-

摘要:

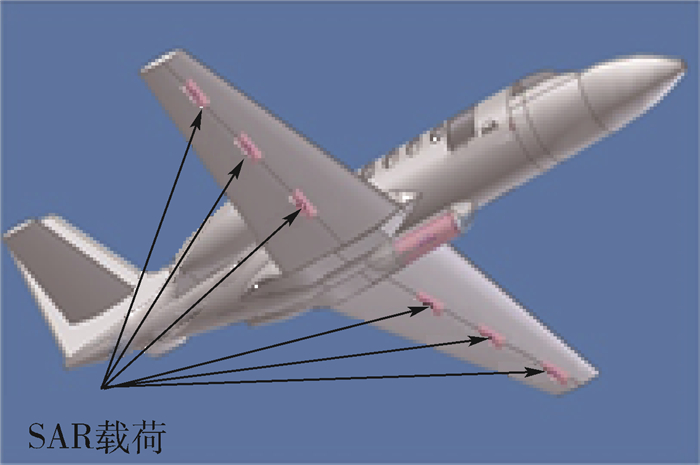

针对多节点InSAR机翼挠曲变形误差问题,提出了一种基于机理模型综合参数辨识的方法对空气扰动影响机翼挠曲变形分层建模。首先,将大气湍流作为InSAR成像工作段的主要空气扰动,并基于Dryden模型分析得出了载机工作高度和速度是影响大气湍流的主要因素,将大气湍流影响机翼挠曲变形建模转换为载机在不同工作状态(高度变化、速度变化)的机翼挠曲变形分层建模。其次,基于空气动力学理论及悬臂梁变形理论建立机翼挠曲变形机理模型,借助计算流体力学与计算结构力学仿真分析获取实验数据辨识模型参数。最后,通过仿真实验验证,所提方法与模态叠加原理计算横向位移精度均优于0.6 mm(相对误差0.3%),轴向位移精度均优于0.015 mm(相对误差0.2%)。对实验室搭建的分布式光纤光栅测量系统进行测试,利用模态叠加原理计算变形量来验证所提方法,横向位移精度优于0.3 mm(相对误差1%),轴向位移精度优于0.06 mm(相对误差3%)。

Abstract:For the problem of multi-node InSAR wing deflection deformation error, a method based on mechanism modeling integrated parameter identification is proposed for the layered modeling of wing deflection deformation induced by air disturbance. First, this model takes atmospheric turbulence as the main air disturbance in the InSAR imaging working section, and based on Dryden model, it is analyzed that the working height and speed of the aircraft are the main factors affecting atmospheric turbulence. Therefore, the modeling of wing deformation affected by atmospheric turbulence is transformed to the layered modeling of wing deformation under different working conditions (height change, velocity change). Second, the wing deformation mechanism model is established based on the combination of the aerodynamic theory and the cantilever beam deformation theory. The parameters of the model are identified by the experimental data obtained from the simulation analysis of computational fluid dynamics and computational structural mechanics. Finally, the simulation experiments show that, calculated by both the proposed method and the mature modal superposition principle, the lateral displacement error is better than 0.6 mm (relative error 0.3%) and the axial displacement error is better than 0.015 mm (relative error 0.2%). In addition, based on the distributed fiber Bragg grating measurement system of wing structure built in the laboratory and the principle of modal superposition, the deformation is calculated to verify the proposed method, the lateral displacement error is better than 0.3 mm (relative error 1%) and the axial relative error is better than 0.06 mm (relative error 3%).

-

表 1 铝合金7075材料属性

Table 1. Aluminum alloy 7075 material properties

参数 数值 密度/(g·cm-3) 2.81 极限抗拉强度/MPa 524 极限屈服强度/MPa 455 弹性模量/GPa 71 泊松比 0.33 工作高度/km 压力/Pa 温度 密度/(g·cm-3) 摄氏度 开尔文 2.0 79 810 2.35 275.5 1.009 3.0 70 510 -3.25 269.9 0.908 7 3.5 66 100 -6.27 266.88 0.862 5 4.0 61 950 -9.29 263.86 0.818 1 4.5 58 070 -12.3 260.85 0.775 6 5.0 54 420 -15.32 257.83 0.734 8 5.5 51 000 -18.34 254.81 0.695 6 6.0 47 680 -21.62 251.53 0.658 9 6.5 44 520 -24.97 248.18 0.623 7 7.0 41 580 -28.32 244.83 0.59 7.5 38 770 -31.65 241.5 0.557 7 8.0 36 080 -35.07 238.08 0.526 8 表 3 载机工作速度影响的参数辨识结果

Table 3. Parameter identification results of carrier speed

测点 u=Av2 R2 SSE u=Av2.014 R2 SSE u=Av2.015 R2 SSE 2 u=6.492×10-7v2 1.000 7.22×10-10 u=6.022×10-8v2.014 1.000 1.33×10-11 u=5.99×10-8v2.015 1.000 4.57×10-12 7 u=1.001×10-6v2 1.000 1.57×10-7 u=9.284×10-7v2.014 1.000 1.52×10-9 u=9.234×10-7v2.015 1.000 3.34×10-11 12 u=2.407×10-6v2 1.000 8.96×10-7 u=2.233×10-6v2.014 1.000 7.67×10-9 u=2.221×10-6v2.015 1.000 1.74×10-9 15 u=3.424×10-6v2 1.000 1.82×10-6 u=3.176×10-6v2.014 1.000 1.52×10-8 u=3.159×10-6v2.015 1.000 2.98×10-9 表 4 载机工作高度影响的参数辨识结果

Table 4. Parameter identification results of carrier's working height

测点 指数函数u=aebP R2 SSE 线性模型u=aP+b R2 SSE 幂函数u=aP0.833 R2 SSE 2 u=2.286×10-8e1.368×10-5P 0.996 1.42×10-18 u=7.27P×10-13+8.696×10-9 1.000 5.08×10-20 u=5.484×10-12P0.833 1.000 8.60×10-21 7 u=3.522×10-7e1.368×10-5P 0.996 3.52×10-16 u=1.121P×10-11+1.339×10-7 1.000 1.51×10-17 u=8.454×10-11P0.833 1.000 2.82×10-18 12 u=8.467×10-7e1.369×10-5P 0.996 2.05×10-15 u=2.696P×10-11+3.215×10-7 1.000 9.16×10-17 u=2.033×10-10P0.833 1.000 1.80×10-17 15 u=1.205×10-6e1.368×10-5P 0.996 4.16×10-15 u=3.834P×10-11+4.585×10-7 1.000 1.89×10-16 u=2.892×10-10P0.833 1.000 3.74×10-17 表 5 本文模型预测Y向变形

Table 5. Y-direction deformation predicted by proposed model

工作速度/(m·s-1) 工作高度/km ANSYS Workbench

Y向变形量/mm本文模型

Y向变形量/mm测点7 测点12 测点15 测点7 测点12 测点15 250 1.5 3.85 4.38 4.30 3.85 4.37 4.31 200 1.5 2.45 2.79 2.74 2.46 2.79 2.75 2.0 2.33 2.65 2.60 2.33 2.65 2.61 6.5 1.44 1.63 1.61 1.43 1.63 1.61 7.0 1.36 1.54 1.52 1.35 1.54 1.52 7.5 1.28 1.46 1.44 1.28 1.45 1.43 8.0 1.21 1.38 1.36 1.20 1.37 1.35 185 2.5 1.89 2.15 2.12 1.89 2.15 2.12 235 2.5 3.07 3.48 3.44 3.06 3.48 3.44 285 2.5 4.52 5.14 5.07 4.52 5.14 5.07 表 6 本文模型预测Z向变形

Table 6. Z-direction deformation predicted by proposed model

工作速度/(m·s-1) 工作高度/km ANSYS Workbench

Z向变形量/mm本文模型

Z向变形量/mm测点7 测点12 测点15 测点7 测点12 测点15 250 1.5 73.36 176.36 250.83 73.24 176.14 250.56 200 1.5 46.80 112.48 159.97 46.72 112.35 159.82 2.0 44.44 106.81 151.91 44.37 106.69 151.77 6.5 27.31 65.67 93.41 27.28 65.61 93.33 7.0 25.81 62.08 88.31 25.77 61.98 88.17 7.5 24.38 58.64 83.43 24.31 58.47 83.17 8.0 23.01 55.35 78.75 22.90 55.07 78.34 185 2.5 36.04 86.66 123.28 36.01 86.60 123.19 235 2.5 58.36 140.34 199.63 58.32 140.24 199.49 285 2.5 86.05 206.92 294.36 86.02 206.86 294.26 表 7 Y向变形模态叠加原理计算结果

Table 7. Y-direction deformation calculated by modal superposition principle

工作速度/(m·s-1) 工作高度/km ANSYS Workbench

Y向变形量/mm模态叠加原理

Y向变形量/mm测点7 测点12 测点15 测点7 测点12 测点15 250 1.5 3.85 4.38 4.30 3.85 4.37 4.30 200 1.5 2.45 2.79 2.74 2.45 2.79 2.74 2.0 2.33 2.65 2.60 2.33 2.65 2.60 6.5 1.44 1.63 1.61 1.44 1.63 1.61 7.0 1.36 1.54 1.52 1.36 1.54 1.52 7.5 1.28 1.46 1.44 1.28 1.46 1.44 8.0 1.21 1.38 1.36 1.21 1.38 1.36 185 2.5 1.89 2.15 2.12 1.89 2.15 2.12 235 2.5 3.07 3.48 3.44 3.07 3.49 3.43 285 2.5 4.52 5.14 5.07 4.52 5.14 5.06 表 8 Z向变形模态叠加原理计算结果

Table 8. Z-direction deformation calculated by modal superposition principle

工作速度/(m·s-1) 工作高度/km ANSYS Workbench

Z向变形量/mm模态叠加原理

Z向变形量/mm测点7 测点12 测点15 测点7 测点12 测点15 250 1.5 73.36 176.36 250.83 73.24 176.03 250.31 200 1.5 46.80 112.48 159.97 46.70 112.23 159.54 2.0 44.44 106.81 151.91 44.35 106.58 151.52 6.5 27.31 65.67 93.41 27.28 65.60 93.31 7.0 25.81 62.08 88.31 25.80 62.02 88.24 7.5 24.38 58.64 83.43 24.37 58.60 83.37 8.0 23.01 55.35 78.75 23.01 55.32 78.72 185 2.5 36.04 86.66 123.28 36.00 86.56 123.13 235 2.5 58.36 140.34 199.63 58.31 140.18 199.40 285 2.5 86.05 206.92 294.36 85.97 206.70 294.02 表 9 本文模型与模态叠加原理计算误差值对比

Table 9. Comparison of error values calculated by proposed model and modal superposition principle

工作速度/(m·s-1) 工作高度/km Y向 Z向 ANSYS仿真位移/mm 模态叠加原理误差/mm 本文模型误差/mm ANSYS仿真位移/mm 模态叠加原理误差/mm 本文模型误差/mm 250 1.5 4.30 0.004 0.011 250.83 0.520 0.303 200 1.5 2.74 0.004 0.013 159.97 0.426 0.182 2.0 2.60 0.004 0.011 151.91 0.388 0.169 6.5 1.61 0.002 0.002 93.41 0.101 0.084 7.0 1.52 0.002 0.004 88.31 0.078 0.146 7.5 1.44 0.002 0.007 83.43 0.054 0.251 8.0 1.36 0.002 0.010 78.75 0.031 0.415 185 2.5 2.12 0.002 0.002 123.28 0.155 0.091 235 2.5 3.44 0.003 0.003 199.63 0.232 0.148 285 2.5 5.07 0.004 0.003 294.36 0.341 0.109 表 10 全站仪测量值

Table 10. Total station measurement values

加载/N Y向位移/mm Z向位移/mm 测点1 测点2 测点1 测点2 4.9 -0.18 -0.18 -2.97 -4.50 9.8 -0.34 -0.42 -5.70 -8.70 14.7 -0.56 -0.57 -8.51 -13.01 19.6 -0.79 -0.84 -11.45 -17.49 24.5 -0.96 -1.06 -14.17 -21.66 29.4 -1.14 -1.32 -16.95 -25.93 34.3 -1.36 -1.55 -19.66 -29.98 39.2 -1.57 -1.81 -22.45 -34.24 44.1 -1.77 -2.04 -25.13 -38.30 49 -2.06 -2.28 -27.88 -42.32 表 11 预测值与全站仪测量值对比

Table 11. Comparison of predicted and total station measurement values

测点 加载/N Y向位移/mm Z向位移/mm 全站仪测量值 本文方法预测值 绝对误差 全站仪测量值 本文方法预测值 绝对误差 测点1 39.2 -1.57 -1.51 0.06 -22.45 -22.52 0.07 44.1 -1.77 -1.78 0.01 -25.13 -25.08 0.05 49 -2.06 -2.06 0 -27.88 -27.57 0.31 测点2 39.2 -1.81 -1.84 0.03 -34.24 -34.41 0.17 44.1 -2.04 -2.09 0.05 -38.3 -38.39 0.09 49 -2.28 -2.34 0.06 -42.32 -42.31 0.01 -

[1] 潘舟浩, 刘波, 张清娟, 等.三基线毫米波InSAR的相位解缠及高程反演[J].红外与毫米波学报, 2013, 32(5):474-480. http://d.old.wanfangdata.com.cn/Periodical/hwyhmb201305017PAN Z H, LIU B, ZHANG Q J, et al.Millimeter-wave InSAR phase unwrapping and DEM reconstruction based on three-baseline[J].Journal of Infrared and Millimeter Waves, 2013, 32(5):474-480(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hwyhmb201305017 [2] XU W, CHANG E C, KWOH L K, et al.Phase-unwrapping of SAR interferogram with multi-frequency or multi-baseline[C]//IEEE International Geoscience and Remote Sensing Symposium.Piscataway, NJ: IEEE Press, 1994: 4986460. [3] ZHANG K, WU D, WANG S, et al.A new method for estimating unambiguous phase observations of re-identified coherent targets for multi-baseline InSAR techniques[J].Remote Sensing Letters, 2017, 8(12):1172-1179. doi: 10.1080/2150704X.2017.1353223 [4] WANG B, DENG Z H, LIU C, et al.Estimation of information sharing error by dynamic deformation between inertial navigation systems[J].IEEE Transactions on Industrial Electronics, 2014, 61(4):2015-2023. doi: 10.1109/TIE.2013.2271595 [5] DAI H D, LUA J H, GUO W.IMU based deformation estimation about the deck of large ship[J].Optik, 2016, 127(7):3535-3540. doi: 10.1016/j.ijleo.2015.12.135 [6] MAJEED S, FANG J.Performance improvement of angular rate matching shipboard transfer alignment[C]//International Conference on Electronic Measurement & Instruments.Piscataway, NJ: IEEE Press, 2009: 10962531. [7] 解春明, 赵剡, 杨传春.传递对准滤波中机翼变形噪声的在线补偿算法[J].系统工程与电子技术, 2011, 33(2):370-375. doi: 10.3969/j.issn.1001-506X.2011.02.28XIE C M, ZHAO Y, YANG C C.Online compensation algorithm of wing flexure noise in transfer alignment filtering[J].Systems Engineering and Electronics, 2011, 33(2):370-375(in Chinese). doi: 10.3969/j.issn.1001-506X.2011.02.28 [8] KAIN J E, CLOUTIER J R.Rapid transfer alignment for tactical weapon applications: AIAA-89-3581[R].Reston: AIAA, 1989. [9] WENDEL J, METZGER J, TROMMER G F.Rapid transfer alignment in the presence of time correlated measurement and system noise: AIAA-2004-4778[R].Reston: AIAA, 2004. [10] DUREN R M, LIEBE C C.The SRTM sub-arcsecond metrology camera[C]//IEEE Aerospace Conference.Piscataway, NJ: IEEE Press, 2001: 2037-2046. [11] RICHARDS L, PARKER A R, KO W L, et al.Fiber optic wing shape sensing on NASA's Ikhana UAV[R]: Washington, D.C.: NASA, 2008: 5-13. [12] 孙东科, 林家浩.利用CFD计算技术进行机翼模型气动特性分析[J].航空计算技术, 2010, 40(1):21-24. doi: 10.3969/j.issn.1671-654X.2010.01.006SUN D K, LIN J H.Aerodynamic analysis of NACA0012 airfoil model using CFD[J].Aeronautical Computing Technique, 2010, 40(1):21-24(in Chinese). doi: 10.3969/j.issn.1671-654X.2010.01.006 [13] 王云, 徐江锋.基于预变形设计的柔性机翼气动性能分析[J].南昌航空大学学报(自然科学版), 2013, 27(2):47-51. doi: 10.3969/j.issn.1001-4926.2013.02.008WANG Y, XU J F.Analysis of aerodynamics characteristic of flexible wing on pre-deformation[J].Joumal of Nanchang Hangkong University(Natural Sciences), 2013, 27(2):47-51(in Chinese). doi: 10.3969/j.issn.1001-4926.2013.02.008 [14] 陈志敏, 徐敏, 陈士橹.跨声速静气动弹性结构响应分析[J].空军工程大学学报(自然科学版), 2005, 6(1):1-4. doi: 10.3969/j.issn.1009-3516.2005.01.001CHEN Z M, XU M, CHEN S L.An analysis of structure response for transonic static aeroelasticity[J].Journal of Air Force Engineering University(Natrnal Science Edition), 2005, 6(1):1-4(in Chinese). doi: 10.3969/j.issn.1009-3516.2005.01.001 [15] 张华, 马东立, 马铁林.弹性变形对柔性机翼气动特性影响分析[J].北京航空航天大学学报, 2008, 34(5):487-490. https://bhxb.buaa.edu.cn/CN/Y2008/V34/I05/487ZHANG H, MA D L, MA T L.Analysis of aerodynamics characteristic of flexible wing caused by deflection[J].Journal of Beijing University of Aeronautics and Astronautics, 2008, 34(5):487-490(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2008/V34/I05/487 [16] GONZALEZ J H, BACHMANN M, SCHEIBER R, et al.TanDEM-X DEM calibration and processing experiments with E-SAR[C]//IEEE International Geoscience and Remote Sensing Symposium.Piscataway, NJ: IEEE Press, 2008: 10460434. [17] LOU Y.Review of the NASA/JPL airborne synthetic aperture radar system[C]//IEEE International Geoscience and Remote Sensing Symposium.Piscataway, NJ: IEEE Press, 2002: 1702-1704. [18] SØREN N M, MARTIN J M, ZEBKER H A.Analysis and evaluation of the NASA/JPL TOPSAR across-track interferometric SAR system[J].IEEE Transactions on Geoscience and Remote Sensing, 1995, 33(2):383-391. doi: 10.1109/TGRS.1995.8746019 [19] 李道京.毫米波干涉合成孔径雷达[J].高科技与产业化, 2013, 9(11):40-43. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gkjycyh201311005LI D J.Millimeter wave interference synthetic aperture radar[J].High-Technology & Industrialization, 2013, 9(11):40-43(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gkjycyh201311005 [20] 黄刚, 刘力荣, 史雪静, 等.国产机载微型InSAR系统的DEM精度分析[J].测绘科学, 2017, 42(8):128-133. http://d.old.wanfangdata.com.cn/Periodical/chkx201708023HUANG G, LIU L R, SHI X J, et al.Accuracy analysis of DEM based on domestic airborne mini-InSAR system[J].Science of Surveying and Mapping, 2017, 42(8):128-133(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/chkx201708023 [21] 朱庄生, 郭韬.分布式POS传递对准对InSAR干涉测量影响的分析[J].中国惯性技术学报, 2014, 22(4):432-438. http://d.old.wanfangdata.com.cn/Periodical/zggxjsxb201404003ZHU Z S, GUO T.Effect of distributed POS transfer alignment on InSAR interferometic measurement[J].Journal of Chinese Inertial Technology, 2014, 22(4):432-438(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/zggxjsxb201404003 [22] 中国人民解放军总装备部.中国参考大气(地面~80 km): GJB 5601-2006[S].北京: 总装备部军标出版发行部, 2006.PLA General Armament Department.China reference atmosphere(ground~80 km): GJB 5601-2006[S].Beijing: General Armament Department Military Standard Publishing Department, 2006(in Chinese). [23] 胡明宝, 肖文建.风廓线雷达中风切变分析方法的初步研究[J].气象科学, 2010, 30(4):510-515. doi: 10.3969/j.issn.1009-0827.2010.04.012HU M B, XIAO W J.The preliminary study on analysis method of wind shear using wind profiler[J].Journal of the Meteorological Sciences, 2010, 30(4):510-515(in Chinese). doi: 10.3969/j.issn.1009-0827.2010.04.012 [24] 张序, 刘岷江.飞行中风切变的判断及处置[J].航空安全, 2008(6):62-64. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgmyhk200806046ZHANG X, LIU M J.Judgement and handlig of windshear during flight[J].Safety & Security, 2008(6):62-64(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgmyhk200806046 [25] 陈楠.某大型客机受突风载荷作用产生的非定常气动力计算[D].南京: 南京航空航天大学, 2013. http://cdmd.cnki.com.cn/article/cdmd-10287-1014059594.htmCHEN N.The calculation of unsteady aerodynamics effected by gusts upon an airliner[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2013(in Chinese). http://cdmd.cnki.com.cn/article/cdmd-10287-1014059594.htm [26] ETKIN B.Turbulent wind and its effect on flight[J].Journal of Aircraft, 2012, 18(5):327-345. doi: 10.2514-3.48243/ [27] 赵震炎, 肖业伦, 施毅坚.Dryden大气紊流模型的数字仿真技术[J].航空学报, 1986, 7(5):433-443. doi: 10.3321/j.issn:1000-6893.1986.05.003ZHAO Z Y, XIAO Y L, SHI Y J.A digital simulation for Dryden atmospheric turbulence model[J].Acta Aeronautica et Astronautica Sinica, 1986, 7(5):433-443(in Chinese). doi: 10.3321/j.issn:1000-6893.1986.05.003 [28] 高静, 洪冠新, 梁灶清.Von Karman模型三维大气紊流仿真理论与方法[J].北京航空航天大学学报, 2012, 38(6):736-740. https://bhxb.buaa.edu.cn/CN/Y2012/V38/I6/736GAO J, HONG G X, LIANG Z Q.Theory and method of numerical simulation for 3D atmospheric turbulence field based on Von Karman model[J].Journal of Beijing University of Aeronautics and Astronautics, 2012, 38(6):736-740(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2012/V38/I6/736 [29] TATOM F B, SMITH S R, FICHTL G H.Simulation of atmospheric turbulent gusts and gust gradients[J].Journal of Aircraft, 1981, 19(4):264-271. doi: 10.2514-3.57388/ [30] 高振兴.复杂大气扰动下大型飞机飞行实时仿真建模研究[D].南京: 南京航空航天大学, 2009. http://cdmd.cnki.com.cn/Article/CDMD-10287-2010080013.htmGAO Z X.Research on real-time flight simulation of large aircraft in complex atmospheric disturbance[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2009(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10287-2010080013.htm [31] 詹斌.石墨烯增强纳米复合材料变形机理与力学建模研究[D]: 杭州: 浙江大学, 2018. http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CMFD&filename=1018068254.nhZHAN B.On deformation mechanism and modeling of graphene-reinforced nanocomposites[D].Hangzhou: Zhejiang University, 2018(in Chinese). http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CMFD&filename=1018068254.nh [32] ANGERER B T, HINTZ C, SCHRODER D.Online identification of a nonlinear mechatronic system[J].Control Engineering Practice, 2004, 12(11):1465-1478. doi: 10.1016/j.conengprac.2004.03.005 [33] SOL H, HUA H, VISSCHER J D, et al.A mixed numerical/experimental technique for the nondestructive identification of the stiffness properties of fibre reinforced composite materials[J].NDT & E International, 1997, 30(2):85-91. http://cn.bing.com/academic/profile?id=084ac09db1c313af6faa3e82b075cdb8&encoded=0&v=paper_preview&mkt=zh-cn [34] 关永亮.复合材料无人机结构和飞行动力学关键技术研究[D].北京: 中国科学院大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-80139-1017063974.htmGUAN Y L.Research on key tecnologies of structural and flight dynamics for a composite unmanned aerial vehicle[D].Beijing: University of Chinese Academy of Sciences, 2017(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-80139-1017063974.htm [35] 张立.机翼结构的多约束拓扑优化方法及其应用研究[D].沈阳: 沈阳航空航天大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10143-1017046473.htmZHANG L.Multi constrainst optimization method and application research of wing structure[D].Shenyang: Shenyang Aerospace University, 2017(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10143-1017046473.htm [36] 刘鸿文.材料力学[M].4版.北京:高等教育出版社, 2004:188-190.LIU H W.Mechanics of materials[M].4th ed.Beijing:Higher Education Press, 2004:188-190(in Chinese). [37] 史志伟, 倪芳原, 陈永亮.基于两步线性回归的状态空间模型建立与验证[J].空气动力学学报, 2013, 31(6):699-703. http://d.old.wanfangdata.com.cn/Periodical/kqdlxxb201306003SHI Z W, NI F Y, CHEN Y L.The state-space models based on two-step linear regression method[J].Acta Aerodynamica Sinica, 2013, 31(6):699-703(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/kqdlxxb201306003 [38] KIM H I, KANG L H, HAN J H.Shape estimation with distributed fiber Bragg grating sensors for rotating structures[J].Smart Materials & Structures, 2011, 20(3):035011. http://cn.bing.com/academic/profile?id=4123f249d01166b17250b160b857c7fb&encoded=0&v=paper_preview&mkt=zh-cn -

下载:

下载: