Reliability evaluation of slip ring based on multi-field coupling modeling and Bootstrap method

-

摘要:

导电滑环作为卫星太阳电池矩阵驱动机构的核心部件,其可靠性关系到卫星寿命的长短,由于空间用滑环寿命试验费用昂贵、试验周期长、样本数据量少等特点,无法获取大样本寿命数据,利用传统大样本数据进行统计推断,从而进行可靠性评估的方法存在困难。因此提出一种基于摩擦磨损模型的可靠性评估方法,应用赫兹理论、传热学方法分别计算摩擦副磨损过程中的接触区域变化和温度变化,量化热力电多场耦合对摩擦副磨损的影响,提出基于粘着磨损的多物理场耦合磨损模型,基于该模型得到的寿命数据,运用改进Bootstrap方法得到滑环寿命分布的参数估计,最后与传统可靠性预测方法结合,得到一系列滑环可靠性指标。方法对比结果表明,改进Bootstrap方法不仅具有较高的评估精度,还具有主观性小、适用性强的特点,由该方法所得的各可靠性指标均符合工程实际,具有很强的工程应用价值。

-

关键词:

- 空间滑环 /

- 多场耦合建模 /

- 寿命预估 /

- Bootstrap方法 /

- 可靠性评估

Abstract:The aerospace electric slip ring is a core component of the satellite solar battery array drive assembly. Its reliability is related to the satellite life. Due to the high cost of the space slip ring life test, the long test period and the small amount of sample data, it is difficult to obtain the large-size sample life data. Thus, it is difficult to conduct reliability evaluation using traditional statistical method. In order to solve these issues above, this paper proposes a reliability evaluation method based on friction and wear model. The Hertz theory and heat transfer method are used to calculate the contact area and temperature rising in the process of the friction pair wear, respectively. The effect of thermoelectric multi-field coupling on the friction pair wear is quantified. A multi-physics coupled wear model based on adhesive wear is established. The parameters of slip ring life distribution are estimated using improved Bootstrap method with the life data obtained from the multi-physics coupled wear model. Finally, a series of slip ring reliability indicators are obtained combined with the conventional reliability prediction method. The method comparison results indicate that the improved Bootstrap method provides not only high evaluation accuracy, but also weak subjectivity and flexible applicability. The method evaluation results show that all reliability indicators obtained from the proposed method are in line with the engineering reality, which have powerful application values in practical engineering.

-

表 1 滑环跑合试验参数

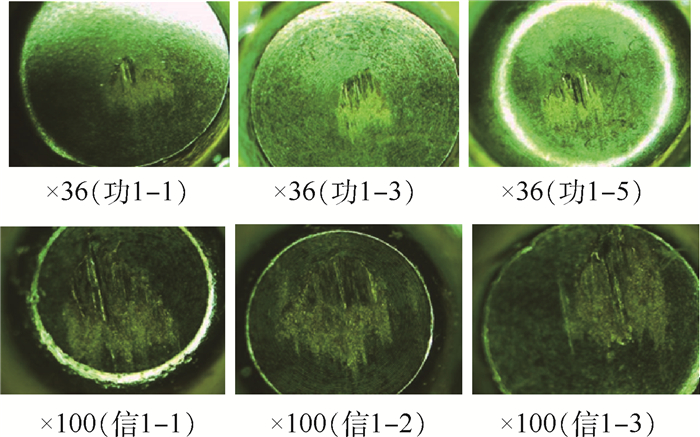

Table 1. Running-in test parameters of slip ring

参数 数值 大气跑合 真空跑合 温度 常温 (20±5)℃ 湿度 相对湿度不大于50% 真空 压力 常压 真空度优于1×10-3Pa 通电情况 功率环和信号环全部通0.25A 功率环通7A,信号环通0.25A 跑合速度 2r/min 0.3r/min 跑合时长 正反转各跑合24h 累计运转5万转 表 2 模型部分输入参数

Table 2. Some of model input parameters

参数 设定值 接触载荷 0.17~0.20N 功率电流 7A 汇流盘电阻率 1.65×10-8Ω·m 旋转半径 6.5cm 信号电流 0.25A 汇流盘角速度 0.6πrad/min 表 3 分布假设检验结果

Table 3. Test results of distribution hypothesis

分布类型 h p k c′ 威布尔分布 0 0.8449 0.1596 0.3614 正态分布 0 0.8398 0.1606 0.3614 -

[1] HUANG S, FENG Y, LIU H, et al.Electrical sliding friction and wear properties of Cu-MoS2-graphite-WS2, nanotubes composites in air and vacuum conditions[J]. Materials Science and Engineering:A, 2013, 560(2):685-692. [2] 刘军涛.导电滑环接触材料摩擦磨损特性研究[D].大连: 大连理工大学, 2013: 41-43.LIU J T.Research on the friction and wear characteristic of contact materials for the conductive slip ring[D]. Dalian: Dalian University of Technology, 2013: 41-43(in Chinese). [3] DING T, CHEN G X, ZHU M H, et al.Influence of the spring stiffness on friction and wear behaviours of stainless steel/copper-impregnated metallized carbon couple with electrical current[J]. Wear, 2009, 267(5):1080-1086. [4] XIE X L, ZHANG L, XIAO J K, et al.Sliding electrical contact behavior of AuAgCu brush on Au plating[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(9):3029-3036. doi: 10.1016/S1003-6326(15)63930-9 [5] MONNIER A, FROIDUROT B, JARRIGE C, et al.A mechanical, electrical, thermal coupled-field simulation of a sphere-plane electrical contact[J]. IEEE Transactions on Components & Packaging Technologies, 2007, 30(4):787-795. [6] 于艳艳.风电滑环接触材料加速摩擦磨损试验研究[D].大连: 大连理工大学, 2016: 47-50.YU Y Y.Test on the accelerated friction and wear of contact materials for the wind energy slip ring[D]. Dalian: Dalian University of Technology, 2016: 47-50(in Chinese). [7] GRANDIN M, WIKLUND U.Wear and electrical performance of a slip-ring system with silver-graphite in continuous sliding against PVD coated wires[J]. Wear, 2016, s348-349:138-147. [8] KOBAYASHI T, SAWA K, ENDO K, et al.A study of sliding characteristics of small-size slip-ring system for electric power supply[C]//2007 IEEE Holm Conference on Electrical Contacts.Piscataway, NJ: IEEE Press, 2007: 194-199. [9] 杨兆军, 李洪洲, 陈传海, 等.考虑定时截尾数据的数控机床可靠性Bootstrap区间估计方法[J].机械工程学报, 2017, 53(7):129-137.YANG Z J, LI H Z, CHEN C H, et al.Bootstrap interval estimation of reliability for numerical controlled machine tools considering the time-censored data[J]. Journal of Mechanical Engineering, 2017, 53(7):129-137(in Chinese). [10] 吴云洁, 王建敏, 杨文光.基于小样本的试验系统可信度评估方法[J].北京航空航天大学学报, 2016, 42(9):1911-1917. https://bhxb.buaa.edu.cn/CN/abstract/abstract14061.shtmlWU Y J, WANG J M, YANG W G.Approach of credibility evaluation for testing system with small samples[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(9):1911-1917(in Chinese). https://bhxb.buaa.edu.cn/CN/abstract/abstract14061.shtml [11] 黄玮, 冯蕴雯, 吕震宙.基于Bootstrap方法的小子样试验评估方法研究[J].机械科学与技术, 2006(1):31-35. doi: 10.3321/j.issn:1003-8728.2006.01.011HUANG W, FENG Y W, LU Z Z.Study on small scale sample test estimation method based on bootstrap method[J]. Mechanical Science and Technology for Aerospace Engineering, 2006(1):31-35(in Chinese). doi: 10.3321/j.issn:1003-8728.2006.01.011 [12] 刘建, 吴翊, 谭璐.对Bootstrap方法的自助抽样的改进[J].数学理论与应用, 2006, 26(1):69-72.LIU J, WU Y, TAN L.An Improvement to the resampling procedure of Bootstrap method[J]. Mathematical Theory and Applications, 2006, 26(1):69-72(in Chinese). [13] 邹艳, 罗文强.改进的Bootstrap方法对比及应用研究[J].应用数学, 2008, 21(S1):62-66.ZOU Y, LUO W Q.Comparative study anel application of improved Bootstrap method[J]. Mathematica Applicata, 2008, 21(S1):62-66(in Chinese). [14] 李超, 王学强, 戴飞, 等.空间滑环磨屑特征与可靠性设计[J].电子产品可靠性与环境试验, 2018, 36(2):1-5. doi: 10.3969/j.issn.1672-5468.2018.02.001LI C, WANG X Q, DAI F, et al.The debris characteristics and reliability design of aerospace slip ring[J]. Electronic Product Reliability and Environmental Testing, 2018, 36(2):1-5(in Chinese). doi: 10.3969/j.issn.1672-5468.2018.02.001 [15] HENNESSY R P, MCGRUER N E, ADAMS G G.Modeling of a thermal-electrical-mechanical coupled field contact[J]. Journal of Tribology, 2012, 134(4):041402-041410. doi: 10.1115/1.4007270 [16] 王天壹, 宣益民.热辐射对气膜冷却叶片冷却性能影响[J].航空动力学报, 2018, 33(8):1801-1810.WANG T Y, XUAN Y M.Effect of thermal radiation on the heat transfer performance of a film cooling vane[J]. Journal of Aerospace Power, 2018, 33(8):1801-1810(in Chinese). [17] 李聪波, 何娇, 杜彦斌, 等.基于Archard模型的机床导轨磨损模型及有限元分析[J].机械工程学报, 2016, 52(15):106-113.LI C B, HE J, DU Y B, et al.Archard model based machine tool wear model and finite element analysis[J]. Journal of Mechanical Engineering, 2016, 52(15):106-113(in Chinese). [18] 周文韬.导电滑环的接触力学特征与磨损寿命分析[D].湘潭: 湘潭大学, 2014: 30-35.ZHOU W T.Analysis of the characteristics of contact mechanics and wear life of slip ring with electrical contact[D]. Xiangtan: Xiangtan University, 2014: 30-35(in Chinese). [19] 刘强.基于失效物理的性能可靠性技术及应用研究[D].长沙: 国防科技大学, 2011: 6-8.LIU Q.Research on the performance reliability technology and the application based on physics of failure[D]. Changsha: National University of Defense Technology, 2011: 6-8(in Chinese). [20] 刘强, 黄秀平, 周经伦, 等.基于失效物理的动量轮贝叶斯可靠性评估[J].航空学报, 2009, 30(8):1392-1397. doi: 10.3321/j.issn:1000-6893.2009.08.006LIU Q, HUANG X P, ZHOU J L, et al.Failure-physics-analysis-based method of Bayesian reliability estimation for momentum wheel[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(8):1392-1397(in Chinese). doi: 10.3321/j.issn:1000-6893.2009.08.006 [21] 王大伟, 苗学问, 洪杰.某发动机涡轮叶片使用寿命可靠性分析[J].北京航空航天大学学报, 2006, 32(8):903-907. doi: 10.3969/j.issn.1001-5965.2006.08.007WANG D W, MIAO X W, HONG J.Reliability lifetime analysis of the turbine blade of turbofan engine[J]. Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(8):903-907(in Chinese). doi: 10.3969/j.issn.1001-5965.2006.08.007 [22] EFRON B, TIBSHIRANI R J.An Introduction to the Bootstrap[M]. London:Chapman and Hall, 1993. [23] 黄玮, 冯蕴雯, 吕震宙.极小子样试验的虚拟增广样本评估方法[J].西北工业大学学报, 2005, 23(3):384-387. doi: 10.3969/j.issn.1000-2758.2005.03.024HUANG W, FENG Y W, LU Z Z.Virtually expanded sample estimation method for extremely small-scale sample test[J]. Journal of Northwestern Polytechnical University, 2005, 23(3):384-387(in Chinese). doi: 10.3969/j.issn.1000-2758.2005.03.024 [24] 马宇鹏, 张建国, 邱继伟.基于Bootstrap-SVR-SOC的小子样结构机构可靠性分析方法[J].北京邮电大学学报, 2018, 41(4):81-85.MA P Y, ZHANG J G, QIU J W.Reliability analyzing method of small sample structures and mechanisms based on Bootstrap-SVR-SOC[J]. Journal of Beijing University of Posts and Telecommunications, 2018, 41(4):81-85(in Chinese). [25] 蒋喜, 刘宏昭, 刘丽兰, 等.基于伪寿命分布的电主轴极小子样可靠性研究[J].振动与冲击, 2013, 32(19):80-85. doi: 10.3969/j.issn.1000-3835.2013.19.015JIANG X, LIU H Z, LIU L L, et al.Extremely small-scale sample's reliability of an electric spindle based on distribution of false lifetime[J]. Journal of Vibration and Shock, 2013, 32(19):80-85(in Chinese). doi: 10.3969/j.issn.1000-3835.2013.19.015 -

下载:

下载: