, et al. Catalytic coupling of biomass-derived aldehydes into intermediates for biofuels and materials[J]. Catalysis Science & Technology, 2018, 8(7): 1777-1798. [5] LI Z, ZHANG J J, NIELSEN M M, et al. Efficient C—C bond formation between two levulinic acid molecules to produce C10 compounds with the cooperation effect of lewis and brønsted acids[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(5): 5708-5711. [6] LI H, RIISAGER A, SARAVANAMURUGAN S, et al. Carbon-increasing catalytic strategies for upgrading biomass into energy-intensive fuels and chemicals[J]. ACS Catalysis, 2018, 8(1): 148-187. doi: 10.1021/acscatal.7b02577 [7] SUBRAHMANYAM A V, THAYUMANAVAN S, HUBER G W. C—C bond formation reactions for biomass-derived molecules[J]. ChemSusChem, 2010, 3(10): 1158-1161. doi: 10.1002/cssc.201000136 [8] FABA L, DÍAZ E, ORDÓÑEZ S. Base-catalyzed condensation of levulinic acid: A new biorefinery upgrading approach[J]. ChemCatChem, 2016, 8(8): 1490-1494. doi: 10.1002/cctc.201600064 [9] AMARASEKARA A S, WIREDU B, GRADY T L, et al. Solid acid catalyzed aldol dimerization of levulinic acid for the preparation of C10 renewable fuel and chemical feedstocks[J]. Catalysis Communications, 2019, 124: 6-11. doi: 10.1016/j.catcom.2019.02.022 [10] NILGES P, DOS SANTOS T R, HARNISCH F, et al. Electrochemistry for biofuel generation: Electrochemical conversion of levulinic acid to octane[J]. Energy & Environmental Science, 2012, 5(1): 5231-5235. [11] HUANG Y B, YANG Z, DAI J J, et al. Production of high quality fuels from lignocellulose-derived chemicals: A convenient C—C bond formation of furfural, 5-methylfurfural and aromatic aldehyde[J]. RSC Advances, 2012, 2(30): 11211-11214. doi: 10.1039/c2ra22008c [12] HRONEC M, FULAJTAROVÁ K. Selective transformation of furfural to cyclopentanone[J]. Catalysis Communications, 2012, 24: 100-104. doi: 10.1016/j.catcom.2012.03.020 [13] YANG Y L, DU Z T, HUANG Y Z, et al. Conversion of furfural into cyclopentanone over Ni-Cu bimetallic catalysts[J]. Green Chemistry, 2013, 15(7): 1932. doi: 10.1039/c3gc37133f [14] YANG J F, LI N, LI G Y, et al. Synthesis of renewable high-density fuels using cyclopentanone derived from lignocellulose[J]. Chemical Communications, 2014, 50(20): 2572-2574. doi: 10.1039/c3cc46588h [15] WEGENHART B L, YANG L N, KWAN S C, et al. From furfural to fuel: Synthesis of furoins by organocatalysis and their hydrodeoxygenation by cascade catalysis[J]. ChemSusChem, 2014, 7(9): 2742-2747. doi: 10.1002/cssc.201402056 [16] WANG T J, LI K, LIU Q Y, et al. Aviation fuel synthesis by catalytic conversion of biomass hydrolysate in aqueous phase[J]. Applied Energy, 2014, 136: 775-780. doi: 10.1016/j.apenergy.2014.06.035 [17] CORMA A, DELATORRE O, RENZ M, et al. Production of high-quality diesel from biomass waste products[J]. Angewandte Chemie International Edition, 2011, 50(10): 2375-2378. doi: 10.1002/anie.201007508 [18] YANG W, GROCHOWSKI M R, SEN A. Selective reduction of biomass by hydriodic acid and its in situ regeneration from iodine by metal/hydrogen[J]. ChemSusChem, 2012, 5(7): 1218-1222. doi: 10.1002/cssc.201100669 [19] TAN J, WANG C G, ZHANG Q, et al. One-pot condensation of furfural and levulinates: A novel method for cassava use in synthesis of biofuel precursors[J]. Energy & Fuels, 2018, 32(6): 6807-6812. [20] LIANG G F, WANG A Q, ZHAO X C, et al. Selective aldol condensation of biomass-derived levulinic acid and furfural in aqueous-phase over MgO and ZnO[J]. Green Chemistry, 2016, 18(11): 3430-3438. doi: 10.1039/C6GC00118A [21] AMARASEKARA A S, SINGH T B, LARKIN E, et al. NaOH catalyzed condensation reactions between levulinic acid and biomass derived furan-aldehydes in water[J]. Industrial Crops and Products, 2015, 65: 546-549. doi: 10.1016/j.indcrop.2014.10.005 [22] 张琦, 李宇萍, 陈伦刚, 等. 百吨/年规模生物质水相合成航油类烃过程的物质与能量转化[J]. 天津大学学报(自然科学与工程技术版), 2017, 50(1): 13-18.ZHANG Q, LI Y P, CHEN L G, et al. Material and energy conversion of integrated 100 t/a-scale bio-jet fuel-range hydrocarbon production system via aqueous conversion of biomass[J]. Journal of Tianjin University (Science and Technology), 2017, 50(1): 13-18(in Chinese). [23] LI Y P, CHEN L G, ZHANG X H, et al. Process and techno-economic analysis of bio-jet fuel-range hydrocarbon production from lignocellulosic biomass via aqueous phase deconstruction and catalytic conversion[J]. Energy Procedia, 2017, 105: 675-680. doi: 10.1016/j.egypro.2017.03.374 [24] ZHAO L W, ELECHI N, QIAN R, et al. Origin of the regioselectivity in the aldol condensation between hydroxymethylfurfural and levulinic acid: A DFT investigation[J]. The Journal of Physical Chemistry A, 2017, 121(9): 1985-1992. doi: 10.1021/acs.jpca.6b11100 [25] STEVENS J G, BOURNE R A, TWIGG M V, et al. Real-time product switching using a twin catalyst system for the hydrogenation of furfural in supercritical CO2[J]. Angewandte Chemie, 2010, 49(47): 8856-8859. doi: 10.1002/anie.201005092 [26] VAN BUIJTENEN J, LANGE J P, PRICE R J. Process for preparing a hydrocarbon or mixture of hydrocarbons: US20110173877[P]. 2011-07-21. [27] KUMALAPUTRI A J, BOTTARI G, ERNE P M, et al. Tunable and selective conversion of 5-HMF to 2, 5-furandimethanol and 2, 5-dimethylfuran over copper-doped porous metal oxides[J]. ChemSusChem, 2014, 7(8): 2266-2275. [28] LIU H Z, JIANG T, HAN B X, et al. Selective phenol hydrogenation to cyclohexanone over a dual supported Pd-Lewis acid catalyst[J]. Science, 2009, 326(5957): 1250-1252. doi: 10.1126/science.1179713 [29] XU G Y, GUO J H, ZHANG Y, et al. Selective hydrogenation of phenol to cyclohexanone over Pd-HAP catalyst in aqueous media[J]. ChemCatChem, 2015, 7(16): 2485-2492. doi: 10.1002/cctc.201500442 [30] LIU Q Y, ZHANG C H, SHI N, et al. Production of renewable long-chained cycloalkanes from biomass-derived furfurals and cyclic ketones[J]. RSC Advances, 2018, 8(25): 13686-13696. -

下载:

下载: