-

摘要:

为研究分级喷注超燃冲压发动机火焰稳定、燃烧状态及火焰传播特性,以双支板超燃燃烧室为基本构型,开展了当量比连续调节试验研究。模拟低飞行马赫数5.5工况,燃烧室入口马赫数为2,总温1 436 K,试验表明:燃烧室单独上游喷注熄火当量比为0.19,该值不受下游燃烧的影响;单独下游喷注熄火当量比为0.46,上游火焰会削弱下游当量比变化对壁面压力的影响,并且会使下游熄火当量比值降低。通过调节上游当量比可实现燃烧状态的转换,转换过程存在迟滞。模拟高飞行马赫数6.5工况,燃烧室入口马赫数为3,总温1 899 K,试验表明:随着总温的增加,单独上游喷注可实现点火和稳焰,上游火焰发生抬举,燃烧室抗反压能力增强,可喷注更多燃料。

Abstract:In order to investigate the flame stabilization, combustion state and flame propagation characteristics of scramjet, based on a dual-struts supersonic combustor with staged injections, experiments with continuously adjusted equivalence ratio were conducted. Experiments with combustor inlet Mach number of 2 and total temperature of 1 436 K were conducted to simulate flight Mach number of 5.5. The results show that when injecting fuel is solely from the upstream strut, the extinction equivalence ratio is 0.19 and it is not affected by the downstream combustion. When injecting fuel is solely from the downstream strut, the extinction equivalence ratio is 0.46, and the effect of downstream equivalence ratio change on wall pressure would be reduced by upstream flame, with which the extinction equivalence ratio would be decreased. Transformation between two combustion states could be realized by adjusting the upstream equivalence ratio, and hysteresis could be observed in the transformation process. Experiments with combustor inlet Mach number of 3 and total temperature of 1 899 K were conducted to simulate flight Mach number of 6.5. The results show that as the total temperature of incoming flow increases, ignition and stable flame can be realized by fuel injection solely at the upstream strut, the upstream flame is lifted, back-pressure capability of the combustor can be strengthened, and more fuel can be injected into the flow.

-

Key words:

- scramjet /

- combustion /

- strut /

- equivalence ratio /

- hysteresis

-

超燃冲压发动机一直以来被认为是高超声速推进的最佳动力选择。超燃冲压发动机的核心在于燃烧室,实现可靠稳焰和高效燃烧是国内外学者研究的关键问题之一。目前火焰稳定装置有很多形式,其中以支板、凹腔和斜坡较为多见[1]。

支板作为重要的火焰稳定工具, 由美国国家航空航天局Langley研究中心率先提出[2]。支板可以把燃料喷注到燃烧室气流核心区,提高燃烧效率。宋冈霖等[3]研究了支板凹腔一体化燃烧室,认为支板后低速回流区是稳焰的重要区域。Tabejamaat等[4]研究了不同厚度的支板,认为支板稳焰能力取决于支板的厚度,对于氢燃料来讲,如果支板厚度小于7 mm,将无法实现点火和稳焰,如果要实现可靠的火焰稳定,支板厚度不能小于10 mm。范周琴等[5]认为,燃料从支板尾部喷出后形成典型的扩散火焰,增大支板的厚度可使燃烧释热速度变快,能够满足燃烧室快速燃烧的要求,有利于减小燃烧室长度。对于碳氢燃料发动机,火焰稳定所需要的支板厚度将会更大。支板厚度增加也会带来一定的问题,其中最主要的是支板阻力的增大。苏义和刘卫东[6]通过试验研究认为:支板阻力会随着支板厚度增加而增加。在支板后形成稳定火焰后支板阻力会减小,且当量比(ER) 越大支板阻力越小。

如果燃烧室只有单级支板进行喷注,局部集中释热难以使掺混效果和燃烧效率提高。为了解决这一问题,研究人员提出了多级支板组合喷注方案。多级喷注可以明显改善释热集中、燃烧效率低等问题[7-11]。

多级喷注必然会涉及到燃料分配问题,不同的燃料分配比例会造成燃烧现象和燃烧室性能的显著差异。Nakaya等[12]研究了乙醇燃料超燃燃烧室,发现在不同当量比下,燃烧室存在2种燃烧状态:瞬时燃烧状态和强燃烧状态,强燃烧状态会造成燃烧室出现较大压升,而瞬时燃烧状态不会对燃烧室压力分布造成影响。Hande和Marathe[13]利用数值模拟技术研究了基于多支板喷注的超燃燃烧室特性,认为燃料合理分配可以带来燃烧效率的增加,同时使燃烧室出口温度分布更加均匀。宗有海[14]利用试验手段研究了煤油燃料多支板超燃燃烧室,结果发现增加支板数量将喷注分散开来可以增强掺混,燃烧更易向上游传播,但上游的燃烧会削弱下游的燃烧强度,利用支板喷注结合凹腔稳焰可以使燃烧效果更好,有利于提高燃烧室比冲。

燃料也会影响多级喷注超燃燃烧室工作特点,用于超燃燃烧室的燃料主要有氢气、乙烯和煤油。氢气、乙烯为小分子气态燃料,容易实现点火和火焰稳定。煤油为大分子液态碳氢燃料,较难实现点火和稳定燃烧。范学军等[15]证明了两级喷注可以显著提高煤油燃料燃烧室性能,且两级喷注的喷孔数量和孔径不会影响燃烧室性能。冮强等[16]基于直连试验,研究了支板凹槽组合构型燃烧室工作特性,在宽泛的当量比范围内实现了燃烧室的可靠点火与稳定燃烧。

以上不仅研究了支板喷注和稳焰特性,也证明了煤油燃料超燃燃烧室分级喷注对于燃烧室性能提升的有效性。但是受到支板稳焰能力的限制和不同的当量比分配的影响,两级喷注未必能够实现分级燃烧,燃烧现象的差异将影响燃烧室工作特性。此外,对于两级喷注和稳焰来讲,分级燃烧间必然存在影响与联系。如何根据需要实现不同的燃烧状态的转换以及燃烧状态转换特性的研究是必要的。

本文使用线性连续可调文氏管控制燃料流量,研究不同当量比分配下双支板燃烧室稳焰特性和燃烧状态,通过当量比调节实现了燃烧状态的转换,并对转换特性进行了研究。

1. 试验方法

1.1 试验设备

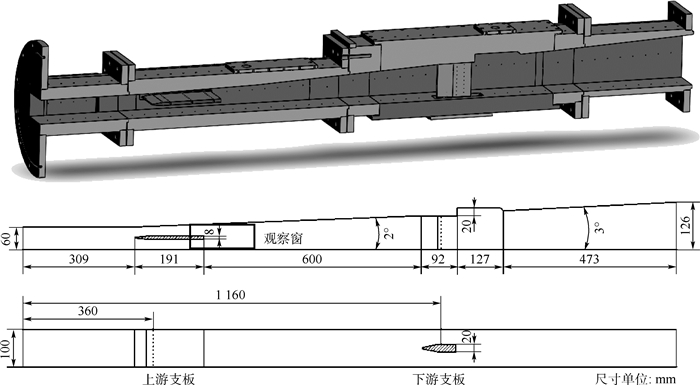

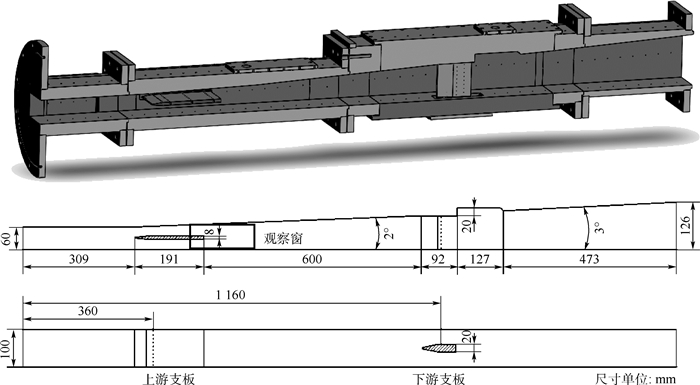

试验在北航直连式超燃冲压发动机试验台上进行。用氢气在空气中燃烧来模拟高焓气流,空气在加热前混入一定质量的氧气,保证加热后气流的氧气摩尔分数与加热前一致。加热后的空气经过拉瓦尔喷管膨胀加速,经隔离段进入燃烧室。表 1为试验发动机的入口参数。燃烧室构型如图 1所示,共有上下游两级支板,上游支板厚度为8 mm,下游支板厚度为20 mm,两级支板90°垂直分布,下游支板后置有凹腔。支板喷孔直径0.4 mm,上游支板喷孔距离支板尾缘140 mm,下游支板喷孔距离支板尾缘40 mm。燃烧室上壁面单边扩张,两级支板间扩张角为2°,凹腔后扩张角为3°。

表 1 入口参数Table 1. Inlet parameters入口参数

类别总质量流量/

(kg·s-1)模拟飞行

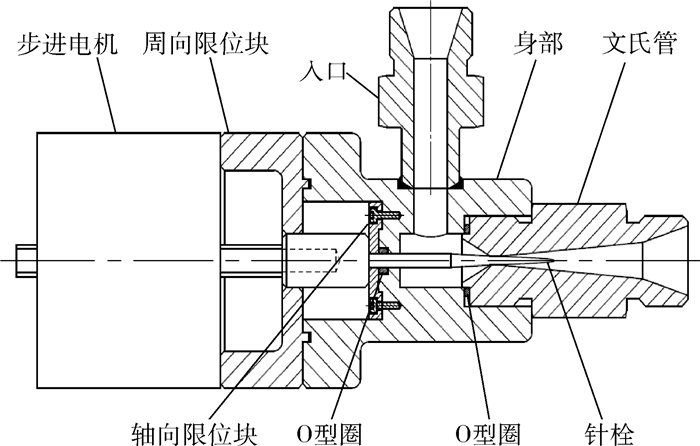

马赫数马赫数 总温/K 总压/MPa a 2.655 5.5 2.0 1 436 0.78 b 2.044 6.5 3.0 1 899 2.13 发动机使用煤油燃料,煤油经过支板喷孔垂直喷注到燃烧室中。试验中所有气体工质均使用音速喷嘴控制流量,所有液体工质均使用文氏管控制流量。为了实现煤油流量随时间线性变化的要求,试验设计了一组可调文氏管,结构如图 2所示。针栓通过壳体和周向限位块进行支承定位,针栓可以在线性步进电机的驱动下实现相对于文氏管喉部的水平移动。针栓行程最小时(标定时以此位置为0点),针栓尾部定位块紧贴轴向限位块左侧;针栓行程最大时,针栓尾部定位块紧贴步进电机右侧。

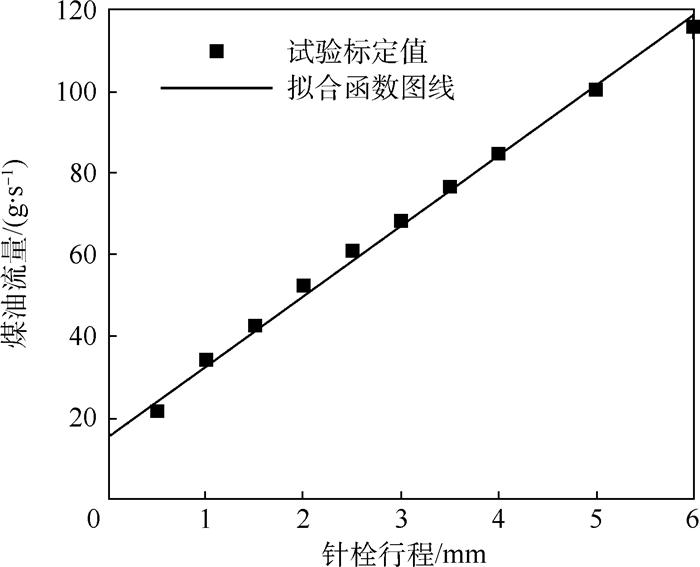

可调文氏管的标定结果如图 3所示。各散点是可调文氏管入口压力为6 MPa试验标定的数据,直线为散点拟合处理得到的针栓行程与煤油流量关系函数的图像。在试验结果分析时,通过不同时刻针栓的行程数值代入拟合函数进行计算,可得到该行程位置的煤油流量值。

可调文氏管能够实现煤油15~120 g/s范围流量调节。根据标定结果,煤油流量与针栓行程之间的线性函数式可以表达为

m=17.259a+15.154

式中:m为煤油流量,g/s;a为针栓行程,mm。

可调文氏管在针栓线均匀进给的条件下,能够实现流量线性变化。另外在多次标定和针栓往复调节的情况下,流量数据也呈现了很好的重复性。

1.2 试验工况

试验当量比分配、当量比变化范围及调节时间如表 2所示。

表 2 试验工况Table 2. Experiment condition工况 入口参数类别 上游当量比(线性匀速调节) 下游当量比(线性匀速调节) 当量比调节时间/s Case 1 a 0.3减少至0.1 0.7 3 Case 2 a 0 0.6减少至0.3 2 Case 3 a 0.3减少至0.1 0 3 Case 4 a 0.3减少至0.1 0.6,点火后变至0 3 Case 5 a 0.4 0.6减少至0.3,再增加至0.6 2.4 Case 6 a 0.4减少至0.1,再增加至0.4 0.7 2.4 Case 7 b 0.5减少至0.3,再增加至0.5 0 2.4 2. 试验结果与分析

2.1 低飞行马赫数燃烧室稳焰特性

2.1.1 燃烧室稳焰形式

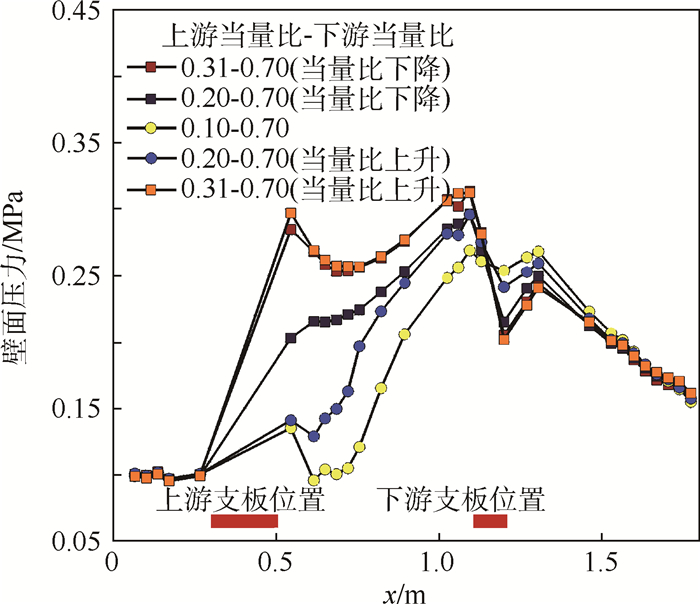

由于燃烧室单边扩张,沿流向燃烧室截面积增加,因此可容纳的释热量也增加。试验发现,双支板燃烧室上游当量比超过0.4,燃烧室将发生溢流,因此需要将大部分燃料分配至燃烧室下游喷注。在下游大当量比喷注时,双级喷注燃烧室存在2种不同的燃烧现象。以Case 1为例,上游当量比由0.3下降到0.1的过程中,上游当量比变化导致燃烧状态发生改变。在上游支板喷注当量比较高时,上下游支板均能实现稳定的火焰驻留,称为上游燃烧状态;在上游支板喷注当量比较低时,上游火焰熄灭,喷注的燃料全部集中到下游支板后燃烧,称为下游燃烧状态。图 4为Case 1工况燃烧室壁面压力分布。在上游燃烧状态,上游当量比的变化只会影响下游支板前的壁面压力分布,上游燃烧状态变化到下游燃烧状态的上游当量比为0.19。

在上游燃烧状态,燃烧室壁面压力表现有3个峰值,峰值位置分别对应上游支板尾缘、下游支板前缘和凹腔。而对于下游燃烧状态,燃烧室壁面压力表现有一个峰值,峰值位置对应下游支板前缘到凹腔。根据壁面压力随当量比调节的变化特点,可以使用部分位置的压力测点来对燃烧室特征进行描述。上游支板尾缘处压力测点记作特征点1,下游支板尾缘处压力测点记作特征点2,特征点1和特征点2可反映燃烧状态的变化;凹腔后扩张段压力测点记作特征点3,其中特征点3可以反映下游当量比变化对燃烧室带来的影响,以上位置在图 4中已作出标记。

一维冲量分析法可以根据燃烧室构型和试验壁面压力等数据反算沿程马赫数分布,文献[1]对一维冲量分析的逆方法做出了详细阐述。采用一维冲量分析法对双支板燃烧室沿程马赫数进行处理,可知2种燃烧状态的沿程马赫数分布存在较大差异,如图 5所示:对于上游燃烧状态,气流从上游支板位置开始减速,在下游支板前缘位置气流马赫数降到最低,此时气流已降至亚声速,气流在下游支板处短暂加速,随后在下游燃烧作用下再次变为亚声速,气流在凹腔下游扩张通道内形成热力喉道;对于下游燃烧状态,气流马赫数经过上游支板略有下降,在上游支板尾部流道扩张的作用下得以恢复,气流在下游支板壅塞和下游燃烧综合作用下形成大范围亚声速区,随后在凹腔下游扩张通道内膨胀加速,其热力喉道位置较上游燃烧状态略偏下游。由于燃烧室下游支板厚度达到20 mm,占燃烧室流道宽度的1/5,只要燃烧室实现稳定燃烧,不论哪种燃烧状态,其下游一定存在较大亚声速范围。

2.1.2 单级喷注稳焰特性

通常情况下,在燃烧室点火和稳焰方面,两级支板是存在相互作用和影响的。为了探究二者之间的相互作用关系,首先需要开展基于单级喷注的试验研究。

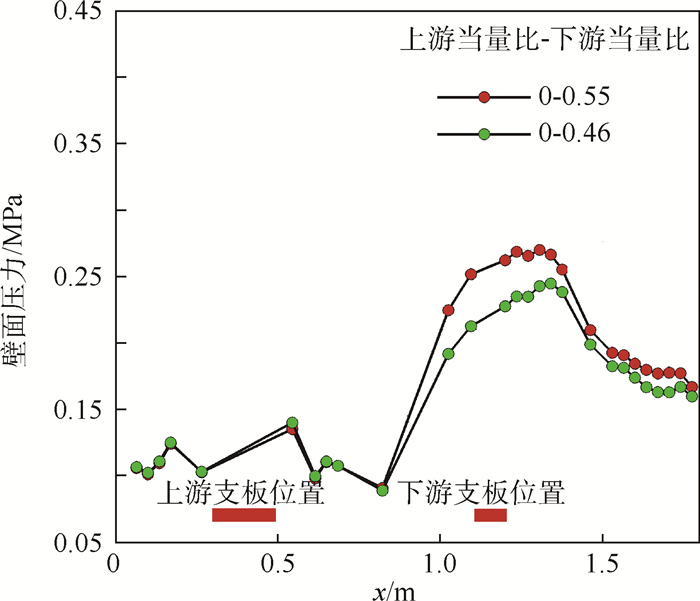

Case 2主要研究单独下游喷注燃烧室工作特性,下游喷注当量比从0.6线性下降至0.3,当量比调节耗时2 s。特征点2和特征点3压力随时间变化曲线如图 6所示,燃烧室沿程壁面压力如图 7所示,燃烧室壁面压力峰值随着当量比的减小而下降。当量比低于0.46,燃烧室发生熄火,因此燃烧室单独下游喷注的熄火极限当量比为0.46。

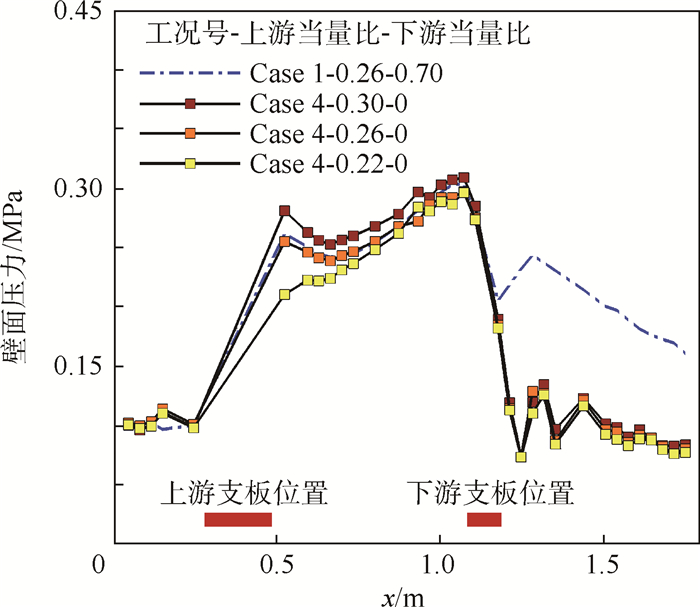

Case 3设计目的是研究燃烧室单独上游稳焰特性,但该工况始终不能成功点火。为此设计了Case 4试验,试验先通过双级喷注进行点火,等点火完成关闭下游喷注,单独对上游喷注燃料流量进行调节。试验证明,Case 4可以实现单独上游火焰稳定。图 8为部分工况的沿程壁面压力分布。与Case 1相比,燃烧室下游支板后压力峰消失,下游支板前的压力分布并不会受到影响。单独上游喷注的熄火极限当量比仍为0.19。

根据试验结果,显然并不是支板厚度越大熄火当量比越小,相比于氢燃料,煤油燃料多出雾化和蒸发过程,因此喷孔与支板尾缘的距离会直接影响支板熄火当量比。从Case 2和Case 4试验现象来看,煤油从喷孔喷注后,大约需要40 mm左右的距离蒸发完毕。下游支板厚度大,但喷孔距离支板尾缘距离短,在到达支板尾部回流区时燃料尚来不及充分蒸发和掺混,因此即便配合凹腔来稳焰,下游熄火当量比仍然达到0.46。上游支板厚度小,点火困难,但喷孔距离支板尾缘距离长,在到达尾部回流区前燃料已经全部蒸发,因此熄火当量比低至0.19。

上游单独自持的火焰配合下游支板的几何壅塞作用可使燃烧室上游气流减速,气流减速又促进了上游燃烧的进行,这是一个耦合的过程,一旦打破便不能实现上游单独点火和稳焰。显然两级支板在点火和稳焰方面存在相互作用,以下将展开相关试验研究。

2.1.3 双级喷注稳焰特性

一般来说,上游喷注当量比过大会引起燃烧室溢流(试验中上游当量比超过0.4,燃烧室发生溢流),所以大部分燃料要在燃烧室下游完成喷注,为了研究下游当量比变化对燃烧室的影响,展开Case 5下游变当量比试验研究。

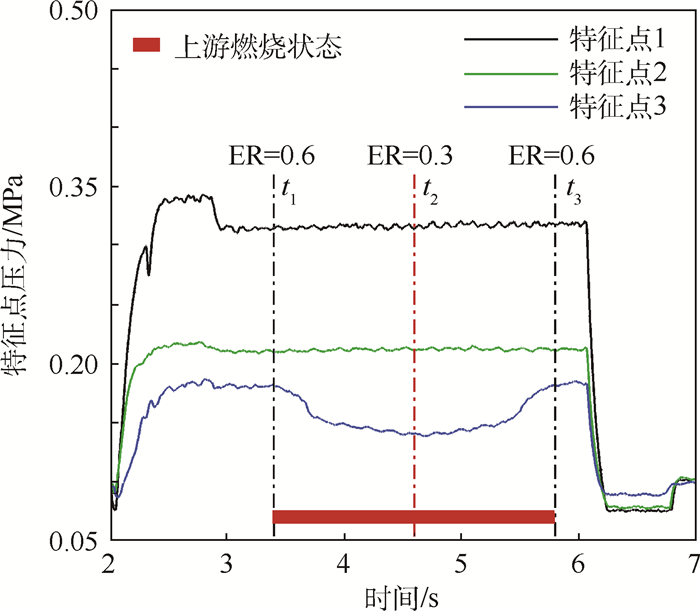

图 9为Case 5下游文氏管后压力随时间的变化曲线,文氏管后压力可用来表征煤油流量随时间变化特点。图 10为Case 5燃烧室特征点压力随时间的变化曲线,根据整个时间进程内的压力变化特点,曲线可分为如下几段:t1之前为点火阶段,t1为可调文氏管动作起点,t1至t2为当量比线性下降阶段;t2至t3为当量比线性上升阶段,t3之后保持当量比工作到试验结束。

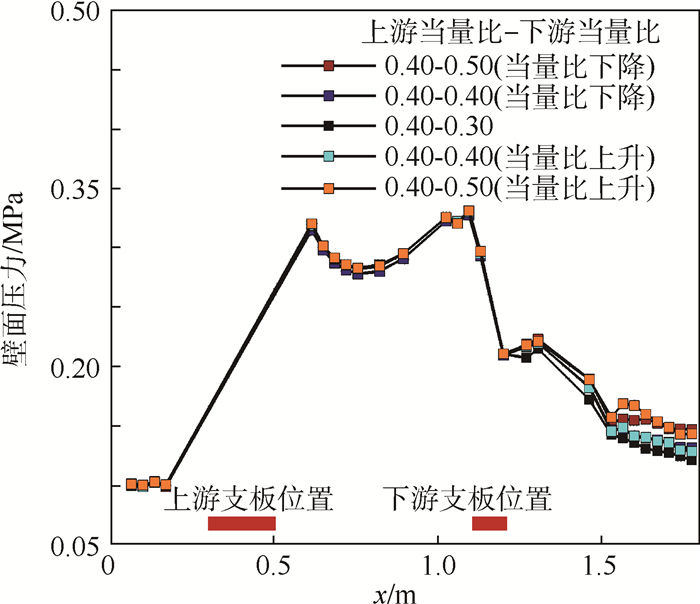

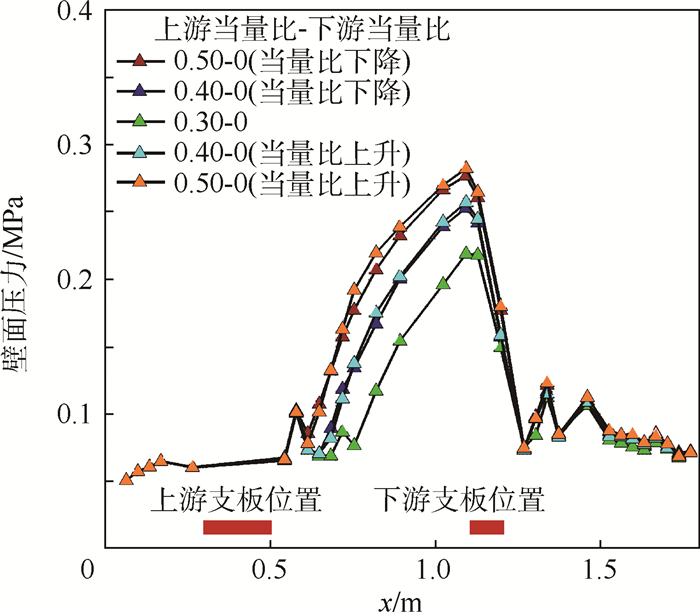

下游煤油流量按t2时刻对称,特征点压力分布也按照t2对称,下游当量比变化只会影响下游特征点3附近的压力分布,并不会影响到其他特征点压力分布。下游当量比从0.6下降到0.3再上升到0.6,下游特征点3压力随当量比变化趋势而变化,但变化范围不超过0.04 MPa。图 11为Case 5部分代表工况壁面压力分布,和Case 1单独下游变当量比喷注试验相比,燃烧室上游的燃烧会削弱下游当量比变化对燃烧室壁面压力的影响,且下游当量比的变化只会影响下游支板后的壁面压力分布。从当量比往复变化的角度来看,燃烧室壁面压力分布与下游当量比往复路径无关。

在试验中,上游火焰会提高下游的总温,因此下游当量比为0.3也可以实现下游稳定燃烧。可以认为,上游火焰会使下游稳焰极限当量比降低。

双支板超燃燃烧室存在2种燃烧状态,为了使燃烧室在宽泛的当量比范围稳定工作,就必须要实现2种燃烧状态的转换,研究燃烧状态转换过程中燃烧室的特性。2种燃烧状态转换的关键问题是:燃烧室在下游燃烧状态如何实现上游再点火。使用强迫点火实现上游再点火会引入额外能量,不利于燃烧室平稳工作和发动机的控制,因此通过当量比调节实现2种燃烧状态的转换无疑是最佳的选择。

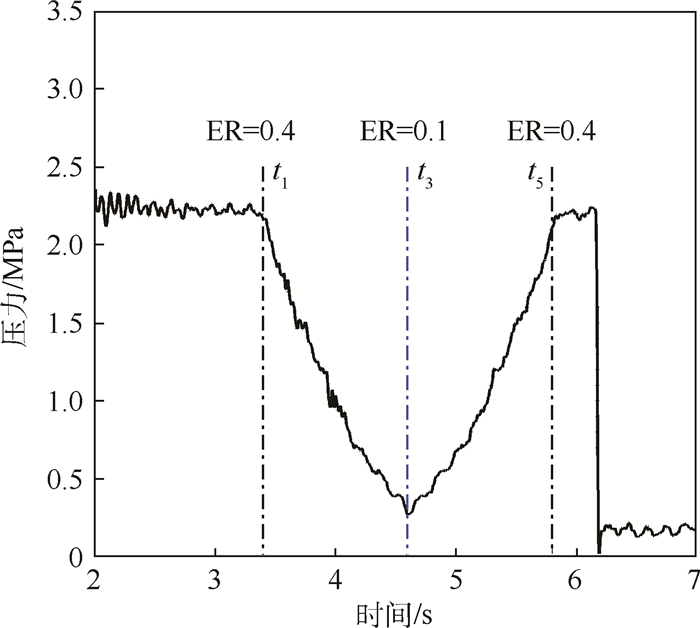

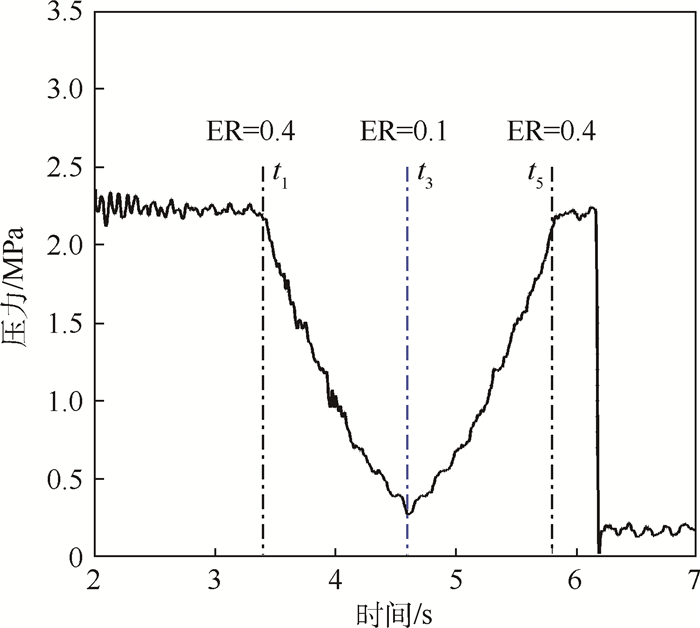

Case 6实现了利用上游当量比控制2种燃烧状态的转换。图 12为Case 6文氏管后压力随时间的变化曲线,图 13为Case 6特征点压力随时间的变化曲线。根据时间进程内的压力变化特点,曲线可分为如下几段:t1之前为点火阶段,t1为可调文氏管动作起点,t1至t3为当量比线性下降阶段, 其中t2为上游熄火点;t3至t5为当量比线性上升阶段, 其中t4为上游再点火点,t5之后保持当量比工作到试验结束。

虽然当量比按t3时刻对称,但是特征点压力分布并不对称,上游火焰在t2=4.24 s时刻熄灭,对应上游当量比约为0.19;燃烧室在t4=5.12 s时刻再点火,此时对应上游当量比约为0.23。在上游未实现再点火前,随着上游当量比的增加,下游的燃烧逐渐增强,压力前传使得上游特征点压力抬升,当压力抬升达到一定程度时就会出现火焰沿流场低速区前传,但是火焰的前传是不稳定的,图 13圈内为火焰前传过程对特征点1压力的影响。燃烧室必然存在某一次火焰前传使得上游支板稳焰区再点火。

图 14为高速摄影捕捉的火焰前传使得上游再点火的过程,照片采集频率为2 000 Hz。图 14(a)为上游当量比增加过程中下游火焰前传的过程,在上游再点火完成前,该过程会一直重复出现。图 14(b)为某一次下游火焰前传使得上游再点火过程,前传火焰首先点燃上支板尾部局部区域,随后局部火焰迅速传播至整个支板尾部。

对于超燃冲压发动机燃烧室,火焰不借助稳焰装置难以在超声速气流中传播与驻留,然而双支板构型的两级支板间并不存在任何火焰稳定装置。为了揭示火焰传播机制,需要借助数值模拟结果进行分析。以燃烧室入口气流方向为x正方向,图 15为上游当量比0.1,下游当量比0.7时燃烧室x方向速度与附面层分离区云图,此时燃烧室处于下游燃烧状态,燃烧室两级支板间存在明显附面层分离区。附面层分离区由强逆压梯度引起,除了下游的燃烧外,下游支板对气流具有较强的壅塞作用,2个因素共同造成下游支板前出现强逆压梯度。随着上游当量比的增加,逆压梯度逐渐增大,两级支板间各截面附面层分离面积迅速增加。燃烧室上游喷注的燃料在分离区内可完成一定程度的掺混,下游火焰借助分离区内的低速旋涡得以向上游传播。

上游当量比往复变化形成闭环的过程中,相同当量比位置壁面压力分布出现不重合,这种现象叫做迟滞。图 16为Case 6相同当量比代表工况的沿程壁面压力:上游当量比为0.31,往复过程对燃烧室壁面压力影响不大;上游当量比为0.2,往复过程的壁面压力分别呈现出2种燃烧状态的特征;上游当量比降到0.1,燃烧室完全处于下游燃烧状态。上述壁面压力变化特性证实,双支板超燃燃烧室2种燃烧状态的转换存在迟滞。在上游燃烧状态,上游支板稳焰能力与上游当量比是上游熄火的控制因素;在下游燃烧状态,上游支板稳焰能力、下游火焰前传能力与上游当量比是上游再点火的控制因素,控制因素的不同导致了燃烧状态转换的迟滞。

2.2 高飞行马赫数燃烧室稳焰特性

在模拟低飞行马赫数工况,燃烧室入口总温较低,因此煤油的点火和火焰稳定都是比较困难的,燃烧室易出现熄火。随着模拟飞行马赫数的提高,燃烧室入口总温增加,燃烧室燃烧规律将会发生显著变化。

模拟低飞行马赫数下,为研究单独上游喷注燃烧特性而设计的Case 3不能成功点火,只有借助Case 4的点火方式进行研究。在模拟高飞行马赫数下,设计了类似的Case 7。Case 7实现了单独上游点火与火焰稳定,与Case 4不同的是,Case 7壁面压力(见图 17) 抬升位置在上游支板尾缘后,随着当量比的减小,压力抬升位置向下游推移,说明在高总温下,火焰并未在上游支板尾部回流立即燃烧,而是发生了一定程度的抬举,喷注的当量比越小,火焰抬举距离越远。

模拟低飞行马赫数工况,上游当量比超过0.4即发生溢流;模拟高飞行马赫数工况,上游喷注当量比0.5仍远未达到溢流极限。因此可认为,入口马赫数增加会有效提高燃烧室抗反压能力,火焰的抬举使压力抬升位置向下游推移,为上游喷入更多燃料提供了可能。通过一维冲量分析可知,上游当量比为0.3,燃烧室仍处于亚燃模态,在当量比往复变化的过程中发现,壁面压力与当量比变化路径无关,不存在迟滞现象。

3. 结论

本文模拟2种飞行马赫数工况,研究了煤油燃料双支板超燃燃烧室的燃烧特性,主要结论如下:

1) 双支板燃烧室每一级支板都可实现稳焰,单独下游稳焰熄火当量比为0.46,单独上游稳焰熄火当量比为0.19。对于煤油燃料超燃燃烧室,支板稳焰的熄火当量比不仅与支板厚度有关,还受到喷孔距支板尾缘距离的影响。

2) 上游火焰会使下游稳焰极限当量比降低,同时会削弱下游当量比变化对沿程壁面压力的影响;下游火焰则可促进上游点火,但不会影响上游熄火当量比。两级支板同时稳焰,上游当量比只影响两级支板间壁压,下游当量比只影响下游支板后壁压。

3) 通过调节上游当量比可以实现燃烧状态的转换,转换过程存在迟滞。下游火焰沿着附面层分离区前传是导致上游再点火的原因。

4) 随着燃烧室入口总温和马赫数的增加,单独上游喷注可实现点火,由于燃烧室抗反压能力增强,因此上游可喷注更大当量比。在高马赫数和高总温气流中支板火焰发生抬举,上游当量比越小,火焰抬举距离越大。

-

表 1 入口参数

Table 1. Inlet parameters

入口参数

类别总质量流量/

(kg·s-1)模拟飞行

马赫数马赫数 总温/K 总压/MPa a 2.655 5.5 2.0 1 436 0.78 b 2.044 6.5 3.0 1 899 2.13 表 2 试验工况

Table 2. Experiment condition

工况 入口参数类别 上游当量比(线性匀速调节) 下游当量比(线性匀速调节) 当量比调节时间/s Case 1 a 0.3减少至0.1 0.7 3 Case 2 a 0 0.6减少至0.3 2 Case 3 a 0.3减少至0.1 0 3 Case 4 a 0.3减少至0.1 0.6,点火后变至0 3 Case 5 a 0.4 0.6减少至0.3,再增加至0.6 2.4 Case 6 a 0.4减少至0.1,再增加至0.4 0.7 2.4 Case 7 b 0.5减少至0.3,再增加至0.5 0 2.4 -

[1] 徐旭,陈兵,徐大军.冲压发动机原理及技术[M].北京:北京航空航天大学出版社,2014:202-204.XU X,CHEN B,XU D J.Principle and technology of ramjet[M].Beijing:Beihang University Press,2014:202-204(in Chinese). [2] ROGERS R C, CAPRIOT TI D P, GUY R W.Experimental supersonic combustion research at NASA Langley:AIAA-1998-2506[R].Reston:AIAA,1998. [3] 宋冈霖,冮强,王辽,等.碳氢燃料超燃冲压发动机支板凹腔一体化稳焰性能研究[J].推进技术,2013,34(11):1499-1506. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201311008.htmSONG G L,GANG Q,WANG L,et al. Studies of strut-cavity flameholder performance in scramjet combustor with hydrocarbon fuel[J]. Journal of Propulsion Technology,2013,34(11):1499-1506(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201311008.htm [4] TABEJAMAAT S,KOBAYASHI H,NIIOKIA T.Numerical and experimental studies of injection modeling for supersonic flame-holding[J].Journal of Propulsion and Power,2005,21(3):504-511. doi: 10.2514/1.8307 [5] 范周琴,刘卫东,林志勇,等.支板喷射超声速燃烧火焰结构实验[J].推进技术,2012,33(6):923-927. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201206015.htmFAN Z Q, LIU W D,LIN Z Y,et al. Experimental investigation of supersonic combustion flame structure with strut injectors[J].Journal of Propulsion Technology,2012,33(6):923-927(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201206015.htm [6] 苏义,刘卫东.支板阻力特性实验[J].航空动力学报,2009,24(12):2643-2648. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200912001.htmSU Y, LIU W D.Experimental investigation on drag of strut[J].Journal of Aerospace Power,2009,24(12):2643-2648(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200912001.htm [7] TOMIOKA S, MURAKAMIT A,KUDO K,et al.Effects of injection scheme on performance of a staged supersonic combustor:AIAA-1999-2107[R].Reston:AIAA,1999. [8] TOMIOKA S,KOBAYASHI K,KUDO K,et al.Distributed injection for performance improvement of a supersonic combustor with multi-staged wall-injections:AIAA-2003-6991[R].Reston:AIAA,2003. [9] TOMIOKA S, MURAKAMI A,KUDO K,et al.Combustion tests of a staged supersonic combustor with a strut[J].Journal of Propulsion and Power,2001,17(2):293-300. doi: 10.2514/2.5741 [10] VELLARAMKALAYIL J J,SCHEUERMANN T.Analysis of a two-staged supersonic combustion chamber using experiments and simulations:AIAA-2011-2247[R].Reston:AIAA,2011. [11] FUHRMANN S,HUPFER A,KAU H P.The investigations on multi-stage supersonic combustion in a model combustor:AIAA-2011-2332[R].Reston:AIAA,2011. [12] NAKAYA S,HIKICHI Y,NAKAZAWA Y,et al.Ignition and supersonic combustion behavior of liquid ethanol in a scramjet model combustor with cavity flame holder[J].Proceedings of the Combustion Institute,2015,35(2):2091-2099. doi: 10.1016/j.proci.2014.07.023 [13] HANDE R O,MARATHE A G.A computational study on supersonic combustion with struts as flame holder:AIAA-2008-4712[R].Reston:AIAA,2008. [14] 宗有海.基于支板喷射技术的液体碳氢燃料超声速燃烧组织研究[D].哈尔滨:哈尔滨工业大学,2013.ZONG Y H. Combustion organization of liquid hydrocarbon fueled scramjet based on strut injection technology[D]. Harbin:Harbin Institute of Technology,2013(in Chinese). [15] FAN X J,YU G,LI J G. Performance of supersonic model combustors with distributed injection of supercritical kerosene:AIAA-2007-5406[R].Reston:AIAA,2007. [16] 冮强,周乐仪,覃正,等.液体碳氢燃料超燃冲压发动机支板凹槽稳焰技术试验[J].推进技术,2011,32(5):680-683. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201105014.htmGANG Q,ZHOU L Y,QIN Z,et al.Experimental investigation of strut-cavity flameholder technology in liquid hydrocarbon fueled scramjet combustor[J].Journal of Propulsion Technology,2011,32(5):680-683(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201105014.htm 期刊类型引用(1)

1. 赵超凡,董昊,朱剑琴,程泽源,戎毅. 基于双向耦合的燃烧室与冷却通道的传热研究. 北京航空航天大学学报. 2024(03): 962-974 .  本站查看

本站查看其他类型引用(3)

-

下载:

下载:

下载:

下载: