Metal structure crack monitoring based on copper film sensor in corrosion environment

-

摘要:

铜薄膜传感器在飞机金属结构损伤监测过程中,将长期面临大气腐蚀环境的影响。针对此背景,研究了铜薄膜传感器在腐蚀环境下的耐蚀性能,及腐蚀后的疲劳裂纹监测性能。首先,采用脉冲偏压多弧离子镀技术在不同弧电流和基体负偏压水平下制备了一系列铜薄膜,对其耐蚀性能进行了对比研究。结果表明,在弧电流60 A和基体负偏压250 V时沉积的铜薄膜耐蚀性能最佳。然后,结合耐蚀性能最佳的沉积工艺参数,在2A12-T4铝合金中心孔板试件上制备了同心环状铜薄膜传感器阵列,并开展了盐雾腐蚀试验。最后,对腐蚀试验后的铜薄膜传感器进行了疲劳裂纹监测试验。结果表明:铜薄膜传感器在腐蚀环境下具有良好的耐蚀性能,耐蚀时间达1 000 h;腐蚀试验后的铜薄膜传感器对裂纹变化敏感,能实现对裂纹定量监测,监测精度为1 mm,监测结果具有良好的可重复性。

Abstract:In the process of monitoring aircraft metal structure crack, copper film sensor is exposed to atmospheric corrosion environment. The corrosion resistance of copper film sensor and crack monitoring performance after corrosion experiment were researched under the background. First, copper films were deposited by pulsed bias arc ion plating technique at difference levels of current and negative substrate bias. The corrosion resistance was researched. The result shows that the optimal corrosion resistance of copper film was deposited at level of current 60 A and negative substrate bias 250 V. Then, a concentric ring copper film sensor array was deposited on 2A12-T4 aluminum alloy using the optimal depositing parameter. A salt-spray environment experiment was carried out. Finally, a fatigue crack monitoring experiment was carried out using the copper film sensor which was exposed in corrosion environment. The results show that the copper film sensor has good corrosion resistance. The corrosion resistance time reaches 1 000 h. The copper film sensor is very sensitive to fatigue crack and can realize quantitative monitoring with the accuracy of 1 mm. Besides, the monitoring results are repeatable.

-

Key words:

- structure health monitoring /

- copper film sensor /

- corrosion resistance /

- crack /

- metal structure

-

表 1 铜薄膜沉积工艺参数

Table 1. Copper film deposition process parameters

参数 数值 基体负偏压/V 依据设计参数 氩气气压/Pa 2.2~2.4 沉积时间/min 12~15 弧电流/A 依据设计参数 表 2 盐雾腐蚀试验条件

Table 2. Salt-spray corrosion test condition

参数 数值 盐雾沉积速度/(mL·h-1·80 cm-2) 1~2 NaCl溶液浓度/(g·L-1) 50±5 喷雾气源压力/Pa 100~140 相对湿度/% ≥90 温度/℃ 40±2 pH 4±0.2 腐蚀率范围 腐蚀评级 无腐蚀 10 0 < A≤0.1 9 0.1 < A≤0.25 8 0.25 < A≤0.5 7 0.5 < A≤1.0 6 1.0 < A≤2.5 5 2.5 < A≤5.0 4 5.0 < A≤10 3 10 < A≤25 2 25 < A≤50 1 50 < A 0 外观评级 试样表面外观的变化 A 无变化 B 轻微到中度的变色 C 严重变色到极轻微的失光 D 轻微的失光或出现极轻微的腐蚀产物 E 严重的失光,或在试样局部表面上布有薄层的腐蚀产物或点蚀 F 有腐蚀物或点蚀,且其中之一集中斑布在整个试样表面上 G 整个表面上布有厚的腐蚀产物层或点蚀,并有深的点蚀 H 整个表面上布有非常厚的腐蚀产物或点蚀,并有深的点蚀 表 5 第1组铜薄膜试件盐雾腐蚀试验结果

Table 5. Results of the first group copper filmafter salt-spray corrosion test

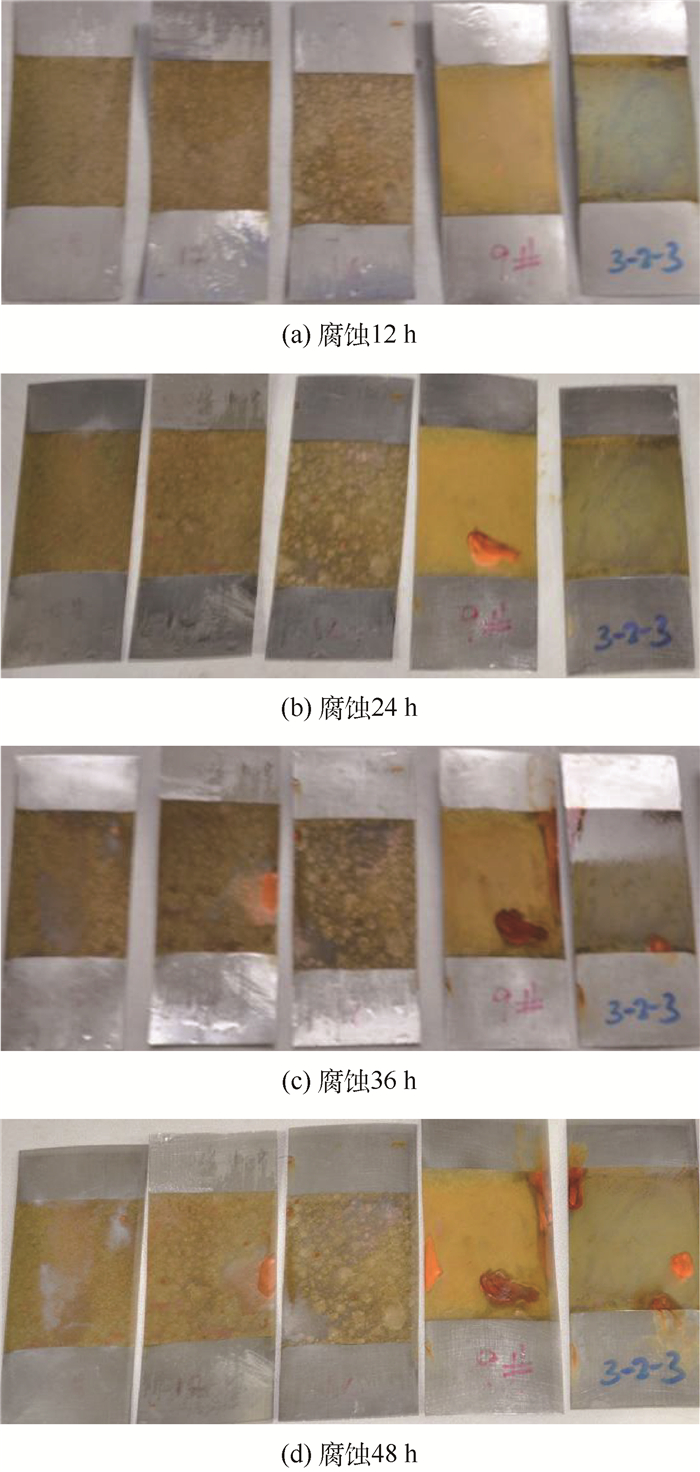

参数组合(弧电流,A/基体负偏压,V) 腐蚀等级(腐蚀评级/外观评级) 腐蚀12 h 腐蚀24 h 腐蚀36 h 腐蚀48 h 40/100 10/C 5/E 2/F 50/100 10/C 5/E 2/F 60/100 10/C 5/E 2/F 70/100 10/A 4/D 3/E 2/F 80/100 10/B 5/D 3/E 2/F 表 6 第2组铜薄膜试件盐雾腐蚀试验结果

Table 6. Results of the second group copper film after salt-spray corrosion test

参数组合(弧电流,A/基体负偏压,V) 腐蚀等级(腐蚀评级/外观评级) 腐蚀12 h 腐蚀24 h 腐蚀36 h 腐蚀48 h 腐蚀60 h 腐蚀72 h 腐蚀84 h 60/20 5/D 5/E 2/G 60/60 10/C 5/E 2/G 60/100 10/C 5/E 2/F 60/140 10/B 6/D 5/D 5/D 3/E 3/E 2/F 60/180 10/B 6/D 3/F 2/F 表 7 铜薄膜耐蚀性最佳的沉积工艺参数组合

Table 7. Deposition process parameter combination for optimal corrosion resistance of copper film

参数组合(弧电流,A/基体负偏压,V) 腐蚀等级(腐蚀评级/外观评级) 腐蚀12 h 腐蚀24 h 腐蚀36 h 腐蚀48 h 腐蚀60 h 腐蚀84 h 腐蚀204 h 60/250 10/A 10/A 10/B 10/C 10/D 9/E 9/E 70/150 10/B 5/D 4/D 3/E 2/E 70/200 6/D 6/D 4/D 3/E 2/E 80/100 10/B 5/D 3/E 2/F 表 8 硫酸-硼酸阳极氧化工艺参数

Table 8. Sulfuric acid/boric acid anodic oxidation process parameters

参数 溶液浓度/(g·L-1) 温度/℃ 直流电压/V 时间/min H2SO4 H3B3 Al3+ 数值 40~60 10~15 < 5.5 20~30 15~20 30~40 -

[1] 袁慎芳.结构健康监控[M].北京:国防工业出版社, 2007:1-10.YUAN S F.Structural health monitoring and damage control[M].Beijing:National Defense Industry Press, 2007:1-10(in Chinese). [2] 丁华, 何宇廷, 杜金强, 等.花萼状涡流传感器及其飞机金属结构疲劳损伤监测试验研究[J].机械工程学报, 2013, 49(2):1-7. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201302002.htmDING H, HE Y T, DU J Q, et al.Rosette eddy current sensor and its experimental research on aircraft metal structure fatigue damage monitoring[J].Chinese Journal of Mechanical Engineering, 2013, 49(2):1-7(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201302002.htm [3] KUANG K S C, CANTWELL W J.Use of conventional optical fibers and fiber Bragg grating for damage detection in advanced composite structures:A review[J].Applied Mechanics Reviews, 2003, 56(5):493-513. doi: 10.1115/1.1582883 [4] 陈祥林, 丁天怀, 黄毅平.新型接近式柔性点涡流阵列传感器系统[J].机械工程学报, 2006, 42(8):150-153. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200608026.htmCHEN X L, DING T H, HUANG Y P.Novel flexible eddy current array sensor system for proximity sensing[J].Chinese Journal of Mechanical Engineering, 2006, 42(8):150-153(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200608026.htm [5] RABIEI M, MODARRES M.Quantitative methods for structural health management using in situ acoustic emission monitoring[J].International Journal of Fatigue, 2013, 49:81-89. doi: 10.1016/j.ijfatigue.2012.12.001 [6] WHWATLEY G, KOLLGAARD J R.Automated detection of cracks on the faying surface within high-load transfer bolted specimen[C]//NED for Health Monitoring and Diagnostics.Piscataway, NJ:IEEE Press, 2003:161-168. [7] 杜金强, 何宇廷, 崔荣洪, 等.基于电位法原理的金属结构裂纹监测传感器研究[J].南京航空航天学报, 2010, 42(3):387-391. http://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201003027.htmDU J Q, HE Y T, CUI R H, et al.Research on surface crack monitoring sensor of metallic structure based on electric potential method[J].Journal of Nanjing University of Aeronautics and Astronautics, 2010, 42(3):387-391(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201003027.htm [8] HOU B, HE Y T, CUI R H, et al.Crack monitoring method based on Cu coating sensor and electrical potential technique for metal structure[J].Journal of Aeronautics, 2015, 28(3):932-938. doi: 10.1016/j.cja.2015.02.016 [9] 侯波, 何宇廷, 崔荣洪, 等.基于涂层传感器的金属结构疲劳裂纹监测[J].北京航空航天大学学报, 2013, 39(10):1298-1302. http://bhxb.buaa.edu.cn/CN/abstract/abstract12742.shtmlHOU B, HE Y T, CUI R H, et al.Fatigue crack monitoring of metallic structure based on coating sensor[J].Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(10):1298-1302(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract12742.shtml [10] LIU M B, SUN Y, WANG Z, et al.A validation study for a SHM technology under operational environment[C]//Proceedings of 2014 Annual Reliability and Maintainability Symposium (RAMS).Piscataway, NJ:IEEE Press, 2014:14253775. [11] HU F, LIU M B, HONG G H, et al.Flaw-detected coating sensors applied in aircraft R & M[C]//Proceedings of Annual Reliability and Maintainability Symposium, 2009.Piscataway, NJ:IEEE Press, 2009:95-99. [12] SAREMI M, YEGANEH M.Investigation of corrosion behaviour of nanostructured copper thin film produced by radio frequency sputtering[J].Micro & Nano Letters, 2010, 5(2):70-75. https://www.researchgate.net/publication/224135081_Investigation_of_corrosion_behaviour_of_nanostructured_copper_thin_film_produced_by_radio_frequency_sputtering [13] YEGANEH M, TORABI Z.Comparison between the experimental and theoretical electrochemical impedance for microcrystalline and nanocrystalline copper immersed in near neutral chloride solution[J].Micro & Nano Letters, 2012, 7(3):208-211. http://ieeexplore.ieee.org/document/6179244/ [14] YEGANEH M, SAREMI M.Corrosion behaviour of nanostructured copper thin films in comparison with copper sheet in drinking water[J].Micro & Nano Letters, 2011, 6(1):26-28. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=5696817 [15] GOBI SARAVANAN K, ANATHA KUMAR R, RAMACHANDRAN D, et al.Structural and corrosion behaviour of bilayer and alloyed films of Cu-Ni[C]//Proceedings of the International Conference on Advanced Nanomaterials & Emerging Engineering Technologies (ICANMEET-20J3).Piscataway, NJ:IEEE Press, 2013:179-180. [16] 崔荣洪, 于志明, 何宇廷, 等.超声电沉积铜叠层膜及其耐蚀性能研究[J].中国腐蚀与防护学报, 2011, 31(2):145-148. http://www.cnki.com.cn/Article/CJFDTotal-ZGFF201102015.htmCUI R H, YU Z M, HE Y T, et al.Preparation and corrosion resistance of copper multilayer coating obtained by ultrasonic electro deposition[J].Chinese Journal of Corrosion and Protection, 2011, 31(2):145-148(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-ZGFF201102015.htm [17] 崔荣洪, 于志明, 何宇廷, 等.超声电沉积铜薄膜的耐腐蚀性能研究[J].腐蚀科学与防护技术, 2010, 22(3):169-172. http://www.cnki.com.cn/Article/CJFDTOTAL-FSFJ201003005.htmCUI R H, YU Z M, HE Y T, et al.Corrosion performance of ultrasonic-eletrodeposited Cu coating[J].Corrosion Science and Protection Technology, 2010, 22(3):169-172(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-FSFJ201003005.htm [18] 邓乐乐, 侯波, 何宇廷, 等.工艺参数对电弧离子镀沉积铜薄膜微膜结构及性能的影响[J].功能材料, 2015, 46(7):7127-7130. http://www.cnki.com.cn/Article/CJFDTOTAL-GNCL201507028.htmDENG L L, HOU B, HE Y T, et al.Effect of process parameters on the microstructure and properties of copper film deposited by arc ion plating[J].Journal of Function Materials, 2015, 46(7):7127-7130(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GNCL201507028.htm [19] 全国金属与非金属覆盖层标准化技术委员会. 金属基体上金属和其他无机覆盖层经腐蚀试验后的试样和试件的评级: GB/T 6461—2002[S]. 北京: 中华人民共和国国家质量监督检验检疫总局, 2002: 3-4.National Metal and Nonmetal Coating Layer Standardization Technical Committee.Methods for corrosion testing of metallic and other inorganic coatings on metallic substrates—Rating of test specimens and manufactured articles subjected to corrosion tests:GB/T 6461—2002[S].Beijing:The State Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, 2002:3-4(in Chinese). [20] 顾讯.现代表面技术的应用[J].金属热处理, 1994(4):1-6. http://www.cnki.com.cn/Article/CJFDTOTAL-JSRC904.000.htmGU X.Application of modern surface technology[J].Heat Treatment of Metals, 1994(4):1-6(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSRC904.000.htm [21] 韩克, 欧忠文, 蒲滕, 等.铝及铝合金硬质阳极氧化的研究进展[J].表面技术, 2011, 40(5):92-96. http://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201105030.htmHAN K, OU Z W, PU T, et al.Development of hard anodizing of aluminum and aluminum alloy[J].Surface Technology, 2011, 40(5):92-96(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201105030.htm [22] 张钧, 赵彦辉.多弧离子镀技术与应用[M].北京:冶金工业出版社, 2007:14-19.ZHANG J, ZHAO Y H.Multi arc ion plating technology and application[M].Beijing:Metallurgical Industry Press, 2007:14-19(in Chinese). [23] 侯波, 崔荣洪, 何宇廷, 等.同心环状薄膜传感器阵列及其飞机金属结构裂纹监测研究[J].机械工程学报, 2015, 51(24):9-14. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201524002.htmHOU B, CUI R H, HE Y T, et al.Concentric ring film sensor array and its experimental research on crack monitoring for aircraft metallic structure[J].Journal of Mechanical Engineering, 2015, 51(24):9-14(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201524002.htm [24] 左卫, 刘元海.典型海洋环境当量加速试验环境谱研究[J].包装工程, 2011, 23(32):133-136. http://www.cnki.com.cn/Article/CJFDTOTAL-BZGC201123039.htmZHUO W, LIU Y H.Research on equivalent accelerated test environment spectrum of typical marine environment[J].Packaging Engineering, 2011, 23(32):133-136(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-BZGC201123039.htm [25] ANDERSSON M, PERSSON C, MELIN S.Experimental and numerical investigation of crack closure measurements with electrical potential drop technique[J].International Journal of Fatigue, 2006, 28(9):1059-1068. doi: 10.1016/j.ijfatigue.2005.11.005 -

下载:

下载: