Optimization of pressing force considering instantaneous springback in skin-side pressed drilling

-

摘要:

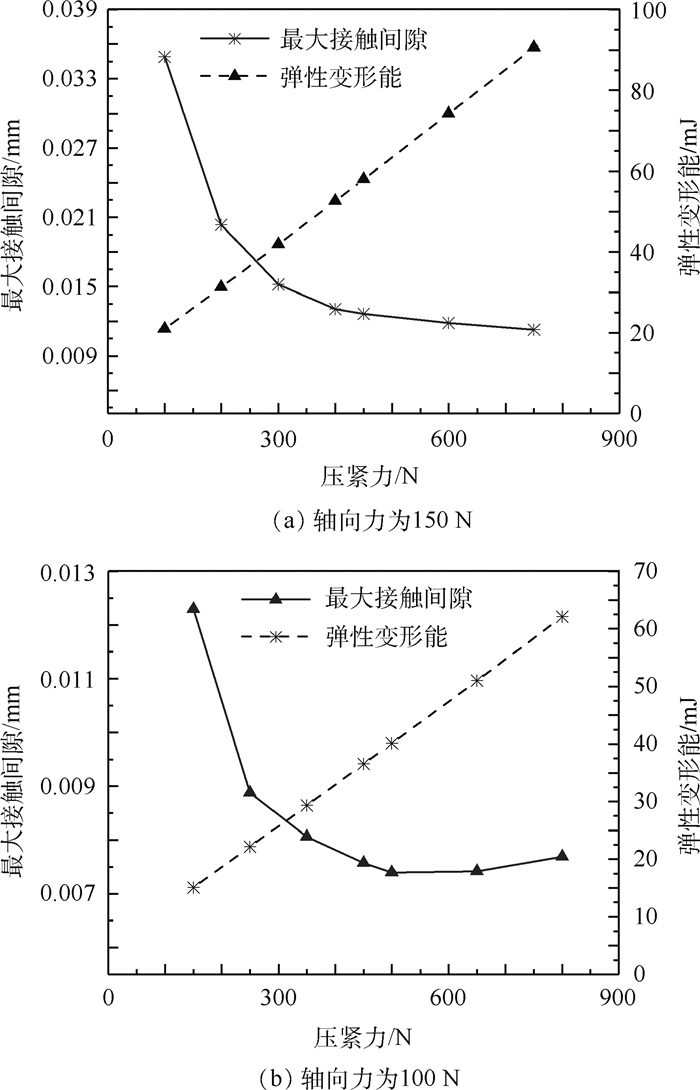

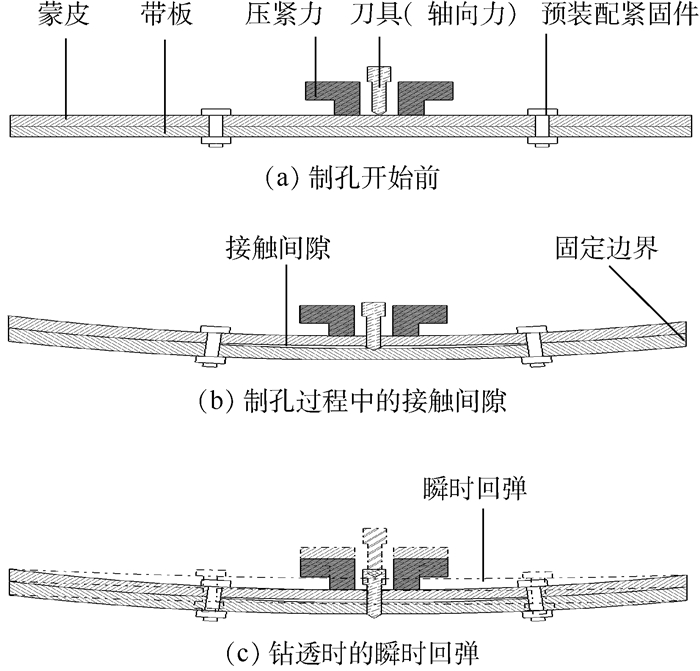

飞机大部件对接自动化制孔采用蒙皮侧单向压紧制孔技术,而由于在常见的自动化制孔系统中叠层材料被钻透的瞬间产生瞬时回弹,对制孔设备和加工质量等方面造成严重的影响,针对该问题进行机身蒙皮侧制孔压紧力优化分析。通过有限元分析方法进行制孔过程的模拟仿真,根据不同环境下的回弹现象,确定压紧力优化分析方案,综合考虑接触间隙、瞬时回弹和制孔刚性的影响,进行多目标优化分析,从而得到最优的压紧力工艺参数。计算结果表明,在飞机常见框间对接段自动化钻孔中,采用轴向力为150 N的麻花钻时压紧力的最优解为314.54 N,采用轴向力为100 N的自动化一体钻时压紧力的最优解为362.73 N。通过现场试验,压紧力最优解满足生产要求,实际最优压紧力低于最优解不超过20 N,因此考虑不同加工环境等因素构建合理的工艺参数选定范围。

Abstract:The automatic drilling for the docking of large parts of aircraft adopts the skin-side pressed drilling technology, and the instantaneous springback of the lamination material in the common automatic drilling system has serious influence on the drilling equipment and hole quality. The optimization analysis of the pressing force of the skin-side pressed drilling was carried out for this problem. The finite element simulation analysis method was used for the simulation of hole making process. According to the springback phenomenon in different environments, the optimal analysis scheme of pressing force was determined. Considering the influence of contact gap, instantaneous springback and drilling rigidity, multi-objective optimization analysis was carried out to obtain the optimal pressing force process parameters. The calculation results show that, in the automatic drilling of the docking area between the common frames of the aircraft, the optimal solution of the pressing force is 314.54 N when using twist drill with an axial force of 150 N, and 362.73 N when using automated integrated drill with an axial force of 100 N. Through on-site test, it was verified that the pressing force optimization analysis results meet the production requirements, and the actual optimal pressing force is less than 20 N lower than the pressing force optimization analysis results. Therefore, the different processing environments and other factors were considered to construct a reasonable range of process parameters.

-

Key words:

- aircraft assembly /

- automatic drilling /

- skin-side pressed /

- springback /

- parameter optimization

-

表 1 零件材料属性

Table 1. Parts' material properties

零件 弹性模量E/MPa 泊松比μ 长桁 78 620 0.31 带板 72 400 0.33 预装配紧固件 210 000 0.33 接头 71 030 0.33 框 71 820 0.33 蒙皮 72 400 0.33 表 2 分析方案的具体数据

Table 2. Specific data for analysis scheme

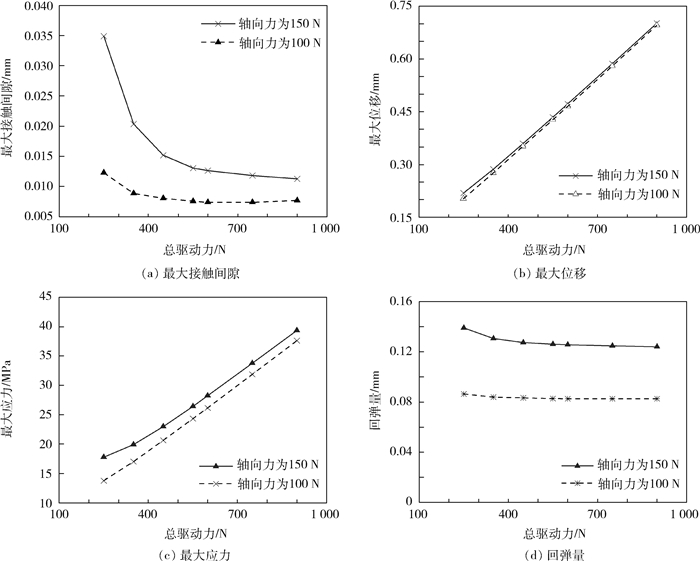

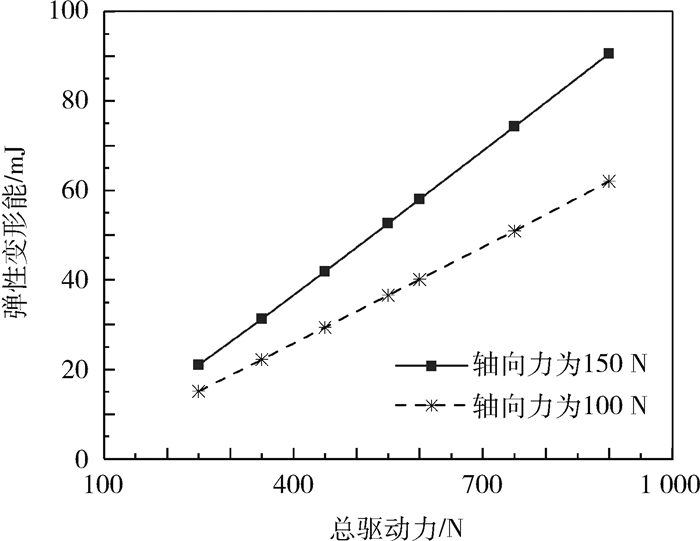

总驱动力/N 制孔压紧力/N 轴向力为150 N 轴向力为100 N 250 100 150 350 200 250 450 300 350 550 400 450 600 450 500 750 600 650 900 750 800 表 3 分析结果的响应值数据

Table 3. Response value data of analysis results

轴向力/ N 变量 不同总驱动力下的响应值 250 N 350 N 450 N 550 N 600 N 750 N 900 N 100 最大接触间隙/mm 0.012 29 0.008 88 0.008 06 0.007 57 0.007 13 0.006 88 0.006 66 最大位移/mm 0.202 76 0.276 15 0.351 30 0.426 89 0.464 90 0.576 89 0.698 24 最大应力/MPa 13.760 11 17.020 30 20.644 38 24.315 68 26.359 10 32.546 80 37.852 30 回弹量/mm 0.086 29 0.083 88 0.083 24 0.082 71 0.082 62 0.082 57 0.082 52 弹性变形能/mJ 15.077 72 22.186 64 29.345 37 36.536 90 40.145 80 50.972 51 62.066 76 150 最大接触间隙/mm 0.034 89 0.020 36 0.015 19 0.013 06 0.012 63 0.011 85 0.011 28 最大位移/mm 0.218 89 0.286 68 0.359 30 0.433 93 0.471 76 0.585 87 0.700 86 最大应力/MPa 17.765 17 19.922 66 22.961 21 26.400 89 28.237 01 33.755 51 39.355 15 回弹量/mm 0.139 06 0.130 58 0.127 39 0.125 99 0.125 53 0.124 64 0.123 99 弹性变形能/mJ 20.966 45 31.261 66 41.890 20 52.640 29 58.032 72 74.226 01 90.571 33 -

[1] 许国康.大型飞机自动化装配技术[J].航空学报, 2008, 29(3):734-740. doi: 10.3321/j.issn:1000-6893.2008.03.032XU G K.Automatic assembly technology for large aircraft[J].Acta Aeronautica et Astronautica Sinica, 2008, 29(3):734-740(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.032 [2] 王珉, 陈文亮, 张得礼, 等.飞机轻型自动化制孔系统及关键技术[J].航空制造技术, 2012(19):40-43.WANG M, CHEN W L, ZHANG D L, et al.Light-weight automatic drilling system and key technology for aircraft[J].Aeronantical Manufacturing Technology, 2012(19):40-43(in Chinese). [3] 王珉, 薛少丁, 陈文亮, 等.面向飞机自动化装配的单向压紧制孔毛刺控制技术[J].航空制造技术, 2011(9):26-29. doi: 10.3969/j.issn.1671-833X.2011.09.001WANG M, XUE S D, CHEN W L, et al.One-side pressed burrless drilling technology for aircraft automatic assembly[J].Aeronantical Manufacturing Technology, 2011(9):26-29(in Chinese). doi: 10.3969/j.issn.1671-833X.2011.09.001 [4] GILLESPIE L K, BLOTTER P T.The formation and properties of machining burrs[J].Journal of Manufacturing Science and Engineering, 1976, 98(1):66-74. [5] 王贵成.金属切削毛刺生成机理的研究及其发展[J].中国机械工程, 1994, 5(6):7-8. doi: 10.3321/j.issn:1004-132X.1994.06.004WANG G C.Studying and development of burr formation mechanism in metal cutting[J].China Mechanical Engineering, 1994, 5(6):7-8(in Chinese). doi: 10.3321/j.issn:1004-132X.1994.06.004 [6] 陈镇宇, 王贵成.毛剌的研究现状及去除技术[J].现代制造工程, 2004(2):126-128. doi: 10.3969/j.issn.1671-3133.2004.02.049CHEN Z Y, WANG G C.Studying status of burr and deburring technology[J].Machinery Manufacturing Engineer, 2004(2):126-128(in Chinese). doi: 10.3969/j.issn.1671-3133.2004.02.049 [7] 谢俊锋.钻削加工毛刺的形成及解决方法[J].轻工机械, 2007, 25(1):85-87. doi: 10.3969/j.issn.1005-2895.2007.01.027XIE J F.Formation and solution of burr in drilling[J].Light Industry Machinery, 2007, 25(1):85-87(in Chinese). doi: 10.3969/j.issn.1005-2895.2007.01.027 [8] 王磊, 王贵成, 马利杰.钻削加工有限元仿真的研究进展[J].工具技术, 2007, 41(8):8-13. doi: 10.3969/j.issn.1000-7008.2007.08.002WANG L, WANG G C, MA L J.Overview of finite element modeling of drilling process[J].Tool Engineering, 2007, 41(8):8-13(in Chinese). doi: 10.3969/j.issn.1000-7008.2007.08.002 [9] OLSSON T, HAAGE M, KIHLMAN H, et al.Cost-efficient drilling using industrial robots with high-bandwidth force feedback[J].Robotics and Computer Integrated Manufacturing, 2010, 26(1):24-38. doi: 10.1016/j.rcim.2009.01.002 [10] MELKOTE S N, NEWTON T R, HELLSTERN C, et al.Interfacial burr formation in drilling of stacked aerospace materials[C]//Proceedings of the CIRP International Conference on Burrs.Berlin: Springer, 2010: 89-98. [11] 王珉, 薛少丁, 蒋红宇, 等.飞机大部件对接自动化制孔单向压紧力分析[J].南京航空航天大学学报, 2012, 44(4):553-558. doi: 10.3969/j.issn.1005-2615.2012.04.020WANG M, XUE S D, JIANG H Y, et al.One-side pressure-force analysis of automatic drilling of aircraft fuselage section-Joint assembly[J].Journal of Nanjing University of Aeronautics & Astronautics, 2012, 44(4):553-558(in Chinese). doi: 10.3969/j.issn.1005-2615.2012.04.020 [12] 姜丽萍, 陈文亮, 王珉, 等.单向压紧制孔工艺的自适应响应面优化方法[J].中国机械工程, 2015, 26(23):3156-3161. doi: 10.3969/j.issn.1004-132X.2015.23.007JIANG L P, CHEN W L, WANG M, et al.An approach to adaptive response surface optimization of one-side process[J].China Mechanical Engineering, 2015, 26(23):3156-3161(in Chinese). doi: 10.3969/j.issn.1004-132X.2015.23.007 [13] 李源, 胡永祥, 姚振强.预压紧力下叠层铝合金钻孔层间毛刺试验研究[J].组合机床与自动化加工技术, 2014(2):110-113.LI Y, HU Y X, YAO Z Q.Experimental investigation of the effect of clamping force on the inter-layer drilling burr of stacked aluminum alloy sheets[J].Modular Machine Tool & Automatic Manufacturing Technique, 2014(2):110-113(in Chinese). [14] 洪华舟, 韦红余, 陈文亮, 等.航空薄壁件制孔毛刺生长控制工艺研究[J].中国机械工程, 2012, 23(19):2312-2316. doi: 10.3969/j.issn.1004-132X.2012.19.009HONG H Z, WEI H Y, CHEN W L, et al.Control process for drilling burr growth of aerospace thin-walled workpiece[J].China Mechanical Engineering, 2012, 23(19):2312-2316(in Chinese). doi: 10.3969/j.issn.1004-132X.2012.19.009 [15] 陈威, 朱伟东, 章明, 等.叠层结构机器人制孔压紧力预测[J].浙江大学学报(工学版), 2015, 49(12):2282-2289.CHEN W, ZHU W D, ZHANG M, et al.Clamping force prediction for robotic drilling of stacked structure[J].Journal of Zhejiang University(Engineering Science), 2015, 49(12):2282-2289(in Chinese). [16] 李聪.面向机器人自动化叠层制孔过程的压紧力优化[D].杭州: 浙江大学, 2016: 28-35.LI C.Clamping force optimization of stacks for robotic automatic drilling system[D].Hangzhou: Zhejiang University, 2016: 28-35(in Chinese). [17] 曾长.飞机装配自主移动机构研制[D].南京: 南京航空航天大学, 2013: 52-63.ZENG Z.Research of autonomous mobile mechanism for aircraft assembly[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2013: 52-63(in Chinese). [18] 刘姿.飞机壁板叠层材料精密制孔工艺研究[D].南京: 南京航空航天大学, 2015: 28-59.LIU Z.Research on precision hole making process for laminated materials of aircraft panel[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2015: 28-59(in Chinese). [19] 李夏.机器人自动化螺旋铣制孔过程压脚压紧力优化[D].杭州: 浙江大学, 2015: 13-37.LI X.Pressure-force optimization in the process of robotic automatic orbital drilling[D].Hangzhou: Zhejiang University, 2015: 13-37(in Chinese). [20] 毕运波, 李夏, 严伟苗, 等.面向螺旋铣制孔过程的压脚压紧力优化[J].浙江大学学报(工学版), 2016, 50(1):102-110. doi: 10.3785/j.issn.1008-973X.2016.01.015BI Y B, LI X, YAN W M, et al.Pressure-force optimization of press-foot device for orbital drilling process[J].Journal of Zhejiang University(Engineering Science), 2016, 50(1):102-110(in Chinese). doi: 10.3785/j.issn.1008-973X.2016.01.015 [21] 刘雪锋.机器人制孔压紧力研究[D].杭州: 浙江大学, 2017: 24-34.LIU X F.Clamping force research on robot drilling[D].Hangzhou: Zhejiang University, 2017: 24-34(in Chinese). -

下载:

下载: