-

摘要:

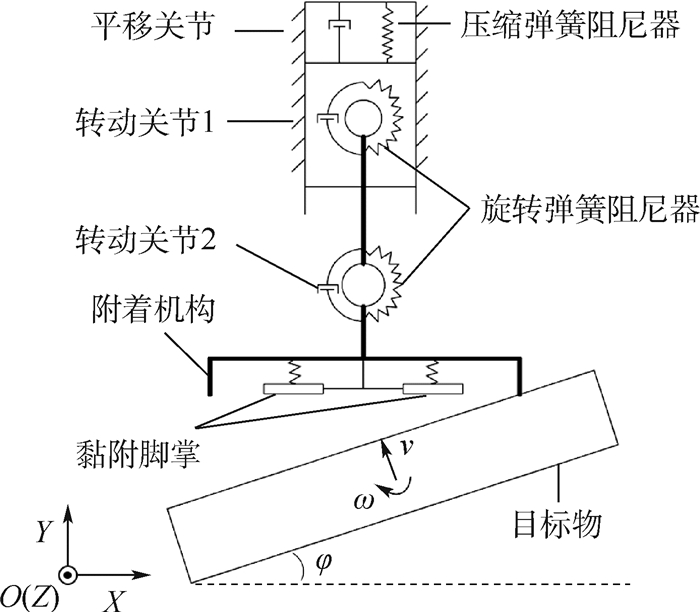

为提高仿生附着装置在捕获空间非合作目标物时对目标运动参数的适应性,设计了一种3自由度串联柔顺关节,可通过关节嵌入系统后的协调运动来辅助装置被动适应运动目标物姿态,并在运动过程中基于弹簧、阻尼缓冲器组成的关节柔顺机构及其能量耗散原理来降低目标物动能。为验证、优化关节性能,通过ADAMS虚拟样机软件建立了基于柔顺关节的仿生附着装置捕获过程运动学与动力学模型,分析了柔顺关节3组弹簧刚度系数、黏滞阻尼系数对非合作目标物捕获状态的影响,并利用ADAMS-iSIGHT联合仿真平台,通过多岛遗传算法对上述弹簧、阻尼器的重要参数进行了优化,极大提高了柔顺关节的能量耗散效果,同时保证了可捕获目标物运动参数达到规定要求。

Abstract:In order to improve the adaptability of the bionic adhesive device to target motion parameters when capturing non-cooperative objects in space, a 3-degree-of-freedom series compliant joint is designed. When the joints are embedded in the system, the device can passively adapt to the moving object posture through the coordinated movement of the joints. Meanwhile, the kinetic energy of the target is gradually reduced based on the joints' compliant mechanism consisting of springs, dampers and their energy dissipation function. In order to verify and optimize the joints' performance, a kinematics and dynamics model are established for bionic adhesive device's capture process based on compliant joints using virtual prototyping software ADAMS. The effects of spring stiffness coefficient and damping coefficient on the capture state of non-cooperative objects in the three groups of compliant joints are analyzed. By the ADAMS and iSIGHT co-simulation method, a multi-island genetic algorithm is used to optimize the spring stiffness and damping coefficient of compliant joints. Through parameter optimization, the energy dissipation effect of the bionic adhesive device compliant joints is improved. The motion parameters of the target that can be captured reach the specified envelope range.

-

表 1 零件关键物理参数

Table 1. Parts' key physical parameters

零件 质量/kg 绕质心转动惯量/(kg·mm2) 基座 224.67 3.27×106 平移滑块 1.80×10-2 2.37 连杆1 0.29 0.28 连杆2+附着机构框架 0.562 13.65 目标物 31.37 1.58×105 表 2 接触和摩擦模型参数

Table 2. Contact and friction model parameters

参数 数值 材料等效刚度k/(N·mm-1) 100 000 非线性指数e 2.2 材料最大等效阻尼系数Cmax /(N·s·mm-1) 10 构件最大变形深度dmax/mm 0.1 静摩擦系数μs 0.3 动摩擦系数μd 0.1 静摩擦临界速度vs/(mm·s-1) 100 动摩擦临界速度vd/(mm·s-1) 1 000 表 3 柔顺单元相关参数

Table 3. Related parameters of compliant units

参数 数值 平移关节压缩弹簧刚度系数/(N·mm-1) 0.1 平移关节黏滞阻尼系数/(N·s·mm-1) 0.1 转动关节1旋转弹簧刚度系数/(N·mm·(°)-1) 0.1 转动关节1黏滞阻尼系数/(N·mm·s·(°)-1) 0.1 转动关节2旋转弹簧刚度系数/(N·mm·(°)-1) 0.1 转动关节2黏滞阻尼系数/(N·mm·s·(°)-1) 0.1 表 4 目标物运动参数

Table 4. Target motion parameters

参数 数值 线速度/(m·s-1) 0.1 角速度/((°)·s-1) 0.1 偏航角/(°) 20 表 5 设计变量范围

Table 5. Design variable range

变量 变化区间 平移关节压缩弹簧刚度系数x1/(N·mm-1) [0, 1] 平移关节黏滞阻尼系数x2/(N·s ·mm-1) [0, 1] 转动关节1旋转弹簧刚度系数x3/(N·mm·(°)-1) [0, 1.5] 转动关节1黏滞阻尼系数x4/(N·mm·s·(°)-1) [0, 1.5] 转动关节2旋转弹簧刚度系数x5/(N·mm·(°)-1) [0, 1.5] 转动关节2黏滞阻尼系数x6/(N·mm·s·(°)-1) [0, 1.5] 表 6 优化变量对比

Table 6. Optimized variable comparison

变量 初始值 优化值 x1/(N·mm-1) 0.1 0.103 66 x2/(N·s ·mm-1) 0.1 0.897 07 x3/(N·mm·(°)-1) 0.1 0.176 26 x4/(N·mm·s·(°)-1) 0.1 0.211 61 x5/(N·mm·(°)-1) 0.1 0.117 29 x6/(N·mm·s·(°)-1) 0.1 0.397 71 表 7 优化目标对比

Table 7. Optimization target comparison

参数 优化前 优化后 目标物初始动能/mJ 156.85 156.85 目标物残余动能/mJ 139.51 108.58 动能耗散量/mJ 17.34 48.27 对齐角速度/((°)·s-1) 1.8 4.9 -

[1] 王超, 董正宏, 尹航, 等.空间目标在轨捕获技术研究综述[J].装备学院学报, 2013, 24(4):63-66. doi: 10.3783/j.issn.2095-3828.2013.04.016WANG C, DONG Z H, YIN H, et al.Research summarizing of on-orbit oapture technology for space target[J].Journal of Academy of Equipment, 2013, 24(4):63-66(in Chinese). doi: 10.3783/j.issn.2095-3828.2013.04.016 [2] 陈罗婧, 傅丹膺, 袁春柱, 等.仿生壁虎微纳米黏附阵列的空间应用[J].航天器环境工程, 2013, 30(6):616-622. doi: 10.3969/j.issn.1673-1379.2013.06.010CHEN L J, FU D Y, YUAN C Z, et al.Biomimetic gecko micro/nano-structure adhesive array in space application[J].Spacecraft Environment Engineering, 2013, 30(6):616-622(in Chinese). doi: 10.3969/j.issn.1673-1379.2013.06.010 [3] 张昊.大壁虎运动行为研究及仿壁虎机器人研制[D].南京: 南京航空航天大学, 2010: 7-11. http://cdmd.cnki.com.cn/Article/CDMD-10287-1011291444.htmZHANG H.Research on gecko's moving behavior and developing gecko-like robot[D].Nanjing: Nanjing University of Aeronautic and Astronautics, 2010: 7-11(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10287-1011291444.htm [4] HAWKES E W, EASON E V, ASBECK A T, et al.The gecko's toe:Scaling directional adhesives for climbing applications[J].IEEE/ASME Transactions on Mechatronics, 2013, 18(2):518-526. doi: 10.1109/TMECH.2012.2209672 [5] HAWKES E W, CHRISTENSEN D L, EASON E V, et al.Dynamic surface grasping with directional adhesion[C]//IEEE International Conference on Intelligent Robots and Systems.Piscataway, NJ: IEEE Press, 2013, 8215(2): 5487-5493. https://www.researchgate.net/publication/261353633_Dynamic_surface_grasping_with_directional_adhesion [6] ESTRADA M A, JIANG H, NOLL B, et al.Force and moment constraints of a curved surface gripper and wrist for assistive free flyers[C]//IEEE International Conference on Robotics and Automation.Piscataway, NJ: IEEE Press, 2017: 2824-2830. http://www.researchgate.net/publication/318688860_Force_and_moment_constraints_of_a_curved_surface_gripper_and_wrist_for_assistive_free_flyers [7] JIANG H, HAWKES E W, FULLER C, et al.A robotic device using gecko-inspired adhesives can grasp and manipulate large objects in microgravity[J].Science Robotics, 2017, 2(7):n4545. doi: 10.1126/scirobotics.aan4545 [8] 叶家宇.空间仿生附着机构的设计与实现[D].北京: 北京工业大学, 2017: 25-41.YE J Y.Design and implementation of spatial biomimetic adhesive device[D].Beijing: Beijing University of Technology, 2017: 25-41(in Chinese). [9] 崔晶, 楚中毅, 叶家宇, 等.一种基于复合恒力弹簧加载的仿生干黏附机构: 2016108360112[P].2017-03-15.CUI J, CHU Z Y, YE J Y, et al.A biomimetic dry adhesion mechanism based on composite constant force spring loading: 2016108360112[P].2017-03-15(in Chinese). [10] YE J Y, CHU Z Y, CUI J.Optimization design of microstroke table for gecko adhesives actuating[C]//IEEE International Conference on Nanotechnology.Piscataway, NJ: IEEE Press, 2017: 330-333. [11] HAWKES E W.Applying dry adhesives to the real world[D].Palo Alto: Stanford University, 2015: 7-9. [12] 刘坤明, 徐国艳, 余贵珍.驾驶机器人机械腿动力学建模与仿真分析[J].北京航空航天大学学报, 2016, 42(8):1709-1714. http://bhxb.buaa.edu.cn/CN/abstract/abstract13712.shtmlLIU K M, XU G Y, YU G Z.Dynamic modeling and simulation analysis of robot driver's mechanical legs[J].Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(8):1709-1714(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract13712.shtml [13] KATO H.Anisotropic adhesion model for translational and rotational motion[C]//IEEE/SICE International Symposium on System Integration.Piscataway, NJ: IEEE Press, 2013: 385-391. [14] 吴建云, 王春洁, 汪翰.月球着陆器模型参数修正[J].北京航空航天大学学报, 2013, 39(10):1366-1369. http://bhxb.buaa.edu.cn/CN/abstract/abstract12754.shtmlWU J Y, WANG C J, WANG H.Model parameters updating of lunar lander[J].Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(10):1366-1369(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract12754.shtml [15] 赖宇阳, 姜欣.Isight参数优化理论与实例详解[M].北京:北京航空航天大学出版社, 2012:139-140.LAI Y Y, JIANG X.Isight parameter optimization theory and example explanation[M].Beijing:Beihang University Press, 2012:139-140(in Chinese). [16] 赵德建, 王延奎, 周平, 等.基于多岛遗传算法的二维翼型吸气减阻优化[J].北京航空航天大学学报, 2015, 41(5):941-946. http://bhxb.buaa.edu.cn/CN/Y2015/V41/I5/941ZHAO D J, WANG Y K, ZHOU P, et al.Optimization of drag-reduction by suction using multi-island genetic algorithm[J].Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(5):941-946(in Chinese). http://bhxb.buaa.edu.cn/CN/Y2015/V41/I5/941 [17] 张鼎逆, 刘毅.基于改进遗传算法和序列二次规划的再入轨迹优化[J].浙江大学学报(工学版), 2014, 48(1):161-167. http://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC201401025.htmZHANG D N, LIU Y.Reentry trajectory optimization based on improved genetic algorithm and sequential quadratic programming[J].Journal of Zhejiang University(Engineering Science), 2014, 48(1):161-167(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC201401025.htm -

下载:

下载: