-

摘要:

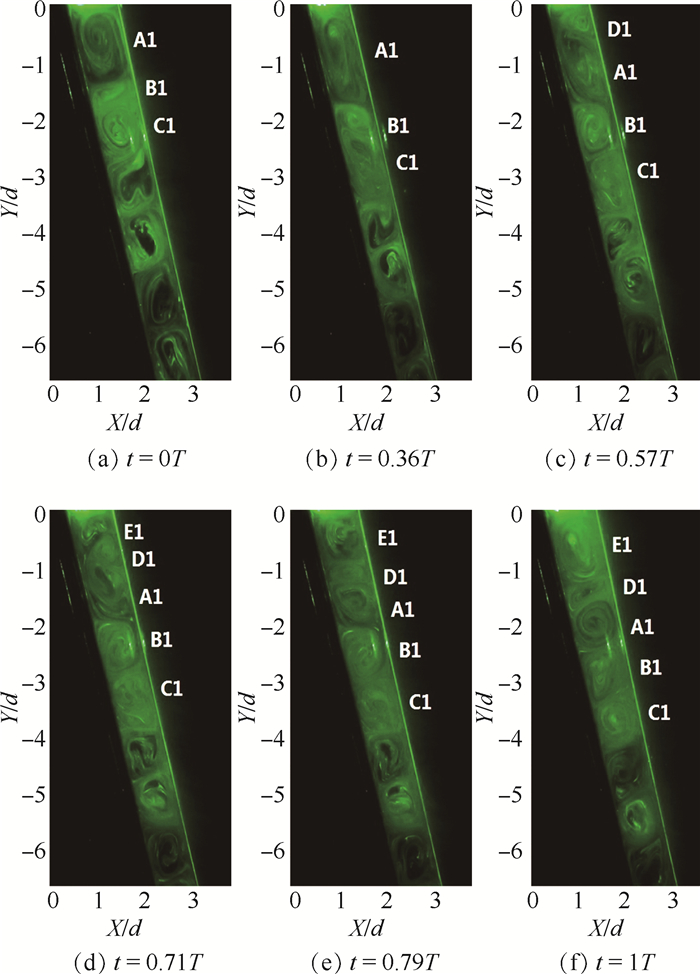

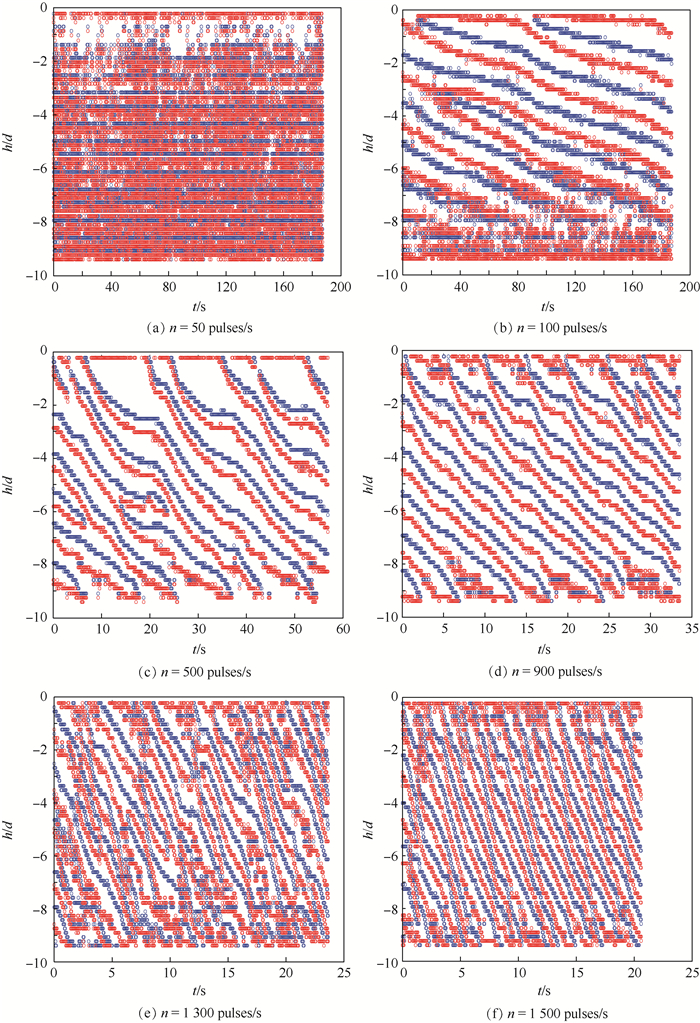

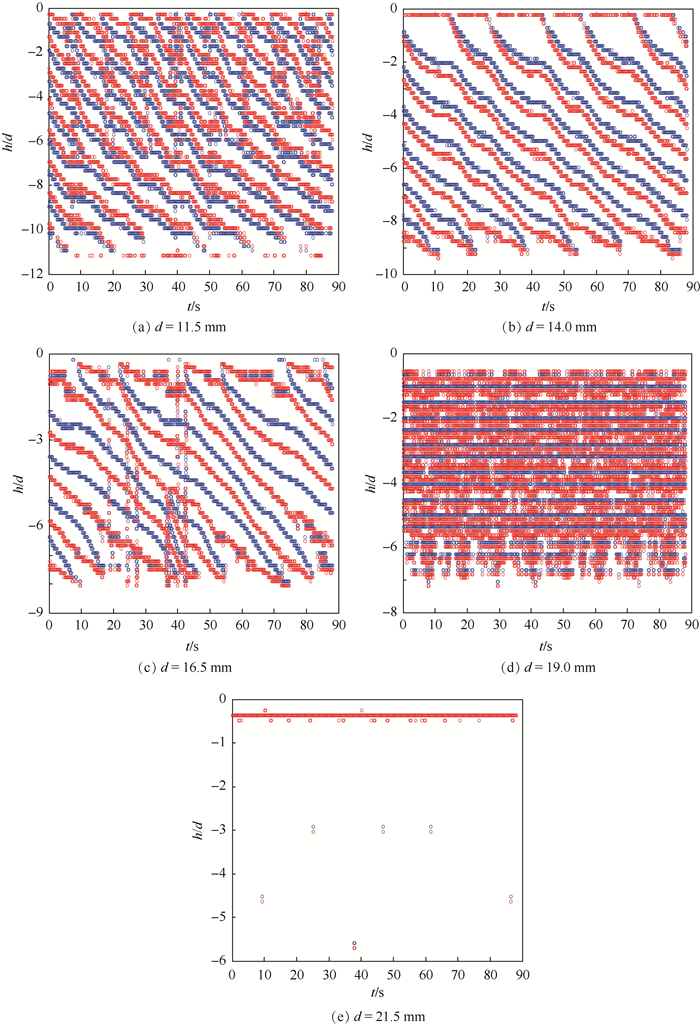

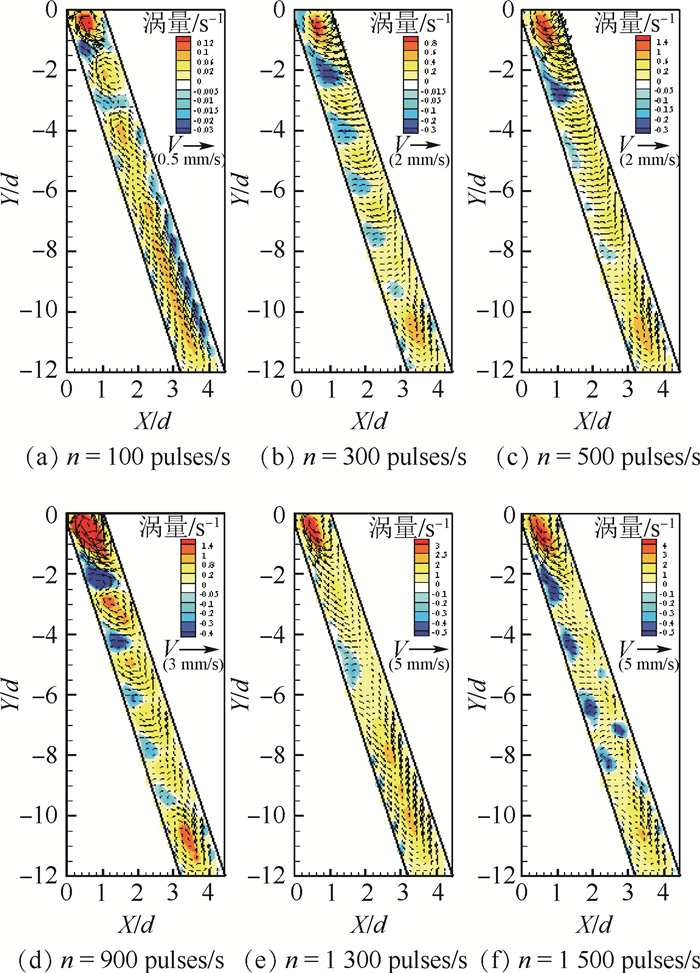

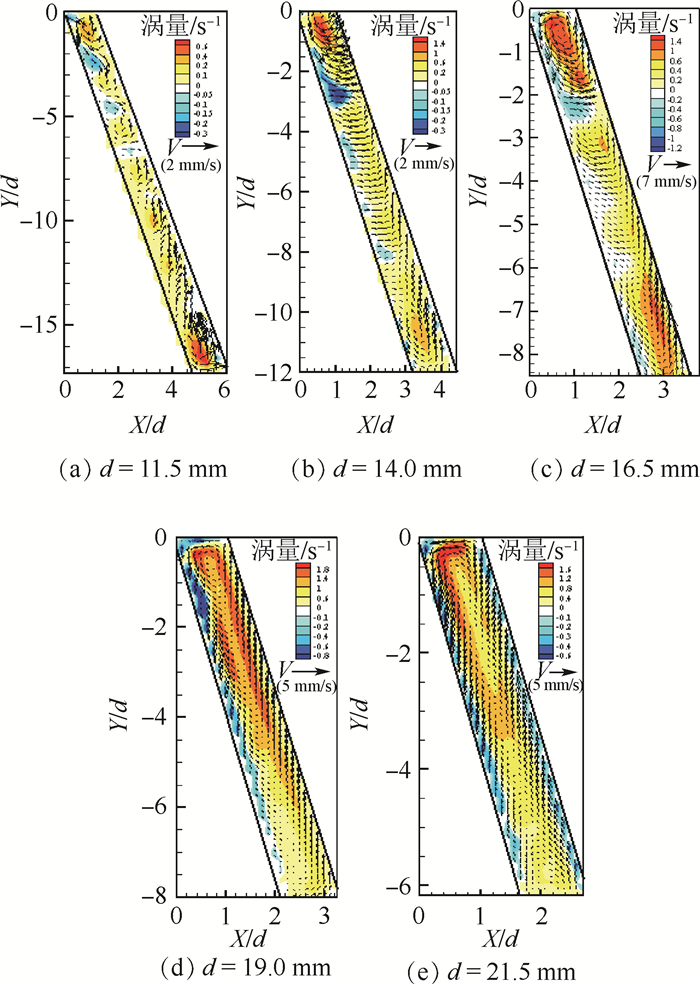

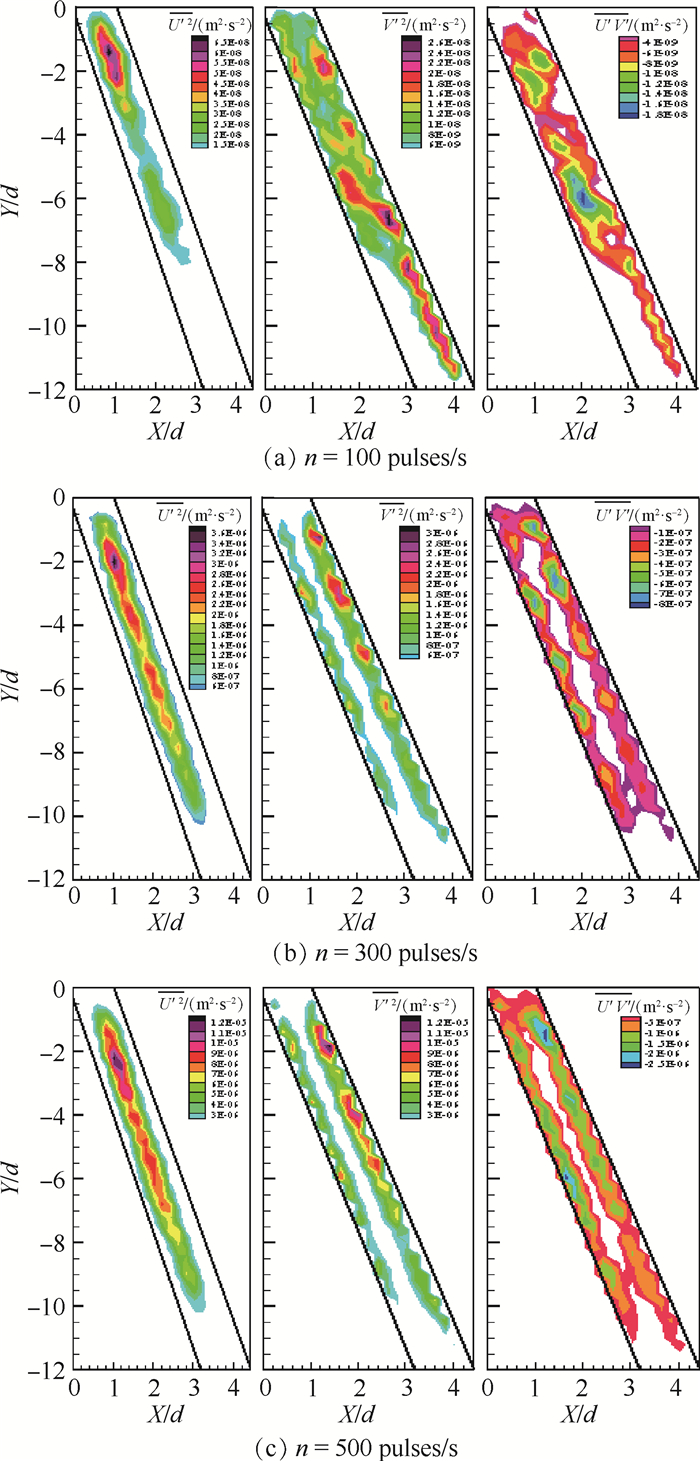

针对同轴旋转倒置圆台环隙间流体复杂流动问题, 对其环隙间流动特性进行了实验研究。重点进行染色液流动显示实验和PIV流场测速实验, 对实验结果做定性及定量分析, 研究内筒转速和环隙宽度对环隙间流动特性的影响。染色液流动显示实验和PIV流场测速实验分别定性和定量地展现了环隙间螺旋涡的产生及变化过程。对不同内筒转速和环隙宽度下的螺旋涡涡心运动周期进行分析, 结果表明, 内筒转速升高, 周期减小;环隙宽度增大, 周期增大。运用瞬时流动和时均流场解析了环隙间螺旋涡运动产生机制, 探究内筒转速和环隙宽度对3种雷诺应力大小的影响与分布情况。内筒转速变化, 雷诺径向正应力始终最大;环隙宽度变化, 雷诺切应力始终最小。

Abstract:In order to solve the problem of complex flow between annulus of coaxial rotating conical cylinders, the flow characteristics of fluid between annular spaces were studied experimentally. Experimental studies were carried out for the complex flow characteristics of fluid between annulus of coaxial rotating conical cylinders. Emphasis was placed on staining fluid visualization experiment and PIV flow field measurements. The experimental results were analyzed qualitatively and quantitatively concerning the effects of rotating speed and annular width on interannular flow characteristics. Staining fluid visualization experiment and PIV flow field speed measurement experiment displayed the generation and variation of interannular spiral vortices qualitatively and quantitatively respectively. The period of motion of spiral vortex core under different inner cylinder speed and annulus width was analyzed. The results reveal that the period of motion decreases with the increase of inner cylinder speed, and the period of motion increases with the increase of annulus width. Instantaneous and time-averaged flow field were checked to analyze the mechanism of interannular spiral vortex motion and generation. The influence of inner cylinder speed and annulus width on three kinds of Reynolds stress and their distribution were studied. The radial normal Reynolds stress is always the largest when the inner cylinder speed is variable, and the Reynolds shear stress stays minimum when the annular width changes.

-

Key words:

- interannular flow /

- periodic motion of vortex center /

- staining fluid /

- PIV /

- inner cylinder speed

-

-

[1] TAYLOR G I.Stability of a viscous liquid contained between two rotating cylinders[J].Philosophical Transactions of the Royal Society of London, 1923, 223(718):289-343. [2] DANIEL C, KUNIHIKO T.Two-dimensional compressible viscous flow around a circular cylinder[J].Journal of Fluid Mechanics, 2015, 785:349-371. doi: 10.1017/jfm.2015.635 [3] 韩晓婷, 常青, 毛玉红, 等.Taylor-Couette流场数值模拟及絮凝效果研究[J].环境科学学报, 2013, 33(6):1637-1641.HAN X T, CHANG Q, MAO Y H, et al.Numerical simulation and flocculation efficiencies of Taylor-Couette flow[J].Acta Scientiae Circumstantiae, 2013, 33(6):1637-1641(in Chinese). [4] 毛玉红.流场涡形态对混凝效果的影响研究[D].兰州: 兰州交通大学, 2017.MAO Y H.A study of the influence of the vortices regime on the coagulation effects[D].Lanzhou: Lanzhou Jiaotong University, 2017(in Chinese). [5] 朱鹣, 刘栋, 汤承, 等.沟槽深宽比对泰勒涡流影响的研究[J].工程热物理学报, 2016, 37(6):1208-1211.ZHU J, LIU D, TANG C, et al.Study of slit wall aspect ratio effect on the Taylor vortex flow[J].Journal of Engineering Thermophysics, 2016, 37(6):1208-1211(in Chinese). [6] 李华鹏.非平行间隙同轴旋转圆台间流体流动的数值模拟和理论分析[D].北京: 北京化工大学, 2014.LI H P.Numerical study and theoretical analysis of the flow between two rotating conical cylinders with non-parallel gap[D].Beijing: Beijing University of Chemical Technology, 2014(in Chinese). [7] JIRKOVSKY L, BO-OT L M.Taylor-Couette flow and a molecule dependent transport equation[J].Physica A-Statistical Mechanics and Its Applications, 2014, 415:205-209. doi: 10.1016/j.physa.2014.08.004 [8] WIMMER M.Taylor vortices at different geometries[M]//EGBERS C, PFISTER G.Physics of rotating fluids.Berlin: Springer, 1999: 194-212. [9] WIMMER M.An experimental investigation of Taylor vortex flow between conical cylinders[J].Journal of Fluid Mechanics, 2006, 292(1):205-227. [10] 文普.同轴旋转圆台间流体流动的理论研究和数值模拟[D].北京: 北京化工大学, 2010.WEN P.Theoretical and numerical study of the flow between rotating conical cylinders[D].Beijing: Beijing University of Chemical Technology, 2010(in Chinese). [11] 张晶晶.旋转液膜反应器内流体流动的动力学研究[D].北京: 北京化工大学, 2013.ZHANG J J.Dynamic study of the flow in the rotating liquid film rractor[D].Beijing: Beijing University of Chemical Technology, 2013(in Chinese). [12] 张晶晶, 张艺晓, 许兰喜.旋转液膜反应器内流动机理研究[J].北京化工大学学报(自然科学版), 2013, 40(2):117-120. doi: 10.3969/j.issn.1671-4628.2013.02.022ZHANG J J, ZHANG Y X, XU L X.A study of the flow mechanism of rotating liquid film reactor[J].Journal of Beijing University of Chemical Technology(Natural Science Edition), 2013, 40(2):117-120(in Chinese). doi: 10.3969/j.issn.1671-4628.2013.02.022 [13] 鲍锋, 曾华轮, 邹赫, 等.同轴旋转圆台环隙流动机制及实验研究[J].北京航空航天大学学报, 2018, 44(8):12-21. doi: 10.13700/j.bh.1001-5965.2017.0614BAO F, ZENG H L, ZOU H, et al.Mechanism and experimental research on fluid flow in annulus of coaxial rotating conical cylinders[J].Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(8):12-21(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0614 [14] 王强.流动显示技术综述[J].电力环境保护, 1992, 8(4):32-35.WANG Q.Summarize of flow display technology[J].Environmental Protection of Electric Power, 1992, 8(4):32-35(in Chinese). [15] 李聪洲, 张新曙, 胡晓峰, 等.高雷诺数下多柱绕流特性研究[J].力学学报, 2018, 50(2):233-243.LI C Z, ZHANG X S, HU X F, et al.The study of flow past multiple cylinders at high Reynolds numbers[J].Chinese Journal of Theoretical and Applied Mechanics, 2018, 50(2):233-243(in Chinese). -

下载:

下载: