-

摘要:

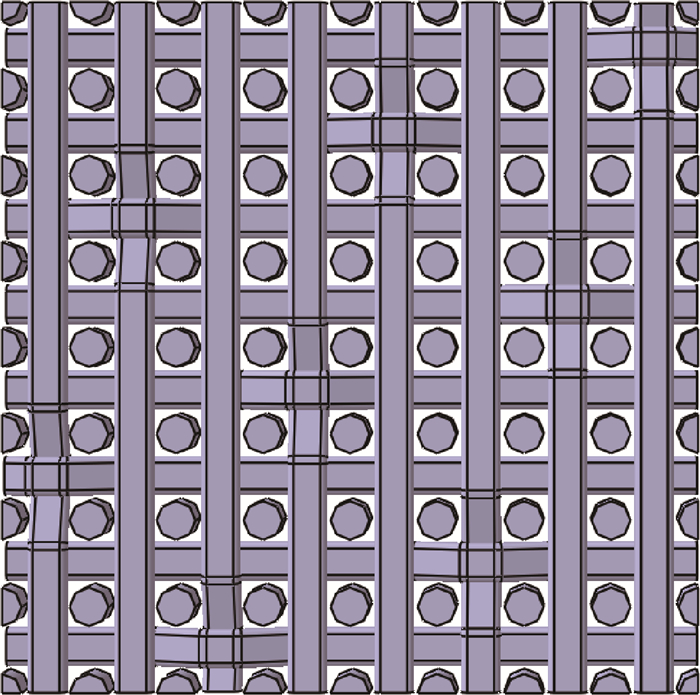

缎纹编织复合材料紧固件中螺牙细节尺寸已达到细观尺度量级,若在数值模拟过程中对于螺牙采用统一的材料属性,则不能准确地模拟其真实失效模式。针对此问题,建立的紧固件螺牙有限元模型是由若干层简化缎纹编织复合材料细观结构代表体积单元堆叠而成,如此模型可包含必要的纤维分区和基体分区。对螺牙模型进行拉拔试验模拟,并基于各组分材料的失效判据,实现对紧固件破坏载荷的预报。完成了缎纹编织碳/碳复合材料单螺牙紧固件拉拔试验。模拟失效模式与真实失效模式吻合良好,二者破坏载荷误差为5.17%,验证了有限元模型的合理性。

Abstract:Detailed sizes of threads in the satin weave composite fastener have reached the meso scale. It is not accurate to simulate the real failure mode if the uniform material is applied to the thread in the process of numerical simulation. For this problem, the finite element model of the fastener thread is established by stacking several layers of simplified satin weave composite meso-structure representative volume elements, which results in that the model includes essential fiber region and matrix region. Numerical simulation for the tensile test of thread model is carried out. Based on the failure criterion of each component material, prediction on the damage force of fastener is achieved. Tensile test for the satin weave carbon/carbon composite single thread fastener are accomplished. Good agreement between simulated failure mode and real damage mode is observed and the error of damage forces between the both methods is 5.17%, which verifies the rationality of the finite element model.

-

Key words:

- carbon/carbon composite /

- fastener /

- fabric /

- finite element method /

- failure analysis

-

几何参数 数值 单胞宽度/mm 10.40 单胞厚度/mm 0.46 经纬向纤维束宽度/mm 0.60 经纬向纤维束高度/mm 0.20 穿刺纤维束横截面直径/mm 0.58 表 2 缎纹编织碳/碳复合材料试验件尺寸

Table 2. Sizes of satin weave carbon/carbon composite specimen

几何尺寸 数值 螺牙间距/mm 1.5 螺牙顶角/(°) 60 螺牙高度/mm 1.3 光杆直径/mm 10 性能参数 数值 纵向弹性模量Ef1/GPa 230 横向弹性模量Ef2/GPa 15 纵横剪切模量Gf12/GPa 15 纵横主泊松比νf21 0.2 横向剪切模量Gf23/GPa 7 横向泊松比νf23 0.07 纵向拉伸强度XfT/MPa 2 500 纵向压缩强度XfC/MPa 2 000 表 4 无孔隙碳基体材料力学性能

Table 4. Mechanical properties of pure carbon matrix

表 5 缎纹编织碳/碳复合材料单牙紧固件拉拔试验结果

Table 5. Results of satin weave carbon/carbon composite single thread fastener tensile test

试验名称 破坏载荷/N 单牙螺钉拉拔 905.70 表 6 碳布有效力学性能

Table 6. Effective mechanical properties of carbon cloth

性能参数 数值 面内弹性模量/GPa 58.4 面内泊松比 0.010 5 面内剪切模量/GPa 5.41 离面弹性模量/GPa 12.2 离面泊松比 0.18 离面剪切模量/GPa 7.44 表 7 螺母有效力学性能

Table 7. Effective mechanical properties of nut

性能参数 数值 螺母弹性模量/GPa[16] 39.92 螺母泊松比 0.05 表 8 试验和有限元方法破坏载荷

Table 8. Damage forces of test and FEM

试验名称 破坏载荷 试验/N FEM/N 误差/% 单牙螺钉拉拔 905.70 858.86 5.17 -

[1] 魏高峰,孙晓强,刘国永,等.三维编织复合材料几何建模及数值分析[J].固体力学学报,2011,32(增刊):65-69. http://www.cnki.com.cn/Article/CJFDTOTAL-GTLX2011S1013.htmWEI G F,SUN X Q,LIU G Y,et al.Geometric model for three-dimensional braided composites and its numerical analysis[J].Chinese Journal of Solid Mechanics,2011,32(Suppl.):65-69(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GTLX2011S1013.htm [2] 董伟锋,肖军,李勇,等.2.5维编织复合材料弹性性能的理论研究[J].南京航空航天大学学报,2005,37(5):659-663. http://www.cnki.com.cn/Article/CJFDTOTAL-NJHK200505024.htmDONG W F,XIAO J,LI Y,et al.Theoretical study on elastic properties of 2.5D braided composites[J].Journal of Nanjing University of Aeronautics and Astronautics,2005,37(5):659-663(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-NJHK200505024.htm [3] 郑君,温卫东,崔海涛,等.2.5维机织结构复合材料的几何模型[J].复合材料学报,2008,25(2):143-148. http://www.cnki.com.cn/Article/CJFDTOTAL-FUHE200802023.htmZHENG J,WEN W D,CUI H T,et al.Geometric model of 2.5 dimensional woven structures[J].Acta Materiae Compositae Sinica,2008,25(2):143-148(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-FUHE200802023.htm [4] 曹海建,钱坤,盛东晓.2.5维机织复合材料的几何结构模型与验证[J].纺织学报,2009,30(5):58-62. http://www.cnki.com.cn/Article/CJFDTOTAL-FZXB200905015.htmCAO H J,QIAN K,SHENG D X.Geometry model and experimental verification of 2.5-D woven composites[J].Journal of Textile Research,2009,30(5):58-62(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-FZXB200905015.htm [5] 杨振宇,俸翔,苏洲,等.2.5D编织复合材料细观结构及弹性性能[J].宇航材料工艺,2010(2):67-71. http://www.cnki.com.cn/Article/CJFDTOTAL-YHCG201002019.htmYANG Z Y,FENG X,SU Z,et al.Meso-structure and elastic properties of 2.5D braided composites[J].Aerospace Materials and Technology,2010(2):67-71(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-YHCG201002019.htm [6] 卢子兴,冯志海,寇长河,等.编织复合材料拉伸力学性能的研究[J].复合材料学报,1999,16(3):129-134. http://www.cnki.com.cn/Article/CJFDTOTAL-FUHE903.023.htmLU Z X,FENG Z H,KOU C H,et al.Studies on tensile properties of braided structural composite materials[J].Acta Materiae Compositae Sinica,1999,16(3):129-134(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-FUHE903.023.htm [7] COX B N,DADKHAH M S,MORRIS W L.On the tensile failure of 3D woven composites[J].Composites Part A:Applied Science and Manufacturing,1996,27(4):47-58. http://cn.bing.com/academic/profile?id=e991613b42b1a9f1c12168e2edb9de91&encoded=0&v=paper_preview&mkt=zh-cn [8] CALLUS P J,MOURITZ A P,BANNISTER M K,et al.Tensile properties and failure mechanisms of 3D woven GRP composites[J].Composites Part A:Applied Science and Manufacturing,1999,30(12):77-87. http://cn.bing.com/academic/profile?id=474eb87e92eaa10459686a5452cf5a8d&encoded=0&v=paper_preview&mkt=zh-cn [9] BIGAUD D,HAMELIN P.Mechanical properties prediction of textile reinforced composite materials using a multiscale energetic approach[J].Composite Structures,1997,38(1-4):361-371. doi: 10.1016/S0263-8223(97)00071-8 [10] 卢子兴,刘振国,麦汉超,等.三维编织复合材料强度的数值预报[J].北京航空航天大学学报,2002,28(5):563-565. http://bhxb.buaa.edu.cn/CN/abstract/abstract10779.shtmlLU Z X,LIU Z G,MAI H C,et al.Numerical prediction of strength for 3D braided composites[J].Journal of Beijing University of Aeronautics and Astronautics,2002,28(5):563-565(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract10779.shtml [11] ZENG T,WU L Z,GUO L C.A finite element model for failure analysis of 3D braided composites[J].Materials Science and Engineering:A,2004,366(1):144-151. doi: 10.1016/j.msea.2003.09.054 [12] WAN Y M,WANG Y J,GU B H.Finite element prediction of the impact compressive properties of three-dimensional braided composites using multi-scale model[J].Composite Structures,2015,128:381-394. doi: 10.1016/j.compstruct.2015.03.066 [13] LU Z X,ZHOU Y,YANG Z Y,et al.Multi-scale finite element analysis of 2.5D woven fabric composites under on-axis and off-axis tension[J].Computational Materials Science,2013,79:485-494. doi: 10.1016/j.commatsci.2013.07.003 [14] YU X G,CUI J Z.The prediction on mechanical properties of 4-step braided composites via two-scale method[J].Composites Science and Technology,2007,67(3-4):471-480. doi: 10.1016/j.compscitech.2006.08.028 [15] 袁辉.碳/碳复合材料刚度与强度预测模型研究[D].南京:南京航空航天大学,2009:23-50,113.YUAN H.Research on prediction models for stiffness and strength of C/C composites[D].Nanjing:Nanjing University of Aeronautics and Astronautics,2009:23-50,113(in Chinese). [16] 阚晋.碳/碳复合材料微细观结构的表征及对有效性能的影响研究[D].哈尔滨:哈尔滨工业大学,2010:39,91-95.KAN J.Investigation on characterization of micro and meso structures and their influence on effective properties of carbon/carbon composites[D].Harbin:Harbin Institute of Technology,2010:39,91-95(in Chinese). [17] MU J W,GUAN Z D,BIAN T Y,et al.The experiment and numerical simulation of composite countersunk-head fasteners pull-through mechanical behavior[J].Applied Composite Materials,2014,21(5):773-787. doi: 10.1007/s10443-013-9379-7 [18] GUAN Z D,MU J W,SU F,et al.Pull-through mechanical behavior of composite fastener threads[J].Applied Composite Materials,2015,22(3):251-267. doi: 10.1007/s10443-014-9404-5 [19] 卢子兴,廖强,杨振宇,等.C/SiC复合材料螺栓螺牙承载能力[J].复合材料学报,2015,32(1):182-187. http://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201501024.htmLU Z X,LIAO Q,YANG Z Y,et al.Load bearing capability pf thread teeth of C/SiC composite bolts[J].Acta Materiae Compositae Sinica,2015,32(1):182-187(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201501024.htm [20] SODEN P D,HINTON M J,KADDOUR A S.Lamina properties,lay-up configurations and loading conditions for a range of fiber-reinforced composite laminates[J].Composites Science and Technology,1998,58(7):1011-1022. doi: 10.1016/S0266-3538(98)00078-5 [21] American Society for Testing and Materials International.Standard test method for measuring the fastener pull-through resistance of a fiber-reinforced polymer matrix composite:ASTM D7332/D7332-15a[S].West Conshohocken,PA:American Society for Testing and Materials International,2007. [22] BIAN T Y,GUAN Z D,MU J W,et al.An analytical model for predicting the tension modulus and Poisson's ratio of satin weave composites[C/OL]//Proceedings of 20th International Conference on Composite Materials(ICCM).[S.l.]:International Committee on Composite Materials,2015[2015-05-18] http://www.iccm-central.org/Proceedings/ICCM20proceedings/papers/paper-P105-4.pdf. [23] 李星,关志东,刘璐,等.基于应变不变量失效理论的复合材料损伤模拟[J].北京航空航天大学学报,2013,39(2):190-195. http://bhxb.buaa.edu.cn/CN/abstract/abstract12528.shtmlLI X,GUAN Z D,LIU L,et al.Damage simulation of composite materials based on strain invariant failure theory[J].Journal of Beijing University of Aeronautics and Astronautics,2013,39(2):190-195(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract12528.shtml -

下载:

下载: